What is inert molding

Insert molding is an overmolding manufacturing technology to produce pre-formed plastic parts; sometimes we call it metal insert molding or overmolding, which means insert molding is a type of overmolding (the substrate for overmolding is inserts instead of plastic parts). Before molding, the insert is inserted into an injection overmold, creating a single final product that combines a single molding part with inserts. The insert, which can be made of metals, ceramics, copper screws, or other plastic or metal materials, is inserted in a mold cavity before being injected with plastic resin.

If the inserts are constructed of plastic or molded plastic pieces, we call this over molding, whereas the first shot of the plastic insert part is referred to as substrate. If the inserts consist of metal, we will refer to the process as metal insert molding.

Many industries on the global market, including electronics, automotive, furniture, and many more, use insert molding extensively to reduce assembly costs for parts that require extreme strength, durability, and precision. Insert moulding can produce complex plastic products with different insert materials or components in a single molding process, eliminating the need for separate assembly steps and lowering production costs. In addition, insert molding can increase part quality and reliability by forming a strong link between the insert and the plastic resin. We call this metal brass insert molding or screw insert molding when we insert metal screws and plastics into a molded part, or when we mold different brass screws or materials into a single molding part.

Custom insert molding not only lowers assembly and labor costs, but it also outperforms assembly parts by reducing the size and weight of the part, enhancing component reliability, and delivering improved part strength and structure with enhanced design flexibility.

Today, over 90% of insert molding parts come from Chinese mold manufacturing companies, where low labor costs and high-quality control are significant factors. China has the capability to assemble all of your final parts and then ship them to you.

We have been professionals in plastic mold making and manufacturing for over 18 years, with a strong engineering team, a mold maker team, and a quality control production team.

We can handle your project from start to finish, regardless of whether it involves normal molding, 2K injection molding, custom insert molding, medical plastic molding, metal insert molding, automobile industrial, cosmetic injection molding parts, home appliances injection molding, final product assebmly service, and more.

The Process of insert molding

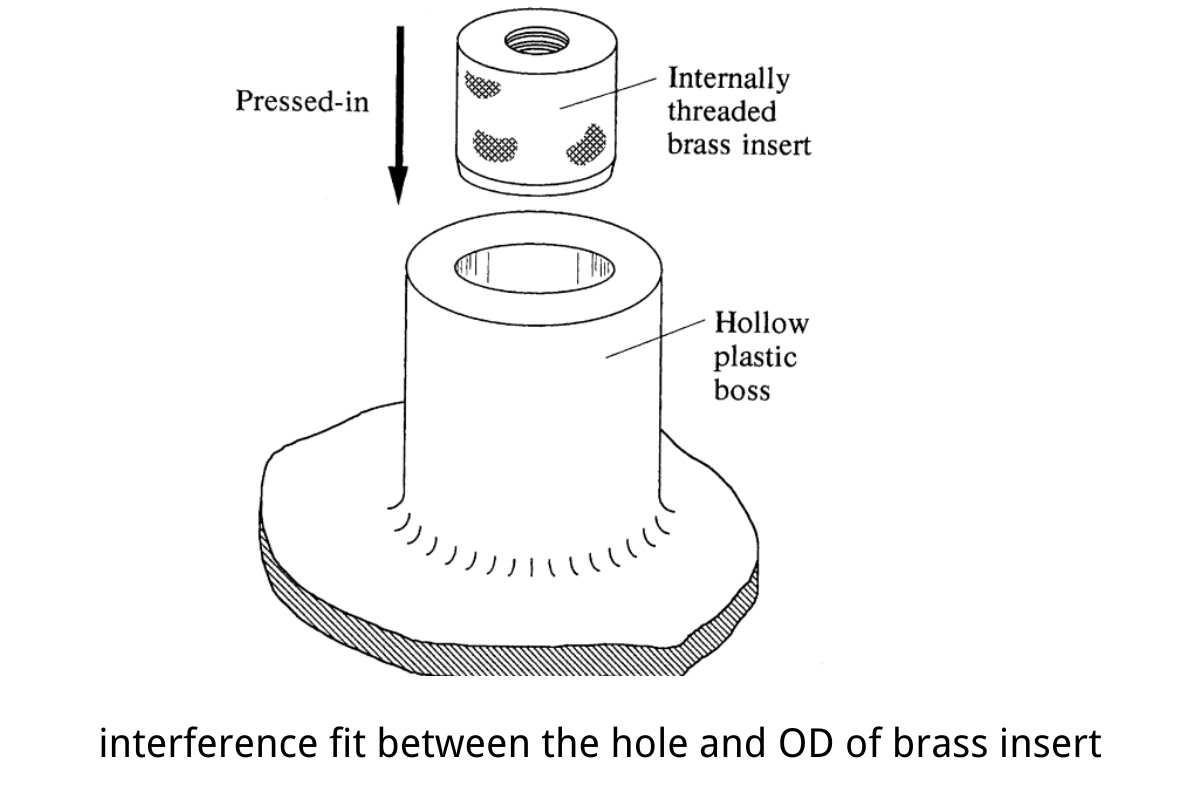

The insert molding process starts off by either inserting the metal inserts before the injection molding process (normally used technology) or they can be inserted after the injection molding process (pressed in). An insert molding process operator or a robotic arm will load the inserts into the mold if you choose to insert them before the plastic injection molding process.

If it is chosen to insert the metal inserts after the plastic injection molding process, some pressing tools may be needed after the plastic injection molding process is complete and the part is cooled. Then, press the thread inserts into the hole or hollow boss. There are two types of pressed-in insert molding: cold pressed in and hot pressed in.

Simply put, cold pressed in insert molding presses a cold metal screw or other insert into the hole position, while hot pressed in insert molding inserts a hot metal insert into the hole position and cools the metal part. Both types of insert molding necessitate an interference fit between the diameter of the hole and the metal insert.

Typically, insert molding integrates the insert into the mold prior to the injection molding process, which is its primary benefit. Everything we discuss below pertains to this process, which we can refer to as insert injection molding or overmolding.

This procedure ideally reduces insertion costs, which can save our customers substantial costs on insert molding projects. If you want to know more about insert injection molding, you can go to the insert injection molding page for more information.

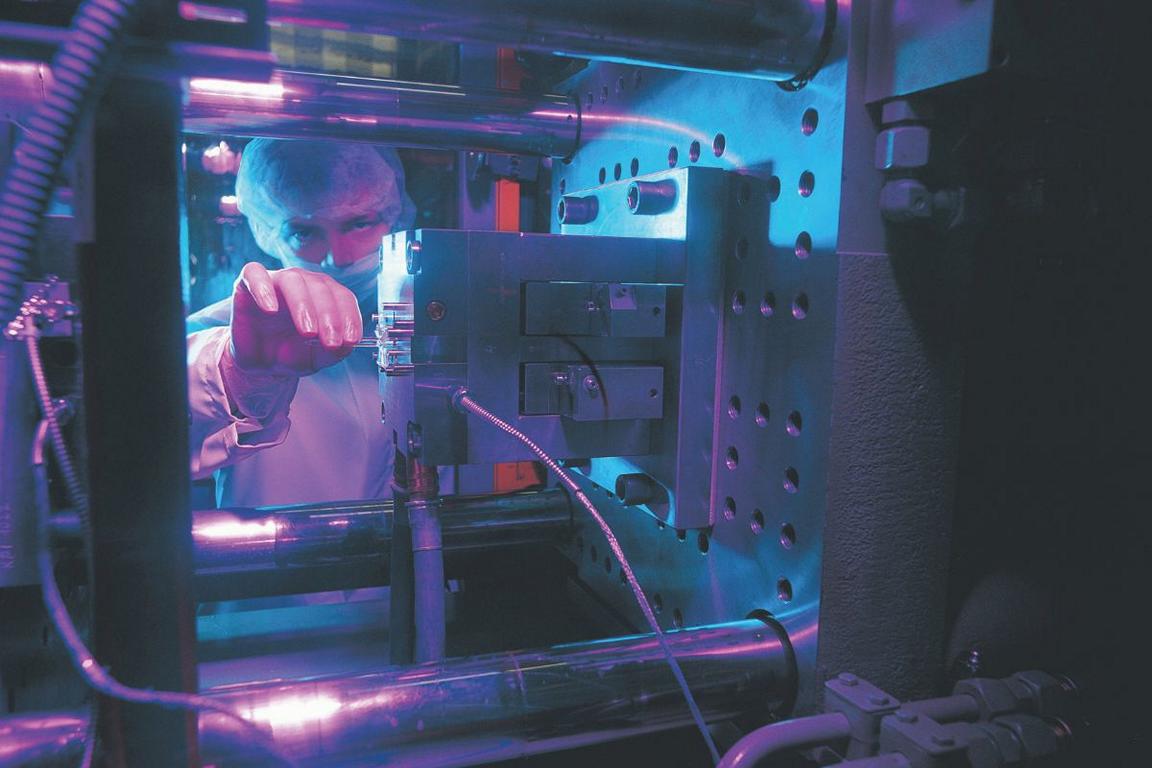

In the context of the insert molding process, the use of a robotic arm for part handling can yield significant benefits. When it comes to removing the molded parts and getting them ready for more processes, a multiple-axis robot can do that faster and more accurately than a human. After the molded part is created and ejected from the mold, the robot grips the part and moves it to either a location to be held or onto a system to be inspected. The general layout of the manufacturing equipment and the type of product under creation determine this decision.

In order to assure a high level of quality for many parts that go through insert molding, robots can have vision systems mounted on them. These vision systems inspect parts faster than humans and know exactly what the metal component’s placement accuracy is.

Several industries thrive on the products created through the insert moulding process. Indeed, this type of custom injection insert molding process produces a wide range of products.

Buying inset molding from a Chinese injection mold company will save a lot of money since the labor costs are low in China. Below is the plastic injection molding part that is created through this type of custom insert molding process. This is the brass insert molding part, which has more than 20 metal screws molded together with the PC plastic material.

Insert moulding costs.

There are some factors that affect insert moulding costs.

The price of the insert determines the first component. You can create inserts using a variety of molding materials, such as plastics like ABS, PC, or PA, and metal inserts like steel or aluminum. The material utilized, the size and complexity of the insert, and the quantity needed will all affect the cost of the inserts. Making 100 pieces of inserts, as opposed to 1000 metal inserts, will result in a significantly different price per unit.

The cost of the insert mold contributes significantly to the total cost of insert moulding. The mold plays a crucial role in the injection molding process since it defines the finished part’s shape and characteristics. This initial cost will exceed the unit cost; if you plan to manufacture thousands of parts, creating insert molds will be beneficial. If the insert is made of plastic by injection molding technology, then we may call it overmolding. This will require two molds, one for the first plastic parts and one for overmolding, which will increase the initial mold cost.

Another significant factor in insert injection molding costs is labor. Compared to standard injection molding, injection insert molding involves more labor since operators need to manually place the inserts in the mold before each shot. This will increase the cycling time and the manual cost.

Consulting with a professional injection molding manufacturer will yield an accurate estimate of insert injection molding costs. They can evaluate your specific project requirements and provide a detailed cost analysis based on 3D data and specifications, waste rate, and production volume. This will help you make an informed decision and determine if insert injection molding is the right choice for your project. You are welcome to send us your insert injection molding project, and we will quote you a price in 24 hours.

Below are some of the custom insert injection molding parts we made before. If you have any project that needs brass insert molding, over molding, or any metal insert molding, send us your requirements for a quotation.

Advantages of Insert Moulding

An extremely effective substitute for conventional techniques of assembling insert pieces with adhesives, connections, welding, soldering, or fasteners is insert injection molding. There are numerous advantages to this cutting-edge method that can greatly improve the effectiveness and caliber of your molded components. Below are some advantages of injection insert molding over traditional injection molding.

Reducing the final molding parts

The smaller molding pieces produced by insert molding are among its main benefits. Compared to conventional assembly techniques, insert molding creates smaller pieces by molding metal inserts with plastic during the molding process. This shrinkage enhances the overall performance of the molding process in addition to saving material costs. Additionally, a significant reduction in the parts’ weight enhances both performance and cost-effectiveness.

Decreased labor and assembly expenses

Insert molding not only reduces size but also significantly lowers labor and assembly costs. In contrast to labor-intensive, multi-step traditional assembly methods, insert injection molding integrates two or more elements into a single molding part in a single shot. This efficient method significantly reduces labor and assembly costs. Complex assembly procedures are not necessary because all that is required of a worker during the molding production process is to simply place the metal item into the mold. Moreover, a single shot is perfect for intricate insert molding parts since it may shape one or several inserts.

Enhanced Trustworthiness

The enhanced dependability that insert molding provides is yet another noteworthy benefit. The insert molding process ensures a strong and long-lasting bond by tightly molding each component in thermoplastic. This prevents common assembly process issues like part loosening, mismatch, and misalignment, among others. The use of plastic resin in the molding process further increases the parts’ resistance to stress and vibration, thereby enhancing their dependability and durability.

Enhanced Flexibility in Design

Insert molding makes it easy for designers to think about how those parts should be assembled together. By eliminating the need to think about how to assemble pieces or attach metal and plastic components together, designers can save time and focus on other aspects of the design. This insert molding process simplifies the solution to numerous design problems.

Lower injection molding expenses and enhanced productivity

Insert molding helps improve efficiency and lowers overall injection molding costs. Operators may find it difficult to set inserts during the molding step, particularly if they are working with small or many metal pieces that are prone to falling. On the other hand, using vertical injection machines greatly increases productivity, saves time, and lowers the possibility of dropped or misplaced inserts. This helps reduce the cost of injection molding while also improving the molding process’s overall efficiency.

If you have an insert moulding project in hand, contact us to get a price. We have been in this field for over 18 years, making custom insert molding. We are experts at providing insert molding services that are tailored to each individual client’s needs.

Since every project is different, Sincere Tech is one of the top 10 mold manufacturers in China and provides a variety of custom insert molding options to meet the specific requirements of each of our clients. To guarantee that we offer the highest quality insert mold and any other custom injection mold, we have skilled mold makers that operate with cutting-edge machinery.

Our insert molding services are excellent and reasonably priced. In order to maintain cheap prices while producing high-quality insert molding goods, we employ cutting-edge technology. This enables us to offer low pricing to our clients without sacrificing quality.