Thermoplastic elastomers or TPE material is a special type of semi-crystalline multiphase thermoplastic materials that have both the characteristics; of the elasticity of rubber polymers and the processability of thermoplastic materials. As with most thermoplastic elastomers or TPEs, these materials are widely used across many industries including automotive and medical equipment manufacturing. In this article, we will discuss TPE material in terms of chemical composition, manufacturing technologies, i.e. injection molding, and place in the polymeric hierarchy. We also look at the potential and drawbacks of TPE plastic in addition to some of the newest developments.

What is the TPE (Thermoplastic Elastomer) Injection Molding?

TPE injection molding is one of the molding techniques that entails parts formation with TPE by molding the material through a melt injection technique. This process is popular because it is fast, environmentally friendly, and can manufacture thin, strong parts. TPE injection molding provides tolerance design flexibility and is ideal for large-scale automated manufacturing. So, it is popular in the automobile and consumer electronics industries.

What are Thermoplastic Elastomers (TPE) Plastic?

TPEs are a family of thermoplastic elastomers that afford rubber-like elasticity in application and plastic processability. When heated, these ceramics can be softened many times and they can also be hardened many times through heating followed by an opposite process of cooling without deleterious changes. This particular aspect, they point out is in a position to differentiate TPE material from thermoset rubber. So, this makes it easier to recycle and mold.

TPE (Thermoplastic Elastomer) Formation Process

Let’s go through the complete process involved in the formation of TPE plastic

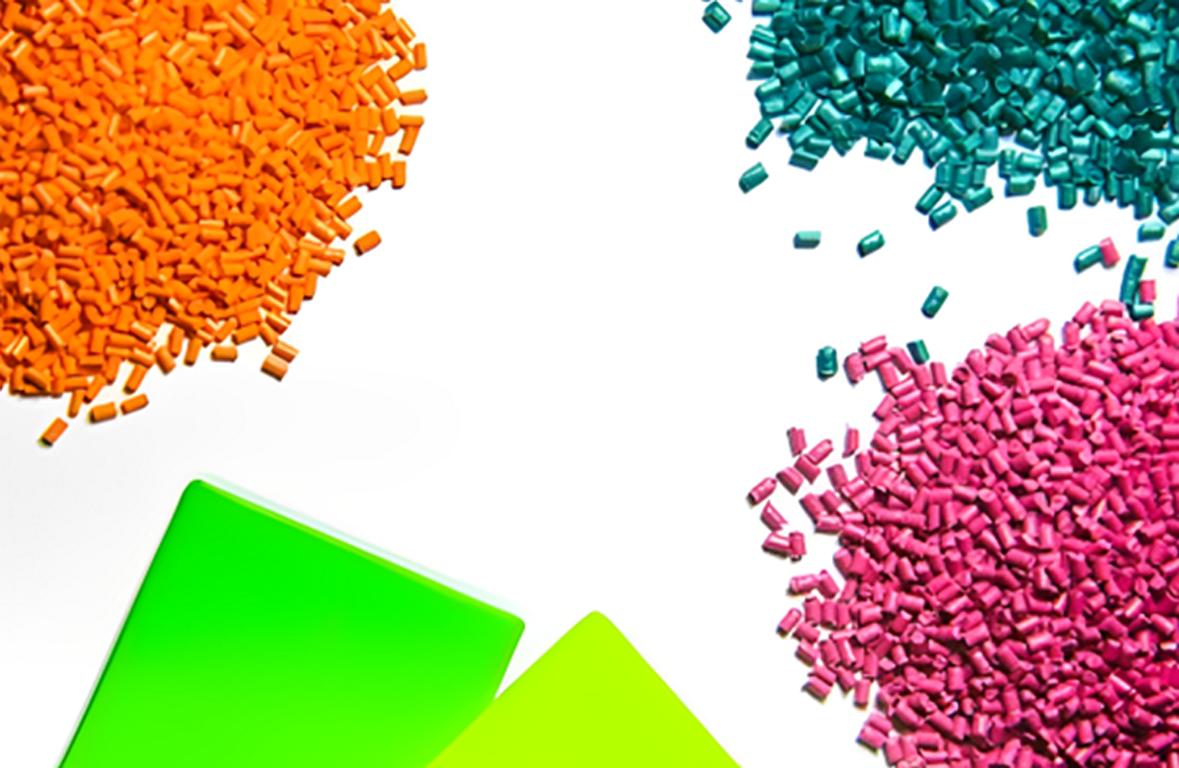

1. Raw Material Preparation:

TPE materials in pellet form are collected and fed into a hopper, usually above the injection molding machine. The ingredients are combined in a single pellet, which means it is equally efficient at each stage of forming and heating. This makes the results highly predictable and reduces material handling problems throughout the process.

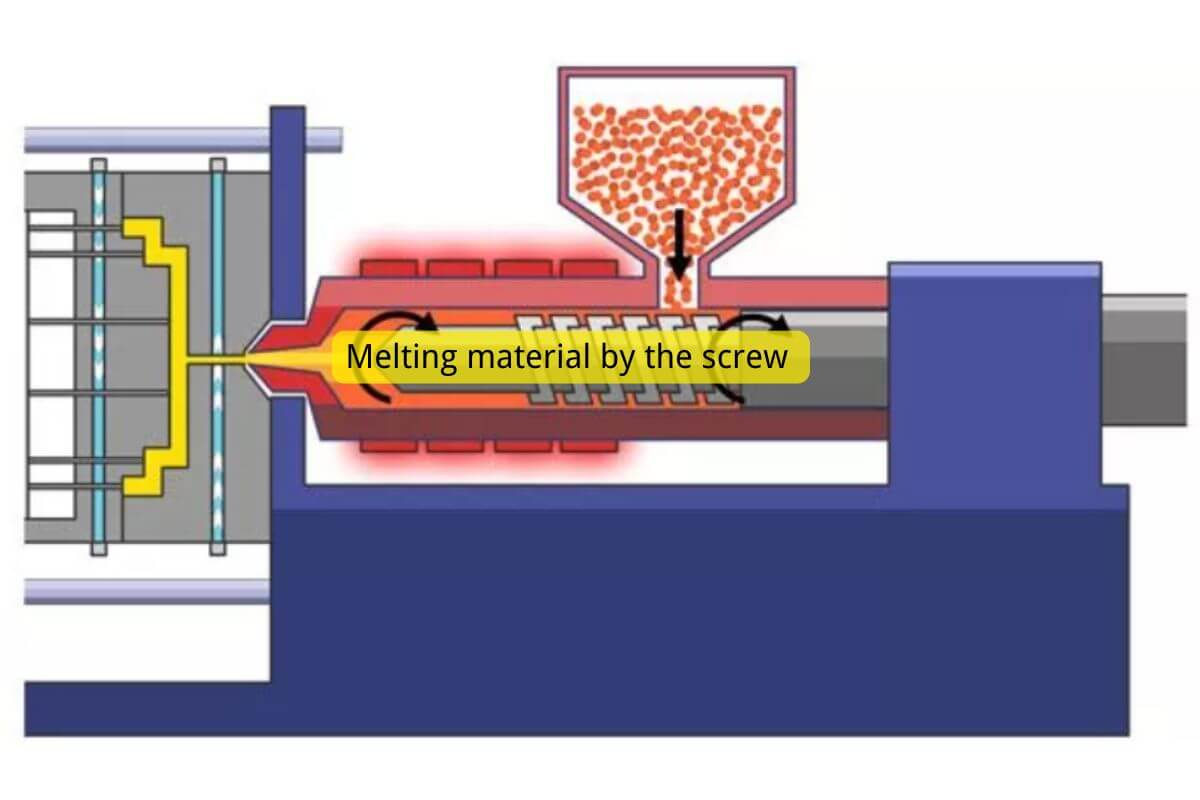

2. Melting Stage

These TPE pellets are then transported from the hopper to the heating chamber where the pellets are heated (usually at about 200-250 °C. This temperature range depends on the type of TPE material to be used). The heat softens the pellets to a liquid-like mass and can be easily modeled into the required shape. Especially the temperature aspect has to be well monitored in this process as too high a temperature can damage the material and affect the quality of the product.

3. Injection Stage

The screw or plunger forces the TPE material under high pressure into the shape of the cavity of the mold. It takes the mold shape of the desired part and might contain a complex shape wherein the final product attributes are concerned. This stage must be closely monitored to ensure top side hundreds’ pours, without shrinkage, voids, or air bubbles in the final part.

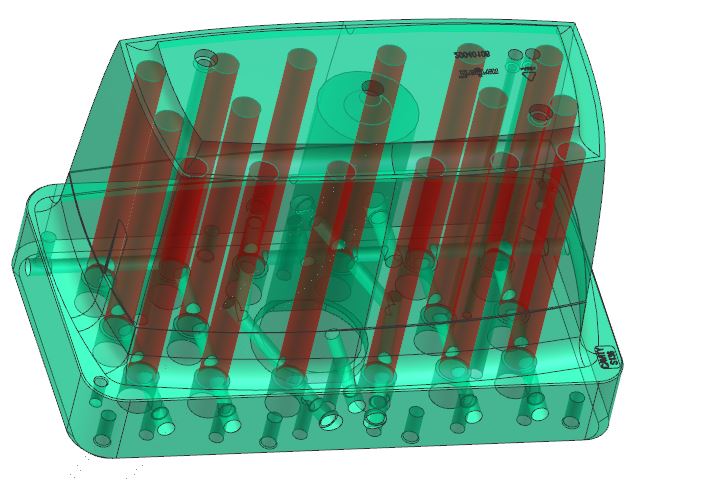

4. Cooling and Solidification

During mold cavity filling, the molten TPE cools, and forms a mold of the cavity, solidifying in the process. To regulate the product cooling rate and to minimize uneven temperature distribution which affects part distortion. Here the mold may be provided with a cooling system such as waterways. Another advantage of controlled cooling is that it eliminates warping and minimizes the probability of shrinkage also, the final size will be accurate.

5. Ejection Stage

After the TPE part has been solidified the mold cavity pushes it out using ejector pins or the like. It is then deboned and made ready for any further operation that is required for it. This stage has a critical timing factor whereby ejection earlier than required may distort the part while ejection thereafter may affect the overall production rate.

What is the Difference Between TPE and TPR material

The following table gives a detailed comparison of TPE vs. TPR; you can go to tpr material page to know more about what is TPR plastic.

| Feature | TPE (Thermoplastic Elastomers) | TPR (Thermoplastic Rubber) |

| Composition | A blend of plastic and rubber-like polymers (e.g., SEBS, TPU) | Styrenic-based elastomer, typically SEBS |

| Hardness (Shore A) | 20–90 | 10–80 |

| Elasticity | High, rubber-like | Slightly softer, high flexibility |

| Max Temp. Resistance | Up to 120°C | Up to 100°C |

| Applications | Automotive, medical, electronics | Footwear, grips, household items |

| Chemical Resistance | Moderate to high | Moderate |

| Recyclability | High | Moderate |

Different Categories of Thermoplastic Elastomers (TPE)

Thermoplastic Elastomers (TPE) are divided into several categories based on their chemical structure and properties:

- Styrenic Block Copolymers (SBCs)

Styrenic Block Copolymers (SBCs) are one of the most widely used types of TPEs due to their unique composition of styrene and rubbery blocks, which allows them to combine flexibility with the strength of a plastic. SBCs can be processed through various methods such as extrusion, injection molding, and blow molding, making them adaptable to a wide range of applications.

These TPEs exhibit excellent elasticity, transparency, and flexibility, and are also easily colorable. They are commonly used in applications requiring soft touch and flexible materials, such as grips, handles, medical devices, packaging materials, and household items. SBCs also offer excellent resistance to moisture and good clarity, which makes them an ideal choice for clear packaging materials and specialty uses in personal care products.

- Thermoplastic Polyurethanes (TPU)

Thermoplastic Polyurethanes (TPU) are known for their outstanding durability and flexibility, making them a popular choice for demanding applications. TPU materials have excellent abrasion resistance, which contributes to their longevity in high-wear applications, and they also offer great elasticity, low-temperature flexibility, and resistance to oils, greases, and solvents.

These properties make TPUs particularly suitable for automotive, footwear, and medical applications. In the automotive industry, TPUs are commonly used for suspension bushings, seals, and interior components. In footwear, they are used for soles that require both flexibility and durability. In medical settings, TPUs are employed in tubing, catheters, and other devices that demand resilience and compatibility with the human body. Due to their versatility, TPUs can be customized for different hardness levels and degrees of transparency. Go to TPU injection molding page to know more.

- Thermoplastic Olefins (TPO)

Thermoplastic Olefins (TPO) are blends of polypropylene (PP) and elastomers, providing a material that combines the properties of both rubber and plastic. TPOs offer superior chemical resistance, impact strength, and UV resistance compared to standard polypropylene, which makes them well-suited for outdoor and high-stress applications.

They are commonly used in automotive applications, especially for bumper covers, interior trims, and dashboard components, as well as roofing membranes in construction, where durability and weather resistance are critical. In household appliances, TPOs contribute to components that require impact resistance and strength. These materials are valued for their ability to be recycled, which enhances their appeal in sustainable product design.

- Thermoplastic Vulcanizates (TPV)

Thermoplastic Vulcanizates (TPV) are a unique blend of thermoplastics and rubber, where the rubber phase is dynamically cross-linked. This cross-linking process enhances the elasticity, heat resistance, and overall durability of the material, allowing TPVs to mimic many of the performance characteristics of traditional vulcanized rubber while still offering the processing advantages of thermoplastics.

They are commonly used in applications that require heat and chemical resistance, such as automotive weather seals, hoses, and gaskets. TPVs provide excellent resilience and can withstand repeated compression and flexing, making them a preferred choice in dynamic applications. Additionally, they are lightweight, which contributes to improved fuel efficiency when used in automotive parts.

- Copolyester Elastomers (COPE)

Copolyester Elastomers (COPE) are valued for their balance between flexibility and strength, allowing them to perform well under high-stress conditions. COPEs are often used in applications requiring resistance to high temperatures, fuels, and oils, making them suitable for engineering applications, particularly in the automotive and industrial sectors.

For instance, COPEs are used in the production of gears, belts, and dampers, as they retain their flexibility and structural integrity even when exposed to challenging environmental factors. In addition to automotive applications, COPEs find utility in sporting goods and electronics where both resilience and flexibility are required. These elastomers are highly resistant to flex fatigue, which means they can endure repeated bending and twisting without significant wear.

- Polyether Block Amides (PEBA)

Polyether Block Amides (PEBA) offer an outstanding combination of flexibility, chemical resistance, and lightweight properties. Known for their excellent flex life and low density, PEBAs are commonly used in applications where weight savings and durability are crucial. In the medical field, PEBA is used for components like catheter tubing and balloon angioplasty, as it provides the necessary flexibility, biocompatibility, and resistance to bodily fluids.

In sports equipment, it contributes to lightweight and high-performance products, such as athletic shoes and ski boots, where resilience, low temperature flexibility, and impact resistance are key. Additionally, PEBA is highly resistant to oils, greases, and various chemicals, allowing it to maintain performance even in harsh environments.

- Cyclic Olefin Copolymers (COC)

Cyclic Olefin Copolymers (COC) are unique among TPEs due to their high optical clarity, low moisture absorption, and dimensional stability. These materials possess a random polymer structure, which gives them exceptional transparency, similar to glass. COCs are often used in medical and optical applications where clarity, chemical resistance, and purity are essential, such as in diagnostic devices, pharmaceutical packaging, and optical lenses.

Their low moisture absorption makes them highly suitable for medical packaging, as it helps protect sensitive medical and pharmaceutical contents. Additionally, the high glass transition temperature of COCs makes them suitable for applications requiring heat resistance, while their low birefringence is advantageous in optical devices. COCs are often chosen for advanced packaging materials and lenses that require both transparency and strength.

Each category of TPE offers unique properties that make it suitable for specialized applications across industries, including automotive, medical, consumer products, and industrial engineering. By selecting the appropriate type of TPE, manufacturers can optimize product performance, durability, and cost-effectiveness in various applications.

Important Properties of TPE Material

Let’s explore the different properties of TPE;

1. Elasticity

TPE has the characteristics of a rubber elastic, which can be stretched and retraced due to relatively rubber elasticity characteristics. This makes it suitable where flexibility and resilience have applications, i.e. seals, gaskets, and other soft-touch applications.

2. Thermoplasticity

TPE has properties identical to rubber but is unique because it can be melted and reused at high temperatures. It is a thermoplastic, which means it can be melted and used to form products, then remolded, which is convenient for making and recycling.

3. Durability

TPE offers excellent wear, abrasion, and impact properties with different applications. Especially where durable parts are needed such as automotive parts and electronics.

Recyclability

Like any other thermoplastic, TPE is recyclable and reduces the impact of manufacturing on the environment. This recyclability is helpful in industries that are trying to minimize or eliminate waste more so when trying to be productive in the use of the packaging material.

What’s the difference between TPE vs. TPR Silicone or Rubber?

The following table gives a detailed comparison of TPE and TPR silicon and natural rubber; Go to TPE vs silicone page to know more about difference between TPE and silicone. if you want to know more about silicone, please go to is silicoen safe page.

| Feature | TPE (Thermoplastic Elastomers) | Silicone | Rubber (Natural/ Synthetic) |

| Composition | Blend of thermoplastics and elastomers | Synthetic polymer, silica-based | Natural (latex) or synthetic (e.g., SBR) |

| Hardness (Shore A) | 20–90 | 10–80 | 30–90 |

| Elasticity | High, rubber-like | Very high, flexible at low temps | Very high |

| Max Temp. Resistance | Up to 120°C | Up to 200°C | Up to 100°C (natural), 150°C (synthetic) |

| Chemical Resistance | Moderate to high | Excellent | Good (synthetic), moderate (natural) |

| Processing | Injection molding, extrusion | Compression molding, extrusion | Vulcanization, compression, extrusion |

| Recyclability | High | Low | Low to moderate |

| Applications | Automotive, medical, consumer goods | Medical, food contact, electronics | Tires, gaskets, seals, footwear |

| Cost | $$ (Cost-effective, recyclable) | $$$ (Higher cost, durable) | $$ (Varies by type, limited recyclability) |

Key Considerations When Choosing TPE Material

Here are some of the important key points when choosing TPE material;

1. Application Requirements

Determine the specific mechanical properties needed for the application such as tensile strength, flexibility, and hardness. The typical properties of TPE vary depending on the composition of P and E-PO and the performance of similar TPE formulations changes depending on the environment in which it is being used.

2. Temperature Range

Take into account the temperature conditions under which the TPE shall be used. TPEs also have a maximum temperature limit, and choosing the right grade to provide the necessary performance characteristic in high or low-temperature operating conditions.

3. Chemical Compatibility

Self-assess the extent of chemical exposure the TPE will encounter. Some TPEs are chemically superior to others; knowing the environment that is, the conditions and situations in which the material is to be used helps to reveal a material that cannot deteriorate or lose its properties.

4. Processing Method

Identify the planned processing method ( injection molding/extrusion etc). Some TPEs may be specifically designed to function well in certain processes and make a world of difference in manufacturing outcomes and costs.

5. Regulatory Compliance

TPE complies with the applicable code in the industries. This may include medical or food-related. Its product and the materials have to meet safety and environmental requirements.

Environmental and Recycling Factors for TPE

Let’s discuss some of the important environmental and recycling factories for TPE;

- Recyclability: TPEs are often recyclable and this is one of the biggest benefits over some other rubber types. Determine if the concept of TPEs is recyclable and can be reused after it has been utilized, and is reusable.

- Environmental Impact: Analyze the appropriateness of the TPE in terms of its ecological impact in usage, production, and disposal. Also, evaluate the procurement and the source from where you get the product material or manufactured for renewability.

- End-of-Life Considerations: Identify a plan for handling the product at the lifecycle end. Know some of the options that the TPE will be recycled, reused, or discharged.

- Biodegradability: TPEs are not biodegradable and are environmentally friendly in the market.

- Sustainability Practices:

Evaluate energy consumption, emission, and disposal of the manufacturer for TPEs and other relevant issues. This should be done with suppliers willing to practice sustainable production processes.

Applications of TPE

Here are some of the important applications of TPE;

- Automotive Components: TPE is useful in seals, gaskets, and interior automotive parts because of its higher strength and flexibility.

- Medical Devices: The main applications of TPE are tubing, catheters, and the syringe seal because of its biocompatibility.

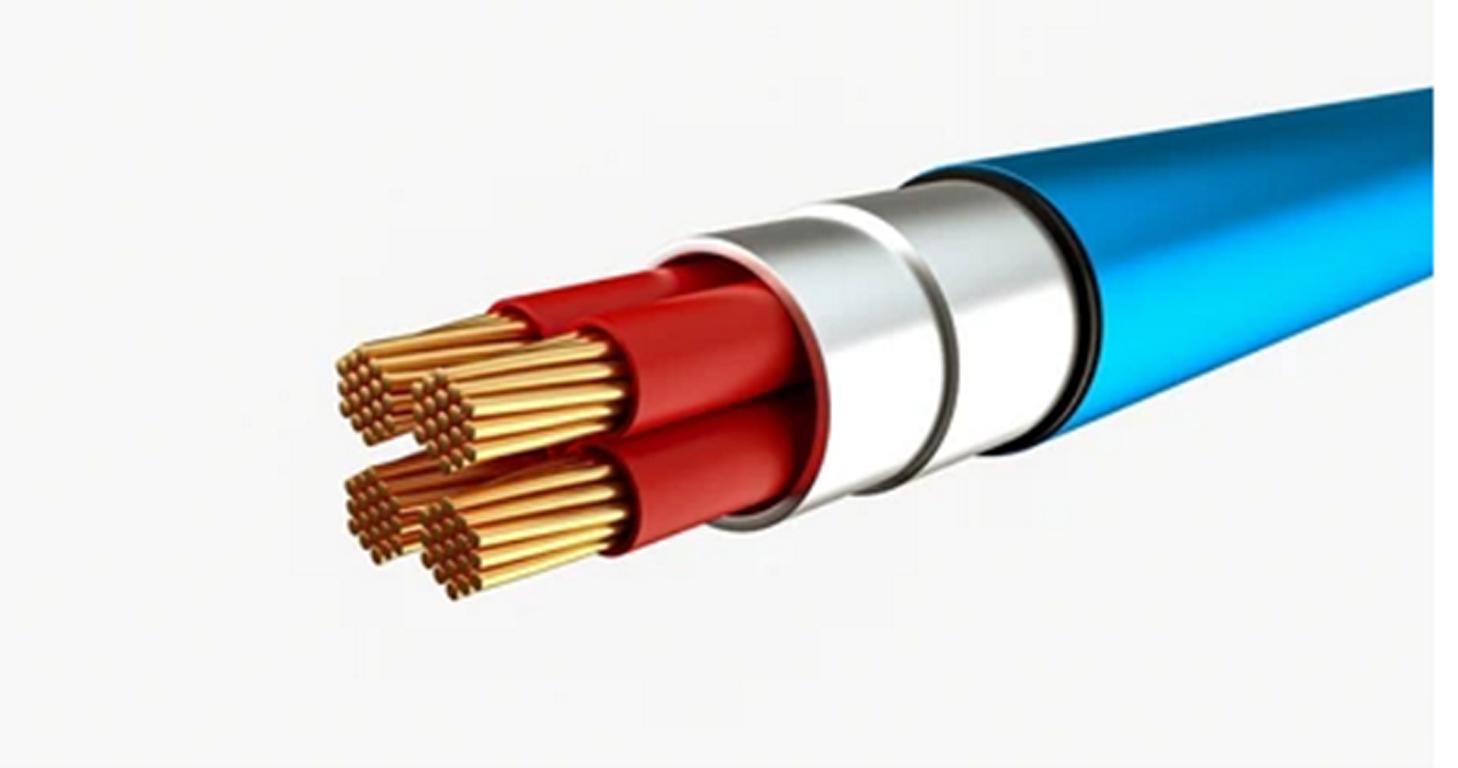

- Consumer Electronics: It is well known in cable, plug, and soft-touch grip applications.

- Footwear: TPE is light, has excellent properties and flexibility, and is thus widely used for the soles of shoes.

- Packaging: Due to the strength and moldability of TPE it is used in flexible films, caps, and seals.

Pros and Cons of TPE

The following are some of the benefits and limitations of TPE

Pros:

- Recyclable and cost-effective

- It is easy to process by injection molding

- A material that also offers some extensibility is both elastic and thermoplastic.

- Offers design flexibility

- Wide range of hardness levels

Cons:

- They also have poor heat resistance as compared to other flame retardants.

- Nevertheless, the chemical resistance of these laminates is rather modest in some grades.

- The material cost is high compared to other conventional plastics.

- It is also unsuitable for application in high-temperature areas.

When Should I Use TPEs

Here are some points where TPEs can be a suitable option;

- Flexible Applications: Most useful where flexibility of material is desired as with seals and gaskets because of the rubber-like nature of this class of material.

- Molded Parts: Used primarily in large quantities manufacturing of different shapes. They’re intricate via both injection molding and extrusion techniques.

- Environmental Considerations: It will be suitable for products using TPEs since it meet the requirement of being environmentally green as they are recyclable.

- Regulatory Compliance: Best for use in industries and businesses that require compliance with health standards such as medical and food contact industries.

When Not to Use TPEs

The following are some points where you must avoid using TPES;

- High-Temperature Applications: Not applicable for use in environments above 120 degrees Celsius as TPEs are known to degrade or lose properties in such surroundings.

- Extreme Chemical Exposure: It is advisable not to use a product where you have to come across strong chemicals or solvents that may affect the material.

- Cost-Intensive Applications: If lower cost is more appropriate for performance requirements (rubber or plastic), then one should look at those.

Conclusion

In conclusion, owing to its flexible characteristics and high durability, together with the possibility of easy processing, TPE can meet the requirements of versatile applications such as the automotive industry and consumer electronics. Because sustainability is gaining great significance with time, TPE’s recyclability and the possibility of using biomaterials make it even more appealing. As innovations take place, TPE is expected to embrace more functions in different product designs across various industries.

FAQs

Q1. What is TPE material?

TPE plastic is a polymer and its traits are rubbery elasticity and thermoplasticity and can be processed to be shaped.

Q2. What are the differences between TPE and rubber?

Unlike rubber, however, TPE plastic material can be melted and remolded and this process can be repeated severally.

Q3. What industries use TPE plastic material?

TPE plastic material finds application in the automotive, medical, Electronics, and consumer goods industries.

Q4. Can TPE plastic material be recycled?

Indeed, TPE material can be recycled and reprocessed while experiencing modest or negligible changes in properties.

Q5. Is TPE plastics heat resistant?

It is more flexible than most other engineering thermoplastics but has a low heat resistance. Besides this, it is not suitable under high-temperature conditions.

Q6. What are the different types of TPEs,

Some of the elastomers include the Styrenic Block Copolymers (SBC), Thermoplastic Polyurethane (TPU), and Thermoplastic Olefins (TPO).