What Means PMMA Injection Molding

PMMA Injection Molding Technology

PMMA is the highest transperant plastic materils but PMMA is easy to break comparing to PC or ABS, so PMMA’s modification appears one after another such as copolymerization between methyl methacrylate and styrene and butadiene, a blend of PMMA and PC, etc. 372 PMMA is the copolymer of methyl methacrylate and styrene. If you add a small amount of nitrile rubber (about 50%) in the 372 PMMA, it will become 373 PMMA.

The fluidity of injection molding PMMA is poorer than that of PS, ABS and its melt viscosity is rather sensitive to the change of temperature. In molding, it changes the melt viscosity mainly from the injection temperature. PMMA is an amorphous polymer, the melt temperature is above 200 Celsius degree and the decomposition temperature can reach 270 Celsius degree.

- Processing of plastic

PMMA plastics has a certain degree of water absorption of 0.3-0.4%. The injection molding PMMA moisture must be less than 0.1%. Typically, it is 0.04%. The presence of moisture causes bubbles, gas lines, and low transparency. So it should be dried. Dying temperature is 80–90 degrees Celsius, and drying time is 3 hours or more. In some cases, the utilization of recycled materials can reach 100%. The actual quantity depends on the requirements for quality. Usually, it can reach 30%. You should make sure there is no pollution of recycled materials, or it will influence the transparency and nature of the finished products. - Selection of an injection molding machine

The Injection molding PMMA material doesn’t have special requirements for the injection molding machine. Due to the great melt viscosity, it requires the grooves to be deeper and the nozzle hole to have a larger diameter. If you need products with higher strength requirements, you should use a larger aspect ratio of the screw to implement low-temperature plastics. In addition, PMMA molding resin must use a drying hopper to store material. - Design of mold and gate

PMMA injection Mold temperature can be 60–80 °C. The diameter of the sprue should match the internal taper. The optimum angle is 5 to 7. If the wall thickness of injecting molding products is 4 mm or more, the angle should be 7, the diameter of the mainstream channel should be 8 to 10 mm, and the overall length of the gate should not exceed 50 mm.

For PMMA injection molding products with a wall thickness less than 4 mm, the diameter of the flow channel should be 6–8 mm. If the PMMA wall thickness is more than 4 mm, the diameter of the flow channel should be 8–12 mm. The depth of the fan-shaped and tab-shaped gates should be 0.7 to 0.9 t (t is the wall thickness of the product), and the diameter of the pin gate should be 0.8 to 2 mm. Injection molding PMMA Products with lower viscosity should choose the smaller size. The common venting hole’s depth is 0.05 to 0.07 mm, its width is 6 mm, the stripping slope is 30′-1, and the and the cavity portions are between 35′-1 and 30.

- Melt temperature

You can use the air injection method to measure temperatures ranging from 210 to 270 degrees Celsius, which depends on the information provided by the supplier. - Injection temperature

You can use rapid injection to avoid generating a high degree of internal stress when work with PMMA injection molding material. It’s suitable to use multi-level injection, such as slow, fast, slow, etc. When injecting the thick parts, you should use a slow speed. - Dwell time

If the temperature is 260 degrees Celsius, the dwell time is within 10 minutes. If the temperature is 270 degrees Celsius, the dwell time is within 8 minutes.

Applications of PMMA Plastic Injection Molding

There are many industries that need PMMA injection molding parts. Below are a few components that use injection molding PMMA parts:

- Eyeglass lenses: PMMA is one of the best materials for eyeglasses due to its excellent optical properties. It has the highest transparency of all other plastic materials, PMMA injection molding making it the best choice for eyewear.

- Plexiglass windows: PMMA, also known as plexiglass or acrylic glass, is a popular alternative to traditional glass windows due to its high impact resistance and optical clarity. It is commonly used in buildings, aquariums, and even airplane windows.

- Mobile phone casings: PMMA is used in the manufacturing of mobile phone casings due to its high impact resistance, scratch resistance, and optical clarity. It is also lightweight and can be easily molded into various shapes and sizes.

- Computer and electronics casings: Similar to mobile phone casings, PMMA is used in the manufacturing of computer and electronics casings due to its durability, impact resistance, and optical clarity. It is also lightweight and can be easily molded into various shapes and sizes.

- Vehicle windshields: PMMA is commonly used in the manufacturing of vehicle windshields due to its high impact resistance and optical clarity. It is also lighter than glass, which can improve fuel efficiency.

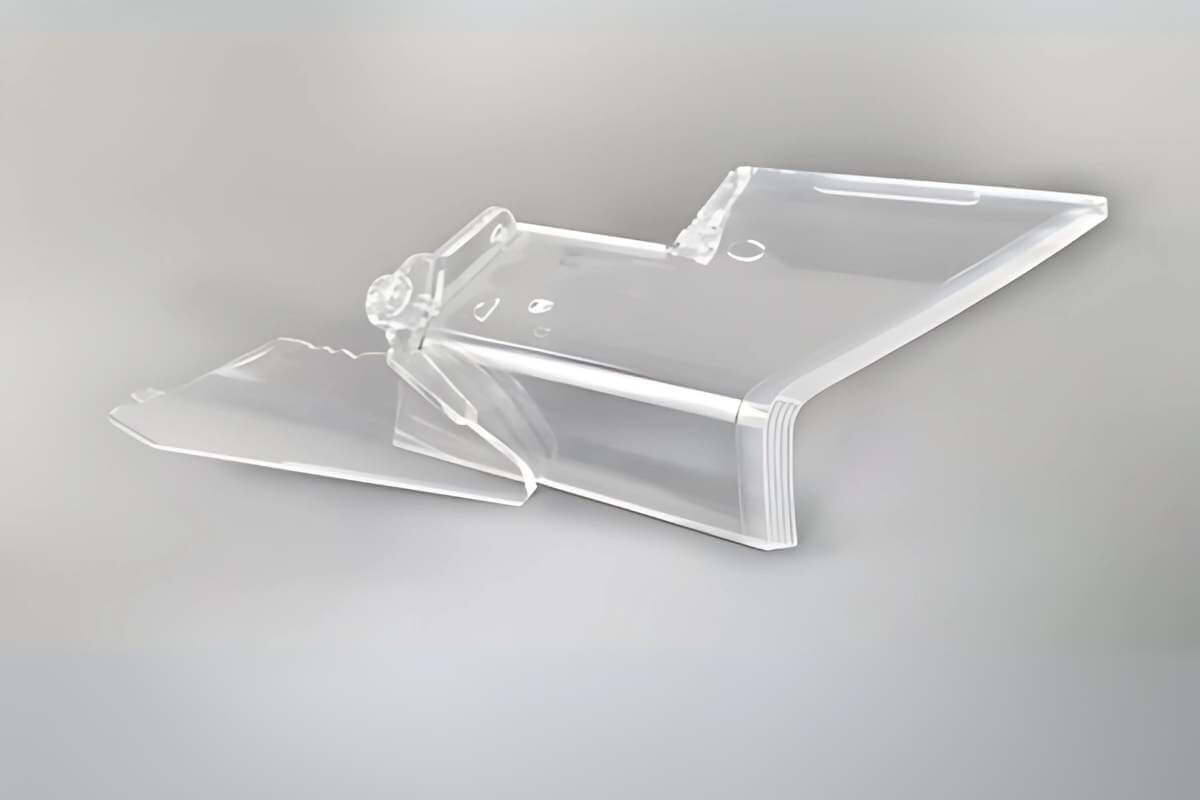

- LED lens: You see the light on the street and your house; that small lens inside is made of PMMA injection molding parts. This is very popular in the light industry.

Injection molding PMMA

Advantages of PMMA injection molding (acrylic injection molding)

1. It produces scratch-resistant products.

2. It produces light transperant products.

3. PMMA injection molding can produce complex designs.

4. High Production Efficiency

5. Enhancement of Color Flexibility

6. Special material for high requirements of transparent plastic molding.

PMMA material called acrylic, or plexiglass, has a transmittance of up to 92%, which is higher than glass. That means clear acrylic box molding is one of the best options for high-requirement transparent injection molding parts, such as glass, optical glass, lenses, car lights, transparent pipes, etc.

Disadvantages of Acrylic PMMA Plastic Injection Molding

Like any other molding manufacturing process, it has its own set of disadvantages that must be taken into consideration. Below are some of the disadvantages of acrylic PMMA plastic injection molding.

- The materials produced have a lower resistance to impact compared to those produced by metal injection molding.

- The heat resistance of most products produced by the PMMA injection process is low (about 80 degrees Celsius).

- Most items produced by the process have lower mechanical strengths, which limit their loading capacities.

- Some acrylic products have poor chemical resistance, which makes them prone to reacting with organic compounds.

- PMMA injection molding needs to invert the special injection mold, which means the initial tooling cost is high. This is not beneficial for low volumes of production.

- Limited design flexibility. The process is best suited for producing products with simple and uniform shapes. Complex designs with intricate details may be difficult to achieve using acrylic PMMA plastic injection molding. This limitation can be a significant drawback for manufacturers looking to create unique and innovative products.

Tips to make high quality PMMA injection molding parts.

Making PMMA injection molding parts is a little different than other injection molding parts because, mostly when we make PMMA molded parts, we will make high-glass PMMA parts. In that case, some special equipment is needed, especially for some thick wall PMMA injection molding parts. Below are some tips for you to make high-quality PMMA injection molding parts.

Mold design

Since PMMA is a transmission material, any flow marks will be easy to see, and this could be an issue as well. Using moldflow analysis, it will be very important to check where the best gate location is. Once the gate location has been determined, the gate shape is important as well. Mostly, we suggest designing a side gate or fan gate, which will make it easier to fill the cavity and avoid the flow marks.

The injection molding machine and the hot water tank are in use.

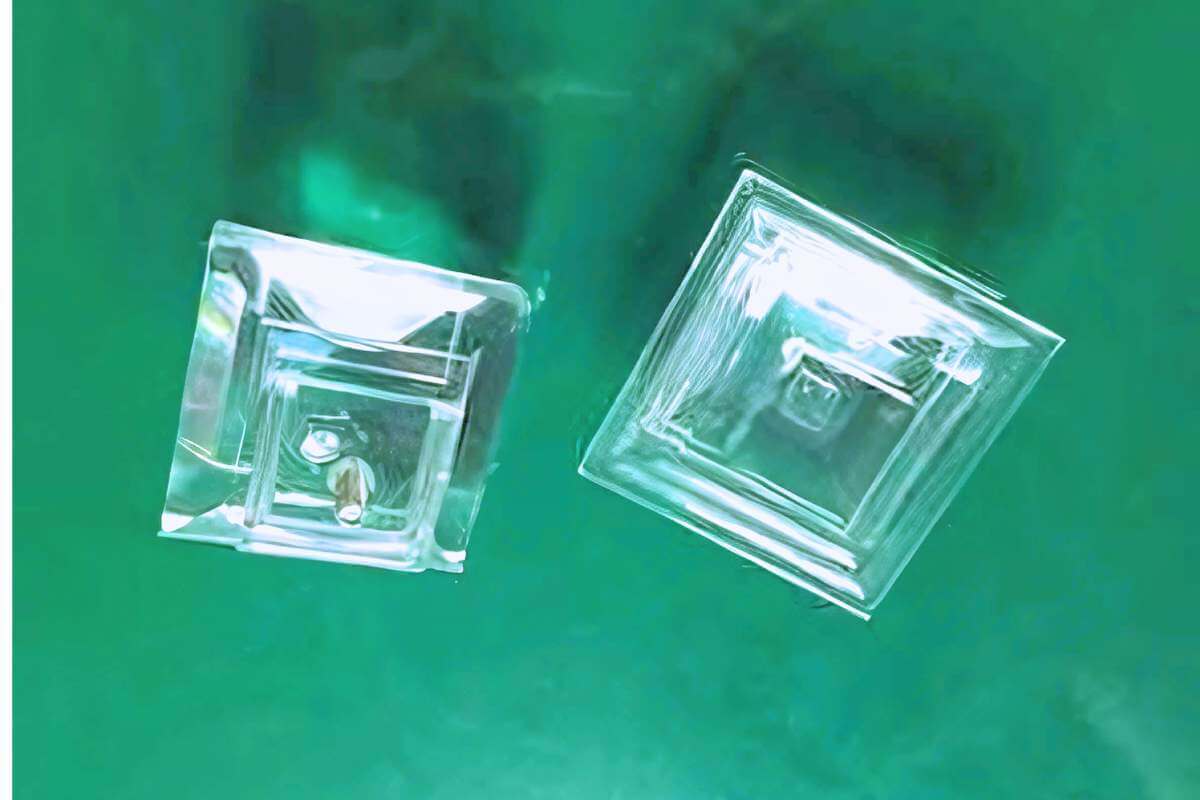

If you are making thick-wall PMMA injection molding parts, then you will always have sink and bubble issues because plastics have a shrinkage rate. The thicker the wall, the higher the shrinkage rate, so there will be bubbles inside the parts, no matter how long the cooling time is, and when you use a long cooling time, the cycle time will be increased as well, which will increase the cost.

In that case, a hot water tank can improve these issues. Use 60–80 degree temperature water in the water tank. Once you pick the PMMA injection molding parts from the mold cavity and put them into the hot water tank for 6–12 minutes, you take out the molded parts, so the sink and bubble issues will be greatly improved.

Making high-quality PMMA molding parts is not an easy task. If you have a project that needs PMMA molding parts, finding a professional PMMA injection molding contractor is very important. This will make sure your project is successful or not.