Plastic industrial crate mould is an essential component of the plastic manufacturing process, as they help shape and form plastic materials into useful and practical products. These moulds are used in a variety of industries, including agriculture, automotive, food and beverage, pharmaceuticals, and more. In this article, we will explore the role of plastic industrial crate moulds in the manufacturing process, the different types of moulds available, and the key considerations for choosing the right mould for your specific needs.

What are Plastic Industrial Crate Moulds?

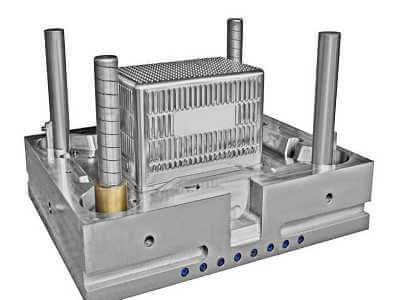

Plastic industrial crate moulds are specialized tools used to shape and form plastic materials into desired shapes and sizes. These moulds are typically made from metal, such as steel or aluminum, and are designed to withstand the high pressures and temperatures involved in the plastic injection moulding process.

The plastic injection moulding process involves heating plastic resin to a liquid state and injecting it into a mould cavity under high pressure. The mould is then cooled to solidify the plastic into the desired shape. The mould is then opened and the newly formed plastic part is removed. This process can be repeated multiple times to produce a large number of identical plastic parts.

Types of Plastic Industrial Crate Moulds

There are several different types of plastic industrial crate moulds available, each suited for specific applications and industries. Some common types of moulds include:

- Single Cavity Moulds: These moulds have a single cavity, or space, where the plastic resin is injected and solidified. Single cavity moulds are typically used for producing small quantities of parts, as they are not as efficient as multi-cavity moulds for high volume production.

- Multi-Cavity Moulds: These moulds have multiple cavities, allowing for the production of multiple parts with each injection cycle. Multi-cavity moulds are more efficient than single cavity moulds and are typically used for high volume production.

- Stack Moulds: Stack moulds consist of multiple mould cavities stacked on top of each other, allowing for the production of multiple parts with each injection cycle. Stack moulds are very efficient and are often used for high volume production.

- Hot Runner Moulds: Hot runner moulds have a heated channel, or runner, that transports the molten plastic from the injection machine to the mould cavities. Hot runner moulds are typically more expensive than cold runner moulds, but they offer several benefits, including faster cycle times, reduced material waste, and improved part quality.

Key Considerations for Choosing Plastic Industrial Crate Moulds

When choosing a plastic industrial crate mould, there are several key factors to consider to ensure you select the right mould for your specific needs. Some important considerations include:

- Production Volume: As mentioned earlier, different types of moulds are better suited for different production volumes. Single cavity moulds are best for low volume production, while multi-cavity and stack moulds are more efficient for high volume production.

- Material: The type of plastic material you will be using will influence the type of mould you choose. Different plastics have different melting points and shrinkage rates, which must be taken into account when designing the mould.

- Part Design: The complexity of the part you are producing will also impact the type of mould you choose. Simple, geometric shapes are easier to mould than complex, intricate shapes, and may require a different type of mould.

- Cycle Time: The cycle time, or the time it takes to produce one part, is an important consideration for high volume production. Faster cycle times can increase efficiency and reduce costs , and can be achieved by using hot runner moulds or optimally designed moulds with efficient cooling systems.

- Cost: The cost of the mould is also an important factor to consider, as it can have a significant impact on your overall production costs. Moulds can range in price from a few thousand dollars for simple, single cavity moulds to hundreds of thousands of dollars for complex, multi-cavity moulds. It is important to carefully consider your production needs and budget when selecting a mould.

- Mould Life: The mould life, or the number of parts that can be produced before the mould wears out, is also an important consideration. Moulds with a longer mould life will require less maintenance and downtime, resulting in increased efficiency and reduced costs.

- Mould Maintenance: Regular maintenance and upkeep of the mould is important to ensure it is in good working order and to extend its mould life. Properly caring for the mould can also help prevent defects in the finished parts.

- Mould Accuracy: The accuracy of the mould is critical for producing high quality parts with precise dimensions. Poorly made moulds or moulds that are not properly maintained can result in defective parts, which can lead to costly rework or scrap.

In summary, plastic industrial crate moulds play a vital role in the plastic manufacturing process, and choosing the right mould is an important decision. Careful consideration of your production needs, material, part design, cycle time, cost, mould life, maintenance, and accuracy will help ensure you select the best mould for your specific application.

Looking for mould suppliers for your crate moulds, Contact Sincere Tech China mold maker to get the best price now.