Two Plate Injection Mold

What is two plate injection mold?

Two plate injection mold (2 plate injection mold), 3 plate injection mold and all of other type of plastic injection molds are type of molds used in plastic injection molding, in 2 plate mold where two separate mold plates are used to form the mold cavity, one plate we called “A” plate or A pocket plate, which contains the cavity and it is fixing half, and normally we called this cavity side, the other plate is “B” plate (or core side/movable side), which contains core inserts which is moving half, the ejector systmes is also staying at the core side.

The plastic is injected into the mold cavity through the sprue, and then the B plate is closed against the A plate to form the part. Once the plastic has cooled and solidified, the B plate is opened and the part is ejected. This type of mold is generally used for smaller, simpler parts with minimal undercuts or complex geometries.

Advantages of the Two-Plate Mold

two plate injection mold

The beauty of the two-plate design lies in its simplicity. This translates into several advantages:

- Cost-effective: With fewer parts and a straightforward design, two-plate molds are the most economical option. It makes the two plate injection mold recommended for high-volume production of parts that are less intricate.

- Easy maintenance: Due to their basic design, two-plate molds are easier to maintain and repair.

- Fast cycle times: The simple opening and closing mechanism allows for quicker production cycles compared to more complex molds.

- Suitable for a variety of materials: They can handle a wide range of thermoplastics, making them versatile for various applications.

Disadvantages of two plate injection moulding

While two-plate molds offer numerous benefits, they also have limitations:

- Gate mark aesthetics: The point where the molten plastic enters the cavity (the gate) can leave a visible mark on the final product.

- Part complexity: They struggle with parts that have undercuts, deep cores, or threads. These features require additional mechanisms that increase complexity and cost.

- Runner waste: The runner system attached to the molded part needs to be removed, generating plastic waste.

The Molding Process in Action

The injection molding two plate mold undergoes a precise cycle to produce plastic parts. Here’s a simplified breakdown:

- Clamping: This is when the B-side and the A-side are closed securely together to apply high pressure that guarantees a perfect seal.

- Injection: The molten plastic will be injected at high pressure through the designated part or the sprue into the mold cavity.

- Packing and Holding: After filling the cavity, pressure will be retained to even out the shrinkage of the plastic while it cools.

- Cooling: The mold is cooled with water channels to solidify the plastic part.

- Mold Opening: The B-side retracts, creating a parting line where the two mold halves separate.

- Ejection: Pins or other mechanisms push the finished plastic part out of the cavity.

- Runner Removal: The leftover plastic from the sprue and channels (called the runner) might need to be manually removed from the part.

Difference between two plate and three plate mould

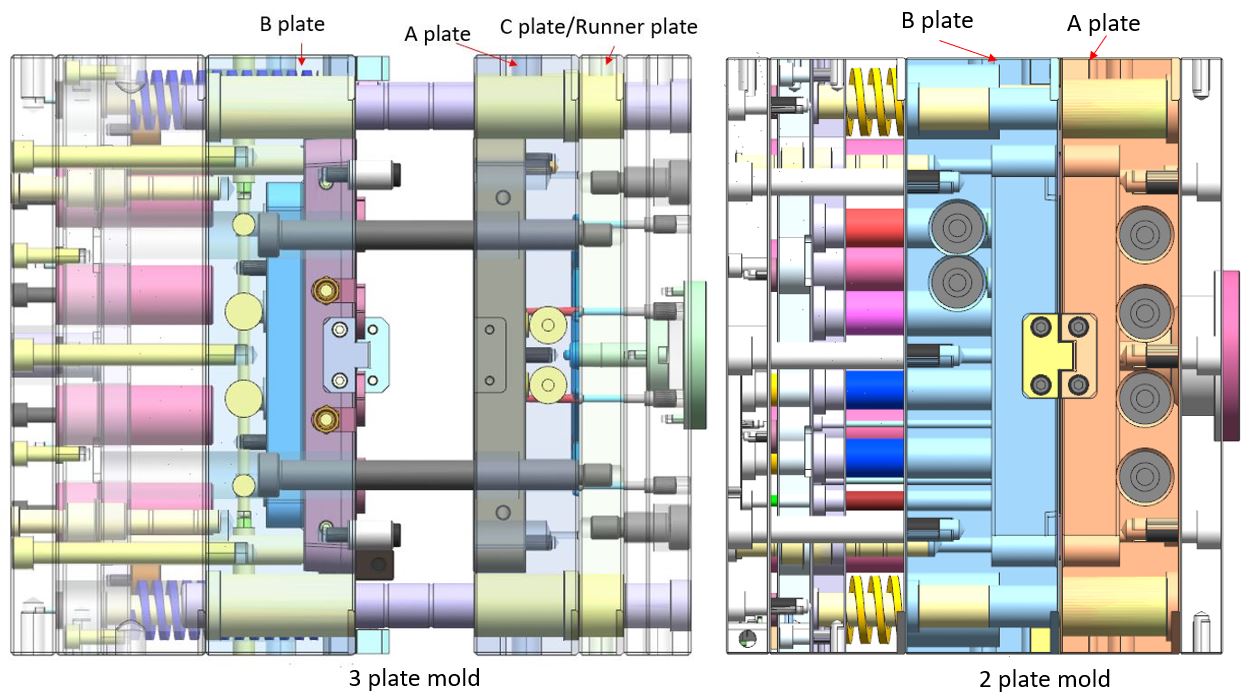

A two plate mold and a three plate mold are different types of molds used in plastic injection molding, with the main difference being the number of plates used to form the mold cavity.

Two plate molds:

Imagine a clamshell. This is the fundamental concept of a 2 plate injection mold. This is made up of two key components. First is the fixed plate or also referred to as the “A-side” and second is the moving plate or the “B-side”.

The magic happens within these two halves. The A-side houses a cavity that replicates the desired shape of the final plastic part. The B-side might have a core that forms internal features or simply acts as a counter to the cavity. These two sides come together to create a sealed enclosure where molten plastic is injected.

- have two separate mold plates, the “A” plate and the “B” plate.

- The A plate contains the cavity and core, and the B plate contains the ejector mechanism.

- The plastic is injected into the mold cavity through the sprue, and then the B plate is closed against the A plate to form the part.

- Once the plastic has cooled and solidified, the B plate is opened and the part is ejected.

- This type of mold is generally used for smaller, simpler parts with minimal undercuts or complex geometries.

Three plate molds:

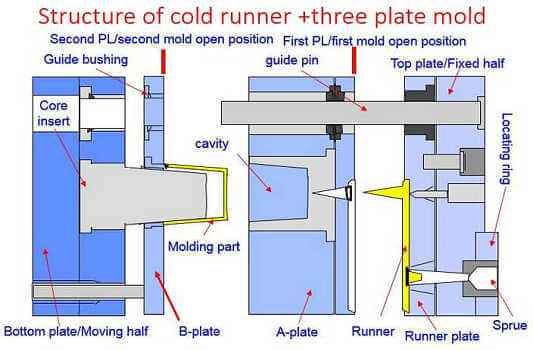

- have three separate mold plates, the “A” plate, “B” plate and the “C” plate (or runner plate).

- The A plate contains the cavity, the B plate contains the core, and the C plate contains the runner the runner pusher with ejector at cavity side (this ejector only ejecting the runner which we call runner pusher as well).

- The plastic is injected into the mold cavity through the C plate (runner plate), and then the B plate is closed against the A plate to form the part.

- Once the plastic has cooled and solidified, The C plate is opening to pull the runner stick with C plate and then use pusher to ejector the runner off the runner plate, then B plate is opened, and the part is ejected.

- This type of mold is generally used for larger, more complex parts with undercuts or other features that cannot be formed with a two plate injection mold.

3 plate mold vs 2 plate mold

In summary, the main difference between two plate and three plate moulds is that two plate mold has the runner which is located on the A or B plate which is on the parting line layer, and ejected out by the ejector systems with part together, the three plate moulds which the runner will stick with C plate ( runner plate), and later one will be ejected by the pusher, and will be more complex and expensive than two plate mold.

Do you have a project that need plastic mould suppliers? Please contact us to get a price, we are processional in 2 plate or 3 plate injection mold.