Top 10 Plastic Injection Molding Companies Near Me

Are you looking for the best plastic injection molding companies near me in 2025? Look no further! Below is a list of the best and most certified plastic injection molding companies near me in the world location, no matter where you are and you can find our the best plastic injection molding company near you.

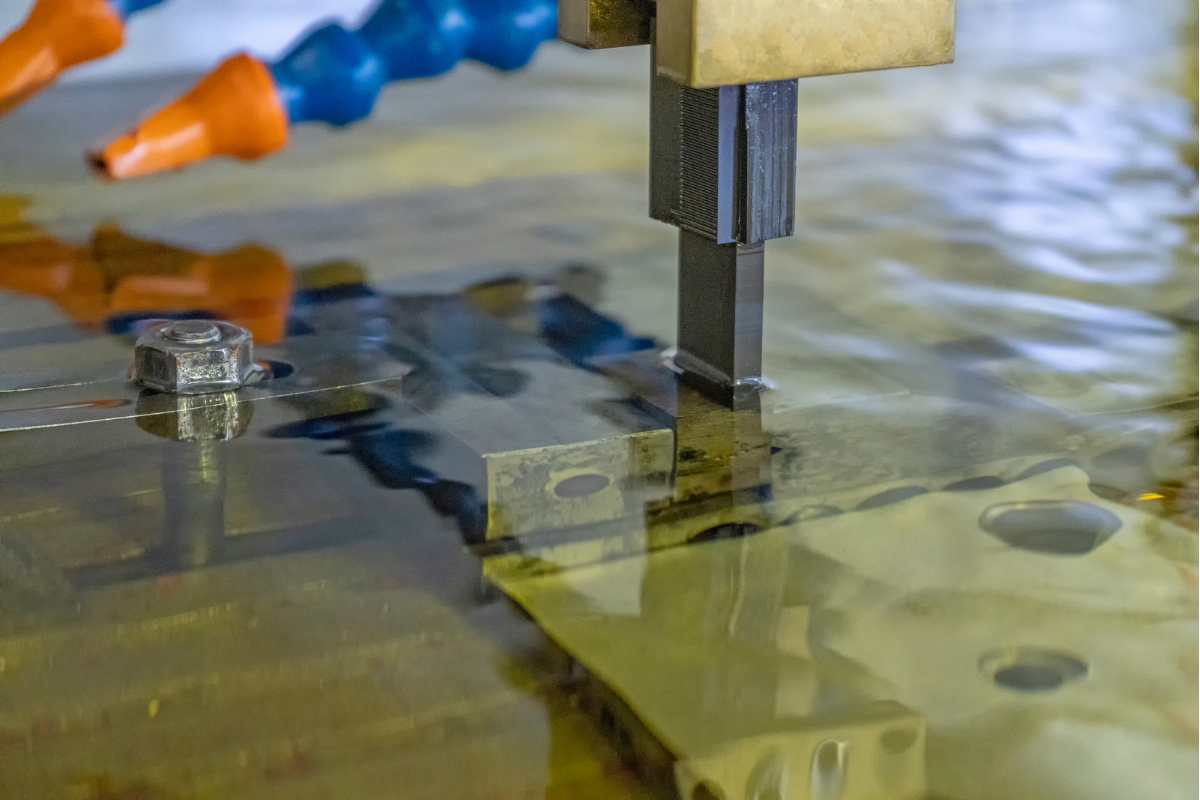

Injection molding is an innovative plastic fabrication technique widely used for mass production. It entails the process of forcing molten plastics into molds to produce a large number of similar products in a production line. Quality is always a priority, so we are focused on identifying the best plastic injection molding near me available at your location. So, let’s explore your top-best plastic mold tooling companies near your area in this blog post.

The plastic injection molding manufacturers mentioned below were selected based on providing consistent support to their valued customers. This criteria includes:

The consistent supply of raw materials

- Compliance Licensing and certification requirements.

- Pricing strategies that are competitive in the market.

- High-quality production of goods.

Here’s the list of top 10 plastic injection molding companies near me on the world location, you can refer which plastic injection molding company near your area.

1. Dongguan Sincere Tech Co.

Year Established: 2015

Location: Guangdong Province, Dongguan City, China

Dongguan Sincere Tech Co., Ltd is a reputable company that offers high-standard quality solutions and is committed to satisfying its clients in the plastic molding sector. Dongguan Sincere Tech has provided the best-in-class on-demand plastic injection molding services in die casting, machining, and surface finish to various industries for over 19 years. They care about their valued customers and offer NDA and excellent customer service for good customer-client relationships.

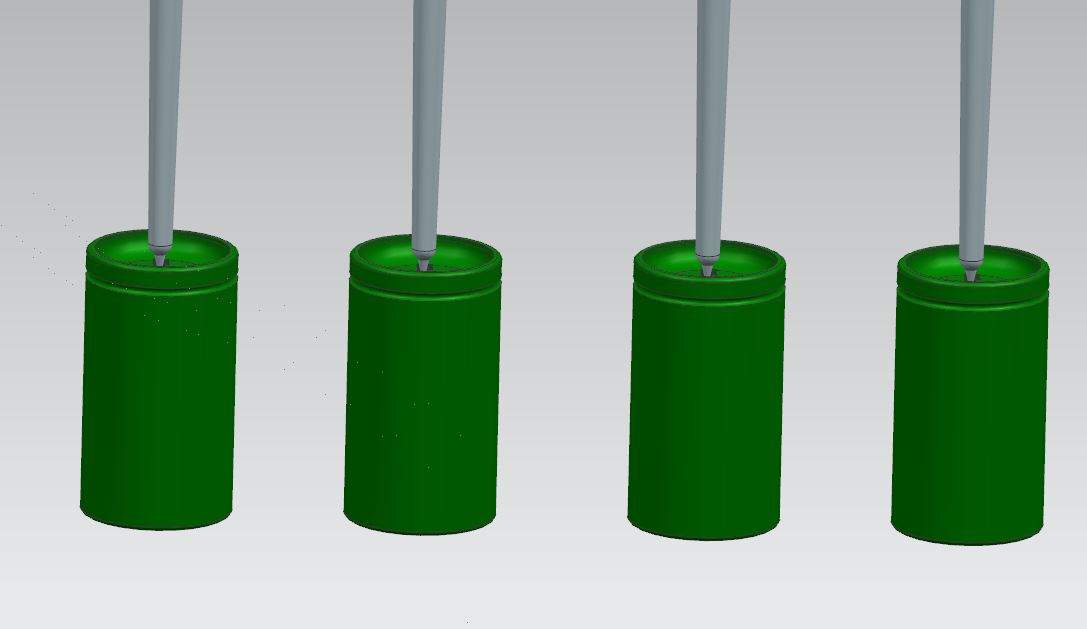

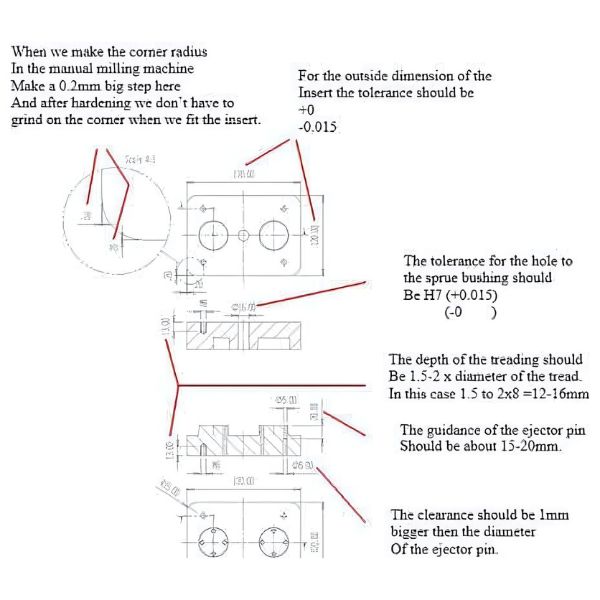

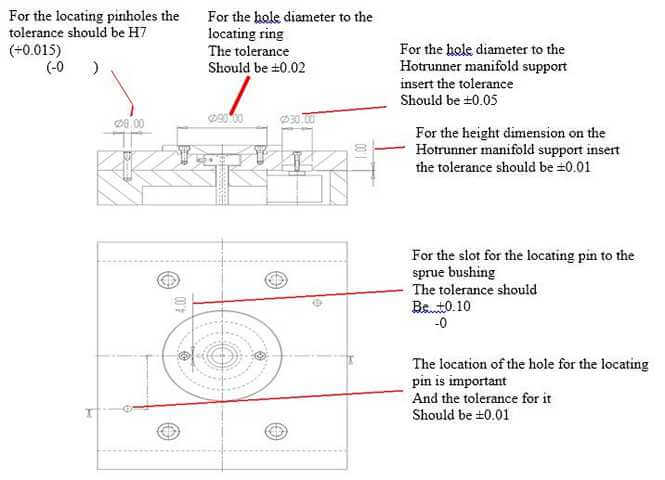

From appropriate raw materials choice to streamlining part manufacturing projects, their faculty provides exceptional services from a wider prospect. Sincere Tech has a wide product portfolio including molds for electronics, household appliances, medical devices, and many more. Moreover, they also offer other services such as 3D printing, CNC machining, aluminum die casting, plastic product designing, and prototype manufacturing.

Sincere Tech is one of the top 10 plastic injection molding companies in China, if you are looking for plastic injection molding near me in China, you are welcome to contact us. We will offer you the mold manufacturing cost as low as $500 and will offer you a 20-40% discount of your mold manufacturing cost for your first project.

Contact us to get a quotation sheet in 24 hours.

2. Rosti GP Germany

Year Founded: 1944

Location: Malmö is the capital of Skane County in Sweden.

Number of Employees: 1,001-5,000

Rosti GP Germany is a leading plastic injection mold company that specializes in offering services such as plastic injection molding, manufacturing of plastics, technical engineering, and design support services and it is located in Malmö, Sweden. Rosti was established in 1944 and it has a strong international network that includes partners in Sweden, Germany, Poland, Romania, the United Kingdom, Turkey, China, and Malaysia, and has around 3,500 employees.

Rosti provides injection moulding solutions for a broad range of industries such as industrial, packaging, consumer appliances, business machines, automotive and medical industries. Being a one-stop solution partner, Rosti is a reliable option for top OEMs globally since they offer finished products with precision parts and sub-assemblies. Rosti is one of top 10 plastic injection molding companies near me if we are lookng for German location injection molding companies.

3. Xometry Enterprise

Founded Year: 2015

Location of Office: Washington DC Metro / Maryland, USA

Business Type: Plastic Molding Manufacturer

Products & Services: Injection Molding Services, Plastic Injection Molding, Plastic Surface Finishing

Company Profile

Xometry Enterprise is one of top 10 plastic injection molding companies in the USA that specializes in high-value manufacturing and efficient supply chain management. Xometry was founded in 2015 and has since assembled a network of over 10,000 manufacturing partners for plastic injection molding, which means it has almost unlimited capacity. This vast network makes it possible for Xometry to cover the entire production process from the validation of new prototypes to production runs. Xometry is committed to helping its clients achieve their growth objectives through offering the best plastic molding services.

Xometry is one of the best plastic injection molding companies near me if we are sinking for USA OEM plastic injection molding contract manufacturing companies.

4. SKYTEC

Year Established: Not specified

Location: Marinha Grande, Portugal

Company Type: Manufacturer/Producer

Main Products/Services: Bi-material molds, gas injection molds (GID), tandem/sandwich molds, rotational molds, insert molding, and molds with high geometric complexity.

Company Size: 11-50 employees

Company Profile:

SKYTEC is an injection molding company that focuses on the production of moulds for the plastic injection sector, with high levels of complexity. Their specialty is bi-material molds, gas injection molds (GID), tandem/sandwich molds, rotational molds, and insert molding. They are involved in the design, development, and production of the product from the conceptual stage, through the creation of prototypes, engineering, and manufacturing to the try-out, validation, and production of parts, and even after-sale service.

SKYTEC has the capability to produce up to 40 tons of products and has a 2000 m² production area with state-of-the-art equipment for various industrial segments. Based in Marinha Grande, the largest plastic injection and moulding sector cluster in Europe, SKYTEC has NP ISO 9001 accreditation.

SKYTEC is a plastic injection molding company near me if you are looking for injection molding companies in Europe.

5. RIGHT DESIGN SERVICES

Year Established: 2001

Location: 110 Middle Road #07-03a, Chiat Hong Building, Singapore 188968

Company Type: Service Provider

Main Products/Services: Product Design & Injection Mold Design Services, Precision Moulds for Automobile, Office Equipment, Technical and Consumer Products

Company Size: 1 – 10 employees

Company Profile:

RIGHT DESIGN SERVICES provides injection mold design services to the mold-making, molding and manufacturing industries for over a decade. They primarily focus on precision moulds and serve automotive, office interior equipment and consumer products industries. Moreover, they offer end-to-end solutions from design to production to deliver quality concepts and manufacturing solutions for intricate components. RIGHT DESIGN SERVICES is a small team that aims at providing unique solutions and keeping close contact with the clients. The company is mainly focused on the export market, and only 20% of its products are sold domestically.

There are a leading plastic injection molding company near me if we are looking for plastic injection molding companies in the Singapore.

6. GDI CORPORATION

Manufacturing Services: Injection Parts, Plastic Packaging

Location: Yablanitsa, Industrial Zone, kv 106, 5750, Bulgaria

Year Established: 2020

Company Type: Manufacturer/Producer

Main Products/Services: Injection molding, Injection stretch blow molding, Printing on plastic parts, Ultrasonic welding, Blister packing, Assembly of products

Company Size: 51 and 100 employees.

Company Profile:

GDI Corporation was founded in 2020 and is located in Bulgaria; the company specializes in injection molding, injection stretch blow molding, and printing on plastic parts. We work in a clean room environment that is ISO 14644-1 certified with class 8 air cleanliness for medical plastic bottles and components. Their services include manufacturing of plastic parts in different sizes and materials like PP, PE, PET, TPE, silicone, PC, PS, and ABS.

They also provide printing services using genuine inks and high-quality production machines in the market. GDI Corporation aims at providing quality products and provides solutions in manufacturing that suit the requirements of the industry.

Advantages of Partnering with GDI CORPORATION:

- Cleanroom manufacturing

- Various plastic molding possibilities

- Printing and finishing services

- Certified quality standards

- Customized manufacturing solutions

They offer services include injection molding, blow molding, printing, ultrasonic welding, blister packaging, and assembly among others. We are certified to ISO 9001, ISO 13485 for medical products, SMETA 2 Pillar, and Lego SQP. We also provide solutions in logistics, product development, product modeling, graphical interface, packaging, storage, and delivery.

GDI is plastic injection molding near me if you are looking for injection molding manufacturers in Europe or Bulgaria.

7. HTP EUROPE – Plastics Injection and Ultrasound Systems

Year Established: 1954

Location: 38 Rue de la Barrière de Fer, 7711 Dottignies, Belgium

Company Type: Manufacturer/Producer

Main Products/Services: Plastic injection, injection blowing, matrices, moulds and tools

Company Size: Small business: 11 – 50 employees

Company Profile:

HTP Europe was established in 1954 and is a market leader in the field of plastic injection, injection blowing, and matrices, moulds, and tools production having over a 60 years of experiece. Their primary services include injection of technical parts, injection blowing (IBM and ISBM) of plastic and composite material bottles in aseptic conditions. They specialize in insert overmolding, metal finishing, textile or flexible TPE/TPU/SEBS materials.

They assemble plastic components through welding processes like ultrasound, mirror, and vibration or bonding. Moreover, they use a variety of thermoplastic materials, including reinforced glass or carbon fibers. HTP Europe provides solutions to medical and pharmaceutical fields, food industry, aviation, electrical, and safety industries. From a quality management perspective they are certified to ISO 9001 and EN 9100 standards.

Their Diverse Services Range:

- Ultrasound systems for processing plastics

- Injection moulding of rubber and plastic

- Industrial plastic products

- Automotive, furniture, clothing, electrical, and electronics industries use plastic products for their production.

Advantages of Partnering with HTP EUROPE:

- More than 60 years of experience in the industry

- Specialization in plastic injection and ultrasound equipment

- Quality assurance and accreditation

- The company deals with a wide range of thermoplastic materials.

HTP Europe is one of top 10 plastic injection molding companies near me if we are looking for plastic injection molding companies in Europe or Belgium.

8. NOCENTE S. A – Custom Mould Design for Plastic Injection

Location: 27 Rue Hector Blanchet, Voiron, Isère, France 38500

Year Established: 1973

Company Type: Manufacturer/Producer

Main Products/Services: Moulds for plastic and rubber industry

Company Size: 11-50 people

Company Profile:

NOCENTE S. A, an Italian company with over 50 years of experience in the plastic injection molding field. They offer services in the creation of compression and injection moulds for thermoplastic and thermo hardening materials. Their in-house design engineering department with CAD, RDM, and MoldFlow rheology facilities, along with a production factory in France, provide clients with high quality custom manufacturing solutions for mould design and production.

Moreover, they provide solutions for small to large scale projects up to 10 tonnes including fine tuning on presses and maintenance. Also, they offer hybrid fabrication solutions through their dealers in Europe and Asia, smooth designs and adjustments done at engineering design office solutions.

Diverse Services Provided By NOCENTE S. A:

- Moulds for plastic and rubber industry

- Thermoplastic moulding

- Steel dies and aluminium moulding Steel dies and aluminium moulding Steel dies and aluminium moulding Steel dies and aluminium moulding

- Plastic injection 3D modeling

- Industrialization of compounds and plastics processing

- Injection tooling and mould manufacturing

Feel free to contact us for more information regarding their services and for any special needs you may have. they are one of the best injection molding near me if you are looking for injection molding manufacturers in France.

- Plastic injection moulds & moulding parts

- Silicone/rubber moulds

- Silicone/rubber moulding parts

- Casting and machining solutions are some of the products offered by the company and they include a diverse range of products.

- Customized manufacturing capabilities

- High precision and quality standards

- They have specialized in plastic injection moulding components

- Logistics centres for efficient distribution

9. APEAK INDUSTRIAL CO. , LTD. – Custom Plastic Injection Moulding Solutions

Location: Xitun dist. , Taichung City, Taiwan

Year Established: 1978

Company Type: Manufacturer/Producer

Main Products/Services: Plastic injection moulds, plastic injection moulding parts, silicone/rubber moulds, silicone/rubber moulding parts

Company Size: Small business: 11-50 employees

Company Profile:

APEAK INDUSTRIAL CO. has been in the business of injection molding for 40 years in the manufacturing of plastic injection moulds and plastic moulding parts. Their prestige to offer reliable solutions to improve your manufacturing operations. They are unique in their ability to develop new, high-quality products that meet market needs and consumer demands at every stage of the product life cycle. They have professional knowledge, advanced technology, and a dynamic team to provide high-quality and competitive customized plastic products.

Their business activities include the manufacturing of plastic injection moulds, plastic injection moulded parts, silicone/rubber moulds, and silicone/rubber moulded parts.

Business Scope:

More than ten years of experience in tooling construction for the European/Oceania regions

Export to Europe 70%, Oceania 20%, America 5%, and others 5%. They have a professional project team for direct customer communication to fulfil their project needs efficiently.

APEAK INDUSTRIAL CO is one of top 10 mold manufacturers in China that offer plastic mold manufacturing and injection molding prodcution, if you are looking for injection molding near me at location of Taiwan, China, they maybe one of your best injection molding suppliers to think about.

10. CraftMach Engineered Solutions Inc.

Location: 1176 Ouellette Avenue, N9A 6S9, Canada

Year Established: N/A

Company Type: Manufacturer/Producer

Main Products/Services: Casting Metal Parts , CNC Machined/Turned Parts, Plastic Injection Moulding Nozzle Tip , Pump Casting Parts

Company Size: 51 – 100 employees

Certifications: ISO 9001, ISO 13485 for medical products, SMETA 2 Pillar, Lego SQP

Company Profile:

CraftMach Engineered Solutions Inc. is a company located in Canada that offers various engineering solutions. Their major products are casting metal parts, CNC machined parts, machining turning parts, nozzle tips for plastic injection moulding and pump casting parts. We offer solutions for various industries in terms of manufacturing and provide innovative and quality solutions.

Advantages of Partnering with CraftMach Engineered Solutions Inc. :

Additional Services:

Supply Chain and Logistic Management

Vendor Managed Inventory (VMI)

Just In Time (JIT) Delivery

Product Development and Modeling

Packaging, Storage and Delivery Solutions

CraftMach Engineered Solutions Inc. is an organization that is focused on delivering quality engineering solutions to their clients in order to meet their needs. We are committed to providing quality, accuracy, and creativity in order to achieve success in different fields.

CraftMach is one of top 10 plastic injection molding companies near me if we are looking for plastic injection molding manufacturers in Canada.

Key Takeaways

Plastic molds have become an essential tool for many organisations in production. On the globe, many compnaies deal in plastic molds, and they offer different services that distinguish them and attract different clients.

So, it’s always important to do research on the company that one intends to work with to ensure that the products produced are of high quality. Evaluate their manufacturing processes to determine their capacity to deliver on your expectations. Especially in light of the current pandemic, it is recommended to work with a company that provides tools for remote meetings and idea presentations. If you are searching for a reliable and trusted plastic mold injection company near me, please do not hesitate to contact us.