Nylon finds it’s into everyday life. It was first created in 1935 by Wallace Carothers of DuPont company for use in making women’s stockings instead of silk. But it just took off during World War II and people started using it for different purposes. Nylon was Initially used in parachutes, truck tires, tents, and fuel tanks. Today it has become the most widely used synthetic fibers ever produced in the world.

Nylon belongs to the polyamide (PA) group. The product’s strength and resilience stem from the amide connections. Some common polyamides include Kevlar, Nomex, and Pebax. Among all, Kevlar is notably a rugged material. Therefore, widely employed in making bulletproof vests. Nomex is heat heat-resistant material used in firefighting apparel. Nylon(PA), nowadays, is used in various products apart from clothing and fabrics. Go to PA6 GF30 page to know more about PA6 material.

Why Can’t Nylon 6(Pa6), Nylon 66(Pa66), and Nylon 12(Pa12) Interchangeably Used?

Different nylons are used for different applications. Choosing the wrong grade of nylon can result in several problems. Here’s what you may encounter:

- Underperformance at Service Temperatures: Nylon 6 has different melting points and thermal resistance from Nylon 66 and Nylon 12. These differences imply that the heat resistance of each material differs greatly when tested under actual use conditions. When using a nylon grade that has insufficient thermal stability, you are likely to experience breakages and contamination that affect the quality of your application.

- Premature Wear: The nylon chosen should have adequate strength and flexibility to avoid failure in the early stages of operation. The use of the wrong nylon grade results in component failure, a vice that compromises the lives of end users. Besides, some failures require an unscheduled maintenance process that increases costs and time wasted on production.

- Unnecessary Expense: The right grade should be opted for the right application. For example, opting for a higher-priced nylon material when a lower-priced one will do so can easily push project costs through the roof. Since Nylon 6, Nylon 66, and Nylon 12 have distinct peculiar benefits and limitations. So, understanding the specific features can help determine which of these materials will be suitable for your project. It can save 1000s on refabrication, repairs, and replacements.

Therefore, a designer or processor must understand and compare the various properties and performances of each nylon grade to achieve the best results in the application of the product.

Various Nylin Grades

Plastic car engine components are slightly similar to nylons in the sense of the idea. Polyamides, known as nylons, are of several types. These include:

- Nylon 6

- Nylon 6/6 (Nylon 66 or Nylon 6,6)

- Nylon 6/9

- Nylon 6/10

- Nylon 6/12

- Nylon 4/6

- Nylon 11

- Nylon 12/12

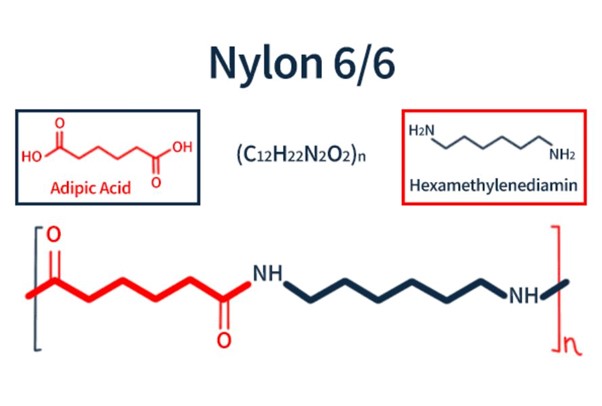

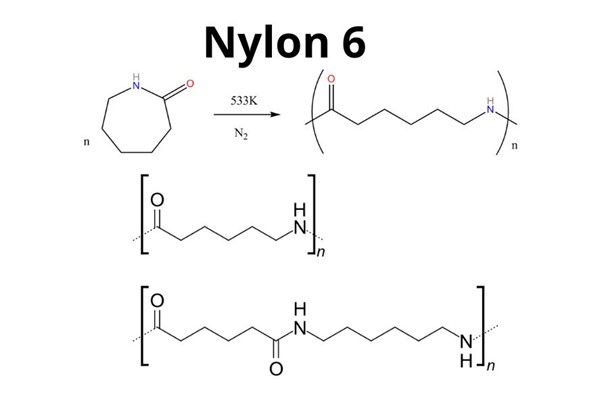

The naming system is associated with the carbon atoms in the base materials of each of the structures. For example, nylon 6 is derived from caprolactam and includes six carbon atoms in its chains. Nylon 6/6 originates from hexamethylene diamine with six carbon atoms and adipic acid with six as well.

In properties, however, they are variant. For example, not as dramatic as in steels, however, structural differences and additives can significantly impact performance. There are almost 90 different types of Nylon 11, provided by a single supplier.

Nylon in Engineering Plastics

Nylon materials are appreciated to have high strength, high stiffness, and high impact strength or toughness. These traits make them favorite materials for engineering plastics. Some of the most familiar are gears, grilles, door handles, two-wheeler wheels, bearings, and sprockets. These products are also employed in power tool housings, terminal blocks, and slide rollers.

However, material may be a disadvantage. As it absorbs moisture which in turn alters both the properties and fabric dimensions. This issue is reduced when reinforcing nylon with glass, resulting in a strong and impact-resistant material. Go to nylon injection molding page to know more about this plastic material.

Heat-resistant nylons are gradually finding their way into such applications as replacements for metals, ceramics, and other polymers. They are applied in automobile engines and oil and gas industries. Nylon 6 and Nylon 6/6 are typically chosen because of their relatively low price and high wear resistance. Go to is nylon safe page to know more about nylon material.

Nylon 6/6 Characteristics

Chemical Formula: [−NH−(CH2)6−NH−CO−(CH2)4−CO−]n

Original nylon 6/6 is normally the least costly. This makes it quite popular. Nylon 6/6 is often used in Germany due to historical reasons connected with supplies. Nylon 6/6 has good high-temperature and moisture resistance and is fairly strong at all temperature and moisture levels. It also provides abrasion resistance, and low permeability to gasoline and oils.

Moreover, Nylon 6/6 features negative consequences. It absorbs moisture rapidly and the effect reduces the impact strength and ductility when the polymer is dry. It is also very prone to UV and oxidative degradation. However, Nylon 6/6 shows lower resistance to weak acids than types such as Nylon 6/10, 6/12, 11, or 12. Besides, Nylon 6/6 is still widely used in electrical components because of the advancement in fire retardancy. It also replaces metal in diecast hand tools.

Properties of Nylon 6

Chemical Formula: [−NH−(CH2)5−CO−]n

Nylon 6 has several properties. These enormous features set it apart from other nylon grades and similar products in the market. Nylon 6 has very good elasticity, accompanied by very high tensile strength. It makes it even more valuable because it does not react with either alkalis or acids.

Further, nylon 6 offers adequate protection against different types of abrasion, as well. It has a melting point of 220℃. The glass transition temperature can be adjusted to 48℃. Nylon 6 filaments have a featureless surface that could be compared to that of glass. Another outstanding property of this material due to its ability to swell and absorb up to 2.4% water. These properties make nylon 6 useful in automotive, aerospace, cosmetic, and consumer products.

Applications of Nylon 6

Nylon 6 is widely applied in those cases where the material must have high strength, impact strength, and wear resistance. Its versatility makes it suitable for:

- Strands: Fibers

- Cleaning: Toothbrush bristles

- Strumming: Guitar strings and picks

- Mechanism: Gears

- Lock: Panel latches

- Shielding: Circuit insulation

- Shell: Power tool housing

- Insert: Medical implants

- Covering: Films, wraps, and packaging

Advantages of Nylon 6

Several advantages make nylon 6 an excellent choice for specific uses:

- It provides very high stiffness and good resistance to abrasion.

- Nylon 6 is suitable for injection molding operations.

- This material performs best in applications where there is a requirement for impact strength.

- It is flexible to regain its original shape after having been deformed.

- Nylon 6 has good dyeing properties and the ability to retain those colors.

Disadvantages of Nylon 6

Despite its benefits, nylon 6 has a few drawbacks:

- It has a low melting point as compared to other materials, that is 220 ℃.

- Due to the hygroscopic property, it tends to absorb moisture content in air and its surrounding atmosphere.

- High temperatures and light reduce its strength and structure; thus, it is not suitable for use under such conditions.

- Nylon 6 is not immune to UV light and thus characters such as color and strength are known to degrade when the material is exposed to sunlight.

Comparison between Nylon 6 and Nylon 6/6

Chemically, Nylon 6/6 has better resistance to calcium chloride as well as better weathering properties. Moreover, it has a higher HDT than Nylon 6. However, all the nylons are proved to be affected by the degradation when they come across the 15% ethanol gasoline.

In the selection of nylon material, there are materials selection tools such as UL Prospector that can be used to meet properties for the intended application. Other related choices such as acetals and thermoplastic polyesters have to be taken into account when making the choice.

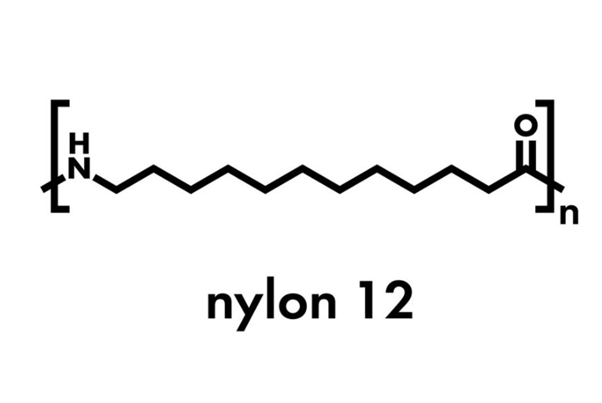

Nylon 12 (PA 12): A Strong Performer with Unique Structure

[−NH−(CH2)11−CO−]n

Nylon 12 (PA 12) is the most common material used in SLS and Multi Jet Fusion printing processes. It is an aliphatic polyamide that has an open structure with an aliphatic carbon backbone with exactly 12 carbons in its polymer backbone. PA 12 has a high chemical, salt, and oil resistance according to the specification in the table below. It has a lower melting point of about 356°F (180°C) but is still a very useful material.

Like PA 11, it has less tendency to absorb moisture making it stable in different climates. PA 12 is offered in black and white grades and the addition of glass and mineral fillers improves mechanical and thermal characteristics. It is widely practiced in printing enclosures, fixtures, catheters, and automobile fuel systems.

PA 12 is also biocompatible to make medical components suitable. Besides its medical use, it is used in cosmetics packing, electrical connections, and many other industrial products.

Table for Nylon 6/6 vs Nylon 6 Vs. Nylon 12:

| Property | Nylon 6 | Nylon 66 | Nylon 12 |

| Resistance to Hydrocarbons | Moderate | Superior | Excellent |

| Mould Shrinkage | Lower Shrinkage | Higher Shrinkage | Minimal Shrinkage |

| Impact Resistance | Superior | Moderate | High |

| Easiness to Colour | Lustrous Colour | Less Eye-Catching | Moderate |

| Water Absorption Speed | High | Moderate | Low |

| Recyclability Potential | Superior | Moderate | High |

| Molecular Mobility | High | Lower | Moderate |

| Elastic Recovery | Superior | Moderate | High |

| Dye Affinity | Superior | Moderate | High |

| Crystallinity | More | Less | Less |

| Heat Deflection Temperature | 180°C – 220°C | 250°C – 265°C | ~ 180°C |

| Melting Point | 215°C – 220°C | 250°C – 265°C | 175°C – 180°C |

| Chemical Acid Resistance | Moderate | Superior | Excellent |

| Rigidity | Moderate | Superior | Flexible |

| Color-fastness | Superior | Moderate | High |

| Temperature Resistance | High | Superior | Moderate |

| Ability to Clean | Moderate | Superior | Excellent |

| Elastic Modulus | Superior | Moderate | High |

| Internal Structure | Less Compact | More Compact | Less Compact |

| Polymerization Formation | Open Ring (Caprolactam) | Condensation (Hexamethylenediamine + Adipic Acid) | Condensation (Laurolactam) |

| Moisture Regain | 4% – 4.5% | 4% – 4.5% | ~ 0.4% |

| Monomer Requirements | 1 (Caprolactam) | 2 (Hexamethylenediamine + Adipic Acid) | 1 (Laurolactam) |

| Density | 1.2 g/ml | 1.15 g/ml | 1.01 g/ml |

| Degree of Polymerization | ~200 | 60 – 80 | ~100 |

Nylons and UV Resistance

Nylons are also very sensitive to ultraviolet (UV) radiation. Suspending them exposes their structure’s capacity to degrade with time. The use of stabilizers in nylon formulations increases their ability to withstand UV degradation. Particularly, nylon 6/6 is vulnerable to such rays while nylon 6 has potential degradation threats if it is not reinforced with appropriate additives.

UV light excites some electrons in the chemical bonds which form nylon polymers. This interaction targets pi electrons and breaks the double bond and aromatic systems, offered by Bowe’s tutelage. For instance, nylon 6 is known to have good UV resistance at its amide bond and thus is likely to degrade. For instance, polyethylene polymers that do not have pi electrons are more resistant to UV radiation than the other polymers.

All material gets degraded due to UV exposure not just the nylon material. Nevertheless, when stabilizers are incorporated, nylon can do fairly well in applications that are characterized by outdoor use. For instance, the mini snap rivets manufactured from nylon 6/6 are suitable for use in outdoor conditions. These rivets are UL94 V-2 flame-rated for fire retardance and functionality in diverse settings.

To optimize the performance of nylon products they are subjected to UV stabilizers since they are usually exposed to sunlight. These additives assist in either absorbing or reflecting ultraviolet rays which are detrimental to nylon parts, thus increasing the service life of nylon parts. The choice of these stabilizers is therefore made in a way that will provide the best performance and at the same time not affect the mechanical properties.

To sum it up, nylon is inherently sensitive to UV action but improvements with stabilizers are possible. The knowledge about the effect of UV light on nylon can help avoid choosing the wrong material for applications that will be exposed to the outdoor environment. Sometimes, to increase the streigth, we will add some glass fiber in nylon material to fix together to make some nylon molded parts, those part which we call glass filled nylon injection molding parts.

Performance Analysis of Nylon 6, Nylon 66, and Nylon 12

Nylon 6 has a very high level of damp strength. It has a high impact strength and flex fatigue. Nylon 6 needs lower processing temperatures compared to Nylon 66. Furthermore, its amorphous nature also means that its molds have less shrinkage than their crystalline counterparts. However, it is also possible to obtain fully transparent grades of Nylon 6 for particular uses. However, this nylon swells and absorbs moisture at higher rates making it dimensionally unstable. Some of these challenges may be overcome by alloying the polymer with low-density polyethylene. Some of the uses of Nylon 6 are for instance for stadium seats and hosiery. Other uses include radiator grills and industrial yarn. In addition, toothbrush fibers and machine guards are also produced using Nylon 6.

Of all the types of nylon, Nylon 66 is reputed to be the most commonly used. It possesses high strength in a range of temperatures. This type demonstrates high abrasion resistance and low permeability. This material is resistant to mineral oils and refrigerants to a great extent. Chemical resistance to saturated calcium chloride is also an advantage. Further, it also presents good weathering characteristics in this nylon. Most often, Nylon 66 competes with metals in die-cast tool bodies and frames. This nylon is okay to be used in wet conditions as well. But, the impact strength is low and so is the ductility. Some of the uses are friction bearings, tire cords, and automotive airbags.

Nylon 12 has different advantages compared to other materials. It shows good chemical resistance in this application, therefore improving the lifetime of the material. The moisture absorption rates are also comparatively low, which makes it dimensionally stable. Nylon 12 is used in 3D printing and auto parts. Moreover, this nylon is used in flexible tubing and medical components. For these reasons, Nylon 12 has become a versatile material for use in many industries. However, Nylon 12 has different advantages over Nylon 6 and Nylon 66 depending on the required application.

Application Comparison of Nylon 6, Nylon 66, and Nylon 12

This paper focuses on the application of two types of nylons, Nylon 6 and Nylon 66. The characteristics of these nylons make a great impact on their applications in several industries.

Nylon 6 has a lower melting point and good processing ability. This makes it suitable for manufacturing lightweight textiles and other industrial parts. Nylon 6 manufactured through nylon injection molding is widely used. This material is suitable for molding different parts such as interior trims of automobiles, appliance parts, and sports items.

To this, Nylon 6 has the advantage of being elastic as well as having a wear resistance ability. These characteristics make it suitable for textiles such as socks and sportswear.

On the other hand, Nylon 66 is appreciated for its higher melting point as well as improved mechanical properties. This makes it more suitable for use in systems where intense temperature and mechanical properties are needed.

In nylon injection molding processes, the Nylon 66 is preferred for making wear-resistant products. Some of the applications are engineering plastics, automotive engine components, and electronic gadgets.

Further, the high-temperature stability of Nylon 66 makes it suitable for application in automobiles and aerospace industries. This implies that its strength under such conditions makes it even more valuable in applications to meet high standards.

Nylon 12 supplements these materials with the following characteristics. A well-known chemical resistant, nylon 12 has applications in autonomous uses such as in fuel tanks, medical applications, etc. Another advantage is that it can remain dimensionally stable in different climates, which will be helpful in different fields.

Hence, every type of nylon has unique benefits that adapt to cater various needs of the market. The type of nylon to be used depends on the application intended and the conditions in which the material will be used.

Other Common Nylon Grades

Different grades of nylon are produced and each of them is used for a particular purpose. Nylon 610 and Nylon 612 have very low moisture absorption and are thus used for electrical insulation. They have more beneficial characteristics, but they have greater expense compared to conventional materials. Characterized by low moisture absorption, Nylon 610 has a relatively low glass transition temperature for sensitive applications.

However, due to its flexible characteristics, Nylon 612 is gradually replacing Nylon 610. This shift is mainly driven by the fact that the price of Nylon 612 is lower compared to Nylon 6 and Nylon 66. Superior heat resistance increases its demand, and it is widely used in most industries.

For their properties, Nylon 612 is usually known to be slightly inferior to Nylon 6 and Nylon 66. It shows the improved ability to resist creep in humid environments, which increases its applicability.

The two types of nylon are Nylon 11 and Nylon 12 and the latter has the lowest moisture absorption rate among all unfilled nylon types. These nylons show improved dimensional stability and also exhibit higher impact and flexural strength than Nylon 6, 66, 610, and 612. However, they are expensive, weaker, and have a lower maximum service temperature as compared to their cold-worked counterparts.

In general, Nylon 11 and Nylon 12 have some benefits over other members of the nylon family, especially because they have outstanding performance in weathering. However, they are threatened by new highly resistant super-tough nylons developed for better performance.

Another is Nylon 1212 which is superior to Nylon 6 and Nylon 66 and more economical than Nylon 11 or Nylon 12. It is used in many fields due to its balanced performance and its reasonable prices.

At high temperatures, Nylon 46 possesses high impact strength as well as moderate levels of creep rates. Moreover, it has a higher modulus and better fatigue strength than the Nylon 66 material as well. However, it has a smaller processing window than those found in Nylon 6T and Nylon 11, which may affect its usability in some processing environments.

Therefore, these nylon grades have unique characteristics that qualify them for various uses in the industry. The analysis of each material shows that strengths, weaknesses, opportunities, and threats are the results of the formulation and application of the material.

Conclusion

The use of Nylon 6, Nylon 66, and Nylon 12 depends on the specific application that one needs. It has good flexibility and shock resistance and therefore is suitable for making light-duty components. Nylon 66 has more strength and heat stability, and Nylon 6 works well in stress applications. Nylon 12 is currently used in outdoor applications due to its low moisture absorption and excellent weathering resistance, but it is slightly expensive.

Understanding the properties of each nylon grade will help you select the right material that will provide the performance you need as well as the cost you want. This results in longer-lasting and better efficient outcomes in the application.

PA6 GF30 VS PA6.6-GF30: What’s the difference?

PA6 GF30 VS PA6.6-GF30: What’s the difference?