Today, manufacturers are at the forefront of innovation, and they use plastic to make it compatible with metals or other materials to produce a wide range of products. Among the main technologies that are driving this progress is insert injection molding, a common technique in plastic injection molding.

This way, manufacturers can combine engineering plastics with inserts made of different materials, which results in products that are wear-resistant, lightweight, and have high tensile strength. The article focuses on comprehensive details on insert injection molding and discusses its pros and cons. Furthermore, we will be looking into the applications of insert injection molding parts and giving you valuable tips and insights on how to achieve success in insert injection molding.

Insert Injection Molding: An Overview

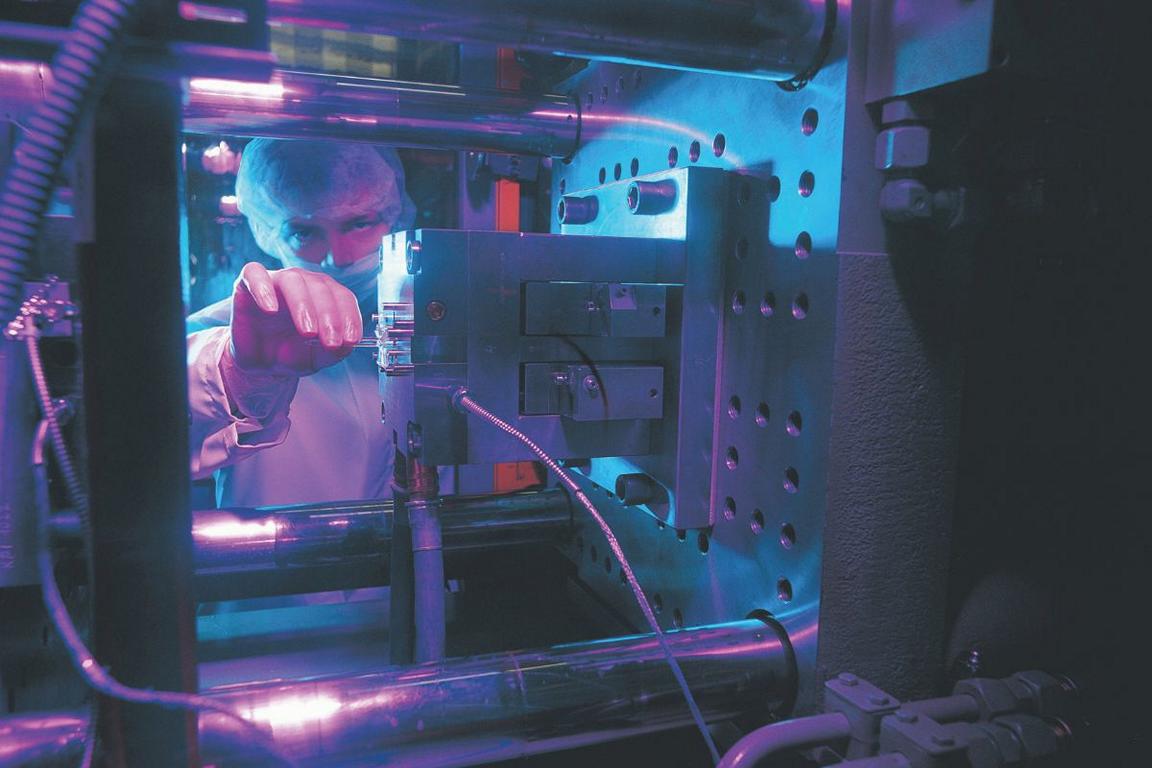

Insert injection molding, also known as insert molding, is a specific type of plastic injection molding process that involves the incorporation or combination of metal inserts with an injection-molded part. The process is about inserting the mold into the cavity and then injecting molten plastic under high pressure around it. Afterwards, as the plastic and inserts cool together in the mold cavity, they combine to form a robust and cohesive part.

By adding metal components, this method produces plastic products that are strong, durable, and lightweight. Many industries widely use metal insert molding, a multi-functional and efficient technique, due to its compatibility and effectiveness in producing high-quality parts.

The Workflow of Insert Injection Molding

Insert molding injection is a conventional molding process for fabricating various end-use products, which involves melting and injecting molten plastic into a mold or die cavity under controlled conditions. Adding injection mold threaded inserts to the mold sets it apart from other traditional injection molding techniques. The below-mentioned steps are involved in the insert injection molding process.

Step 1: Insert loading into mold

The design engineers meticulously design molds for insert injection molding, ensuring that the injection mold inserts are precisely positioned within the mold cavity. Correct mold orientation and placement are of the utmost importance during the molding phase. This technique ensures the inserts remain firmly in place, maintaining their desired orientation and position in the molded part.

There are two primary methods of inserting components into a mold:

- Automated Insertion:

Automated insertion involves the use of robotics and automated systems to insert components into a mold. This method has advantages such as consistent insert placement, increased efficiency, and high precision. Automated machines can deal with high-temperature environments, which ensures a quick production turnaround with the ability to produce more parts per hour. However, the initial investment required for automated systems is higher, leading to a higher production cost.

- Manual Insertion:

Manual insertion is the process of putting components into a mold with the hands. This method is suitable for low-volume production situations. It is more suitable for jobs that require detailed part inspection and for operations that are not costly, like packaging and assembly. Nevertheless, manual insertion does not have the precision and repeatability of automated systems. The operators can also have dexterity issues due to the high temperatures involved, which may require the use of gloves.

Step 2: Push the molten plastic into the mold.

The injection unit injects an engineered-grade plastic resin into a die cavity during the second step of the insert injection molding process. High pressure drives the injection, pushing the plastic to fill every part of the mold. This pressure leads to the ventilation of air through the molds, which in turn certifies that the plastic sticks to the inserts completely. Maintaining the optimal injection temperature, pressure, and temperature within acceptable ranges is of paramount importance for uniform filling and defect-free end-use molded parts.

Step 3: Take off the mold and get the molded part.

The mold then cools down and opens up. An ejector system meticulously removes the final molded part from the mold after cooling and solidifying the molten plastic. Holding pressure during cooling will help prevent the shrinking effects and make sure that there is no backflow into the injection barrel. We carefully monitor the cooling time and temperature to ensure uniform solidification of the molded part, preventing warping or distortion. We then repeat these cycles to ensure continuous production.

Step 4: Remove the molded part from the runner.

Sprues and runners, the channels where the liquid plastic flows in and out of the mold cavity, link the multiple cavities of molded parts. Before implementation, we must separate the molded part from the sprue or runner. We manually perform this separation, primarily using simple tools like scissors or knives. We should closely monitor the molding step to prevent any damage or loss of the part.

If the mold utilizes the sub-gate design, we don’t need to perform this step. This design automatically divides the runner and the molded parts when the mold opens. However, not all parts can utilize the sub-gate design.

Step 5: Postprocessing Treatments

The molding and ejection of the part from the sprue may be followed by other post-processing operations to complete the insert-molded part before final use.

Some common post-processing treatments include:

Deburrs: Deburring involves the removal of excess material or burrs that may affect the appearance or performance of the molded part. Generally, people perform deburring by hand, using tools to eliminate burrs. Generally high quality mold will not have any burrs, if your mold have some burrs then you may need to fix the mold,

Heat Treatment: The molded part may undergo processes such as annealing or stress-relieving to eliminate internal stresses. Furthermore, heat treatment can enhance the strength and dimensional accuracy of the parts.

Surface Finish: There are several ways to carry out the final stage, such as printing, painting, or electroplating. The finishing processes are not only able to make parts beautiful and durable but even give them some special features, such as corrosion resistance.

Humidity control: This is the process of managing the moisture in the environment, which in turn affects the shrinkage of objects, the prevention of oxidation, and the rate of water absorption. Objects typically undergo this process by immersing in hot water baths or exposing them to steam chambers, which create a humid environment.

Pre-Insert Molding Considerations

There are many things to consider before the insert molding so that the production process proceeds smoothly and without any hitch. Just to refresh your memory, these are the areas you should concentrate on:

- Types of Inserts:

Inserts that are used in the insert molding process are one of the most important factors that can lead to the success of the process. Determine the inserts that can endure the temperature and pressure swings, which are usually an inherent part of molding.

- Insert Location:

The positioning of inserts in the molds is one of the most important things to be considered when it comes to the durability and maintenance of the molds in the future. Imagine the forces acting on the insert and make sure there’s enough plastic under and around it to keep it in place.

- Gap Width for Metal Inserts:

It is important to maintain the gap between the metal inserts and the liquid material at a safe distance to avoid its negative impact on the final products. Closing the gap between the mold and the part ensures that the part bonds together to form a reliable finished molded component.

- Resin Selection and Molding Conditions:

The selection of the right resin type and molding conditions is crucial, since through this we can mold complex parts (electronic components, glass). The resin must be strong enough to seal the inserts well and fix them properly.

- Mold Design:

The mold not only shapes the material but also keeps the inserts immobile during the molding process. Use manufactured inserts in your molds to maintain their firmness throughout the production stage.

- Cost Considerations:

The total price should cover the insert costs, the operator’s expenses (for manual insertion), and the price rise that may occur because of the inclusion of inserts. Add a cost-benefit analysis to your decision-making process and make it fact-based.

- Production Volume:

Pick between a manual or automatic loading option based on the production volume. Analyze the production requirements and evaluate the merits and demerits of all loading methods to achieve the highest possible levels of efficiency and cost-effectiveness.

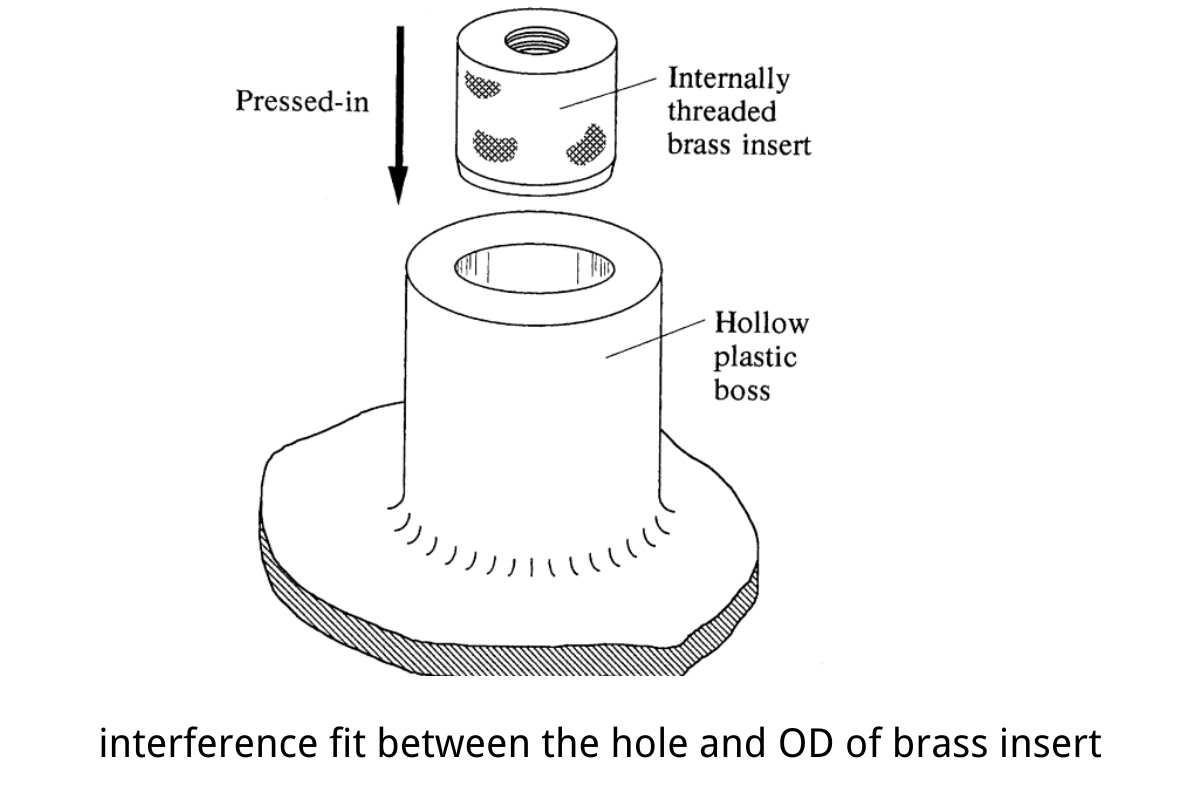

injection molding threaded inserts

Considerations During Insert Injection Molding

Precision in the insert injection molding process is the key point that ensures the highest quality performance. These are the essential points you should keep in mind.

- Mold Design:

The design of the mold plays a crucial role in safeguarding the insert from damage, often caused by high temperatures and pressure. The degree of security and stability the mold requires for successful completion will be the critical factor that determines its design.

- Secure Insert Placement:

Insert placement and stability are critical points that significantly contribute to the successful operation of inserts in the molding process. The smallest shake or move will give us a flawed final product. Find out different ways to achieve the perfect hold of inserts during molding.

- Undercut Features:

The injection molding inserts not only add aesthetic value to the parts but also improve their structural integrity and strength. It binds, which enables the components to remain cohesive.

- Partner Selection:

It would be wise to choose a reliable and experienced partner for insert molding. Working together with corporations gives you the opportunity to leverage the latest innovations and skills in component assembly, enabling you to produce integrated parts of superior quality.

Benefits & Limitations of Insert Injection Molding

Injection molding inserts are a popular choice in manufacturing processes due to their numerous advantages.

Cost-Efficiency: By eliminating the post-molding assembly, insert injection molding reduce assembly and labor costs, resulting in overall cost savings.

Weight Reduction: Inserts are a way to reduce the mass and volume of molded products so they are more portable and easier to handle.

Design Flexibility: Inserts are a design device that designers use to make their products stand out from the crowd by making them more complex and unique.

Enhanced Parts’ Strength: The integration of metal inserts into the molding process gives the molded parts mechanical properties that are stronger than the regular ones, thereby increasing their durability and performance.

Despite these advantages, injection molding inserts also come with certain drawbacks.

Complexity and Cost: The design of insert molds is much more intricate and costly compared to the regular molding processes, which require one to consider additional factors and allocate resources.

Material Compatibility: Due to differences in thermal expansion, some insert materials may not be suitable for molding, causing production issues.

Positioning Accuracy: Errors may be encountered in the molded parts if the injection molding inserts are not properly aligned in the mold, which may result in defects in the end product.

Increased Cycle Time: Inserts require careful positioning within the mold before the molding process begins, which could impact production efficiency.

Insert Injection Molding and Overmolding are compared

Insert injection molding and overmolding are the two distinct injection molding processes that produce molded parts with unique features. Despite sharing similar goals, they differ significantly in their methods of achieving these goals and in the final product they produce.

Overmolding

The insert injection molding process is a unique method that shapes the plastic material around the pre-formed insert in the mold. The plastic material adheres tightly to the insert, forming a single integral part, to achieve this. Insert molding is a one-shot injection molding technique that has the advantages of speed and cost-effectiveness, as well as the economical use of materials.

Primarily, overmolding is a two-shot molding process, which means molding a rubber-like plastic over a plastic substrate. The complexity and cost of this dual injection molding process are higher compared to the single injection molding process, primarily due to the additional layer of material and the additional mold cost.

The main objective of the insert injection molding process is to strengthen the molded parts by adding inserts in the initial design phase. The former adds comfort, beauty, and protective layers to a product, enhancing its functionality and appearance, setting it apart from the latter.

Therefore, the primary goal of insert molding is to improve strength and material efficiency, whereas overmolding focuses more on functional versatility and aesthetics, making each technique suitable for specific applications and design requirements.

In summary, insert injection molding requires only one mold cost (the overmold), whereas the overmolding process requires two mold investments: the substrate mold, which is the first mold, and the overmold, which is the second mold.

Insert injection molding applications in many different industries.

Molding nowadays is a widely demanded manufacturing process due to its diversity and efficiency. Let’s discuss the primary industries that utilize insert injection molding, along with the specific applications within each industry.

Aerospace Industry:

In the aerospace industry, the most popular technique for producing critical parts like aircraft seats, stowage bin latches, lavatories, handles, and user interface switches is injection molding. These aspects should be a mixture of strong, durable, and lightweight designs. All of these attributes can be addressed through injection molding. With the insert molding, the space industry gets lightweight aircraft, high-strength components, shorter manufacturing and assembly times, and design improvement.

Automotive Sector:

In the auto industry, the process of insert injection molding replaces metal parts with more durable plastic ones.

This transformation results in the manufacture of lightweight auto parts, which in turn improves fuel economy and reduces assembly costs. The automotive industry commonly uses insert molding as a manufacturing process to produce interior panels, knobs, handles, electronic connectors, and structural parts. Furthermore, the insert molding technique provides both flexibility and reliability, which allows automotive manufacturers to innovate and come up with new designs and functionalities.

Medical Device Manufacturing:

The medical device manufacturing industry widely uses molding inserts, which demand the highest levels of precision, biocompatibility, and reliability. Insert injection molding techniques enable the production of a wide range of medical devices, from simple tools to sophisticated implants and surgical instruments. Examples of these applications include tubes, components of medical equipment, dental instruments, prosthetics, surgical blades, and enclosures for medical devices. The insert molding process guarantees the smooth transition of different materials and meets the high quality and safety standards of the medical industry.

Consumer Electronics Industry:

In the consumer electronics industry, the insert injection molding technique has revolutionized assembly processes by eliminating the need for fasteners and soldering. The insert molding industry encompasses a wide range of applications, including encapsulating threaded inserts, wire plugs, and producing digital control panels, assemblies, and knobs for appliances. Besides, insert molding has a wide range of applications in military equipment, threaded fasteners, and various electronic components used in consumer electronics.

Defense Sector:

In the defense industry, insert injection molding is a key enabling technology for the manufacture of military-grade equipment that is cost-effective, efficient, and lightweight. Handheld communication devices, weaponry components, battery packs, munitions, and housing for optical instruments like binoculars and monoculars all use this technology. Injection molding insert has the advantage of creating parts with robust and reliable structures, which have intricate designs and functionalities and meet the high standards required for defense applications.

These industries utilize insert injection moulding as the preferred manufacturing method for a wide range of applications due to its ability to unite different materials, increase product durability, reduce manufacturing costs, and improve overall product performance.

FAQ’s

Q1. What is the purpose of inserts in injection molding?

Inserts are the key elements of the molded plastic products that increase their strength and durability; moreover, they are made of metal.

Q2. Can large parts be manufactured using insert injection molding?

Insert molding is the best choice for the production of small and medium-sized parts. Dealing with bigger parts presents challenges such as higher tooling costs and complexity in insert placement.

Q3. Which inserts are commonly used in insert injection molding?

Manufacturers typically use the inserts to enhance the strength and performance of molded parts. Manufacturers construct these inserts from metal components like studs and screws, electronic components like connectors, terminals, switches, and buttons, and plastic parts.

Summing Up:

Insert injection molding, a manufacturing process that blends plastic with non-plastic materials, has gained popularity in industries such as aerospace, defense, automotive, and medical equipment due to its numerous benefits. These include cost-saving, improved part reliability, and better design flexibility.