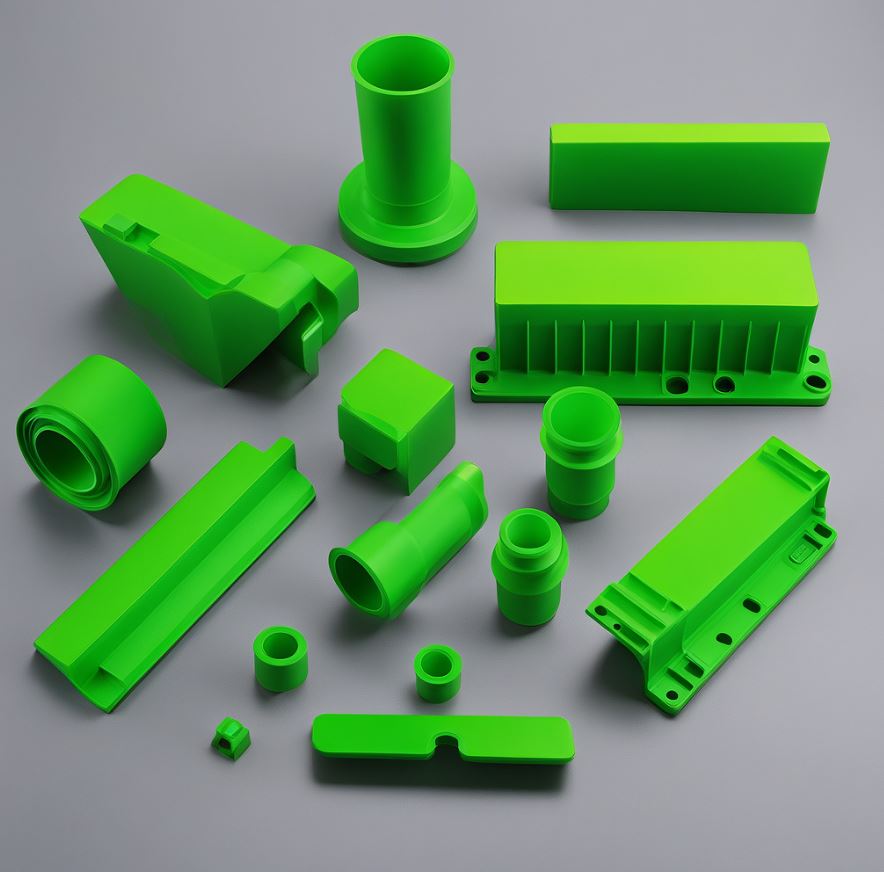

Soft Mold Low Volume Plastic injection molding

In line with the history of the branch, since 1999, completely different companies have been providing innovative soft mold low volume quantity injection moulding solutions to numerous high profile organizations throughout a variety of industries throughout all of the continents. Undoubtedly the addition of low volume injection moulding capabilities to the portfolio makes these establishments a complete one-stop store for quick product growth; providing options from next day concept models all through to soft mold low quantity plastic injection moulded components in actual engineering plastics.

In the first place, let’s discuss injection moulding process. Predominantly, in accordance with the floor end in addition to quantity necessities we select essentially the most applicable in addition to cheap material to produce the plastic mould from, which is mostly aluminium or pre-hardened steel which we call soft mold. Therefore, mould design is created to satisfy the exact benchmarks of your project.

In addition, conventional machining utilizing the newest Excessive Velocity Milling (HSM) and CNC spark erosion techniques. It means that the mould tool is polished in addition to might be textured utilizing acid etching to create the desired surface finish. Moreover, detailed CMM inspections are carried out to guarantee that mouldigs are inside tolerance and of high quality. Last but not least, there’s submit processing of elements; including assembly, printing, portray in addition to chrome plating. All that is full mission managed by the companies.

You ought to perceive that there exist some advantages of low volume y injection molding. For instance, it requires low investment prices; short lead-times (from three weeks); needs as much as 10, 000 parts from a single mould soft steel; and components are available actual engineering plastics. Let us discuss them in more detail.

Perhaps allow us to start with the astonishing determine of as much as 10,000 parts from a single mould tool. Don’t forget that the mold will be designed to lessen costs whereas fulfilling your element’s visual, technical and amount needs. What’s extra, we guarantee that instruments are manufactured as cost effectively as possible, for instance, by designing a manual or automatic device depending on the quantity required.

We proceed to components are made in actual engineering plastics. This means your elements could be moulded in most engineering plastics, which enables the manufacture of parts which are suitable for most production environments.

You know that low funding prices in a mold instrument is a great advantage. By making a soft mold from aluminium, machining time and prices are low and the mold cavity of an aluminum tool may be polished quickly and cost effectively. What you will like concerning the offer is brief lead-times. Your mission can go from CAD & UG design to moulded parts in as little as 3 weeks. And you’ll reveal that there may be moreover environment friendly moulding of small batches. As there may be often no minimum order quantity, your low volume initiatives are all the time produced very cost effectively.

And to prime it, an experienced staff always provide a custom-fit resolution, including over moulding to produce components containing a couple of material, for example a PC-ABS handle over molded with a TPE. Besides, over molding of electrical connections, inserts and steel plates with an engineering plastic can also be attainable.

General, soft mold low volume injection moulding is the ideal answer for low quantity manufacturing, bridging resolution in addition to pre-launch testing, we can offer you the low volume injection mold cost as low as $500, and this will be the best idea for you to open you market. if you have large quality parts, you could go to our high volume injection molding to know more.

Contact us to get a quote.