Would you like to know how acrylic uses span around manufacturing sectors? Most people fail to pay attention to this fantastic material, and they are ignorant of how versatile it is. It is used for making day-to-day products into complex and creative products in many sectors. Learn how this material that is light, strong, and transparent can improve your life and the products you interact with every day.

Acrylic plastic finds uses in both decorative and functional products such as signs, automotive parts, lighting acrylic products, and medical acrylic products as well. It is clear, UV resistant, and easy to fabricate so it is perfect for both practical and cosmetic applications. Learning about the versatility of acrylic can make you aware of its importance in today’s production and design.

You will discover more uses and benefits of acrylic plastic, whether is acrylic plastic anti scratch or not? as you read further and get to know this type of plastic even better. Join us to find out how this unique material is still affecting industries and enriching our lives.

Why Is Acrylic Plastic Used So Often?

Acrylic plastic, familiar to many by its familiar brand names Plexiglas or Lucite, is an artificial material that belongs to the group of polymethyl methacrylate (PMMA). Some of the characteristics of the material make it desirable for use in several fields. Here’s a detailed breakdown of the advantages of acrylic, and why so widely used:

1. Optical Clarity

- High Transparency: Acrylic has excellent light transmission properties with figures in excess of 92% being quite common. That makes it ideal for use where visibility is important, for instance, display cases and protective covers.

- Low Distortion: Acrylic does not distort the vision like some other plastics which makes it ideal for items such as lenses and screens.

2. Lightweight

- Ease of Handling: It is about half the weight of glass which makes it convenient for transportation, fixing, and use in different applications such as furniture, doors, windows, and large signs.

- Design Flexibility: This characteristic implies that the structures that are developed through the help of this type of construction are easier to install and manage.

3. Impact Resistance

- Shatterproof: There is a much higher impact strength in acrylic than there is in glass; this means that acrylic can take a very hard knock and not shatter. This makes it suitable for use in areas of protection like protective shields, and safety glasses among others.

- Durability: Because of the hardness it is more resistant to rough handling and unfavourable environment than most other materials.

4. Weather Resistance

- UV Stability: Acrylic is UV stable and does not become yellow or damaged by UV radiation in the same way that other plastics do. This makes it ideal for use in areas of the building where it is exposed to weather elements such as signs and roof lights.

- Moisture Resistance: The surface does not swell and will not be damaged by rain or humidity which makes it suitable for outdoor application.

5. Applications

- Molding and Fabrication: Acrylic is versatile since it can be cut, drilled as well as made into different shapes. This versatility allows it to be used in diverse applications, including:

- Signage: Transparent and colored acrylic is used in illuminated signs and displays.

- Acrylic Displays: Acrylic is quite commonly used in the retailer’s display cases and stands because of its transparency and versatility.

- Automotive and Aerospace: Acrylic is used for windows, light covers, and instrument panels because of its strength-to-weight ratio.

- Home Decor: Furniture and lighting fixtures and decorative panels among others are made of acrylic because of the material’s beauty and availability in many colors.

6. Cost-Effectiveness

- Long-Term Value: However, acrylic might be costlier than most of the other plastics and that is the reason why it is slightly more expensive in the beginning but the long-term cost is less than the other plastics.

- Reduced Replacement Costs: This applies also an impact resistance which implies that it will not require frequent replacement or repair as other counterparts.

7. Ease of Maintenance

- Cleaning: Cleaning acrylic surfaces is relatively simple as these surfaces only need gentle wiping with a cloth and mild soap. If taken good care of they do not scratch as easily as Glass does, even with the best quality type of material.

- Polishing: It is normally possible to rub out scratches so that the material becomes clear again without having to replace it.

8. Aesthetic Appeal

- Color and Finish Variety: Acrylic is versatile in that it can be purchased in a wide variety of colors, finishes, and surfaces. It could be clear, colorless, or cloudy and colored and may be made in many shades.

- Modern Look: Due to its thin profile and its applicability in various forms of design, it is frequently used in modern design.

What Is Acrylic Plastic? How It Is Made?

Acrylic is also referred to as polymethyl methacrylate- PMMA plastic. It is produced by a variety of chemical processes. Here’s a simpler breakdown of how acrylic is produced:

Raw Materials

Acrylic base is methyl methacrylate (MMA) which is a clear liquid in form. This is a liquid and when in the process of making acrylic, some initiators are added they are chemicals that help bring about a reaction that solidifies MMA.

Polymerization Process

The basic step of making acrylic is called polymerization. This involves a few methods:

- Bulk Polymerization: In this method, MMA is blended with the initiator and heated. When the temperature increases, an initiator causes MMA to bond with each other and form long chains of PMMA.

- Suspension Polymerization: Here, MMA is emulsified in water and polymerized. This forms small beads of acrylic that can be further processed to get the best end product in the market.

- Emulsion Polymerization: In this method, MMA is to be dissolved in water in the presence of surfactants then the mixture formed is to be stable. This polymerization takes place in this emulsion to form fine particles of PMMA The individual particles of the polymer are nanoparticles.

Forming Acrylic Sheets

After polymerization, PMMA can be formed into different shapes:

- Casting: For thick layers, a liquid PMMA is used and the material is poured into molds where it solidifies. It also produces neat and quality papers as compared to the other methods.

- Extrusion: For continuous sheets or other shapes PMMA is heated and then forced through a die to form the sheets or tubes.

- Post-Processing: It is suggested that the formed acrylic sheets can be further cut into different sizes and made into different shapes using tools such as a saw or laser. They can also be reshaped to add clarity and to eliminate blemishes. Also, it is possible to give an acrylic a color during its manufacturing or at a later stage.

Common Acrylic Types Available In the Market

Acrylic, or polymethyl methacrylate (PMMA), can be purchased in several forms and types, each used in particular circumstances and with different properties. Here’s a detailed exploration of the different material options for acrylic:

1. Clear Acrylic

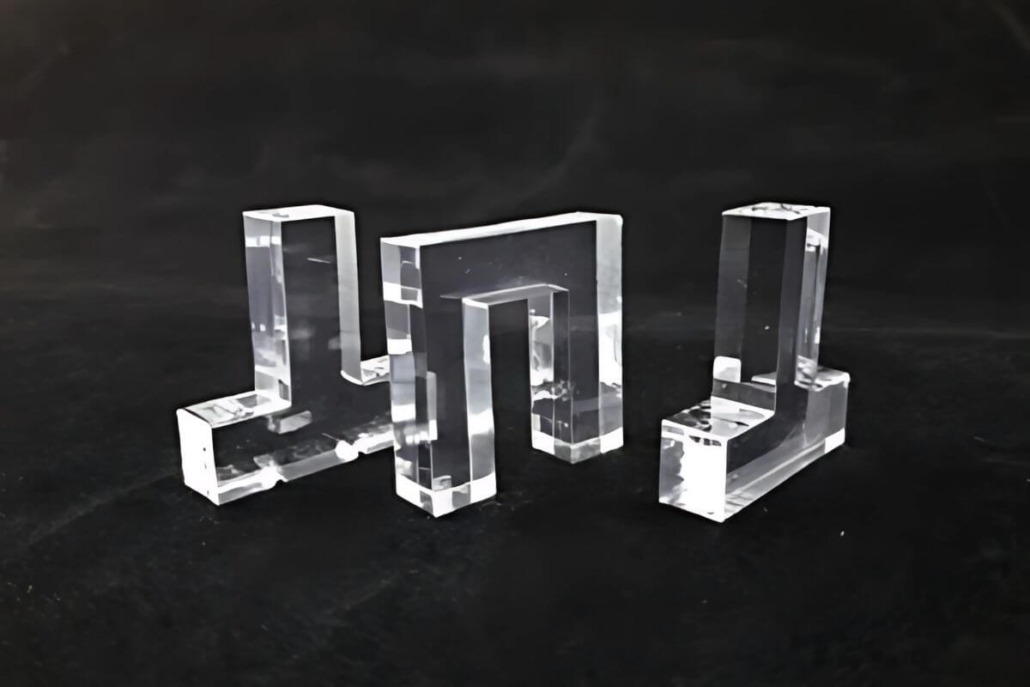

The most familiar type is clear acrylic, which has the highest transparency and light transmission in its class. It transmits up to 92% of visible light, thereby it can be used instead of glass where vision plays a significant role. Transparent acrylic is relatively light and can withstand impacts which makes it suitable for use in displays, aquariums, light wells, and windows. It is relatively easy to polish and this makes it ideal for use as a functional as well as ornamental material.Lots of clear acrylic boxes made by PMMA.

2. Colored Acrylic

Transparent colored acrylic is available in a complete range of colors, and as a result, the number of ideas for design is nearly limitless. Depending on the design and purpose it can be clear or frosted. This type of acrylic is common in signage applications and decorative and architectural applications. This is important because colored acrylic can be not only an aesthetic addition but also may serve as a means of transferring information using colored signs or creating a corresponding light background. The colors can be incorporated right through the material or just on the surface making it suitable for use in different places.

3. Frosted Acrylic

Frosted acrylic has a non-shiny surface with a frosted appearance, which provides privacy to an area, but uses the transmitted light. This makes it ideal for uses such as office dividers or partitions, shower enclosures, and ornamental divider panels. Frosted acrylic can help minimize glare and make spaces more comfortable and less overly exposed at the same time. Its texture can also be aesthetic making it able to improve the looks of interiors. It can also be backlit to provide glowing effects for signs and as an art piece or decoration.

4. Mirrored Acrylic

Mirrored acrylic has a silvered back and can come in different thicknesses; It is a good material as it is a lightweight material as compared to glass mirrors. It is common for it to be used for decorative purposes, for instance in wall cladding, showcasing shelves, and other forms of artwork. Mirrored acrylic is lightweight compared to glass mirrors; thus easier to handle and install and has an appropriate reflective surface for both practical and decorative purposes. That makes it shatter-resistant which in turn gives it an added advantage, especially for use in common areas or areas where children frequent.

5. UV-Resistant Acrylic

UV-resistant acrylic is developed in a way that it can effectively resist UV light, which otherwise would make the material change color to yellow and get degraded. This type is suitable for uses like signages, lights, greenhouse use, and other areas where the type is exposed to light from sunshine. UV-resistant acrylic does not fade or cloud, so the panels stay clear, colored, and protected from tough weather and climate. This property is of great significance for those projects where frequent replacements of the equipment are not expected.

6. Impact-Modified Acrylic

Impact-modified acrylic is further modified to improve its impact resistance. This variation is quite handy in cases where the product needs extra protection, for instance; protective glasses, shields, clothing, and accessories. The modification process of this material involves the incorporation of impact resistance agents that enhance the toughness of the material while keeping the optical transparency of the material intact. This type of acrylic has gained high popularity in places where high impact is probable, thus safer than the usual acrylic.

7. Textured Acrylic

Textured acrylic has surface patterns and those patterns may be for appearance as well as usefulness. The textures can minimize the reflection, increase the friction, or simply make the look more appealing. This type of acrylic is used mainly in architectural applications, signs, and in furniture. That is why textured surfaces can be useful to scatter light and create an interesting design solution. If we employ various patterns, including, but not limited to, wave patterns or geometric shapes intertwined on the fabric surface, we will achieve different visuals and sensations of the material.

8. Casting vs. Extruded Acrylic

- Cast Acrylic: One of these types is made by pouring liquid acrylic into molds which produces thicker sheets but with the best clarity. This type of acrylic is mainly applied in high-quality applications including aquariums, optically clear applications, and fine art applications because of its clarity and its ability to hold fine detail. The casting process also permits a wide variety of thicknesses, which is useful when designing for particular applications.

- Extruded Acrylic: Extruded acrylic is formed by heating acrylic and then forcing it through a die to obtain sheets, rods, or tubes. It is cheaper than cast acrylic and used for items such as sign blanks, light fixtures, protective covers, etc. Compared to the cast acrylic extruded acrylic has slightly less clarity but extremely good optical quality. The item is relatively easier to manufacture in large quantities; thus, it is cheaper compared to other products.

12 Typical Uses of Acrylic Plastic

Here are 12 typical uses of acrylic plastic materials;

1. Signage

Acrylic is widely used in signage because of its good optical characteristics and mechanical durability. It can be made with varying thicknesses ranging from 1/8 inch and up to 1 inch depending on the structural need of the building project. The use of acrylic signs can be done through laser cutting or CNC machining which makes it possible to have designs in detail and dimensions in equal measures. The impact resistance of the material, which is 17 times greater than that of glass, minimizes breakage in areas where there is heavy traffic. In addition, it can also be treated so that it will not become yellow due to exposure to UV lights making it ideal for outdoor use.

2. Display Cases

In retail contexts, acrylic display cases serve the function of a barrier and a showcase at the same time. The material can be thermoformed into various forms and shapes, making designs that do not have joints or seams, which act as weak points. Most display cases are constructed with thickness varying between 3/16 inch and 1 inch depending on the size and weight of the contents. Acrylic has a considerably reduced weight compared to glass – it is about half the weight – making it easier to install and work with; its transparency also provides the best product display. What makes acrylic ideal is that it has a natural scratch-resistant property that can be further improved through surface coatings and this is important to retain the appearance of display cases over the years.

3. Aquariums

Tempered acrylic is used in the construction of the aquarium since it is hard and transparent. The acrylic sheets for aquariums can be fabricated in thickness of up to ¼ inch, and this makes it possible to create large tanks without the danger of cracking or bowing like that which is likely to happen to glass due to pressure difference. Due to the molding capabilities of the acrylic material, it is possible to produce continuous curved patterns that minimize the turbulence of water as well as optimize viewing angles. Also, acrylic is less conductive than glass to heat, meaning it insulates well and will help to minimize the cost of heating the water.

4. Automotive Components

In the automotive industry, acrylic is used in such parts as headlight lenses and instrument panels. Injection molder materiality enables undercuts that improve aerodynamics and the product’s look. Many lenses may be made of acrylic material and as such can be coated with anti-scratch and anti-reflective films to enhance transfer in diverse lighting conditions. UV inhibitors added in the polymer matrix have a function of preventing the material from becoming yellow and opaque after some time especially when used in the exterior parts.

Foe example the automotive lights which made by acrylic injection molding technology.

5. Lighting Solutions

Acrylic is also flexible, and therefore, it is used in lighting as diffusers or lens shields. The material can be engineered with different surface roughness providing the necessary light diffusion properties. For instance, a rough texture is likely to reflect light better than a relatively polished surface done by sandblasting. Due to its refractive index of approximately 1.49, acrylic can control light well and can be used for LED and conventional lighting. Also, it is important to note that acrylic material can withstand high temperatures of up to 80°C, which creates a good performance in the condition of high heat.

6. Furniture Design

The furniture designers appreciate the material for its ornamental value as well as its mechanical characteristics. The material can also be bent into different shapes and forms and can be cut using a computer numeric control machine or laser cutter. Its strength-to-weight ratio enables nice designs that hold strength and at the same time have low weight. Acrylic furniture can also be treated with additional varnish so that furniture becomes resistant to scratch or chemical impact, and thus can be used for homes and offices.

7. Protective Barriers

Acrylic is widely applied to protective enclosures in restaurants, offices, and healthcare centers. The material also guarantees visibility and offers a physical barrier that will help prevent the transmission of particles and droplets. The ability to customize for thickness, which can range between 1/8 inch to 1 inch, means that it is possible to have barriers that provide for specific safety considerations. This aspect makes acrylic ideal for cleaning especially in areas where this is high traffic since it can easily be cleaned and disinfected.

8. Optical Applications

Due to its characteristics, it is used in the manufacture of many optical products such as glasses lenses, camera lenses, and instruments. The manufacturing process sometimes includes precision molding to produce high-quality optical parts. They come in acrylic material, and these lenses can be coated to eliminate the formation of reflection and minimize the chances of getting scratched. Compared to glass, the light weight of the material is also advantageous in wearable optics applications from the perspective of the user.

9. Medical Devices

When used in the medical industry, acrylic is used for several devices because it is biocompatible and can easily be sterilized. This makes it easier for visualization of the contents; a factor that is very important for example in tray set up for surgical instruments and protective eyewear. Acrylic can be manufactured to the medical standards to meet ISO 13485 to guarantee safety and effectiveness. Also, it has a low moisture absorption rate thus making the material stable in medical facilities.

10. Toys and Educational Products

Acrylic is used more often in the manufacture of plastic molding toys and educational products because of its non-toxicity and wear resistance. It can be shaped into elaborate forms that increase play appeal and is non-toxic hence appropriate for children’s use. It also comes in different colors and textures, making it easier to create unique and informative designs. From the point of view of the material, it is impact-resistant, and toys cannot be broken even though they are intensively used.

11. Windows and Skylights

Acrylic is used in windows and skylights because it is lighter than glass and has better heat-resistant qualities than glass. The material can go to rather large thicknesses and remain quite optically clear to allow for large designs. It is resistant to UV radiation, which will help prevent cracking or yellowing and deterioration of the material over time. In addition, because acrylic can retain its thermal performance, it is useful in saving energy for heating and cooling of structures.

12. Artistic Mediums

Another beneficial material is acrylic which is preferred in different works because it has good workability. Acrylic sheets can be cut, drilled, and bonded by artists to make a sculpture or installation work of art. The material can be made in clear, frosted, and colored and thus allow for versatility in the creation process. Due to its relatively low density, large-scale installations are easily created with Acrylic, and its durability means that artwork can be exposed to elements.

Conclusion

This article briefs several uses of acrylic are very many and they are embraced in almost every field of endeavor. Its mechanical, optical, and thermal characteristics and the possibility of new manufacturing technologies make it ideal for applications in areas such as advertising and display to automotive and medical applications. An appreciation of the properties of acrylic and its uses shows that it has a major place in today’s design, protection, and practicality.