When it comes to peek CNC machining, various benefits come to play a vital role like exceptional machineability, and optimal performance of the part being manufactured. PEEK is identified as a widely used thermoplastic polymer. The applications are so widespread across the manufacturing of disposable, or single-use components to highly durable interior automobiles and aircraft components. For example, medical implants and electrical cable insulation are ideal results from CNC PEEK machining.

In addition, PEEK has gained a reputation for its excellent mechanical qualities and ability to withstand corrosive substances, making it a very popular material among manufacturers globally. As it’s frequently used in injection molding and 3D printing, its high melting point hints at its potential applicability in subtractive processes like peek cnc machining. In addition, the machining of PEEK also has its set of limits in terms of annealing, and heat-affected issues.

This blog post is a comprehensive look at machining PEEK from the basics, discussing its material characteristics, the benefits of machining this polymer, typical applications, and useful tips for achieving the best machined PEEK components.

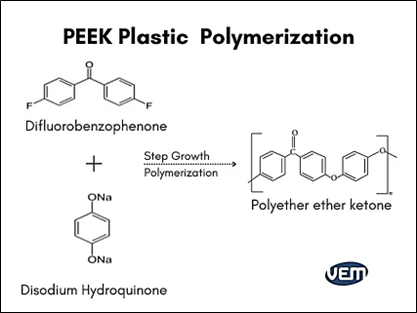

What is PEEK Material?

In particular, PEEK provides a chemical and water resistance similar to PPS, check PPS injection molding page to know more, albeit with a melting point of 343 °C. This makes it resistant to high temperatures and the device can keep functioning up to 250°C. It can also be exposed to hot water or steam without considerable degradation of its physical properties.

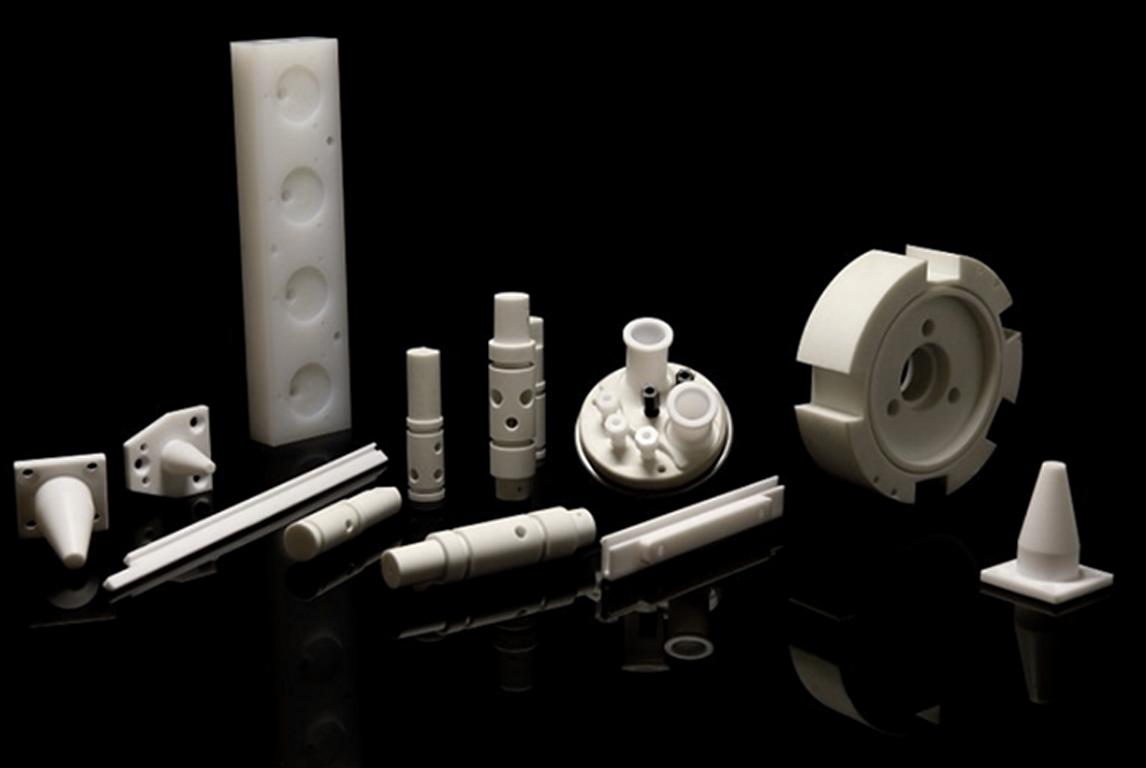

The material can be molded into granular form, filament for the 3D printing process, or bar/rod form for CNC machining. Depending on the application, the PEEK is classified as industrial-grade or medical-grade.

PEEK, or abbreviation of polyether ether ketone, is a part of high-performance PEEK materials and is a widely used engineering thermoplastic. This semi-crystalline polymer is widely employed across industries for its superior strength, wear resistance, and long-lasting quality even under high temperatures.

Medical Grade Vs. Industrial Grade PEEK: Key Differences

A question of industrial-grade or medical-grade PEEK arises when peek machining is considered and this decision should be based on the specific requirements of your application.

PEEK, an industrial material, is flame and abrasion-resistant, with high impact strength and low friction coefficient. Its mechanical properties are not changed even at high temperatures. This grade is applied in the aerospace, automotive, chemical, electronic, petroleum, and food and beverage industries, among others. This degree can be taken for extreme industrial applications.

However, the latter has more advantages, for example, it is biocompatible according to ISO 10993 standards, it is chemically resistant and compatible with sterilization. This PEEK is also non-visible under X-ray, MRI, or CT scans by being radiolucent. For instance, PEEK Optima and Zeniva PEEK. PEEK is suitable for implants that are in touch with blood or tissues for a long time and are imitating the stiffness of the bone. The other composition is better for the development of implants such as articulating joints and spinal devices.

Machining PEEK offers several advantages, which can be categorized into two main areas: the basic material superiority of PEEK and the unique process superiority of using CNC machines for cutting PEEK.

Benefits of PEEK Machining

PEEK’s material advantages in machining include:

- Notably, the material entails exceptional chemical resistance

- Usually, moisture absorption is almost negligible.

- Typically, it has good abrasion resistance as compared to other thermoplastics grades.

- The capability to endure long exposure to hot water or steam.

- Resistance to biodegradation

What are the Limitations of PEEK CNC Machining?

PEEK machining, while popular as a metal substitute, comes with certain limitations: PEEK machining requires processing that addresses the internal stresses and avoids heat-related cracks.

- Annealing is necessarily required

- The heat dissipation properties are not good.

- Drilling deeply can cause cracking because it is susceptible to cracking.

- Special Handling for Stress and Heat-Related Cracks:

Heat-induced cracks and internal stresses in PEEK are best mitigated by taking precision machining measures. Tool selection, toolpaths optimization, and cooling are the main factors to be tackled to overcome these challenges.

- Requirement for Annealing:

The annealing process following the machining is usually done to eliminate the residual stresses in PEEK parts. This step makes sure the dimensional stability and the possibility of distortion in machined PEEK components are reduced.

- Limited Heat Dissipation:

PEEK has an inadequate heat dissipation ability during cutting. The use of advanced cooling techniques to ensure temperature control is vital to prevent overheating, tool wear, and surface defects.

- Risk of Cracking in Deep Drilling:

The deep drilling process can lead to the formation of cracks in PEEK components. To reduce this risk, the monitoring must be accurate, proper tool geometry, and the removal of chips must be efficient.

These obstacles are addressed to ensure successful PEEK manufacturing and fabrication, which is done without compromising the quality and integrity of the final products. PEEK manufacturing and fabrication, while a dependable alternative to metals like steel and aluminum, has notable limitations: PEEK manufacturing and fabrication, while a dependable alternative to metals like steel and aluminum, has notable limitations:

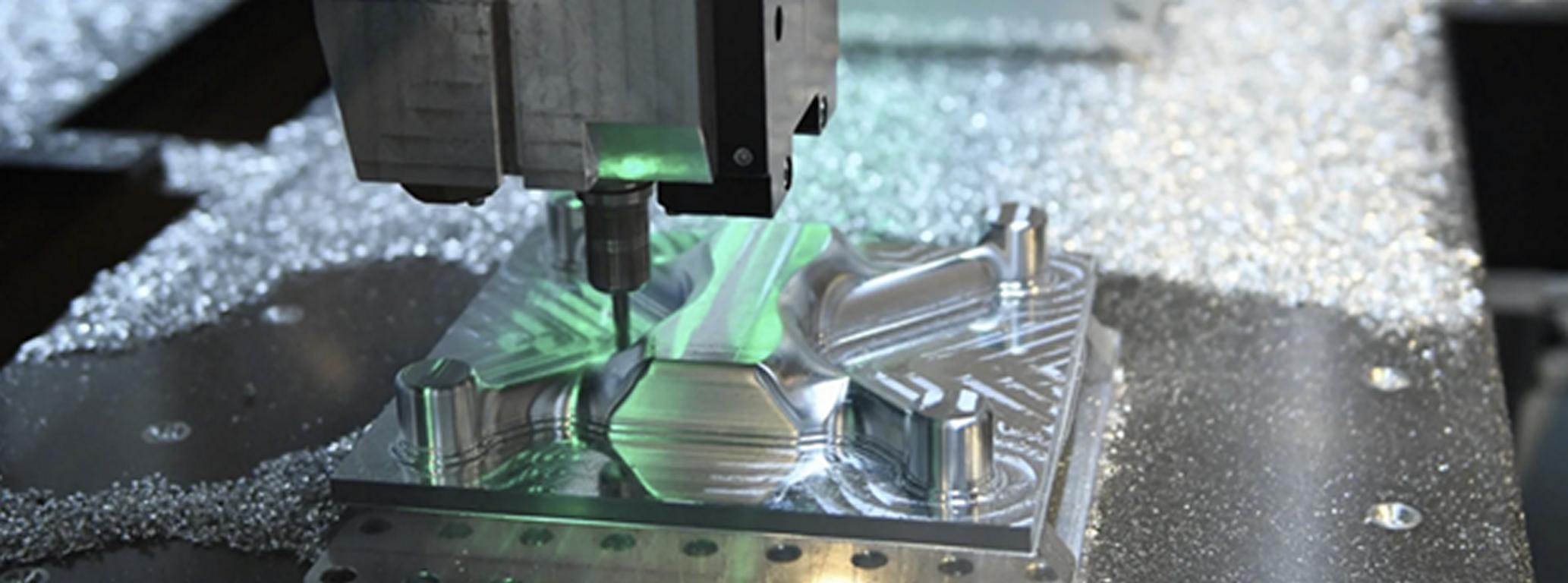

Tips to Effectively Machine PEEK

Here are some tips for machining PEEK plastic effectively: Here are some tips for machining peek effectively:

Annealing of PEEK

Annealing PEEK is a key process of precision PEEK machining. Usually in rod form and with different diameters, PEEK goes through an annealing process before machining to reduce the surface cracks and internal stresses due to heat. Annealing, in addition to lowering stresses, also improves crystallinity and provides a degree of control over the dimensional changes. For longer machining times, intermittent annealing may be needed to keep tight tolerances and flatness, respectively.

Besides, industrial-grade and most medical-grade PEEK materials are machined similarly except for the PEEK reinforced with carbon fiber. The choice of silicon carbide cutting tools for the machining of natural PEEK and the preference of diamond tools for PEEK with carbon fiber reinforcement is appropriate. The biocompatibility of the PEEK for medical purposes must be preserved during the machining. Dry machining is preferred but PEEK doesn’t conduct heat well like metal so coolant may be required in some situations. Air cooling helps to keep biocompatibility in check, which is important for medical-grade PEEK. Scraps of machining PEEK for medical purposes can be re-used in industrial products. There are various other factors also must be considered for effective peek machining.

- Cutting tools: PEEK is typically among the plastic types that can be fabricated by silicon carbide tools or machines. For PEEK materials with higher strength or tighter tolerances, diamond tools are employed. Avoid using tools that are commonly used on metals as this may lead to contamination.

- Cooling: PEEK, moreover, doesn’t dissipate heat well, so liquids should be used as a coolant during machining to prevent deformation or breakage. Nevertheless, the use of pressurized air for cooling is important for medical purposes, to maintain biocompatibility.

- Drilling: Deep hole drilling requires much care as PEEK has lower elongation and is prone to cracks compared to other plastics.

Compatible Techniques For Machining PEEK

PEEK material has the advantage of not only being suitable for CNC machining but also for additive manufacturing (3D printing) and injection molding. The method of choice is dependent on the quality of the final product, time constraints, and budgetary considerations.

3D printing PEEK can be done with FFF filaments as well as SLS powders. PEEK’s accessibility for CNC machining and injection molding is greater than as compared to additive manufacturing at present. 3D printing is coming into the limelight, particularly in the medical sector, as it can create complex and partially hollow geometries with relative ease.

PEEK injection molding resin is a common practice in medical, aerospace, and other industries. Even though it has a very high melting point, it may be a problem for some injection molding machines which may require it to be a specialty material in some cases. PEKK and Ultem are other high-temperature plastics that can also be considered.

Industrial Applications of PEEK Machining parts

Without a doubt, PEEK Maching parts should be applied purposefully to take advantage of its operational advantages. Here are some key components and industries where PEEK CNC machining parts is particularly suitable:

Oil and Gas:

PEEK Machining valves are a great option for downhole tools in oil and gas applications. They are optimized for extreme conditions such as high temperatures and corrosive chemicals, which make them better in terms of chemical resistance and heat tolerance. The valves will be working well in that they will ensure that the flow of the fluids is regulated and hence operations will be safe. In addition, their robustness allows them to extend operation life, decreasing maintenance and replacements.

Medical:

PEEK CNC Machining part is used in orthopedic and spinal surgeries as a crucial component. It is extensively used for implants, especially in spinal fusion operations for the treatment of degenerative disc disease. PEEK cages that are usually filled with bone grafts are free from adverse reactions because they are biocompatible. In addition, PEEK radiolucent property allows clear post-surgery imaging and mechanical support which is similar to the natural bone.

Aerospace:

Components of aircraft, especially in engine and cabin regions, are made of PEEK Machining or PEEK injection molding process. It is for cable sheathing and insulation that is lightweight and hence used for fuel efficiency. PEEK’s ability to withstand high temperatures is another factor that makes it suitable for the aerospace industry, where safety and durability in extreme conditions are critical. PEEK composite materials can substitute metal in some parts, and consequently, the weight is decreased while the strength remains the same.

Electronics

PEEK possesses outstanding electrical insulation properties and thus, it is the best choice for many applications in electronics. PEEK is a material that connectors, insulators, and cable insulators all benefit from. Such as PEEK wafer carriers which are indispensable in semiconductor manufacturing for their capacity to withstand extreme chemicals and high temperatures during chip fabrication.

Automotive

In the automotive industry there is a continuous search for materials that lower the vehicle weight and increase fuel economy. Gears, thrust washers, and seal rings are a few of the components that are using PEEK machining parts. Through its ability to minimize friction and wear, coupled with thermal stability, it is the perfect choice for the parts of engines and transmissions, which are under high stress.

FAQ’s

Q1. Does PEEK provide ease of machining or not?

PEEK presents a challenge during machining because of its special properties. The professional handling by the experts who are skilled in the process is a key factor for the optimized results.

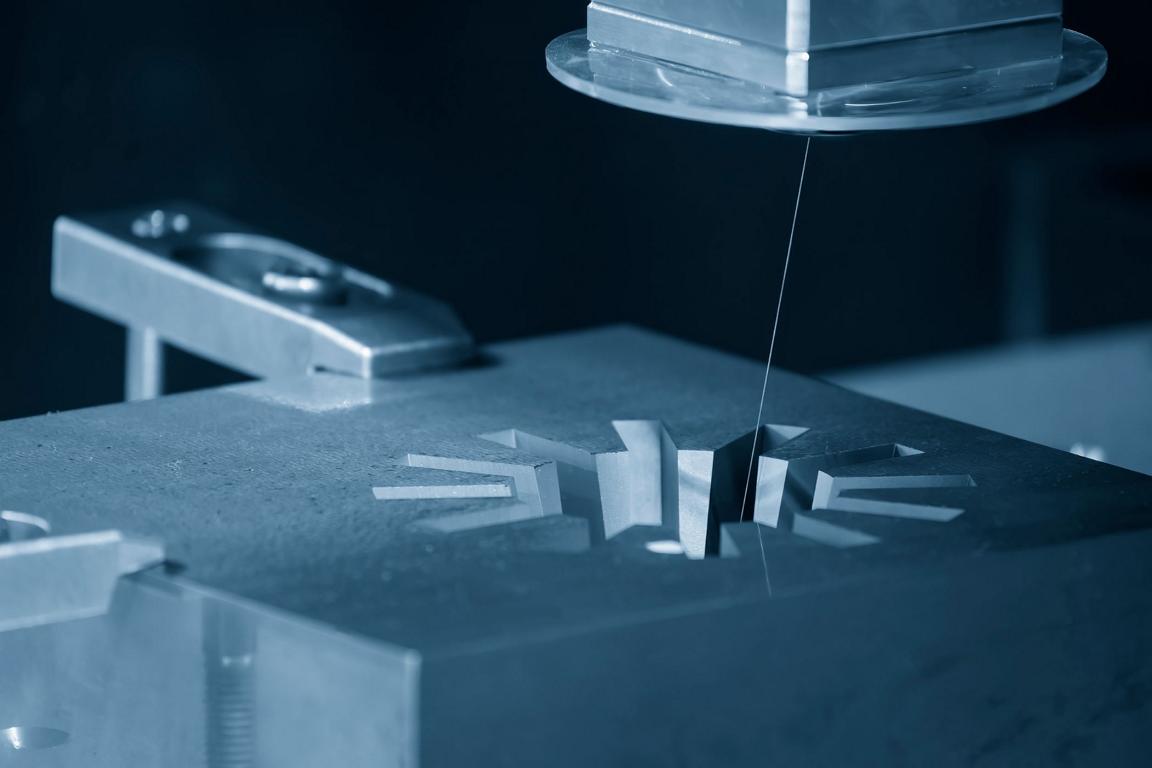

Q2. Can PEEK be EDM machinable?

EDM is very efficient in PEEK and it allows the creation of complex geometries that are unattainable with other methods.

Q3. PEEK, Is It Stronger Than Aluminum?

Even though the PEEK has a higher strength than aluminum (45,000 psi), it is the best among the thermoplastics in the ratio of strength to weight. It is a reliable replacement for metals like steel, glass, and aluminum in different applications.

Wrapping Up

The remarkable PEEK characteristics including chemical resistance, biocompatibility, and close tolerances are the reasons why PEEK is used extensively in various industries. The knowledge gained from this article will help get well-machined PEEK.