Injection Molding vs 3D Printing

You can make plastic products through various methods. Plastic injection molding and 3D printing are two trendy approaches. Each has its unique pros and cons. Therefore, you must assess injection molding vs 3D printing to learn more about these.

Plastic injection molding is an old technique. People first used it in the 18th century. After 100 years of its discovery, a new method called 3D printing was introduced. At present, both approaches are widely prevalent in the plastic industry.

When reviewing injection molding vs 3D printing, you will also learn about their suitability in different fields. For example, injection molding is ideal for large-volume orders. However, 3D printing is great for making prototypes. Similarly, there are more differences. This article will find those and tell you which might work best for your business.

What is Injection Molding?

Injection molding is the most widely used method. As the name suggests, this method injects plastic into a mold and creates varying shapes.

This technique is used to make most of the plastic parts people use every day. Injection molding is widely used for small parts, like toys, and large ones, like kitchen items. This technique is highly effective, especially for creating complex plastic parts. According to experts, this method can achieve up to ±0.1 mm tolerances.

A typical injection molding machine has three central units. (1) The injection unit, which looks like a giant syringe, has three main parts. (a) A hopper receives the plastic pellets and sends them to the main chamber. (b) A heating chamber heats these pellets and creates molten plastic. (c) An extruder helps push the plastic forward towards the mold.

(2) The mold unit shapes the plastic parts into the desired shape. It uses a specific mold for specific plastic parts. So, this unit is adjustable.

(3) The clamp typically opens and closes the mold. A mold usually consists of two halves: the mold unit holds one half, and the clamp unit secures the other. Once an operator pushes the clamp, half of the mold opens and reveals the newly formed plastic part.

How does Injection Molding Work?

The injection molding process begins by feeding the plastic pellets into the hopper. The heating components gradually heat these pellets to form molten plastic. Later, with the help of the extruder, the molten plastic reaches the injection chamber.

When the operator is ready, the injection unit pushes the molten plastic into the cavity. Once cooled, the plastic parts are removed from the injection plastic mold, you can go to our plastic mold technology page to know more about plastic molds.

Injection Molding is Best Suited For:

Injection molding is a highly efficient manufacturing process. This method is perfect for faster production and consistent products. Here are some key pointers where injection molding is the best choice:

- Injection molding is suitable for large-scale production runs. It can produce more than 1,000 parts per run.

- This technique is suitable for final production. It is not ideal for prototyping.

- Injection molding can typically handle all types of designs and sizes. This flexibility makes this method a profitable option.

- Injection molding produces stronger plastic parts. Unlike 3D printing, injection-molded parts are durable and can handle more stress.

- Once the mold is created, injection molding can produce millions of plastic parts. This makes your business more profitable and helps you get a quick return on your investment.

Limitations of Plastic Injection Molding

Injection molding is better for many reasons, but it still has limitations. Because of these limitations, 3D printing is usually a better choice.

- Injection molding requires a high initial cost. You have to make different molds for each specific plastic part.

- This method is not ideal if you are aiming for low-volume orders. The high tooling cost will dramatically increase the production cost.

- This method needs longer turnaround times. It may take 5-7 weeks.

- This method needs more time to set up.

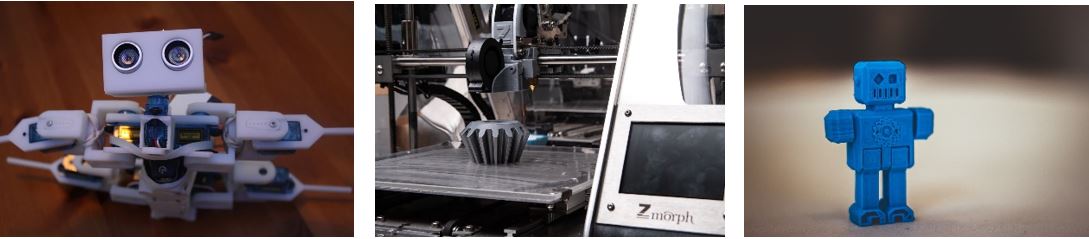

What is 3D printing?

3D printing is one type of additive manufacturing. It generally creates shapes by adding plastic layer by layer, which is why it is called additive manufacturing. However, 3D printing, as the name suggests, creates three-dimensional objects. It mainly uses plastics because they are lightweight and easy to melt.

You can think of traditional manufacturing processes, like CNC machining. They are all subtractive methods. But 3D-printing adds material. As a result, you can create many complex shapes with less material waste.

A 3D printer is generally a box-like structure. A simple 3D printer has four key components.

(1) The frame gives the machine structural support. Depending on the quality of the machine, it is typically made of metal or plastic.

(2) The print bed is usually flat, the same as a laser-cutting machine.

(3) A nozzle or print head is a crucial component of a 3D printer. Most of the time, it comes with an extruder. Based on the programmed path, the print head can generally move along the X, Y, and Z axes.

(4) A control panel typically controls this process, allowing you to connect your computer to the machine.

How Does A 3D Printer Work?

First, you have to prepare your design file. You can use any convenient software, but must ensure the file type is STL or OBJ. Some advanced 3D printer controllers may also support another file type. Once you insert the file into the controller, the machine automatically creates programs for the print head path.

Before that, you must prepare your machine. Check whether you have installed the plastic filament with the extruder and print head. When you start printing, the nozzle heats the filament and melts it into a semi-liquid form. At the same time, the print head follows the programmed path. Gradually, it deposits the semi-liquid plastics layer by layer onto the print head.

In this case, a specialized plastic filament quickly hardens and forms a solid shape. Some popular plastic filaments used in this case are PLA, ABS, PP, PC, PETG, TPU, and many more. However, the process continues to add plastics layer by layer until it creates the whole body.

Once printing is finished, you can remove the unnecessary extensions. In 3D printing, these extra parts are called support structures. However, you can also do more finishing, like smoothing rough edges.

3D Printing is Best Suited For:

3D printing gives you a flexible solution to create many complex plastic parts. It opens up a wide range of possibilities for doing many DIY projects. In manufacturing, the use of 3D printing is vast. Here are some key pointers where 3D printing is the best choice:

- 3D printing is ideal for creating prototypes for any final parts. Plastic prototypes are also used to test the product for many die-casting parts. 3D printing is fast and accurate, which greatly helps rapid prototyping.

- 3D printing is suitable for low-volume orders. For large-scale production, injection molding is a cost-effective solution.

- 3D printing is typically a better option for small to medium-sized plastic parts. However, many modern 3D printers are capable of creating large structures.

- This method can produce parts quickly. It takes only a few minutes to a few hours to complete printing a part.

- 3D printing is perfect for frequent design changes. It allows you to modify and update the designs.

- Indeed, 3D printing is an excellent tool to create complex shapes.

Limitation of 3D Molding

3D printing is famous for its many benefits, but it still has some limitations. That’s where injection molding becomes a suitable option.

- 3D printing is very much limited to certain plastic materials. PLA, ABS, PC, PP, PETG, and TPU plastics are trendy in 3D printing.

- If you want strength in your plastic parts, 3D printing is not ideal. Injection molding is suitable for making robust plastic parts.

- 3D printing is a relatively slow process. It takes a few minutes to a few hours to complete a run. Because of this, 3D printing is not suitable for large-scale production.

- 3D printers need frequent maintenance. After every print job, you must clean the extruder and print head.

Injection Molding VS 3d Printing: Which is Better?

From the above two sections, you are now familiar with these techniques. What are they? How do they work? What are they best suited for? Both methods may be better for a specific use, but the level of suitability may still differ. In this section, we will consider a few factors to determine the best suitability of each method.

Before then, let’s look at the summary of this discussion in the following table.

| Factors | Injection Molding | 3D printing |

| Production Volume | Suitable for high-volume production due to low cost per unit | Suitable for low-volume production |

| Design Complexity | Limited by mold design, you can only make a particular design once the mold is created. | Suitable for a frequent change in design; highly flexible |

| Strength | Produces parts with high-strength | Relatively lower strength |

| Prototyping | Not suitable | Suitable |

| Tooling design | Requires custom molds | No need |

| Turnaround times | Longer setup and production time due to mold creation; faster once setup is complete | Short setup times, quick turnaround time |

| Part Size and Tolerance | Can produce both small and large plastic parts; tolerance up to ±0.1mm | Suitable for small and medium plastic parts; tolerance up to ±0.25mm |

| Customization | Only limited to mold design | Highly customizable |

| Surface finish | Smooth surface finish | It may need post-processing work. |

| Material waste | Less waste | Moderate to high material waste |

| Cost | High initial cost but lower unit costs for large-volume orders | Lower initial cost but high unit costs |

Injection Molding VS 3D Printing: Production Volume

Production volume plays a crucial role in the manufacturing of plastic parts. You might own a small, medium, or large business. You might offer your customers custom or standard designs. So, decide what type of production you will provide to your customers. Then, you will be able to choose the proper manufacturing process.

Injection molding is ideal for large-scale production. Once you have created the mold, you can make millions of plastic parts with the same design. You can create many colors, though the design remains the same.

3D printing is ideal for custom designs. Your customer may order 10 to 100 pieces of custom-designed parts. In this case, 3D printing does a great job. You don’t have to create expensive molds for this work.

Injection Molding VS 3D Printing: Complexity of the Design

You can create very complex designs with both methods. However, injection molding is only limited to mold design. Once the mold is created, you have no option to customize it. Thus, the complexity of the design is only limited to the mold design in injection molding.

3D printing gives you more opportunities to customize your design. You can create complex geometries, like features of dragons or, detailed ancient designs, and more. There is no extra tooling cost.

Injection Molding VS 3D Printing: Strength

Some plastic parts, such as automotive parts, toys, and industrial equipment, require high strength. These items often undergo rough handling and impact forces.

Injection molding can improve the strength of a plastic object. As you know, this method melts plastic pellets completely and then reforms them into solid shapes.

3D printing, on the other hand, converts plastic filaments into semi-liquid form. It builds 3D objects layer by layer. As a result, each layer’s strength is slightly decreased.

Overall, injection molding is the best option in terms of strength.

Injection Molding VS 3D Printing: Prototyping

The prototype is also known as a sample or model of the product. Prototypes or samples typically resemble the shape and properties of the final product.

The best way to make samples is with 3D printing. Even in rapid prototyping, 3D printing can give you the best solution. Injection molding is only suitable for making final parts. Although you will need prototypes when making the molds, 3D printing is also handy in this case.

Injection Molding VS 3D Printing: Tooling Design

Tooling design is a crucial part of plastic injection molding. Molds are also called tooling. Injection molds are expensive and take time to design and produce. According to the 2024 market value, an injection mold costs approximately $3,000 to $100,000.

The high initial cost also increases the cost per unit, so tooling design may not be helpful for small-scale production. However, the price per unit goes down for large-volume orders.

In contrast, 3D printing doesn’t need tooling. You can print directly from a digital design. Because of this, 3D printing is ideal for creating prototypes that can help to make injection molds later.

Injection Molding VS 3D Printing: Turnaround Times

Turnaround time is the total time needed to start production and produce the finished product.

Injection molding has several steps in manufacturing. First, you need to design and create specific molds for plastic parts. Then, you should install them in the right place on the injection molding machine. You have to feed the plastic pellets into the hopper every time. The whole process may take 5 to 7 weeks for simpler plastic parts.

On the other hand, 3D printing generally has a shorter turnaround time. There is no need for complex tooling; it’s like a plug-and-play thing. In this case, for complex plastic parts, the turnaround time is approximately 1 to 2 weeks.

Injection Molding VS 3D Printing: Part Size & Tolerance

Injection molding typically produces plastic parts of all sizes. It can maintain high tolerance even if the part is huge. Because of this, injection molding is highly suitable for high-volume productions.

3D printing has some limitations regarding part size. You can generally work with small—to medium-sized plastic parts. To create large parts, you must make them in sections and assemble them later.

Injection Molding VS 3D Printing: Customization

The 3D printer is the winner for customization. It allows you to create complex designs without needing special tools or molds. If necessary, you can also change the designs and produce unique items. You can make the changes quickly. These benefits make 3D printing ideal for creating personalized products.

Injection molding is less flexible. You can create custom molds if your customer needs high-volume custom plastic parts. However, mold design is a time-consuming process. You might need to adjust the mold to change a small design, and every change adds extra costs. Thus, injection molding is not suitable for customization.

Injection Molding VS 3D Printing: Surface Finish

Injection molding generally offers plastic parts with a smoother finish than 3D printing. Except for the parting line, the injection-molded parts have no rough edges.

In 3D printing, the lower layer generally supports the upper layer. Because of this, you might find some extra parts on the printed object’s surface. These additional parts typically hamper the smoothness of the printed object. Therefore, you might need extra post-processing work to make the surface smoother.

Most consumer products, including car parts, toys, and electronic casings, need high-quality finishing. Injection molding is a better choice for these products.

Injection Molding VS 3D Printing: Material Waste

Injection molding generally produces less waste. You may find some extra material made due to sprues, rubber, and the parting line. Compared to 3D printing, this quantity is significantly less. It’s good that you can reuse this extra material by feeding it into the hopper in the next production run.

3D printing creates many extra layers, which are not necessary. The machine usually creates these extra layers for structural support. However, you can not use this extra material later because 3D printing only uses a roll of plastic filament.

Injection Molding VS 3D Printing: Cost

When you assess the cost, you must first break down it. First, injection molding needs a high initial cost. It may include both machine prices and tooling design. In this case, a 3D printer is a cheaper option.

Based on production volume, injection molding offers a cheaper solution for high-volume productions. The cost per unit for low-volume increases dramatically due to high tooling costs. 3D printing maintains the same price for both low-scale and high-scale production.

Finally, for long-term work, injection molding is the winner. However, 3D printing still maintains a high cost per part. Therefore, 3D printing is only suitable for prototypes, short runs, and rapid changes.

Frequently Asked Questions

Is 3D Printing Cheaper Than Injection Molding?

3D printing is generally cheaper for low-volume production. It doesn’t need tooling costs. Besides, 3D printers are also cheaper than injection molding machines. However, for large-scale production, injection molding offers a more affordable solution. Once you have created the mold, you can make millions of plastic parts using the same mold.

Is PVC used in injection molding?

Yes, PVC is commonly used in injection molding. It is cheaper than PC, ABS, and PP. Because of this, many plastic parts are made of PVC. This plastic offers excellent chemical resistance, durability, and versatility. It is perfect for making pipes, fittings, car parts, and many other consumer goods.

Which country is best for injection molding?

China is the leading injection molding manufacturing country. Many factories in this country offer cost-effective plastic parts while maintaining high quality. For high-volume orders, China is the best place for you to choose for your business.

How much does it cost to make an injection mold?

The plastic injection mold may cost between $3,000 and $100,000. Molds for small and simple design parts may cost $3,000 to $6,000. On the other hand, complex design and high-quality tooling may cost from $25,000 to $50,000. The price depends on the plastic part design, size, and quality.

What is the average price for a good 3D printer?

The average price for a good 3D printer may range from $1,000 to $4,000. You can also find 3D printers at $200, but these are only for kit starters. Besides, the $500 to $1,500 range of 3D printers is ideal for hobbyists. But for professional work, you must set your budget a little higher.

Summary

We have reviewed a detailed guide on plastic injection molding vs 3D printing. The article pointed out every detail you need to choose the best option. However, let’s summarize our pointers and review which might be best for your project.

Injection molding is ideal for high-volume orders. Various factories state that the minimum volume must be more than 500 units. This method is suitable for creating many consumer products, car parts, and more.

3D printing is mainly suitable for rapid prototyping, low-volume orders, and custom plastic parts. Unlike injection molding, 3D printing doesn’t need the least volume. Yet, this technique requires both time and filament costs for large-scale production.

Table 1 Plastic 3D Printing vs Injection Molding: Which is Better?

| Factor | Best Option |

| High-volume Production | Injection Molding |

| Low-volume Production | 3D printing |

| Prototyping | 3D printing |

| Cost-effectiveness | Injection Molding for large-scale production, 3D printing, or low-volume production |

| Material flexibility | Injection Molding |

| Consumer products | Injection Molding |

If you are looking for injection molding services, contact us. Dong Guan Sincere Tech is one of top 10 plastic injection molding companies in China that offer injection plastic molds and custom injection molding serivice. We also offer other services, such as die-casting molds, CNC machining, surface finish, and assembly services.

Leave a Reply

Want to join the discussion?Feel free to contribute!