How Much Does Injection Molding Cost

Injection molding is a common name for plastic part manufacturing. This process injects molten plastic into a mold to create different shapes of plastic. The process is easy to understand but very complex technology, it must be a professional molding factory to handle all of those jobs. However, the cost associated with this method may vary based on various factors. Today, we are going to talk about all these factors affecting the plastic injection molding cost.

People often ask about How Much Does Injection Molding Cost and what factors affect them the most. You might need this information to optimize your project’s total cost. What do you have to consider reducing the total cost? Stay tuned; this article will provide every single detail that you might need for your project.

This article is a comprehensive guide on injection molding costs. Consecutively, you will go through different kinds of expenses. On top of that, you will know what factors are running all these costs. There are some tips that you can use in product planning as well. In general, this guide will be very helpful.

What is Injection Molding?

Before we proceed with the cost analysis, we need first to review injection molding. In short, it is a popular type of plastic part manufacturing process. The term “injection” means that this method injects molten plastic into dies to create different shapes.

You can realize that injection molding heavily relies on high-quality dies. Plastic mold or dies is the core component of injection molding. The total injection molding cost significantly depends on this item. You’ll learn more about it later.

The process normally starts by heating the plastic until it melts. The molten plastic is then injected into the die or mold, which gives it its shape.

When the molten plastic cools and solidifies, it gets the desired shape of the plastic. This stage is very critical because most of the defects come from this stage if not handled carefully. Finally, you can remove the newly produced part from the mold. This is how plastic injection molding components are manufactured in a factory.

The whole process could take seconds or minutes. The specific duration is not fixed; it depends on the part’s size and difficulty. Car industries, consumer goods, and other factories heavily rely on this method. Parts like your car’s dashboard, TV remote, electric items, and many more are noteworthy.

Why is Injection molding so popular? One reason is that it saves a lot of money and is versatile. You can create almost anything if you have the dies for that specific part.

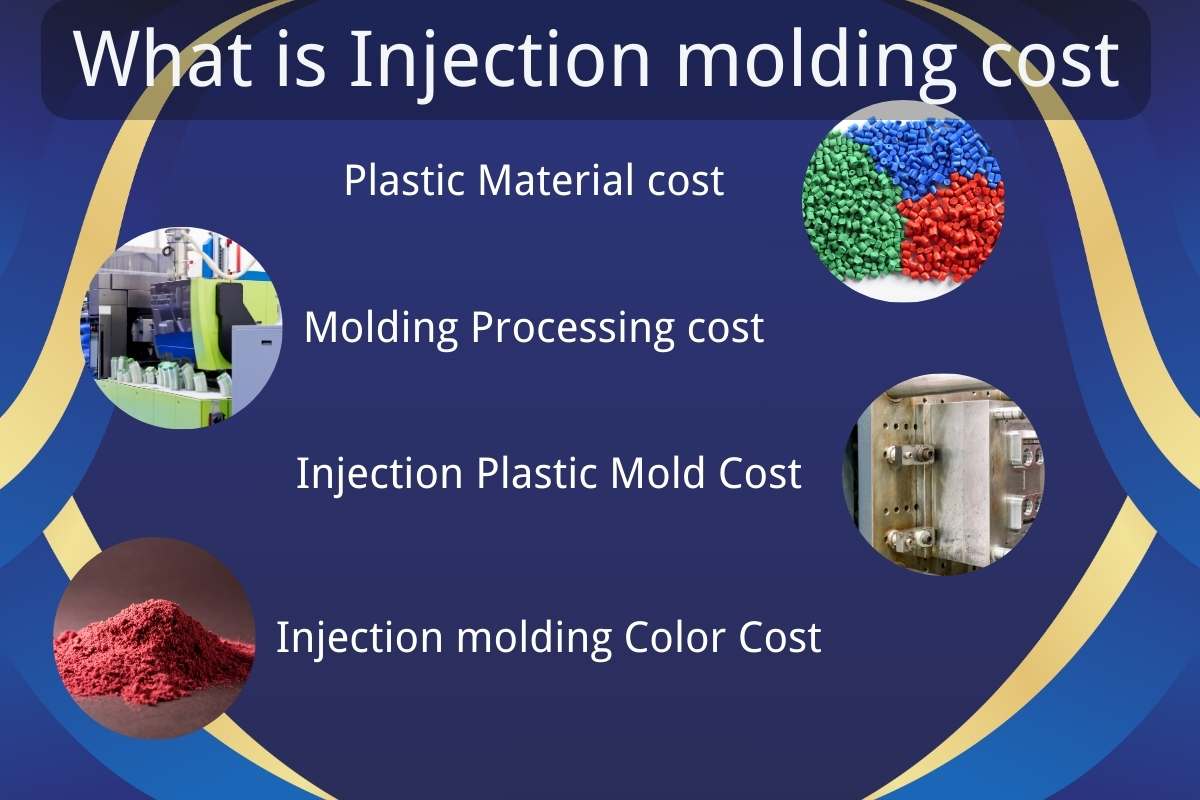

Different Types of Injection Molding Cost

Injection molding costs are not limited to making molds only. There is a wide array of cost differences in each stage of the process, from creating the mold to selecting materials and manual labor. Knowing these prices can help you keep your budget in check and improve production.

Part Design Cost

When you do injection molding, the first thing you do is product design. Usually, you will make a sketch or prototype for your final part in this step. The design cost typically ranges between $500 and $3000, depending on numerous design aspects. The key elements influencing this are the design’s complexity and prototype quality.

A simple design often costs less. On the other hand, a complicated design often has intricate pieces that require professional verification. That will require more time and effort, raising costs.

Moreover, the prototype also plays a role here. A prototype is the first physical representation of the final product. To get an accurate and satisfactory result, a new product first goes through various rapid prototyping processes. This step might need multiple iterations to get it right. Each revision adds up costs. This step is also important to create accurate mold creation.

Injection Molding Machine and Equipment Cost

A major part of injection molding cost generally lies in machines and equipment. A high-quality machine can ensure high precision, adding high expenses. The type of molding machine also influences the price.

For example, hydraulic machines don’t need electricity, while electric machines do. The use of electricity also adds to the injection molding cost. However, it is important to note that hydraulic hoses can handle heavy-duty tasks. These tools are used a lot for bigger plastic parts.

Furthermore, the type of injection molding equipment used may vary depending on the amount of manufacturing. For small amounts of work, desktop injection molding tools are sufficient. You could also use 3D-printed models in this case. However, for bigger plastic parts, you might need a larger machine, which might be costly, ranging from 50 grand to over 200 grand.

Note that purchasing the machine is just the beginning, and it is substantial. However, you must not forget about regular maintenance. Each machine needs to be maintained to ensure it runs smoothly, which also adds to the total injection molding cost.

Injection Molding Mold Cost or Tooling Cost

Creating mold is the most critical step of injection molding. Injection molding mold cost is the single largest upfront cost. This cost is often called tooling cost, go to injection mold cost page to know more about this cost.

The tooling cost or injection molding mold cost also varies based on different criteria. In general, there are two types of molds: single-cavity and multi-cavity. A single-cavity mold generally produces one item at a time. It is much cheaper, but this method is slow and increases downtime.

Multi-cavity molds, on the other hand, may produce multiple parts at once. They cost more than single-cavity molds, but they can speed things up. Making a mold with only one cavity is less expensive than making one with many cavities, but it can’t make cheaper goods in the long run. To get the best deal on mold, you should carefully consider what kind you need for your job.

You can make injection molds in many ways. Three popular methods are CNC machining, EDM machining, and 3D printing.

CNC Machining

You might already be familiar with this technology. This method uses computer programs to move along the designated area. So, there’s no chance of error in this method. Like other machining processes, you can use it to make injection molds. This method works well, quickly, and reliably. This is how you can cut the shape out of a metal block. Note that tooling material plays a crucial role in injection molding. Note that the cost of injection molding also depends on the type of tooling material.

CNC machining is an excellent method for achieving tight tolerances. However, it may be expensive. Setup and tooling can be costly, especially with complex designs. But if you make a lot of parts, it’s a good investment.

EDM Machining

EDM is one of the newest technologies that was discovered in the twentieth century. It is also a common method for producing complex injection molds. If you are looking for details or deep, sharp corners, EDM is the method you should look for. However, EDM is very slow and needs much care. It is also costlier than CNC machining.

3D Printing

3D printing is an excellent option for small and low-volume operations. It’s also an excellent option for creating rapid prototypes. It’s quick, inexpensive, and simple to use. However, it is not always the ideal option for creating long-lasting molds. 3D-printed objects are less durable than CNC or EDM-produced objects. For mass production, you may require a more robust solution.

Injected Material Cost

One of the most important considerations in injection molding is the cost of the injected materials. The material you choose has a huge impact on the cost of injection molding. Different types of plastic have different price tags. Commodity plastics, like polypropylene, are cost-effective materials. But if you need extra strength, then you might go for ABS or PC plastics, which are comparatively expensive.

Conversely, engineering plastic, like nylon, offers a balance between price and performance. High-performance polymers, such as PEEK, are superior but expensive. Thus, selecting the correct material is quite crucial in injection molding cost analysis.

Labor or Service Costs

The injection molding cost list concludes with labor or service costs. If you are dealing with an injection molding company, you can find this in their quotation. Different companies offer different types of service charges. It also depends on several factors.

High-quality products require special manufacturing and modern machinery, skilled workers, and special testing services. On the other hand, low-precision items may not require high-tech and skilled labor, resulting in a significant cost difference.

But how much does labor really cost? It depends. It usually costs between $2 and $3 per part, depending on the intricacy and size of the product.

Various tests and quality control are also added to the bill. The more complex the part, the more time these tasks take, which further increases the labor costs.

What Factors Influence the Injection Molding Cost?

You are already familiar with different types of plastic injection molding costs. In this article, you will learn about a few factors that influence the major costs. When optimizing the costs, you can mainly focus on these points.

Part size and weight

The first factors that influence the cost of plastic injection molding are part size and weight. The heavier and the bigger the part, the more materials you will need. This means higher material costs, which can add up quickly.

Also, bigger parts often require larger machines, which can increase equipment costs. Bigger plastic parts, like water tanks or air conditioner casings, need special care, which also adds up to the labor costs.

Therefore, when making decisions about plastic part design, you must consider size and weight. Try to optimize the weight based on the intended use. Some plastic materials are lightweight and strong enough to handle many jobs. Although the material cost might be a little higher, it can save up many costs in production.

Part Design

Part design is another crucial factor that heavily influences plastic injection molding costs. In this case, complexity and features are the most critical option here.

Intricate designs may look astonishing but can be costlier than simply designed parts. These plastic parts often need higher mold costs and longer production times. As usual, when designs get complicated, it becomes trickier to create the molds. Conversely, simple designs are much easier to make and less prone to defects. Less complexity means fewer mistakes and lower costs.

Another factor you must consider is the assembly process. If parts fit together well, assembly is a breeze, which can cut down on labor costs. Designing with assembly in mind makes the manufacturing process easier.

Production Volume

Production volume is another big factor in determining the cost of plastic injection molding. When you produce parts, you get better costs per part. This means that the fixed costs, like mold creation, are spread out over many units, resulting in a lower cost per part.

Conversely, lower production costs can lead to higher costs. When you don’t produce enough parts, the fixed costs are not shared, and each piece can end up costing more. In this case, labor and material costs matter a lot.

Tooling costs also come into play. High-volume runs allow you to amortize the initial mold costs over a larger number of parts. Thus, the more parts you make, the more profits you can make.

Number of Cavities

The previous section already mentioned that a mold can be of two types: single and multi-cavity molds. In a single cavity, you can create only one plastic part at a time. Multi-cavity parts, on the other hand, allow you to produce multiple pieces at once.

A single-cavity mold is simple to operate, but if you require many pieces, it might become expensive. Molds with more than one hole, on the other hand, can produce many parts simultaneously. Because of this, multi-cavity molds reduce cost per unit, making them a more cost-effective option in the long run.

However, it is important to note that more cavities mean more complex designs in one mold. Therefore, you need to balance the complexity with output. If production volume is high, multi-cavity molds are better. But if your part design is intricate, a single mold cavity might be a better option.

Also, maintenance should be considered here. More cavities usually need more upkeep. You will need to clean it every day before the operation. Take the time to weigh the pros and cons carefully. Pick the best mold for your job.

Mold Material

Most molds are made of high-quality tool steel, a type of carbon alloy steel that lasts a long time. Tool steel is classified into numerous varieties, including HSS, D2, and A2.

HSS is ideal for cutting at high temperatures. It is normally not inexpensive, but it has a long lifespan. D2 steel is robust and wear-resistant. It costs more because of its durability. A2 steel, on the other hand, provides an excellent mix of toughness and cost. However, it costs less than D2 steel.

The plastic substance and manufacturing volume determine the proper amount of tool steel. If you plan on a large production, high-quality tool steel is required. Overall, be careful about your needs. Weigh the cost of the injection mold against the benefits. Getting the right mold material can make production go more smoothly and help you make more money.

Injection Molding Cycle Time

The injection molding processing time is an important factor in the quality of the product. It has three key parts: injection, cooling, and ejection.

The cycle time is based on how you plan to make things. Automated machines can give you a shorter cycle time. On the other hand, manual operations are much slower than those of automated machines.

Automated machines require higher upfront costs, but they save a lot of plastic injection molding costs per part in production. Manual injection molding doesn’t require a higher investment. However, it makes the process much slower, which technically increases the injection molding cost per part.

How Much Does Injection Molding Cost? A General Idea

You are already familiar with the cost of injection molding, which varies depending on several factors. Major factors are design complexity, material choice, production volume, and mold costs. To give a general idea, the following table outlines the price of each factor.

| Cost Factor | 50,000 Units | 100,000 Units |

| Mold Design | $500 – $3,000 | $500 – $3,000 |

| Material Cost | $0.50 x 50,000 = $25,000 | $0.50 x 100,000 = $50,000 |

| Service Charge | $2,500 – $5,000 | $2,500 – $5,000 |

| Injection Mold Cost | $2,500 – $5,000 | $2,500 – $5,000 |

| Total Cost | $30,500 – $38,000 | $55,500 – $63,000 |

| Cost per Part | $0.61 – $0.76 | $0.56 – $0.63 |

As you can see, the more production volume there is, the less cost there is. Also, the cost of plastic injection molding varies a lot on the design of the mold, the material used, the service class, and the cost of the injection mold. Keep in mind that this table is just an example. The real price might be different depending on the type of material used and how the product is designed.

Tips on How to Optimize the Plastic Injection Molding Cost

You are already aware of the different factors influencing plastic injection molding costs. Now, you must learn how to optimize these costs. We have prepared some tips to help you on your journey.

Tip #1: Utilize DFM Analysis

DFM, or design for manufacturing, is an important term. It plays a critical role in injection molding costs. This method finds design problems early on. Using this method, you can eliminate the unnecessary part of a plastic part. This way, you can lower the chance of having to do expensive work over.

Tip #2: Simplify Design Features

Always try to create a design that is as simple as possible. The more complex the design, the costlier it will be to make the mold. Try simplifying where you can. Fewer designs also provide shorter cycle times and lower the total injection molding cost.

Tip #3: Use Universal Molds Instead of Custom Molds

Of course, custom models cost a lot. You can save a lot of money by using standard molds in this case. Once you have standard molds, you can make some design changes.

Tip #4: Choose the Right Injection Molding Material

There are numerous types of plastic, each with its advantages and disadvantages. So, choose a material that offers a fair balance of cost and performance. Avoid using too many high-end items unless absolutely required.

Tip #5: Try Insert Molds

Metals can be added to plastic parts to reduce their weight. This guarantees that they are durable and cost-effective.

Tip #6: Minimize the Number of Cavities in Molds

Too many holes can be a mess. Not only do they cost more to grow, but they also need a lot of upkeep. So, if your output volume allows, keep it simple.

Tip #7: Design Self-Mating Parts

You can also make your plastic parts self-mating to cut costs. This feature generally reduces assembly time and costs. The parts snap or fit together without requiring extra components or fasteners.

Rapid Injection Molding at Sincere Tech

Sincere Tech is a leading manufacturer of high-quality injection molding parts and specializes in rapid injection molding. The company cares most about quality and speed. Modern technology is used in the workplace to ensure the product is accurate. This business also promises to serve on time.

Sincere Tech has many services to choose from. They help with unique molding, prototyping, and production. Their services are not limited to plastics; you can also get various die-casting services. Therefore, any type of product, including plastic and metal parts, can easily be manufactured or assembled at the Sincere Tech factory.

Summary

Let’s wrap everything up! Injection molding is easy to use to make a lot of plastic parts at once. It works quickly and doesn’t cost much. Still, many things affect the cost of injection molding.

This piece discussed the different kinds of plastic injection molding costs and the main factors that determine them. Design, molding, material, equipment, and service charge are five crucial types here. Product design, complexity, and size heavily influence these costs. Technically, the production volume and mold cavities also heavily affect these injection molding costs.

The article also introduced a few tips that could help you optimize on how much does injection molding cost. If you still have questions, don’t hesitate to get in touch with our customer service staff. We are committed to offering excellent customer service.

Leave a Reply

Want to join the discussion?Feel free to contribute!