What Is CNC Milling? Everything You Need To Know!

What Is CNC Milling

Knowledge of what is CNC milling enables one to understand the process. Some of the topics discussed in this blog include spindle speeds, feed rates, axes movements, G-codes, and machine controllers. We will also describe how these parts combine to function as a single unit. There is a lot of precision in CNC milling. Got to what is CNC milling 101 to know more.

How Does CNC Milling Work?

Process Overview

CNC milling employs G-codes and M-codes. This moves the spindle. The table supports the workpiece. What Is CNC Milling is essential to learn. It is used to rotate the cutting tool. They make precise shapes.

This can cut at varying speeds. RPM and feed rate are among the parameters that regulate it. The X, Y, Z axes dictate the process. It produces parts with precision. The movements are coordinated by the machine’s controller.

CNC Programming

The program instructs the CNC mill on what needs to be done. This uses G-codes for movements. M-codes control auxiliary functions. The toolpath defines the movement of the cutting tool.

It starts and stops. The spindle speed matters. They enter parameters for each axis. This ensures precise machining. It is used before cutting to check for errors. CNC controller receives and interprets commands.

Machine Movements

The movements of the machines in CNC milling are accurate. This includes the X axis, the Y axis, and the Z axis. The spindle rotates. It cuts the material. Linearity controls the tool.

They establish feed rates and depths. Inputs are controlled by the control panel. This ensures accuracy which leads to perfect parts. The servo motors control the speed. CNC mills create accurate forms.

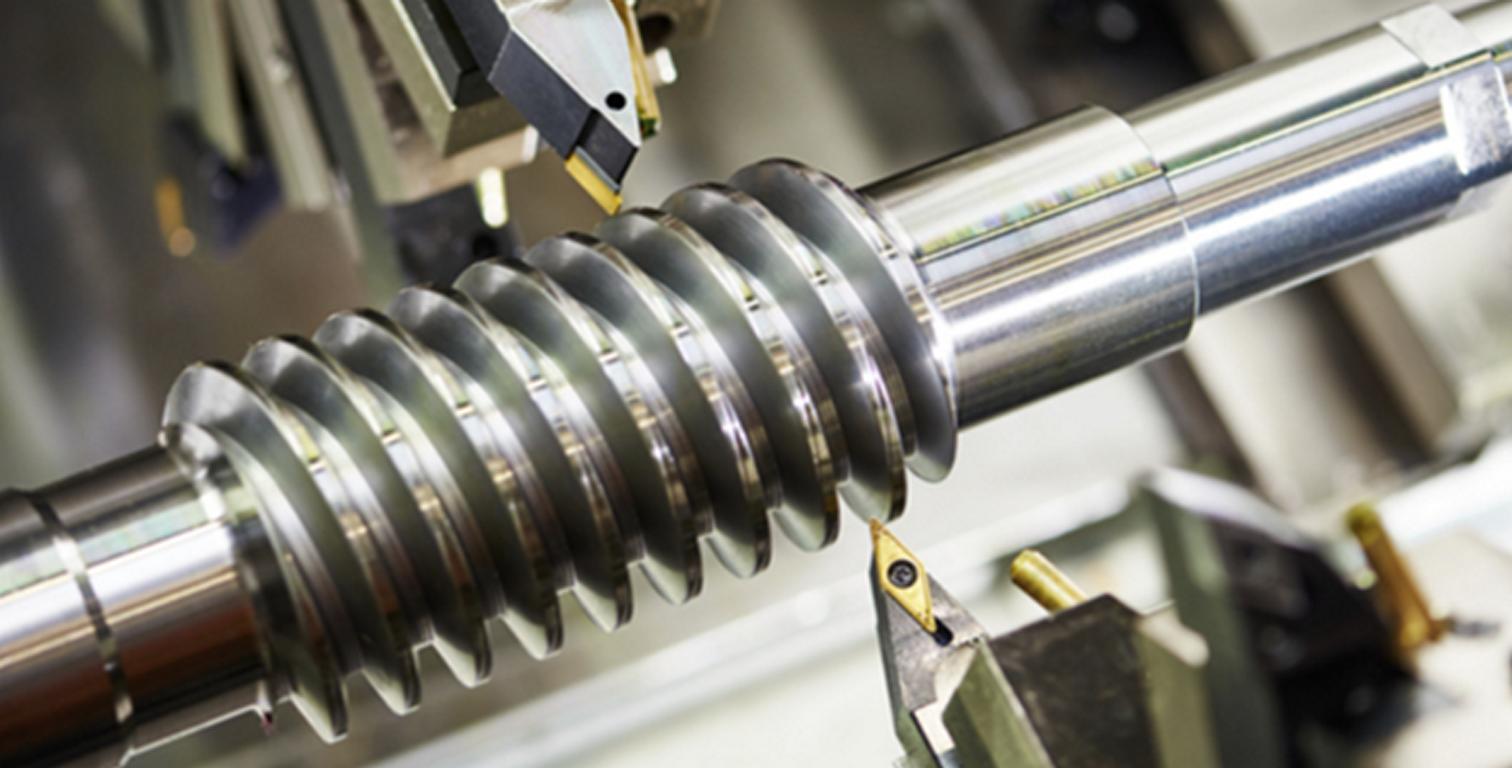

Cutting Tools

Cutting tools in CNC mills are significant. What Is CNC Milling helps you understand it better. This uses end mills and drills. The tool holder secures them. They spin fast. It cuts the material.

It is influenced by parameters such as RPM. The flute number matters. That impacts chip removal. The spindle grips the tool firmly. This ensures clean cuts. One tool creates different shapes.

What Are the Main Components of a CNC Milling Machine?

Machine Frame

The frame supports all the other components of a CNC machine. On this one, it is strong and stable. They require a strong foundation. This is made from metal.

Some of the parts include rails, screws, and bolts. It maintains the stability of the machine. Accuracy is very important in the CNC milling process. That means that small errors can ruin parts.

The frame has to be rigid. Some frames are made from iron. They weigh a lot. Frames can be of different shapes. This assists in supporting the machine. Frames must be well-built.

Spindle

The spindle is central to CNC milling. What Is CNC Milling is good to know. It spins fast. This can go up to many RPM as. They hold cutting tools. It sways up and down. This makes holes. Spindles use bearings.

These reduce friction. They keep it cool. Spindle speed matters. Faster speeds cut faster. It needs cooling fans. Some spindles are electric. Others use air. This part is crucial. That is why it is carefully made.

Control Panel

The control panel operates the CNC machine. It has many buttons. This is where you input commands. Screens show settings. They assist you to track the process. The panel has a CPU. It runs programs.

This can be a touchscreen. Controls are very precise. Inputs are in G-codes. These instruct the machine what to do. Safety switches are important. The panel has to be easy to use. It makes CNC milling possible.

Axis Motors

Axis motors transport the CNC parts. What Is CNC Milling is interesting to know. They regulate the motion in X, Y, and Z directions. It allows precise movements. This can be up to microns.

They use stepper motors. These provide exact control. The motors are powerful. This assists with quantities of parts. Motors require cooling. They can get hot. This means that axis motors require reliability. That is why they are well engineered. Proper setup is crucial.

Tool Changer

The tool changer works very fast. It holds multiple tools. This can be automatic. It reduces downtime. It is important that tools are sharp. It changes them quickly. They have sensors. This ensures correct placement. The tool changer has a magazine. This stores the tools.

It is crucial for increasing productivity. All the tools serve a particular function. Changing them must be fast. It has to be noted that the whole process is fully automated. It makes CNC milling efficient.

| Component | Function | Material | Common Models | Key Specifications | Maintenance |

| Machine Frame | Structural support | Cast iron, steel | Haas VF-2, DMG MORI | Weight: 2,000-3,000 kg | Lubrication, cleaning |

| Spindle | Rotates cutting tool | Alloy steel | BT40, HSK63 | RPM: 12,000-30,000 | Bearing inspection |

| Control Panel | User interface | Plastic, metal | FANUC, Siemens | Screen: 10-15 inches | Software updates |

| Axis Motors | Drives axes movement | Aluminum, steel | NEMA 23, Servo motors | Torque: 2-10 Nm | Alignment checks |

| Tool Changer | Switches cutting tools | Steel, aluminum | Umbrella, Carousel | Capacity: 10-30 tools | Pneumatic checks |

Table on the Main Components of a CNC Milling Machine!

What Materials Can Be Milled Using CNC Machines?

Metals

CNC milling shapes metals such as steel and aluminum. It has a spindle that rotates at 8000 RPM. This machine’s accuracy is 0. 001. The tool head translates in the X, Y, Z directions.

They can switch between tools interchangeably. That saves time. The coolant maintains temperatures low. Chips come off the workpiece. CAD files are used as a reference.

The control unit of the machine follows the program. This makes complex shapes. The metal develops smooth edges. A vise holds it tight. The spindle speed is actually an important factor. The last section is good.

Plastics

CNC milling also forms plastics. The spindle rotates very fast at 12000 RPM. It employs bits for various cuts. They progress in three dimensions. This creates precise parts. The material gets fixed by clamps.

The control unit scans the CAD file. That guides each cut. Chips are put into a vacuum. The tool is cooled by the machine. It prevents melting. Plastics become neat shapes. The table keeps it level. Got to PEEK CNC machining to know more.

The cutting is done by a tool known as the end mills. They make clean edges. It is fast and precise. The plastic part is ready.

Composites

Composites are known to be milled by CNC machines. The spindle rotates at a speed of 10,000 RPM’s. The tool bits cut layers. It also moves on all three axes. The working fluid in the machine cools it.

It reads the CAD file for shapes. This makes complex designs. Chips get cleared by air. The vise keeps it in place. The control unit operates according to the program. It switches tools automatically.

It is at this stage that the composite gets smooth edges. The process is efficient. It produces strong and lightweight components. The table moves precisely. The last part is described in detail.

Wood

The carvings made with CNC milling are smooth on the wood. What Is CNC Milling can explain more. The spindle rotates at 7,500 rpm. Bits are different for different cuts. They travel in X, Y, Z direction. The wood gets compressed firmly. The control unit operates based on CAD files. It guides each cut.

The vacuum clears chips. Coolant has the function of cooling the tool. The machine works and forms precise shapes. The table moves precisely. This ensures accuracy. The end mills cut very well.

They make clean edges. The wood part appears clean. That is how CNC mills wood. The process is swift.

Ceramics

Ceramics can also be milled using cnc. The spindle rotates at 6,000 RPM. It uses diamond-tipped bits. They operate along three dimensions. The coolant prevents cracks. In other words, the CAD file controls the operation of the machine. This makes intricate shapes. Chips are removed by air.

The vise ensures the firm positioning of the ceramic. The control unit switches tools. It is in compliance with the program to the letter. The machine produces sharp edges. It makes strong, detailed parts.

The table moves accurately. The ceramic stays cool. They complete it with touches. The part is durable.

What Are the Types of CNC Milling Machines?

Vertical Milling Machines

CNC milling employs vertical machining with X, Y, and Z movements. These machines are equipped with a spindle and a motor. The spindle also goes up and down. It’s controlled by G-code. This machine type has a table attached to it. The table supports the workpiece. They employ end mill for cutting materials.

This setup allows for precise cutting. The speed can be set as high as 1 200 RPM. Factors such as depth and feed rate are important. Vertical mills are accurate in their operation. They are ideal when it comes to intricate work.

Horizontal Milling Machines

CNC milling encompasses horizontal machines. They have a spindle that runs horizontally. The spindle rotates at 1500 rpm. It uses face mills for cutting materials. This machine has movement along an X-axis.

The Y-axis is useful for left and right movements or shifts. The workpiece is positioned on the table. They handle large tasks. This can easily make deep cuts. The speed and feed rate of the machine is very important. Horizontal mills are powerful. That is why they are used often.

Multi-axis Milling Machines

CNC milling uses multiple axis in its operations. They function with XYZ and A, B axes. The spindle rotates in a number of ways. This allows complex cuts. It has a control panel. The control panel determines the values. For precision, they utilize ball screws. This aids in refinement activities.

The speed of the machine can be 1800 rpm. The workpiece rotates on a trunnion table. Multi-axis mills are advanced. They achieve intricate designs. This is good for detailed work.

Gantry Milling Machines

CNC milling comprises of gantry machines. They possess a fixed bridge. The spindle translates on the gantry. This setup provides stability. It incorporates a powerful motor. The motor operates at 2000 rpm.

This machine deals with large workpieces. The X-axis and Y-axis are wide. They use end mills for cutting and these end mills are of heavy-duty in nature. Control panel shifts settings. Gantry mills are strong. They perform heavy-duty tasks. The precision is unmatched.

Bed Milling Machines

CNC milling has bed-type machines. What Is CNC Milling answers many questions. They contain a fixed spindle. The table translates along the X-axis. It provides stability. The spindle speed is 1600 rpm.

This machine uses a ball screw for accuracy. It is suitable to be used for heavy materials. They handle large tasks. The table is used to provide support to the workpiece. This allows accurate cuts. The control panel specifies values. Bed mills are reliable. They perform robust operations.

How to Select the Right CNC Milling Machine?

Application Requirements

In CNC milling, G-codes are used to translate the movement of the spindle. It needs precision. X, Y and Z axes work. This tool is used for cutting metals or plastics. The spindle spins fast. Figures such as 3000 RPM are significant. CAM software helps plan. Feed rate and depth can make a difference.

They should complement the job that is to be done. That keeps parts accurate. FANUC or Siemens controllers regulate the process. They are crucial. Other cutters include ball or flat end cutters. The orders are implemented with precision by the machine.

Material Compatibility

It must also be remembered that different materials require different environments. CNC milling adjusts. They employ codes in determining where to cut. This is vital. Stainless steel requires low feed rates. It keeps tools safe. Aluminum allows faster cuts. The tool’s hardness matters.

There are various types of cutters for the woods. The spindle speed has to therefore be proportional to the material being worked on. CAM software makes the right decision. Lubricants are used to cool parts. That helps avoid damage. Factors such as torque and power are involved in the process.

Precision Needs

Accuracy is very important when using CNC milling. What Is CNC Milling explains more about it. Microns are used by machines for accuracy. The tool follows G-code. It must be exact. Linear encoders assist in determining movement. This ensures tight tolerances. Contrasting axes need to be in harmony.

Ballscrews and guides help in this. That keeps errors small. Accuracy is a crucial characteristic of the controller, as it determines the results achieved. Features such as backlash compensation do help.

They guarantee correct path of the tool. All of them should be in harmony with the designed part. Checking measurements is important.

Production Volume

CNC milling accommodates different volumes. Both small to medium production volumes and large scale production can be done. This affects settings. They use the same G-codes. They both use the same G-code. Tool changes are automated. Pallet changers assist in speeding up.

The machine’s capacity matters. This decides how many parts it produces. CAM software optimizes paths. Cycle time is crucial. That indicates how long it takes for a particular part. The speed may vary depending on the materials used. Volumetric tasks require strong instruments.

Budget Constraints

CNC milling costs vary. Initial machine price matters. This includes controllers and spindles. Each model has its own price range. Maintenance costs are ongoing. Items such as tools and coolants are part of the total cost. They must be considered. Efficiency saves money. CAM software helps. It reduces waste.

Reduced cutting speed and feed rates also lead to increased costs. This balance is key. Upgrades can be costly. Selecting the right machine will prove to be cost effective in the long run.

What Are the Advantages of CNC Milling?

High Precision

Additionally, CNC milling is advantageous in that it enables the creation of very accurate parts. What Is CNC Milling is good to know. This machine has movements controlled by G-code. It can cut right up to a thickness of 0.001 inch. That’s super tiny! The spindle can rotate up to 30000 RPM.

End mills and drill are some of the equipment used to give the right shape to the parts. The table supports pieces to remain stable. The coolant keeps it cool. This prevents it from overheating.

It is useful for creating small components such as gears and bolts. They are all just right for each other. CNC milling is great for accurate work.

Repeatability

CNC milling’s repeatability of jobs is precise. That means it produces parts constantly. This machine employs coordinates in its movement. This typically follows the same sequence all the time. It employs X, Y, and Z axes. The spindle is set at a specific number of revolutions per minute.

Cutting tools such as face mills and taps cut parts. They keep it all the same. The table supports each piece in position. This ensures no movement. Consistency is important for large quantity orders. CNC milling rocks for this!

Efficiency

CNC milling produces parts quickly and accurately. What Is CNC Milling helps you understand how. This machine begins with CAD files. It uses high-speed cutting tools such as ball mills and reamers. It has feeds and speeds setting. The spindle can run 24/7. It keeps working cool with the help of coolant.

The table moves quickly. That saves lots of time. All these parts are done faster. This can help make many pieces in a short time. Efficiency is very important. They make many things quickly. CNC milling is great!

Flexibility

CNC milling has the ability to shift from one task to another easily. It can make many kinds of shapes and sizes. This machine scans CAD/CAM designs. The spindle has accessories that include fly cutters and boring heads. It shows that the table can be adapted for different parts.

This assists in changing jobs quickly. It employs various materials such as metal, plastic and even wood. All these get chopped cleanly. The software alters tool paths. Flexibility is the ability to perform new things. CNC milling performs many tasks. That’s super handy!

Reduced Labor Costs

Work costs are reduced by CNC milling. What Is CNC Milling will tell you more. This machine operates on its own to a large extent. It operates using NC code. Many tools are managed by the spindle such as chamfer mills and slot drills. The table moves without any assistance. This means fewer workers.

It continues working long hours. Coolant systems make it run well. They are cost effective and time saving. This machine performs many tasks. Less labor cost is always good. CNC milling reduces cost and time!

Conclusion

Knowing what is CNC milling demonstrates its accuracy. It employs G-codes, spindles and feed rates. For more details, visit PLASTICMOLD. CNC milling enables creation of precise components. Find out how CNC machines can work for you.

Leave a Reply

Want to join the discussion?Feel free to contribute!