DFM Design for Manufacturing

What is Design for Manufacturing (DFM)

So what is Design for Manufacturing (manufacturability)? Why do I care? These are a couple questions we hear in the development a new product, before mold manufacturing, this DFM report is an important phase. Design for Manufacturing (DFM) is the process of designing a product in such a way that it is easy and cost-effective to manufacture. This can involve simplifying the design, using standard components, and optimizing the design for the manufacturing process that will be used.

The goal of DFM report is to reduce production costs, improve quality, and increase efficiency. It is an important aspect of the product development process, as it can have a significant impact on the overall success of the product. The basic idea exists in almost all engineering disciplines, but of course the details differ widely depending on the manufacturing technology.

DFM Design for Manufacturing

Why do we need make Design for Manufacturing (DFM) analysis for A new Mold

A Design for Manufacturing (DFM) report analysis is important for a new mold project because it helps to identify potential design and manufacturing issues before the mold is produced, it is similar to the moldflow analysis report for a new mold. This can save time and money, as it is much more cost-effective to make changes to the design before the mold is built, rather than after.

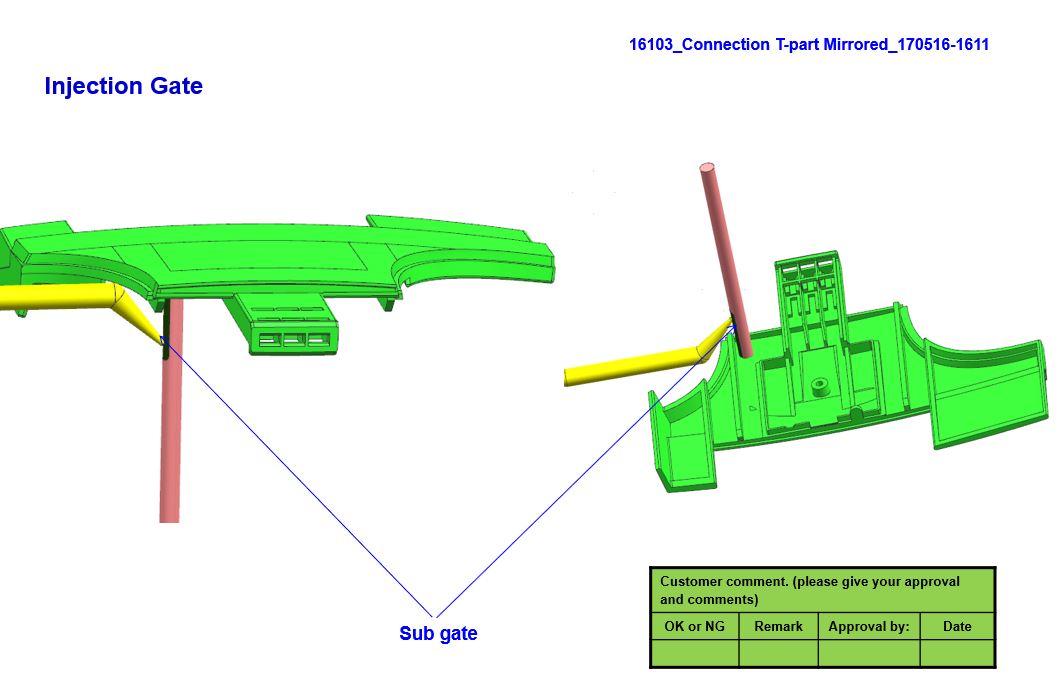

A DFM report analysis includes a detailed examination of the product design and the manufacturing process, and can help to identify issues such as:

- Design features that may be difficult or impossible to manufacture

- Materials that may not be suitable for the manufacturing process

- Assembly processes that are inefficient or unreliable

- Potential quality issues that may arise during production

- Cost-saving opportunities that can be implemented in the design and manufacturing process.

- Part features that may be difficult or impossible to mold

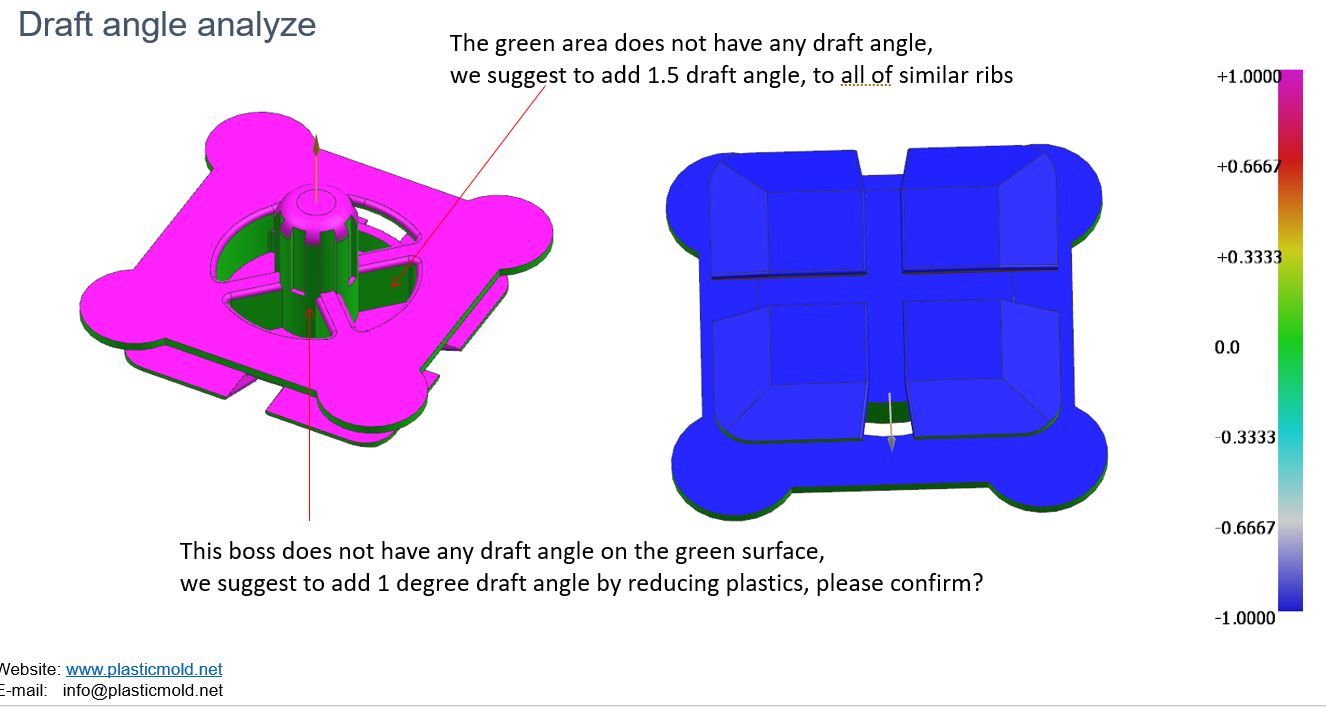

- Draft angles that are insufficient for easy part removal from the mold

- Wall thicknesses that are non-uniform, which can lead to warping or other quality issues

- Undercuts that may require additional mold components, adding cost and complexity to the mold.

Overall, a DFM report analysis can help to ensure that the product design is compatible with the manufacturing process and that the final product will meet the desired quality standards. It also helps to minimize the time and cost of the manufacturing process and can improve the product’s yield rate. Additionally, it helps in identifying cost-saving opportunities and make design improvements that can lead to increase in efficiency, product quality and profitability.

DFM Report Is Intended To Prevent:

I think that is a good overview of the general concept of what DFM (design for manufacturing) is. So the next question is “why is it a problem? There are a number of possible answers for this question.

First possible answer is that the manufacturing technologies are continuously changing so it is difficult to keep up with the new technologies available. This could be true…I am not sold though.

The next answer could be that engineers are not trained properly coming out of college. This is a possible answer but it seems like it blames the problem on someone else.

Last, the answer could be that engineering is no longer performed at the same facility as manufacturing!

With manufacturing moving offshore to locations far away from engineering, the collaboration that existed in the past between design engineering and manufacturing no longer happens. Designs are created and then passed to manufacturing to make parts. Sounds great and very efficient, just not as flawless in practice.

How does an engineer learn about the hidden issue of injection molding? Well, unfortunately, they don’t. Not until they design a part and have it manufactured do they see problems. With that said, there are now services out there to help with the manufacturing process during the product development phase.

We will provide a design for manufacturing (DFM report) for every part before start mold design and mold manufacturing. Go to mold design for injection molding to know more succesfull design for high quality molding. We saw the void created in the industry and want to provide a free service that helps both our customers and us during the mold manufacturing process.

We have seen this as a huge success for customer wanting to proceed to injection molding. This has helped product development companies reduce cost, lead time and ultimately FRUSTRATION.

If you have a new product that plan to make mold and injection molded parts, and you are not sure if your part design is good anough to make high quality molds. Welcome to send us an email to discuss about DFM for your project, we will quote you a price for your project, and will make freee DFM report for you.

If you want to know a completely DFM report, you can download the DFM report sample below.