What is Plastic Mold?

Plastic mold (mould) is a tool or die used in the manufacturing process to create plastic parts and products. The plastic mold is typically made of metal or another hard steel (H13, DIN1.2344, DIN 1.2343, 2083, NAK80, or similar steel) and is designed to hold melted plastic in a specific shape until it cools and solidifies.

Plastic mold manufacturers commonly use this process to make millions of plastic parts. These parts can have complex designs and the same shape. Other methods would find it hard or impossible to create them,Plastic injection molds are used in many industries. These include automotive plastic injection molded products, construction industry, , home application products, furniture industries, electronics industries, plastic molding toys, consumer products, and so on.

Making plastic mold injection is very complex jobs that must be manufactured by a professional injection mold maker. Below are the simple steps to make the plastic molds.

- First, the part designer must create the model you want. Alternatively, you can hire your injection mold supplier to design the final product based on your needs.

- Second, when the product design is approved, you need to find your mould maker to come up with a completely mold design. Once the mold design has been created, you can start to manufacture the plastic mold. The plastic injection mold manufacturing process includes drilling, lather machining, wire cutting, CNC machining, EDM, polishing, etc.

- Third, the last step to making a plastic mold is mould fitting. When mold manufacturing is complete, you need to do the mold fitting. This checks if the components are in the right position. Mold fitting is the only way to check mold quality and improve any possible issues in advance.

- Fourth, when mold fitting is finished, the actual injection molding process can start. At the beginning of the injection molding process, we called it mold trial. From the mold trial to large-scale production, we still need to fix some small injection molding problems. We must do several mold trials because the first one usually has some issues that need to be resolved.

After two or three mold trials until customer approval of the samples, we could start massive production runs. There is a simple process to follow. It includes part design, mold design, and mold manufacturing. This helps create perfect-looking plastic products.

Plastic mold manufacturing is actually a complex process. You must find a professional plastic mold maker to make your plastic molds.

What are the advantages of plastic mold technology?

Here are some of the advantages of plastic mold technology:

High efficiency and quick production

There are many good reasons why plastic injection molding is famous as the most common and successful form of molding. The process is quick compared to other methods. Its high production rate makes it more successful and affordable. Speed depends on the size and complexity of the mold, but just about 15–120 seconds pass between each cycle.

Better strength

Strength is one of the important factors that need to be determined when designing a plastic injection-molded part. The designer needs to know if the part should be rigid or flexible. This information helps them adjust the ribs or gussets. Understanding how the customer will be using the part and what kind of atmosphere the part will be exposed to is also vital.

Finding the right balance of design considerations will help address your parts need for stability and strength. Material selection plays another important role in the strength of the part.

Reduced waste

When searching for a high-volume injection molding supplier, it is important to consider their green manufacturing efforts. These efforts show a commitment to sustainability, quality, and safety.

During the molding process, excess plastic is produced. You want to look for a firm that has a system in place to recycle its excess plastic. The best eco-friendly plastic injection molding companies use advanced machines to cut down on waste, packaging, and transportation.

Low labor costs

Labor costs are generally relatively low in plastic injection molding in comparison with other kinds of molding. The ability to produce parts quickly and at a high quality improves effectiveness and efficiency.

The molding equipment usually operates with a self-gating mechanical tool. This keeps operations smooth and production going with little supervision.

Flexibility, material, and color

Choosing the right color and material for a project is key to making plastic molded parts. Due to the large range of both, the chances are almost limitless. The progress in polymers has led to many different types of resins to choose from.

It is important to work with an injection molder who has experience with different resins and uses. This includes resins that meet RoHS, FDA, NSF, and REACH standards.

To choose the best resin for your project, think about a few important factors. These include tensile strength, impact strength, flexibility, warm deflection, and water absorption.

If you are unsure about the best materials for your plastic molds, you can check injection molding materials. You can also contact us easily by emailing info@plasticmold.net.

What are the disadvantages of plastic mold technology?

Here are some of the disadvantages of plastic mold technology:

High initial investment costs

Quick-production injection molding needs an injection molding machine, injection plastic molds, injection molding equipment, other auxiliary equipment, etc.

The cost of injection molding machines and molds is high. This makes it a big investment. Therefore, it is not ideal for small batches.

High design requirements

To produce parts in large quantities, make sure the design is correct from the start. If you have to replace the mold later because of design problems, it will be very expensive.

High skill requirements: Making mold items depends on many factors. This means the technical skills needed are higher and harder to learn.

Injection molding machine operators need a lot of skill. They usually require 5 to 10 years of experience.

Plastic injection mold design and production workers need more technical skills. They usually require 5 to 10 years of experience.

Longer pre-production lead time is time-consuming.

The main equipment for injection molding is the mold. However, designing the mold takes a long time. Different tool-making methods and mold testing also slow down production.

Depending on the structure and size of the product idea, it generally takes 25–40 days to make the injection mold.

Once the plastic injection mold is ready, it often takes several attempts to adjust the injection molding machine settings. This process happens during the same-making stage. The goal is to find the best settings for fast production. However, this also requires some time.

When do you need plastic molds?

When you have a plastic product design that want to make it in life or sell on the market, you should consider using plastic injection mold technology. It offers great manufacturing options that you might be missing out on. No matter if you worry about accuracy, using plastic instead of metal, or cost, this list can help. We believe it will encourage you to consider plastic injection molding for your product again.

Part standard and accuracy

Plastic injection-molded parts can have high quality and accuracy as required. When using manufacturers in the U.S., accuracy is usually within 0.001 inches. Standard control measures, such as ISO certification, ensure your parts are high quality and accurate. However, the price will be higher than in China.

Volume of production

Once the mold making for plastic parts is made, the volume of production can be scaled up or down as needed.

Cost per plastic part

After the primary cost of the injection mold, the cost per part is extremely low. Choosing the right resin will affect the cost. However, machine wear and labor costs are low. This means that costs per part are lower than other manufacturing options when production volumes are high.

Complexity of parts

Plastics and their inject molds permit greater design freedom than many other producing specs. A skilled plastic mold company can create parts and sets of parts that require less work after they are made. This includes everything from smooth finishes to intricate designs.

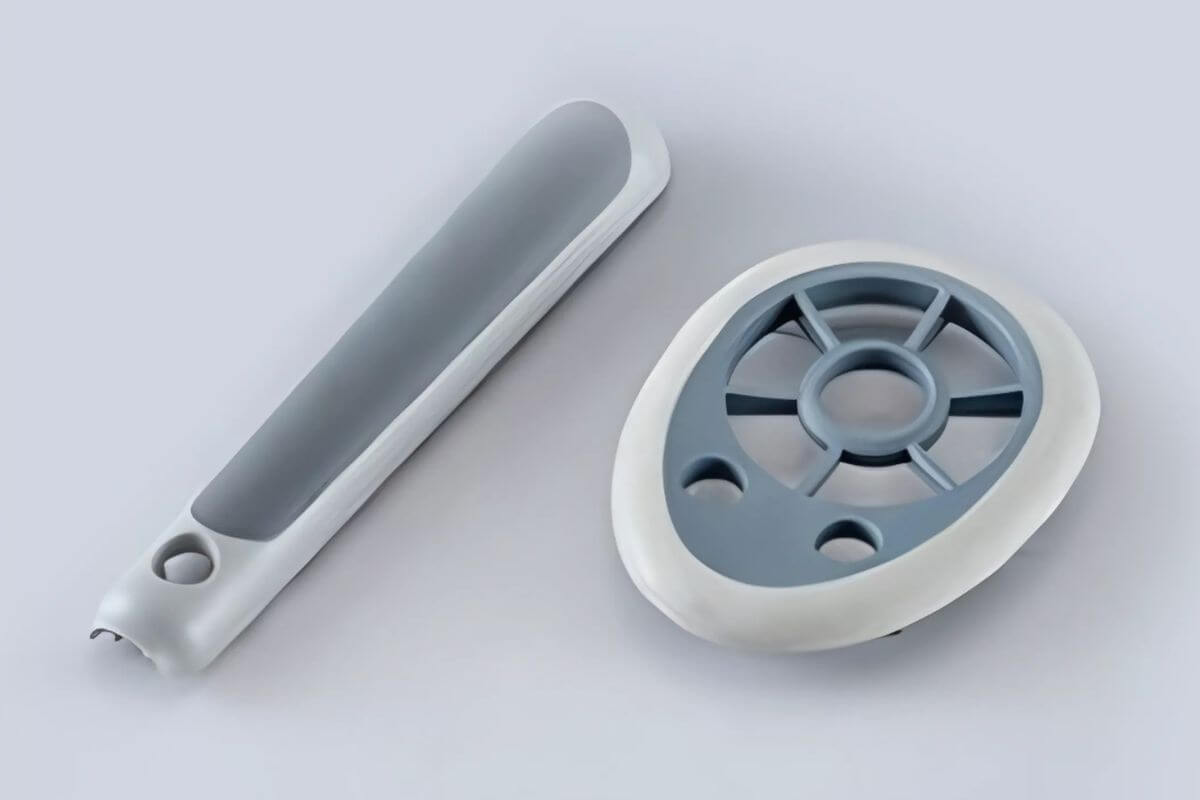

Co-injection, overmolding, and double-shot

Parts don’t have to be made of one plastic. Double-shot molding and overmolding allow two types of plastic to be combined in the mold. These plastics can have different qualities, such as hardness and flexibility.

Co-injection molding allows one polymer to be injected as the core of another. This method creates parts that are more flexible and affordable.

Market-specific materials and standards

Plastic molding technology has been around for a long time and has the tools and standards to meet different markets. For example, if you are making medical parts and need traceability, you have options. These options help ensure that every part can be traced back to its batch.

Injection molding is a process used in most plastic productions and is very preferred by different businesses and firms. This is largely because it is pretty efficient and provides uniformity in all the items manufactured using this process.

To get the best results, it is best to work with a professional injection mold producer. They offer quality plastic injection molding services.

This process requires the use of expertise to make sure that the products meet high standards. Your mold supplier must choose the best material to use. They also need to create a working mould design. Finally, they should make a working prototype to start the production process.

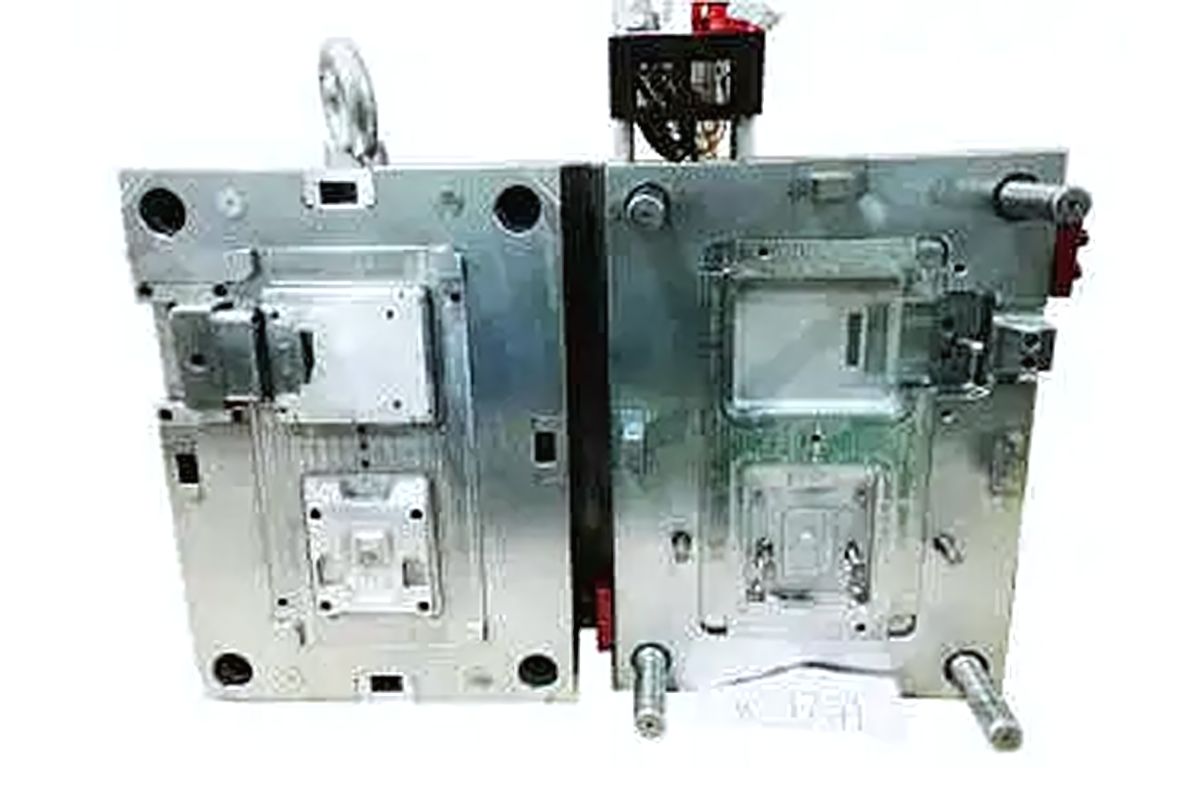

Where can I find the best plastic mold company?

Sincere Tech is one of top 10 mold manufacturers in China. We provide custom plastic injection mold and molding services worldwide. Our services can save you 40% on plastic mold manufacturing and production. We have over 18 years of experience in plastic injection mold manufacturing services and fluent technical English communication.

We 100% guarantee that your project will be successful. You will be impressed and satisfied with our quality, price, and services. We are willing to share with you some of our customers to let you verify our quality and service. Send us your requirements for a quotation; you will not lose anything but our competitive price for reference.

To protect your project from copying, we can sign an NDA document to protect your project. In the following, you will find information about plastic injection molding processes, techniques, specialized molding technology, defects, and troubleshooting solutions.

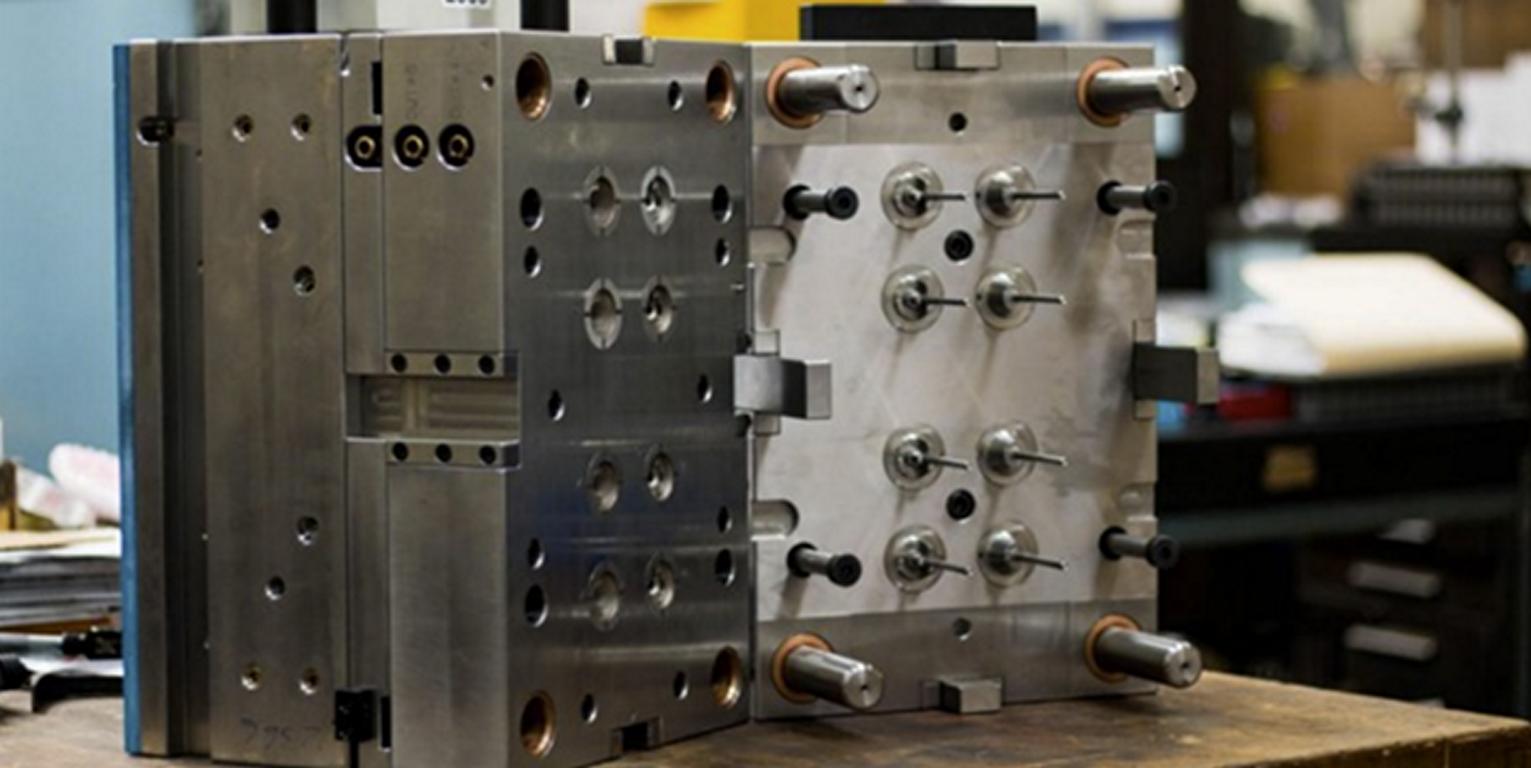

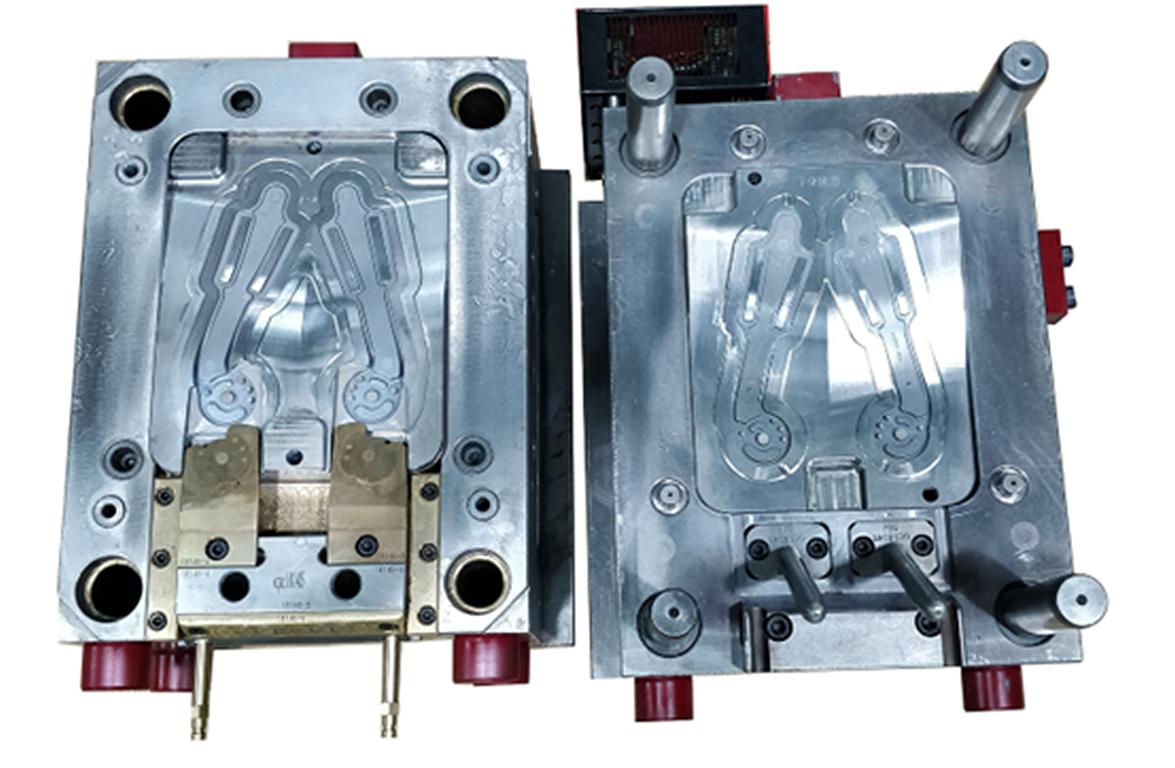

Plastic mold structure

Basically, there are two main parts in the plastic injection mold structure: the mold cavity (fixing half) and the mold core (moving half).

The mold cavity (fixing half) is the mold part that forms the outer shape or contour of the plastic part being generated. The feeding system is located at this point as well.

This part of the mold is designed to define the full size and shape of the part. It is made by creating a reverse impression of the part to be molded. This uses high-precision CNC machines, wire cutting, electrode discharge machining, and other machining methods.

On the other hand, the injection mold core (moving half) side forms the inside features and shapes of the plastic part being generated. It creates the inside geometry of the part, such as bosses, holes, ribs, and other specs.

The mold core is made using reverse impressions of the part. This is done with high-precision CNC machining, wire cutting, and electrode machining. Other machining processes are also used.

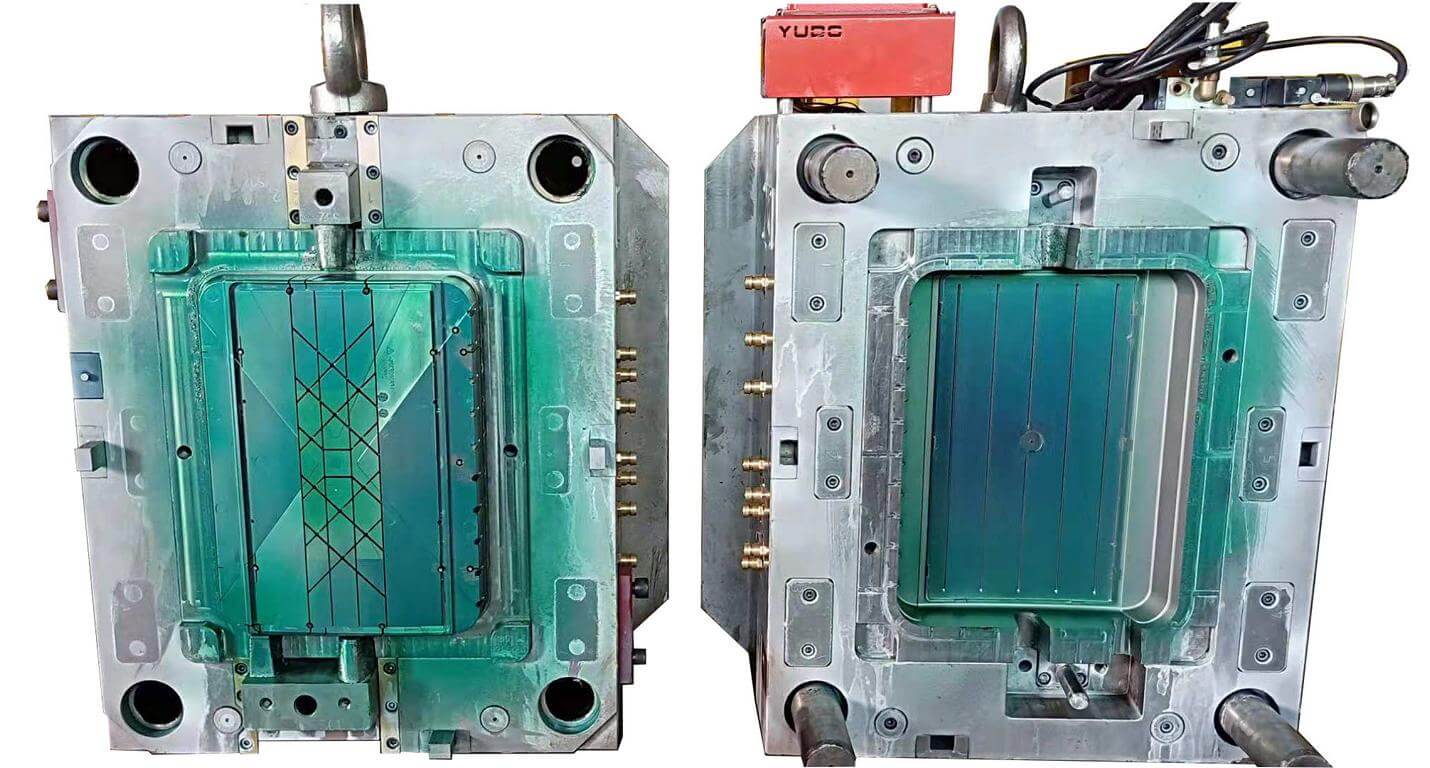

The two parts of the plastic injection mold, the cavity and core, will be put together in the mold base. This mold base has cooling channels, ejector pins, guiding bushinges, runners, spure bushing, fastening screws, and other mechanisms. These mechanisms include lifters, sliders, and other special actions.

The material for the plastic mold structure depends on several factors. These include the type of plastic, the mold’s lifetime, and the budget. Usually, the mold base is made from S50 C. Sometimes, the A and B plates are made from 1.2311. Normal steel for the mold cavity and core will be P20, 1.2738H, S136H, NAK80, 1.3444, 1.3443, H13, etc.

Plastic injection molding needs a lot of precision and accuracy. The mold structure is key to making a high-quality finished product.

Overall, plastic mold is made of a variety of mold plates, inserts, blocks, sliders, lifters, and other metal components. A plastic injection mold has two main parts: the fixed half, called the cavity side, and the ejector half, known as the core side. These parts include several mold plates and inserts.

The cavity is made using inserts that fit the surrounding frame plates (A/B plates). This makes it easier to machine and replace.

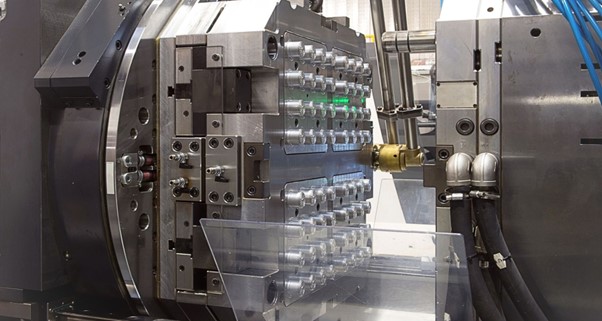

plastic mold injection

The plastic injection mold cavity and core inserts are usually separate blocks. Some of these blocks are made of strong material. They are inserted into pocket plates. These pocket plates are machined into the A and B plates. A and B plates are also called cavity or core retainer plates.

The mold cavity and core inserts are in the pocket plate. They stand above the A/B plate by about 0.1 to 0.5 meters. When both the fix and moving halfes closed, leave a small space between the A and B plates. This will create an excellent fit for the cavity and core inserts.

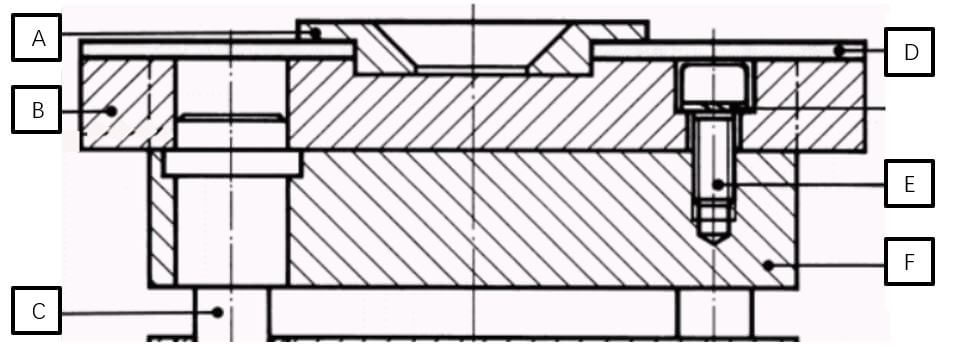

The mold fixed half includes (cavity side):

a: Locating ring; b: basic plate (top plate); c: guide pin; d: insulation plate (for higher mold temperatures or hot runner mold); e: fasten screw; f: frame plate or A plate (cavity if made in solid); see below picture

fixing half-cavity side

Plastic mold ejection half includes (moving half/core side):

a: guide bushing; b: locating bushing; c: supporting bar; d: bottom plate; e: frame plate or B plate (core if made in solid); f: support plate; g: support bar; h: upper ejector plate; i: lower ejector plate.

moving half-core side

Plastic mold materials

There are many types of mold steels that can be used to make injection plastic molds, including aluminum, steel, brass, copper, and many others. The below materials are some of the common mold materials used in the making of plastic molds.

Basic steel, which we use to make plastic molds:

- P20 (1.2311): This is a versatile, low-alloy mold steel with HRC 33-38, which is used a lot for the low- to middle-volume injection mold. This steel has good toughness and machinability. Some time used as A and B plates, and ejector plates as well.

- H13 (1.2344, 1.2343) or S136: Those are excellent heat resistance steels, These steels are usually used for injection molds. They are needed for high production volumes and should last over 1 million shots. This is a very tough, low-hardness steel used for high-quality cavity and core requirements. The hardness of those steels can be hardened to HRC 48–60 degrees.

- 303 Stainless Steel: This material is known for its corrosion resistance and machinability. It’s suitable for molds used in less demanding applications.

420 Stainless Steel: This type of steel is harder and more wear-resistant than 303 stainless steel. It is used for molds where abrasion is a problem. - Aluminum Alloys: Some aluminum alloys are used for prototype molds due to their lightweight nature and good thermal conductivity. The normally used aluminum alloys are 7075 and 6061.

- Beryllium Copper Alloys: These alloys, such as C17200 and MoldMAX, exhibit high thermal conductivity and excellent corrosion resistance. They are used in molds that require rapid heat removal, especially for some of the deep ribs, which are not possible to add a cooling channel to or are not easy to cool during molding.

- 718H (1.2738H) and 2738HH: Those are pre-hardened steels that have a hardness of HRC 28–40, which provides moderately high hardness and good machinability. It is used primarily for cavities and cores, as well as stripper plates. The mold life of those steels is around 0.5 million shots or more.

When selecting the steel for a plastic mold, you may wonder which material you should use. Then, you need to think about some factors, such as the type of plastic material being molded, the expected production volume, the required mold life, and cost considerations. Additionally, the surface finish is also an important factor in selecting the right mold material. When you have a project that requires plastic mold, find professional mold manufacturers in China that will solve your issues quickly, correctly, and at a at a competitive price.

What Is Plastic Molding Technology?

Plastic molding technology is the process of pouring liquid plastic into a mould or die cavity so that it hardens into a customized shape. These plastic molds can be used for a wide range of purposes. and it is a cost-effective process to produce millions of uniform-shaped plastic products.

There are typically five types of molds: compression moulding, extrusion moulding, injection moulding, blow moulding, and rotational moulding. We look at the details pertaining to each of these techniques so that you can decide which one will be the most successful for you to use.

Extrusion moulding

With extrusion molding, warm, melted plastic is pressed via a shaped hole to make a lengthy, shaped plastic part. This customizable shape that the liquid plastic gets pressed into is known as a die. This die is custom-made for the particular outcome that is wanted. It is almost like pressing dough through a press to make cookie-shaped cookies.

Compression moulding

This technique involves liquid plastic being poured into a warmed mould and then being compressed to form the desired shape. The high temperature of the full process ensures the best strength in the end product. The process is finished off by chilling the liquid plastic so that it keeps it from being trimmed and removed from the mould.

Blow moulding

With blow moulding, the custom plastic parts come out thin-walled and hollow. This technique is perfect for when the plastic part has to have a uniform wall thickness. This is extremely similar to the process of glass blowing.

Injection moulding

Injection moulding is quite similar to extrusion moulding. The difference here is that with injection moulding, the melted plastic is injected straight into a custom mould. The injection is done under high pressure so that the mould is packed with a powerful force. As with the other technique, after the mould is packed, the plastic is chilled to keep its new shape, then the mould is opened and the ejector system is used to eject the part out of the mold cavity, then the next cycle continues.

Rotational moulding

Also sometimes known as rotomoulding, this technique involves the liquid or resin being placed inside the mould and then being rotated at high speeds. The liquid then evenly covers the full surface of the mould to create a hollowed part with all the walls evenly thick. After the mould is chilled and the liquid plastic has taken on its fresh form, it is taken out of the mould.

The future of plastic injection molds

The industry of making plastic parts continues to grow thanks to the latest ideas and processes. These creative plastic injection moulding techniques give manufacturers and businesses new ways to mass-produce plastic parts. Here are some new innovations in plastic injection molding that may help your business and make production more efficient.

Micro-injection molding

As technology advances, our equipment and devices grow smaller for easier storage and handling. Many firms and industries keep innovating by creating new designs every year with more compact dimensions. Little plastics are famous in many fields, and using micro-injection molding is the best way to fulfill that need.

The phone and computer industries benefit from micro-injection molding since they use smaller plastic molds for newer phones and computer gadgets. The medical field also uses small medical devices for patients, such as portable IV pumps.

Injection transfer molding

Transfer molding process process involves of making similar injection-molded items simultaneously. Injection transfer molding takes it a step further by using the typical injection molding process and a plunger to press the resin into two or more molds.

The mold would cool simultaneously and eject for a quicker rate of production. This process gives the extra benefit of creating a uniform look across different molded items, such as plastic tube plugs.

Structural foam molding

A big innovation for injection molding is structural foam molding. This process gathers injection molding and gas-assisted injection molding by creating foam comprised of gas-like nitrogen and plastic resin. The combination turns into foam upon injection and expands. The result is an interior of foam and a shell of hard plastic material.

This foam combination makes it easier to make hard shapes and reach small portions of the mold. Plus, it creates powerful plastic. The inside of the plastic is hollow, while the exterior is powerful and detailed, depending on the mould.

Gas-assisted injection molding

Certain injection molds have hard designs and little space to fill. These little spaces make molding a full plastic piece hard since the resin may not reach it. Gas-assisted injection molding makes sure that resin reaches the small portions of the mould by injecting pressurized gas into the fluid while the resin cools.

The gas will release after chilling finishes, and the part will eject from the mold. This innovation in plastic injection moulding is a remarkable way to make hard plastic parts and make sure the plastic surface is powerful since the gas causes it to expand.

What type of materials are used in plastic molding technology

Plastic injection molding is compatible with lots of plastic materials, so its products are common in every industry and household. It is virtually impossible to cover all of them in one write-up. We have hand-picked the most famous ones.

Acrylic (PMMA)

Poly, better known as acrylic, is a thermoplastic material that has perfect mechanical strength, is lightweight, and has a clear, view-through look. Although not ductile, it has the best shatter resistance.

Additionally, one of its largest strengths is its ease of mechinability. After injection molding, acrylic parts are easy to finish and alter. go to PMMA injection molding to lear more.

PMMA has a few issues worth noting. Firstly, it is prone to scratching, which not only affects its clarity but also its full look. Additionally, PMMA has a tendency to accumulate greases and oils, further impacting its surface and clarity properties. Lastly, it exhibits bad performance in high-temperature conditions.

Acrylonitrile Butadiene Styrene (ABS)

ABS is one of the most famous injection molding materials. It has the best toughness and strength, chemical resistance, impact resistance, oils, and bases. It is fully opaque and can be injected-molded in many colors. On top of this, ABS is pretty cheap compared to other plastic injection molding materials on this list. learn more about ABS injection molding.

abs platics

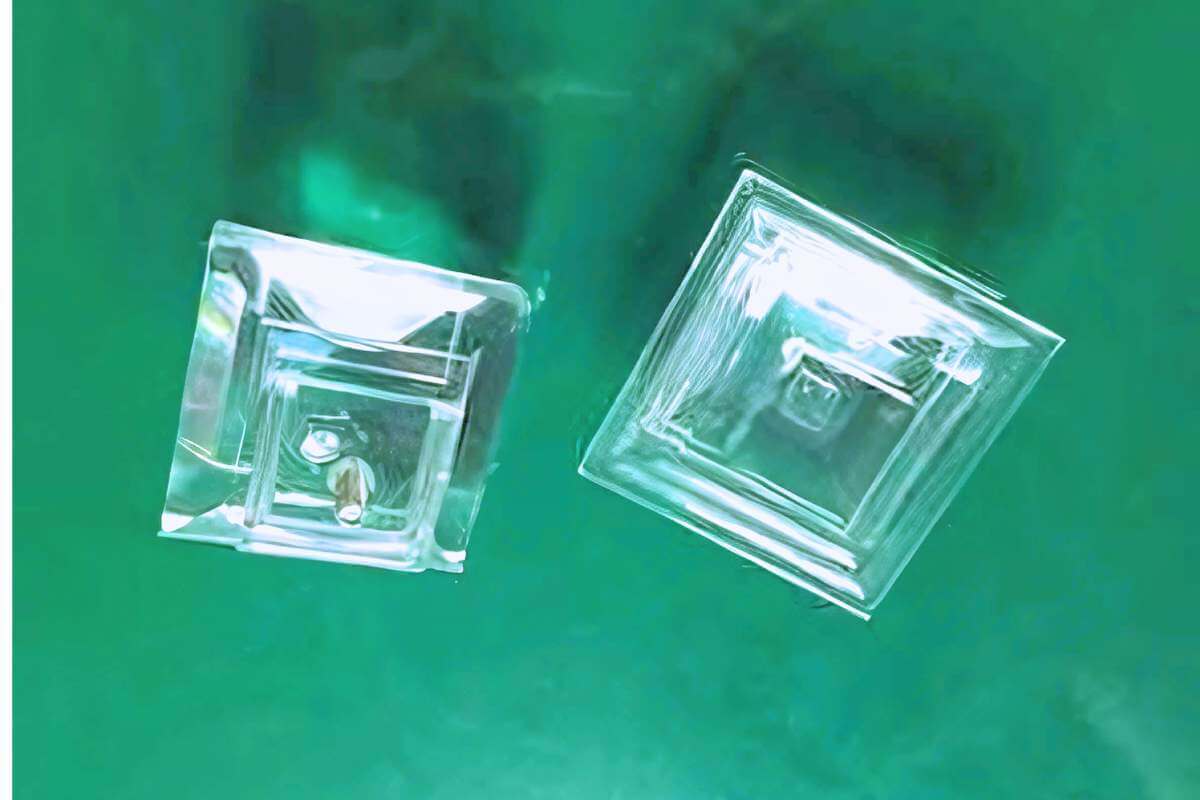

Polycarbonate (PC)

PC has remarkable toughness, impact resistance, and shatter resistance. It has a transparent look. Additionally, it has the desirable standard of maintaining its mechanical features and looking for a wide temperature range. Thus, it runs well in high-temperature atmospheres.

It does have remarkable optical clarity, oftentimes better than glass. This makes it a very famous injection molding material for producing helmet visors, goggles, and protective machine shields. learn more about polycarbonate injection molding.

Polystyrene (PS)

PS is one of the few injection molding materials that is very famous. It is amazingly lightweight, has chemical reactions, resists moisture, and is very perfect for injection molding due to its uniform thermal shrinkage inside the mold.

PS is used to make items like appliances, toys, containers, etc. It also enjoys a unique position in the medical equipment industry as it does not degrade with gamma radiation, the initial technique to sterilize medical equipment. Thus, equipment like culture kits and Petri dishes is injection molded with PS. check more about PS injection molding.

Thermoplastic Elastomer (TPE)

TPE stands out among injection molding materials in the sense that it is a plastic-rubber blend. It gathers the benefits of both materials. It is flexible, can be stretched to strong, long lengths, and is recyclable.

Additionally, its big benefit is that it’s affordable among most rubber alternatives. Lear more about TPE injection molding.

It is, anyway, not perfect for use in high temperatures as it loses some of its material features. Additionally, it should not be stretched too much for too long, as it is susceptible to creep.

What is the cost of plastic molds and plastic injection molding products?

The cost of injection plastic molds and the cost of injection molding products can vary greatly depending on a number of factors, including the size and complexity of the mold, the type of plastic being used, the production volume, and the lead time for production.

These elements, as well as any additional costs for finishing, packaging, and shipping, have an impact on the price of the finished plastic injection molding product. It’s important to work closely with a manufacturer to understand all the costs involved and to get a clear estimate before beginning production.

Below, we will give you some guides on how to get a plastic mold price and a plastic molding price from your mold supplier.

1. How do I get a price for export plastic mold or tooling?

What is an export plastic mold? Which means you will buy the mold only; once the mold is completely finished and ready for massive production, you will take the mold back to your country or your specified manufacturer to mold the parts.

To get a price for export injection plastic mould, there are a few things that you are going to provide to your mould supplier. In order to make sure that you have given the manufacturer all of the information that they need to check the price accurately, below are some key points for mold price estimating. This is the most important information for export molds.

- First of all, send the 3D drawing (STP or IGS format is better) to your mold suppliers. If you do not have the drawing, then you need to have some pictures of a sample with an approximate part size and show your supplier that part structure.

- Second, you need to know how many shots of the mold you require, for example. 0.5 million shots of a lifetime or 1 million shots of a lifetime requirement, because those two requirements will cause a different price.

- Third. The number of cavities: you need to specify how many cavities you need for your mold. Because one cavity and multiple cavities have totally different prices, the single cavity is cheaper than the multiple cavities mold. Because this will affect the mold price as well, if you are not sure, you can ask your supplier for some suggestions.

- Forth. Is it a cold runner or a hot runner that you require for your mold? If a hot runner, what brand of hot runners? YUDO, INCOE, etc.—all of that information will have different prices, so you need to specify your requirements. You could still ask your mold supplier for some suggestions as well.

The above items are very import information to get tooling costs for export mold because all of the information will change the mold price. You are welcome to contact us if you need any support.

2. How to get a price for injection molding products

If you only need plastic molding parts, then you only need to tell us (or another plastic molding company) what the plastics will be, how many parts you need per time, what the surface requirements are, and the colors of the parts, and they will take care of the rest for you.

To get the cost of plastic injection molding products, it is much easier than getting the cost of exporting plastic mold. Simple steps as below make getting the plastic injection molding service price easy.

- What will plastic be? for example, PP, PA66, ABS, PC, PMMA, PC/ABS, PEEK, PPS, etc.

- What color do you require for your molding parts? There are lots of colors; you could take a color reference from pantone color.

- What is the part surface requirement? Texture (graining or matte) or high polishing? The texture code could take references from VDI 3400.

- 3D part design (STP or IGS format file will be great for all of the companies); if you do not have a 3D part design, then send your sample pictures with part size and part weight, or an idea picture and explain it to us, and we can still get the price for you.

- How many parts do you need per time?

- Do you have any special function requirements?

With the above information, you will get a very competitive local mold/tooling cost (at least 40% lower than others) and unit injection molding cost from our side. That information is an important factor in estimating the plastic injection molding cost. Otherwise, any price will not have any references.

Plastic Molds, Molding Defects and Troubleshooting

The quality of the plastic mold is as important as the molding process. The plastic molding company you choose to help you with your product will eventually fight common molding issues. If you have high-quality plastic molds and a good plastic injection molding process, that will bring out the kind of results you expect from the end product.

Molding defects appear in the plastic mold; they can be attributed to the type of raw material used in the plastic injection moulding process, as well as the quality of the plastic mould, injection molding process skill, injection molding machine, etc.

Fortunately, by processing and preventing injection molding defects and using these approaches, mold manufacturers can create high-quality injection plastic molds. Once you have a high-quality mold, all other issues are easy to solve.

To make high-quality plastic mold, you must know how to solve this molding issue. Of course, find good mold suppliers; they will indeed solve this issue for you. Blow are some troubleshooting tips to solve the common molding defects, such as weld lines, etc., and ultimately get high-quality molded parts. There are some key defects that most happened during the mold manufacturing and molding process.

Flow marks

1. Flow Marks

This molding defect normally happens close to the gate area and the joint area (joint line or weld lines), which some people call flow lines, common in narrow sections of components and may be considered minor or serious defects depending on the part wall thickness and expected use.

In order to solve appearance flow line defects, during the molding process we need to increase the injection speed pressure, molten material temperature, and mold temperature. Increasing the gate size or changing the location of the gate is also helpful (last option). Below the right picture of flow mark defects, we increased the gate size to improve flow marks because the wall thickness was too thick (7mm).

Dull areas

2. Dull Areas

The most common is a dull concentric ring that can appear around a halo-like sprue. This usually occurs when the material flow is poor and the viscosity is high. Contrary to what many think, this is not a packaging defect, but a defect that occurs at the beginning of the billing cycle.

To minimize the possibility, the injection rate profile should be adjusted to ensure a uniform flow front speed throughout the filling phase.

It is also helpful to increase the back-pressure and barrel temperature of the screw to reduce dull surfaces resulting from lower melting temperatures. Increasing the mold temperature can also reduce this issue. But there must be a cooling system in the feeding area, especially if it is a hot-runner system; otherwise, it is not easy to solve this issue. For dull surfaces generated by design-related issues, this can be improved by reducing the radius between the part and the gate.

3. Burns Mark defects

The burn marks are defects often seen on plastic injection molding parts and look like a light yellow or black discoloration. This may be a minor defect due to excessive melting temperature, overheating in the presence of trapped air, and excessive injection speed.

Burn marks

Corrective actions for this type of burn mark issu: include reducing temperature, reducing cycle time, and reducing injection speed. Plastic mold manufacturers must also ensure that they have the proper gate size and gas vent gloves to resolve the trapped air problem that leads to this defect.

Because the air trap issue is the most common reason for this burn mark issue and could never be completely solved by adjusting the molding process, To mark defects, adding venting is the best solution, like increasing the venting grove, adding venting inserts to the deep ribs, etc.

4. Gloss difference defects

Gloss differences on textured surfaces tend to be more pronounced, and even if the surface texture is uniform, the gloss of the part may appear irregular. This is a problem that occurs when there is insufficient replication of the mold surface in some areas, and sometimes there are lots of ribs at the core side that can increase the gloss change issue on the textured surface.

It can be corrected by increasing the melting temperature, mold temperature, or holding pressure. The longer the holding time, the more likely the mold surface will be replicated accurately. If the design of the ribs caused this issue, to improve this issue, we can add some radius to all of the ribs. This will reduce the internal stress so that the textured surface can be improved as well.

5. Warping defects (deformation)

Plastic molding parts have warping defects that are normal, especially the long-size molding parts; distortion defects are hard to solve. Improving the mold design is the mean solution, but it is very limited to solving this issue by adjusting the parameters of the molding machine. The reasons and solutions to improve warping and distortion are listed below for reference.

Deformation issue

- When the deformation is caused by the residual stress of the molding process, it can reduce the injection pressure and increase the mold temperature to improve it.

- If the deformation caused by parts sticking can improve the ejection system or add more draft angle to solve this issue,.

- If the warping defects are caused by a poor cooling channel or a poor cooling time, we can add more cooling channels and increase the cooling time to improve this. For example, we could add more cooling water to the deformation area to improve the warping defects, or we could use different mold temperatures for the cavity and core.

- If the distortion issue caused part shrinkage, to solve this warping defect, we must adjust the mold design. Sometimes we need to measure the distortion size from the molding part and do the pre-deformation design on the part. The resin has a large shrinkage rate; usually, crystalline resin (such as POM, PA66, PP, PE, PET, etc.) has a higher warping rate than amorphous resin (such as PMMA, polyvinyl chloride (PVC), polystyrene (PS), ABS, AS, etc.).

Sometimes the gloss fiber material has more deformation issues as well. This is the hardest solution because you may need to adjust the part design two or three times to completely solve this issue, but this is the only way to solve the distortion issue.

6. Short shot defect

A short shot means not completely filling the mold; this molding defect normally happens at the end of the filling area, the end

Short shot defects. after adding venting inserts, the defect completely solved

of the rib, or some thin wall area. There are some reasons to cause this defect below.

- The mold temperature is too low. When material fills in the mold cavity since the mold is too cold, the liquid material is not able to fill to the end of the part or some deeper ribs. An increase in mold temperature could solve this molding issue.

- The material temperature is too low. This issue could also cause the short shot issue; this reason is similar to the issue of low mold temperature. To improve this issue, we can increase the melt temperature of the material to solve this molding defect.

- The injection speed is too slow. The injection speed is directly related to the filling speed. If the injection speed is too low, the liquid material filling speed will be very slow, and the slow flow material will be easy to cold. This will cause the material to get cold in advance. To solve this issue, we could increase the injection speed, injection pressure, and holding pressure.

- Venting issue. This is the most common molding defect we meet during the mold trial; all other defects could be solved by adjusting the molding parameter. If short-shot issues are caused by a venting issue, the best solution is to find a way to release the air out of the cavity. Sometimes reducing the clamping force can help a little, but it is not able to completely solve these defects.

If the air is stuck in the cavity or in the dead-ending area (the end of the ribs, for example), the short-shot issue will happen in that area. To troubleshoot this issue, we need to increase the venting grooves on the parting line and add a venting insert to the dead-ending spot to guide the air out.

7. Sink mark: It is a sink mark on the molded part caused by unbalancing plastic material shrinking in the mold cavity. It looks like there is a lack of material in that sink area that does not match the part geometry. This issue happens to the thick wall area or lack of cooling system in the mold. The mean reason to have this sink mark issue is the uneven wall thickness on the part design.

- If some ribs or some area have a thicker wall than the other place (rib thickness should be around 1/2–7/10 max of the mean wall), then this thicker area will be easy to have a sink mark issue. Below are some suggestions to improve this defect.7. Sink mark: It is a sink mark on the molded part caused by unbalancing plastic material shrinking in the mold cavity. It looks like there is a lack of material in that sink area that does not match the part geometry. This issue happens to the thick wall area or lack of cooling system in the mold. The mean reason to have this sink mark issue is the uneven wall thickness on the part design.

Sink mark

- Change the gate location to be close to the thick wall.

- Add more holding pressure and holding time, and inject more material into the mold cavity. When using this method, you need to double-check that the part dimension is still within the tolerance requirement.

- Increase the cooling time and the cooling channels to improve this issue. Plastic shrinkage rate is normal. If the cooling time is too short and the part is still warm after the mold is opened, then the part shrinks quickly without any cooling system. This will make it easy to have a sink mark. Increase the cooling time until the plastic injection molding part completelycoolsl in the mold cavity, and this defect will be solved.

- If the part design has a serious thick wall on some of the ribs or bosses, to solve this issue, we need to improve the part geometry and add some inserts to the thick area to reduce the wall thickness. This issue could be solved. For this unbalanced wall issue, we could use software to analyze it and prevent it in advance. Before mold manufacturing, we will make a fully DFM report and send it to our customers for approval. Below are sink mark analysis report samples.

Are you ready to start working on your new project and search for your plastic molding facotry? If yes, then let’s go. For your plastic molding project, finding a reliable Chinese mold company is more important. Because this will bring your market up very quickly, and you will win more profits on your project with less cost,

Today, over 80% of big companies are sourcing goods from China. Like the iPhone, some other famous companies buy things from China. So what are you worried about? If you are ready, then speed up to open your market immediately and share your profits.

SINCERE TECH is a one of top 10 plastic injection molding companies in China that offers all in one service worldwide, those service include products development and design, prototype, testing, PCB design and soldering, mold/die casting design and manufacutring, massive production, surface finish, certificate, assembly, final inspection, and packing, we have manufacutring comapny and compeletely goods assembly facotry. We guarantee you will be 100% happy with our service and quality.

We have a very professional technical team to handle your project very carefully and make the perfect plastic molds and parts for you. Some of our customers have moved the molds to our factory for troubleshooting since their current plastic mold supplier is not as professional as us. We can send you some of our current customers for you to verify our service, quality, and price.

Send us an email at info@plasticmold.net to get a price. We will never share your design with others. We are willing to sign an NDA to protect your project.