Product Assembly Services in China

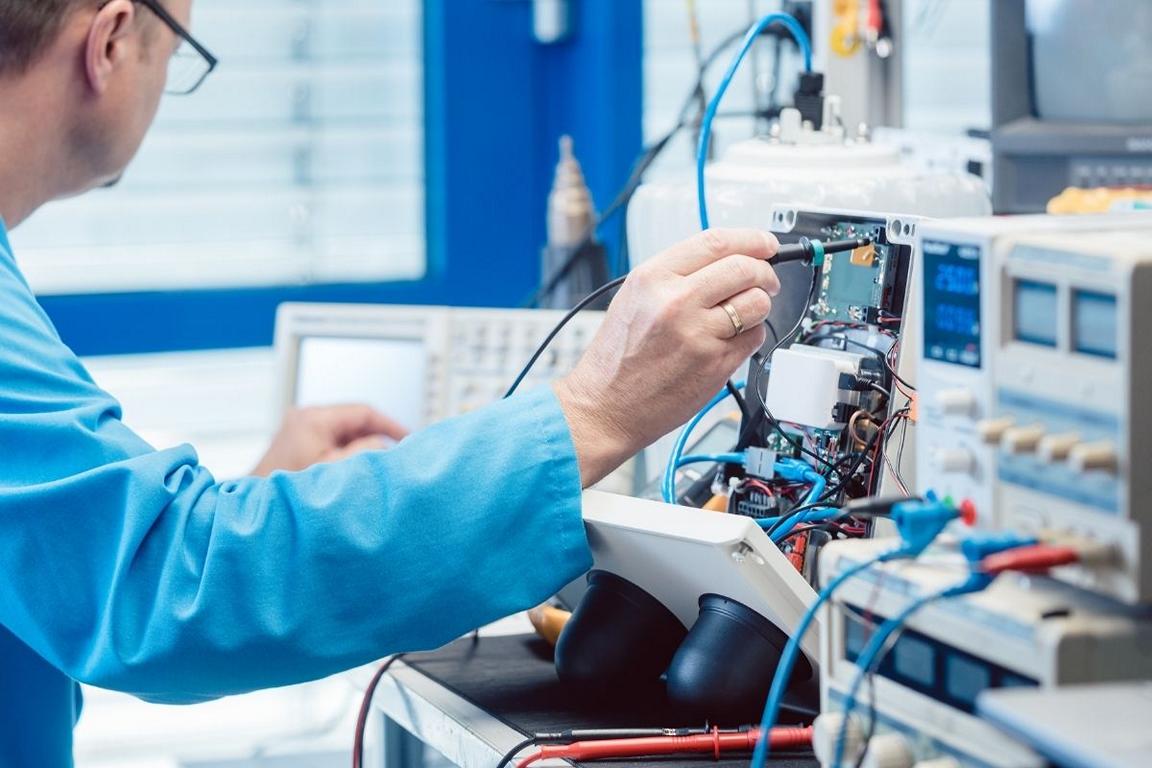

We provide contract product assembly services in China, encompassing ODM and OEM electronic product design and development, mold manufacturing and production, die casting parts, metal parts, plastic parts, PC boards, electronic component assembly, PCB soldering, assembly, packing, and delivery services.

If you are seeking contract product assembly services in China that provide comprehensive services from design to delivery, please reach out to us. We can provide comprehensive services from product design to manufacturing and delivery.

In the United States, a significant number of electronic products bear the label “Made in China.” The news and people around the world may have shaped an image of China as a potential threat to the United States or other countries involved in global trade. As China exports more and more parts of the world, we have all come to the conclusion that China does not pose a threat to any country in the world, but China has allowed people all over the world to enjoy many cost-effective products.

Based on our government export trading report, China has exported goods worth approaching $2,500 billion to the world. China assembles over 30% of electronic products before sending them to other countries. China’s extensive experience stems from its ability to maintain quality control, offer fast lead times for electronic product assembly services, and provide easily manageable equipment and components. This will result in significant time and cost savings for your products.

Product Assembly services China

China is the world’s largest manufacturing country and has a complete, independent, and modern industrial system. The output of more than 220 kinds of industrial products in China ranks first in the world. If you are looking for OEM contract manufacturing and product assembly offshore, I can confirm that finding product assembly services in China will be one of your best places to go.

For many businesses, it is crucial to produce their PCB board, plastic parts, lights, and metal parts in China for the purpose of assembling the complete product. This is due to China’s lower labor costs and superior quality control systems, which would otherwise be significantly more expensive elsewhere. Also, with favorable contracts with an OEM manufacturing company in China, companies are guaranteed to receive great-quality products and exceptional service.

Pros of product assembly services in China

There are numerous pros for businesses partnering with Chinese product assembly services companies. As mentioned earlier, some of the important benefits are the low-cost labor rate, excellent quality control, and simple accessibility for auxiliary accessory requirements. In some cases, the costs of shipping and labor are almost equivalent to those of domestic work, but in general, this process is cheaper in China.

Lower production costs for OEM parts in China ultimately improve sales. As previously mentioned, another advantage is the exceptional service provided by Chinese OEM manufacturing businesses. Chinese contract manufacturers are generally more open to businesses, small or large, as long as you meet their requirements. Additionally, Chinese OEM manufacturers are capable of producing and assembling a large number of components and goods in a short amount of time, such as ten days for the construction of a hospital for 10,000 patients.

I firmly believe that no one else in the world is capable of performing this job. This is why the production and assembly of iPhones has remained in China for over a decade. Because of this, Chinese product assembly manufacturers typically outperform many manufacturing businesses in the United States and around the world. Chinese labor is also very precise when it comes to duplication. This is a significant benefit when it comes to component production.

Cons of product assembly services in China

In addition to the benefits of collaborating when using product assembly services in China, there are some drawbacks to consider. One of the challenges faced by American businesses is locating a reliable and accountable Chinese product assembly service company to collaborate with. Finding one is easy, but most of the time, you may not be able to find a trustworthy and professional Chinese contract assembly company.

It appears to be a challenging task for businesses, but there are strategies that can help them find success. Another barrier that stands between American and Chinese businesses and factories is the difference in languages, which makes communication a challenge. Communication is not only difficult from a communication perspective but also from a cultural perspective. Unlike most Americans, Chinese are exact and take everything you say literally. Making sure the Chinese understand everything you say is crucial to prevent misunderstandings.

If you’re seeking plastic injection molding parts, product development and manufacturing services, contract manufacturing, or OEM product assembly services in China, we recommend collaborating with our team. We possess a technical background and professional communication skills, enabling us to meticulously confirm every detail of the product assembly, thereby preventing any potential issues before they arise.

Manual Plastic Products Assembly Services

As with other material products, plastic molded components often require manual assembly services to produce practical and commercial goods. Normally, large-end electronic products cannot be produced efficiently, and the electronic product is normally manually assembled by smaller parts or subsections. Plastic-molded parts may require attachment to components made of other materials, including metals, alloys, PCBs, sable, wood, and ceramic. All of this depends on the design, which has a business purpose.

The best design for assembly is never better than a well-designed, complete unit that is molded as a single element. However, this is normally impossible, and the end products or subassemblies must be assembled from smaller components. We will discuss the major process that is commonly utilized to assemble plastic products together. The manual assembly company has five applicable methods to assemble the plastic products and other components together, including ultrasonic welding, heat welding, PCB soldering, solvent welding, mechanical fastening, and self-assembly (hook assembly). There are advantages and disadvantages to each assembly process, and there are different processes defined for each assembly method.

Choosing the optimal method will require fundamental knowledge of the materials involved, the joint connection designs, and the practical and end-use service requirements to which the assembly will be exposed. In addition to strength and permanence, there must be careful consideration given to the final appearance, production time, possible manual disassembly requirements, and all production costs, including materials, scrap rates, and labor costs.

Since the function and cost of the final product assembly depend on the plastic used to manufacture the individual plastic products, let us discuss how the plastic substrate affects the assembly process and the resulting joint function. In fact, the plastic substrate material, its manufacturing process, and the joint design are often selected to provide the most advantageous overall joint technology. As a manual assembly company, we need to select the correct assembly process and explain how it can be employed most optimally.

Plastic Injection Molding Parts Assembly Design

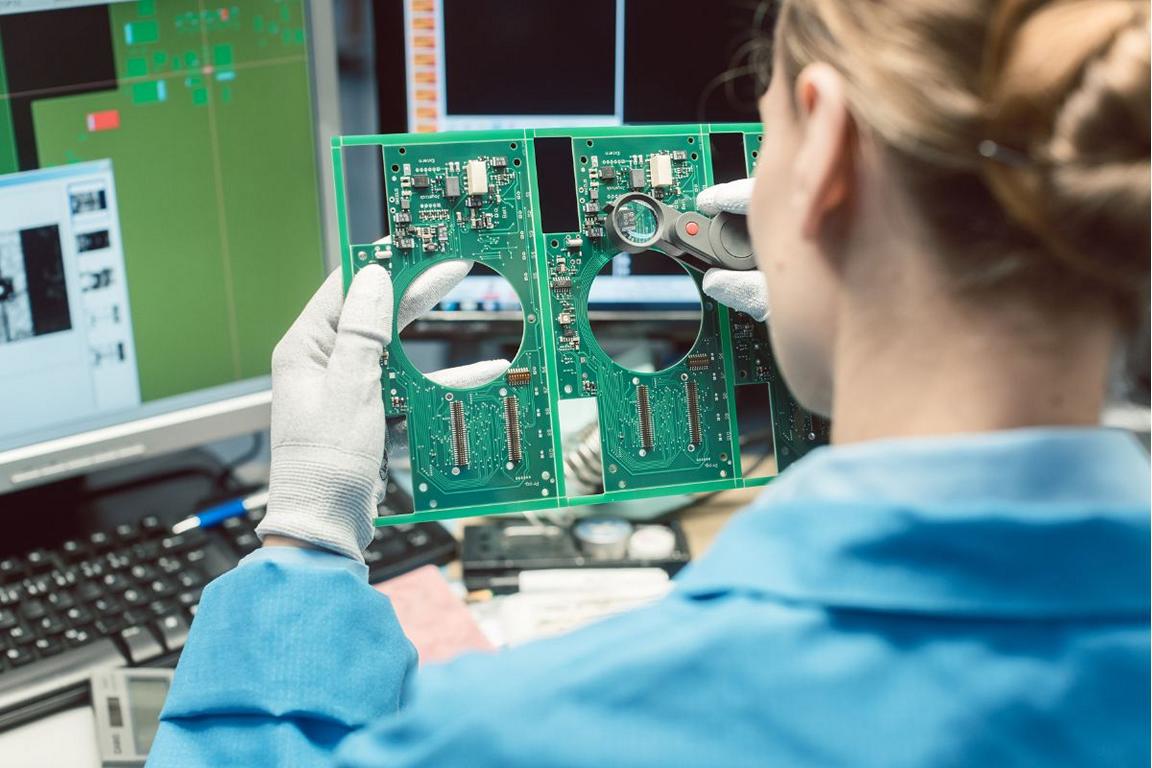

Plastic injection molding products are normally more difficult to assemble than other materials. The result of the joining process may depend on the plastic substrate and how the plastic-molded part is designed and manufactured, depending on the process chosen for assembly. The decision of the product development department determines how the entire set of components will function as a single unit.

After the first sample run, the injection molding companies need to provide suggestions. This is because the part designer, who designed the final plastic product based on a theoretical concept, may encounter practical issues that differ from the theory. These issues could include manual assembly issues, interference issues, material issues, surface finish issues, and more. Based on this type of information, necessary modifications and additional mold trials need to be conducted.

It is important to note that plastic molding products can be modified significantly by different types of polymers and by adding fillers and modifiers, part design changes, and assembly design changes. These modifications can heavily influence the assembly characteristics. Therefore, the part development department must exercise greater caution before initiating the manufacturing process, as it will incur significant costs for repairs and modifications once the mold and tooling are completed.

Dongguan Sincere Tech Co., Ltd. provides high-quality product manufacturing services. We are capable of producing a wide range of custom plastic products, metal parts, aluminum die casting, CNC machining components, surface finish, welding, secondary process manufacturing, product assembly, custom packaging, and shipment services.

To meet your specific needs, we offer a wide range of products for various industries, such as construction, health and medicine, vehicles, cosmetics, food, digital, appliances, toys, and others. We are able to produce our items in high quantity with the help of our professional team. We will deliver it to you at an affordable price while maintaining high quality.

What services we can offer you?

To ensure we are a suitable partner for you, we would like to outline our advantages and areas of expertise. This will make sure you find the right OEM contract manufacturer and product assembly services in China.

We can do model and part design (in-house work) for you, as well as PCB board and electronic design if necessary (outsource from a long-term partner). Have your PCB board supplier send it to us. We do a prototype (in-house), CNC machining (in-house), 3D printing service (in-house), injection mold/metal tooling/aluminum die casting and mold design (in-house work), injection mold, tooling, or die manufacturing (in-house work), massive production (in-house work), secondary processes like painting, chrome powder coating, and anodizing (some of them in-house work), product assembly service and packing (in-house), and shipment to your storage house.

The services listed above are our specialties, and we have been providing them for many years. If your project requires the above services, then you have come to the right place.

Why you should choose us to partner with?

Working with a Chinese product assembly or Chinese OEM contract manufacturer requires effective communication. Fluent English and professional technical communication are the keys to making the project successful and fast. On the other hand, unprofessional communication will delay the project and may fail it altogether.

At Sincere Tech, we have a team that has over 18 years of technical working experience in the plastic and metal fields, fluent English communication, and perfect project management. This advantage is due to our manager’s 7 years of experience managing foreign companies as a project manager.

When we receive a project from our customers, we thoroughly review all potential issues and provide a solution along with an illustrated design for manufacturing analysis. This will be simple and accurate, reducing any possible mistake or misunderstanding. As professionals, we understand that there are numerous mistakes and misunderstandings in communication. It is our responsibility to safeguard this issue.

The other pros are that most of the jobs are done in-house. We can do part design, prototype, mold design and manufacturing, PCB board design and testing, certification, inspection, product assembly, and packing; most of them we do in-house. We could easily control the time plan (especially for some urgent cases; we make molds two weeks faster) and the quality; we can do large orders in large quantities or small quantities. In China, it is very easy and fast to gather employees, even for new hires who can be trained quickly and managed with obedience. This phenomenon can be attributed to the influence of Chinese culture.

Chinese people are known for their hard work and commitment to their families, often working long hours and then taking two days off. If you partner with such companies, I believe your business will face significant challenges. That is why Apple buys 80% of their iPhones from China, which has a short lead time and a large market around the world.

When you work with us, we are with you every step of the way. During the product design and development phase, we will thoroughly review all part design issues, mold manufacturing issues, product assembly issues, potential function issues, and any other problems. We will then compile these issues into a comprehensive report, complete with illustrations and solutions.

After the first model sample is sent to you, we will double-check your requirements again to find any possible issues and provide solutions. In all of these steps, we are checking, improving, and testing until you completely satisfy us. This is what we do for all of our customers, and we hope you will be pleased as well.

If you have a project in progress and a plan to manufacture injection molds, tooling, and other components, I recommend sending it to us for a thorough review. We will provide you with some technology suggestions for your project, allowing you to avoid many potential issues in advance.

If you are looking for an OEM manufacturer and manual product assembly services in China for your injection molding parts and other components, you are welcome to contact us. We can provide all-in-one-stop service to you; you only need to sit back and approve the end goods.