Why need design ribs on the injection molded parts

Injection molding technology is the most common manufacturing technology for producing high volume of plastics parts in the world. The purpose of these parts can range from a picture frame that is never touched to a gear that is used in a moving assembly every day. Many times, the stiffness of a part must increase due to the load applied to the plastic part design. When designing strength into an injection molded part, considerations must be made to accommodate for the manufacturing process. This is where ribs and supports come into the design.

Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. supports are triangular shaped ribs that support a main wall. Ribs and gussets add strength and rigidity to primary walls without the dangers and high costs caused by excessive wall thickness.

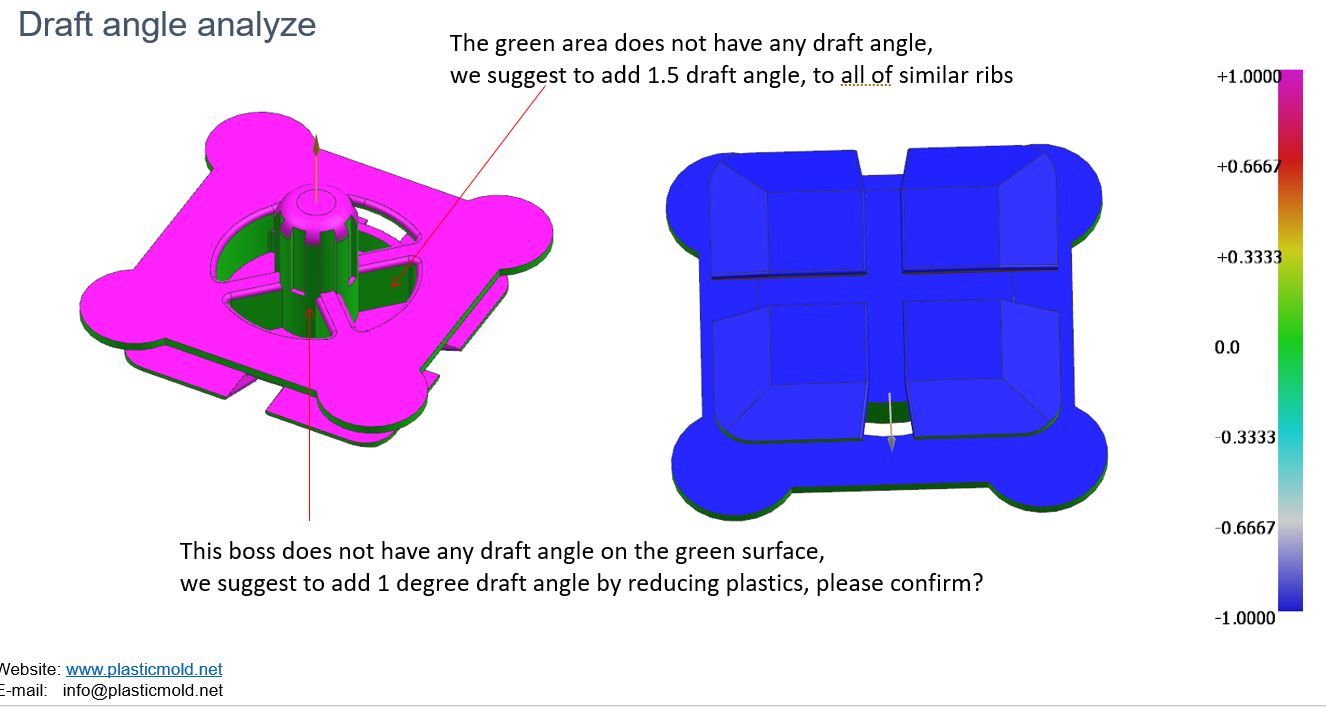

DFM Design for Manufacturing

If the mean wall is too thick, sink marks and distortion may occur on the molded part, resulting in a rejected part design. Ribs solve this problem by providing additional support for thin walls, and are in fact, more effective structurally than just a thick wall. Along with being stronger, ribs also require less material than thick mean walls making them the economical choice as well.

Ribs increase the durability and quality of your part while reducing material cost, but if used incorrectly, can have negative effects on the aesthetics of your molded part. The area where the rib intersects with the main wall will experience a thicker plastic section. If the rib is too thick it will cause a sink mark in the main wall due to inconsistent cooling rates. To avoid this there are several rules to follow when using ribs in your design:

Please send us your part design, we will review your part design and send you a completely DFM report for your project, this will save you a lots of cost and time.