Thermoset vs Thermoplastic is important. This blog helps you understand both. Find out about PE, ABS, PP, and PVC. Discuss chemical structure, thermal stability, and elasticity.

Make pros and cons. Learn how various industries employ them. The choice of material is crucial. Be updated on these basic types of plastics. Make smart choices.

What is Thermoset?

Thermoset hardens when heated. It has a high cross-link density. This is beneficial to car parts. They include epoxy resins which are strong. The heat resistance is high at 150-200°C. It cannot be remolded. Phenolics are brittle and they are categorized under thermoset plastics. It is good for electric insulators. This material once it is set remains rigid. They employ it in many ways. Thermoset has permanent bonds.

What is Thermoplastic?

Thermoplastic melts when heated. Their texture is soft and flexible. They use it for toys and bottles. The melting point is 100-250°C. This can be remolded many times. Some examples include polymers such as polyethylene (PE), ABS, PC, PP, PEEK, Acrylic, Nolon etc. It is appropriate for everyday objects. This has low strength compared to Thermoset. It cools and hardens fast. They have incorporated thermoplastic in their products in different ways. That is the real distinction.

What Are the Key Differences Between Thermoset and Thermoplastic?

Chemical Structure

Thermoset vs Thermoplastic also demonstrates different shapes. Thermosets can develop only solid bonds while they are being fixed. It stays strong. Thermoplastics have chain links. This means they can melt and reshape. They use polymers such as PE and ABS. Thermosets’ cross-links stop melting.

Some thermoplastics for example PTFE have the characteristic of softening when exposed to heat. This flexibility makes recycling easy. The intermolecular forces in thermoplastics are not as strong.

This is because their shapes determine how they are used. Each has specific application in materials.

Manufacturing Process

Thermoset vs Thermoplastic: making is different. Thermosets solidify with heat or chemicals. This creates strong cross-links. Thermoplastics can be melted and shaped using heat.

The cooling makes them solid. Thermosets can’t remold. Many times, thermoplastics like PP can be reshaped. Their flexibility makes it suitable for many applications. Thermosets suit tough jobs.

Each type is made with different tools. Knowing these helps pick the right one. This reveals the best use in products.

Heat Resistance

Thermoset and Thermoplastic differ in the manner they react to heat. Thermosets are resistant to high heat. They are good for hot places. This makes them strong. Thermoplastics, including PA, become more pliable when exposed to heat. This makes them easy to influence.

Thermosets are rigid at high temperatures. They are applied in engines. Thermoplastics can crack with too much heat. This limits their use. Thermosets do not soften or melt once they have been made. Their heat handling determines the application in which they can be used.

Mechanical Properties

Thermoset and Thermoplastic are two types of plastics but they both have different characteristics. Thermosets are rigid and have high mechanical properties. Consequently, they are ideal for use where they are likely to be subjected to a lot of stress. They don’t bend easy.

For example, while PVC is considered as thermoplastics, they are bendy. It allows them to expand and contract without rupture. Thermosets have high pull strength.

They are used in the construction of building parts. Thermoplastics are the types of plastics that can be stretched and then come back to their original form. They suit moving parts. Each is selected with the job in mind. That knowing these helps choose the best material. This makes things go smoothly.

How Does the Manufacturing Process Differ?

Injection Molding

Thermoset vs Thermoplastic is fun! Thermoset becomes rigid when warm. It’s for hot stuff. Thermoplastic melts with heat. This can be reshaped. Essentially, IM (injection molding) incorporates barrels, screws, and nozzles. They push plastic. High pressures up to 2000 psi can cool parts.

Gears, toys and cases emerge! A cooler makes them solid fast. Cycle time is short. A lot of work is accomplished by machines. That makes it easy. Control units monitor speed and temperature. PP and PE plastics are utilized.

Extrusion

The fact Thermoset vs Thermoplastic are a different thing! Thermoset stays hard. Extrusion forces the plastic through a die. Thermoplastic melts and shapes. Extruders have hoppers, barrels and screws.

It forms elongated structures such as pipes and rods. The machine moves fast. It is super long, up to 500 meters! The name of the game is speed and tempo.

That’s important! PE and PVC plastics are the most suitable for use. Cutting systems cut pieces just right. This keeps things neat. They do lots of checks.

Compression Molding

Thermoset vs Thermoplastic makes neat things! Thermoset stays firm. It uses hot molds. Thermoplastic can be melted. Compression molding makes use of large molds. The pressure can be up to 1000 tons.

This makes car parts and stuff. Hydraulic presses apply pressure on the plastic. Heat flows evenly. They monitor pressure and temperature. Therefore, PP and nylon are considered as good plastics.

The platen can also heat up quickly. That contributes to the dispersion of the plastic. Release agents stop sticking. Big parts go big!

Thermoforming

Thermoset vs Thermoplastic means many shapes! Thermoset stays hard. Thermoplastic sheets heat up. They become soft. Thermoforming involves vacuum or pressure. It forms things such as trays and lids.

Heaters reach 200 degrees. The plastic cools fast. This makes sharp details.

Vacuum pumps draw the shape. The speed and the thickness are the critical factors. That makes everything just right. PP and PET are among the favorites. Slicing removes excess portions. They check every part.

What Are the Strengths of Thermoset Materials?

High Heat Resistance

Thermoset and Thermoplastic are not the same. Thermoset remains rigid at 200°C. It uses epoxy resins. This means that the components of an engine work more efficiently. They do not dissolve in hot water.

The polymers make cross-links. That keeps them tough. Phenolic and epoxy compounds do. They do not undergo any change with high heat. They are used in airplanes. The high temperature is not a problem.

Thermoset is a company that produces very sturdy kitchen utensils. The heat resistance is simply incredible.

Dimensional Stability

Thermoset vs Thermoplastic demonstrate differences. Thermosets do not change their shape. It does not vary much. This stability is crucial for PCBs. This means no warping.

This maintains the efficiency of parts. Epoxy resins are used. They have low shrinkage rates. The shape stays correct. Industrial machines require this stability. Thermosets are selected based on precision. They maintain the right size. This stability is key.

Electrical Insulation Properties

Thermoset and Thermoplastic have their own specific applications. Thermoset insulates electricity well. This helps in transformers. The material shields against high voltage. Epoxy is used for insulation.

That makes devices safe. Dielectric strength is high. Switchgear uses thermoset. It keeps electricity inside. The insulation is vital. Other resins used include phenolic resins. Electronic devices need this. The high dielectric strength is needed most of all.

Chemical Resistance

Thermoset and Thermoplastic differ in how they handle chemicals. Thermoset resists acids. It works in the tough places. This helps in chemical plants. Epoxy and vinyl ester resins are tough.

They do not degrade. Pipes and tanks utilize them. The materials stay good. The chemical structure is solid. Thermosets do not dissolve. That keeps parts working. Industrial areas need this. The resistance is great. Thermoset materials last long.

| Property | Thermoset Materials | Thermoplastics | Metals | Ceramics | Composites | Elastomers |

| Heat Resistance | High, 250-300°C | Moderate, 70-150°C | High, >500°C | Very High, >1000°C | Varies, 100-300°C | Low, -50-150°C |

| Dimensional Stability | Excellent | Moderate | Good | Excellent | Good | Poor |

| Electrical Insulation | Excellent, 10⁸-10¹⁵ Ω | Good, 10⁷-10¹⁴ Ω | Poor, Conductive | Excellent, 10¹⁰-10¹⁴ Ω | Varies, 10⁶-10¹⁵ Ω | Poor, Conductive |

| Chemical Resistance | High, Acid/Base | Varies, Solvents | Moderate, Corrosion | High, Inert | High, Tailored | Low, Swell |

| Mechanical Strength | High, 100-200 MPa | Varies, 20-100 MPa | Very High, 200-2000 MPa | Very High, 100-500 MPa | Varies, 50-300 MPa | Low, 5-20 MPa |

| Cost | Low-Medium | Low-Medium | High | Medium-High | Medium-High | Low-Medium |

Table on the Strengths of Thermoset Materials!

What Are the Strengths of Thermoplastic Materials?

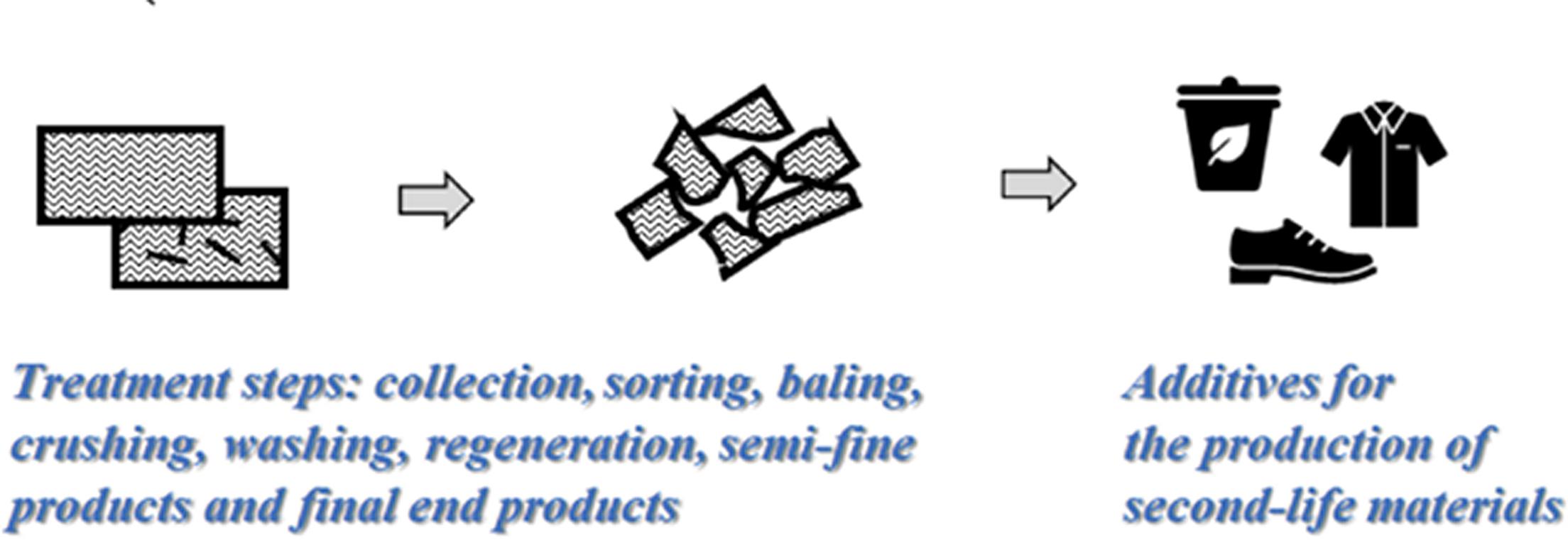

Recyclability

Thermoset vs Thermoplastic makes choices clear. For instance, ABS can be recycled. This means we reuse parts. It is beneficial to nature. These materials can turn into a fluid state and solidify again.

Extruders are some of the machines that assist in recycling. PETG is also recyclable. Recycled materials save energy. That reduces waste. Reuse helps our planet. They assist us in creating new products. Recycling is important.

Flexibility

Thermoset vs Thermoplastic is all about material. TPU bends easily. This makes toys soft. TPE is flexible too. It stretches without breaking. These materials are useful. They can be placed in small spaces.

The softness is suitable for shaping. Rubber-like plastics feel comfy. Flexibility is helpful. They make safe products. Soft materials are good.

Impact Resistance

Thermoset vs Thermoplastic reveals clear preferences. PA is tough. That means it will not break. PC is strong too. These can take hits. They protect items. Safe helmets are made of sturdy materials.

Strong plastics last long. With them, devices remain protected. It matters for safety. Impact resistance is important. Toys and gadgets require it.

Ease Of Processing

Thermoset vs Thermoplastic reveals easy options. PLA and PEEK melt fast. This makes shaping simple. They are used in such machines as 3D printers. Processing is quick. It saves time.

PLA is fun for projects in school. They need low heat. Materials that are easy should be used for kids. That makes learning fun. They help create cool things.

What Are the Challenges in Using Thermoset Materials?

Non-Recyclability

Thermoset vs Thermoplastic materials are different. Thermosets cannot be reused. This makes them wasteful. They employ certain types of chemical bonds. ABS and PET are different. They fuse and recrystallize together. Thermosets do not degrade when exposed to heat.

Some of the varieties of epoxy resins are not recyclable. That is an issue of disposal. Some of the Thermoplastics include Polycarbonate and Nylon which are recyclable. It involves the melting and then recasting. This is important for sustainability.

Processing Difficulty

Thermoset vs Thermoplastic materials are quite difficult. Thermosets need exact temperatures. This makes them costly. They use curing stages. Both the BMC and SMC are forms.

Polyester thermoplastics such as PEEK and PVC can be melted easily. They suit injection molding. Equipment for thermosets varies. Compression molding is common. The process takes time. Thermoplastics are quicker. Choosing materials affects speed. The industry prefers ease of handling.

Brittleness

Thermoset and Thermoplastic materials can be brittle. Thermosets break easily. This is a problem. Some of them include Duroplast and Phenolic. They do not like changes but can break.

Polypropylene and Polystyrene are examples of thermoplastics which bend. This makes them good for toys. Thermosets are very rigid. The molecular structure matters. Injection molding is suitable for thermoplastics. This affects product durability. That is important for safety.

Longer Curing Times

Thermoset vs Thermoplastic materials cure differently. Thermosets take longer. The process needs cross-linking. Some of them include UPR and PUR resins. Thermoplastics cool fast.

They don’t need curing. Polyamide and Acrylic are typical. Thermosets need controlled conditions. This can delay production. Thermoplastics allow quick manufacturing. The industry is also characterized by time and cost considerations. Every material has its advantages.

What Are the Challenges in Using Thermoplastic Materials?

Lower Heat Resistance

Thermoset vs Thermoplastic? It matters when things get hot. Thermoset is like a superhero against heat. This kind doesn’t melt. They stay strong. Thermoplastics melt at 160 and 260.

That’s a problem for hot places. Polyethylene (PE) and polypropylene (PP) melt. Try to picture toys or parts of toys becoming soft and liquid due to heat.

Polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) are somewhat better but they also melt. Engineers require materials that can with stand high temperatures without undergoing any change. Selecting the right one makes things such as clothes and shoes last longer.

Creep Under Load

Thermoset vs Thermoplastic depicts a difference. Creep occurs when things flex gradually. It’s a big deal. Thermoset materials are more resistant to it. Polyvinyl chloride (PVC) and polystyrene (PS) are two types of materials that are known to creep under a heavy load. This is a problem for bridges or for buildings.

Nylon and PEEK do not deform when exposed to it. The load causes the shape of the plastic to alter. Engineers select materials with a view of preventing issues from arising. Then everything remains strong and secure. That is why the choice is so critical.

Higher Cost For High-Performance Types

Cost is also involved in Thermoset vs Thermoplastic. High-performance thermoplastics cost more. Polyetheretherketone (PEEK) is pricey. It’s tough and lightweight. They are applied in planes and cars. Polyimide (PI) is also costly. Engineers need strong materials. High-performance ones handle stress.

This cost is problematic for budgets. Thermosets are cheaper sometimes. They’re less flexible though. Economical and efficient solutions are also important. Choosing the right material means reducing the cost and increasing the quality of the final product. It’s a big choice.

Sensitivity To Solvents

Thermoset vs Thermoplastic: solvents do count. Thermoplastics can dissolve. This is possible with acetone or benzene. Polystyrene (PS) and acrylics dissolve quickly. It’s a problem for fuel tanks or containers. Polyethylene (PE) and polypropylene (PP) are more resistant to solvents.

Thermosets handle solvents well. Epoxy and phenolic are good examples. Engineers choose wisely. They consider where specific items will be applied. Solvent damage should be prevented. Applying proper material keeps things secure and enduring.

Conclusion

Knowledge of the differences between Thermoset vs Thermoplastic assists in making the right selection. Thermoset is rigid and resistant to heat. Thermoplastic is flexible and can be recycled. Both have unique uses. Learn more at PLASTICMOLD. Choose the most appropriate material for your case. Be aware and wise.