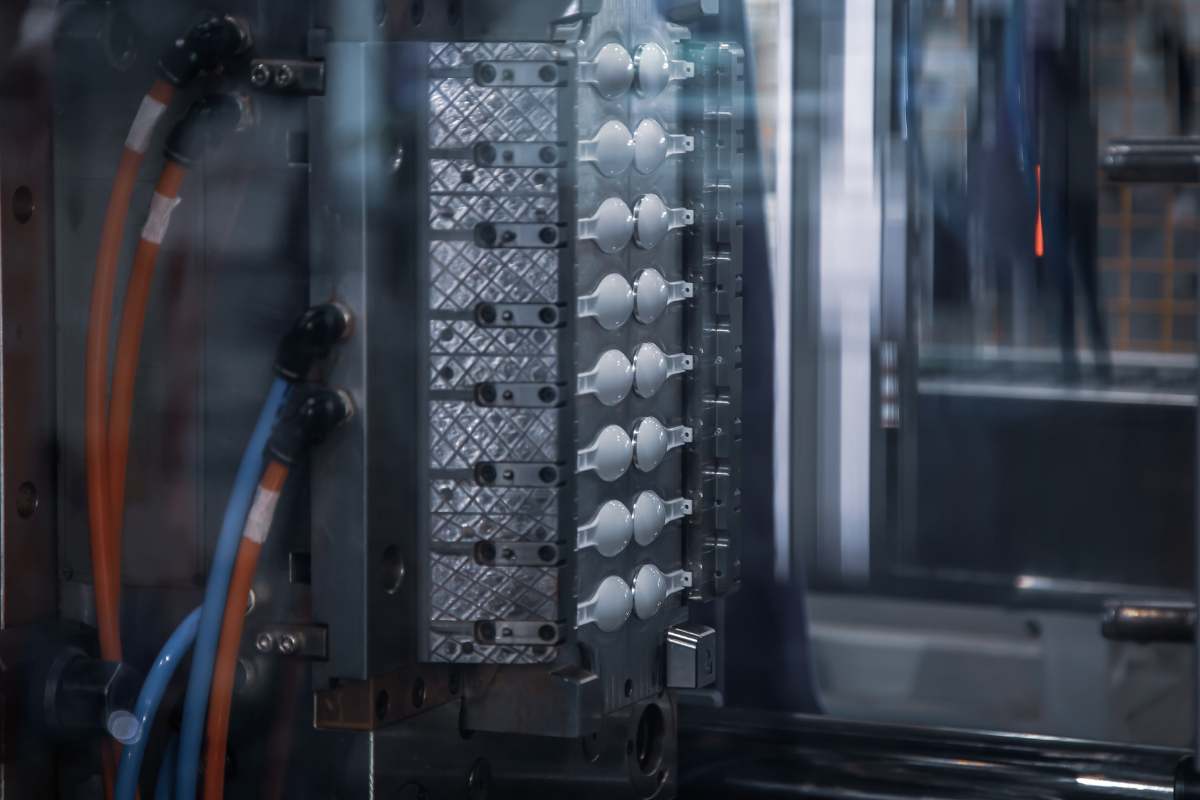

When a new injection mold manufacturing is completely finished, the next step is mold trial (testing), to trial the mold we need to check some important information to avoid any mistake, we need to check the plastic material, samples color, quantity samples that we should send to customer, any special tolerance if needs to be verified during the mold trial, etc, below is our mold trial procedures & processes,

- Set barrel temperature according to recommendations from the material supplier. Middle of recommended in front and lower end of recommended in back, if don’t have date sheet, reference from mold flow report. Record actual melt temp with air shot method. If the customer is to attend the trial, the material data sheet should be printed and present at the machine.

- Set mould temperature to the middle of recommended temp span, if don’t have date sheet, reference from mold flow report. Also, make sure the actual mould temp is right during production.

- Set clamping force according to Moldflow report, or max clamp of customer specified machine.

- Set cooling time according to “time to reach ejection temperature” from Moldflow report.

- Set injection pressure to max. Make sure the mold is properly cleaned before injecting.

- Set injection speed to 50% of customer’s machine if have, otherwise, 50% of our machine, set holding speed to 5-10.

- Set holding pressure to 0 at first.

- Increase the shot size gradually until parts are ~90% full. Check cavity variation. If more than 7% cavity variation, write down in page and mark as the issue needs to improve

- Increase the shot size until parts are 100% full, parts can be sink but not short. If parts have flash, burns or air traps, write down in paper comment as the issue needs to fix

- Set shot size to 97% full, should be done including an estimated holding time.

- Set holding pressure to ½ the actual injection pressure.

- Start making gate freeze analysis and use holding time from where gate freezes.

- Adjust cooling time according to below plastics material.

- Record weight of full shots.

- Increase the holding pressure until part weight stops increasing.

- Adjust cycle time to customer target. Make sure that tool can run properly at this cycle time.

- Runoff samples and mark them trial number and date, this is very important information for us to find which samples are from the previous trial time, quantity according to customer requirements if parts are ok. 1 balance shot and 2-3 runners should always be sent together with the samples.

By above mold trial processes, the injection mold should be running very well at our customer’s mold shop.

If you have any more questions, you are welcome to contact us, if you have are interested in our service, you are welcome to send us your requirement for a quotation.

| MATERIAL | |||||||

| Wall thickness | ABS | Nylon | HDPE | LDPE | PP | PS | PVC |

| 0,5 | n/a | n/a | 1,8 | n/a | 1.8 | 1 | n/a |

| 0,76 | 1,8 | 2,5 | 3,0 | 2,3 | 3,0 | 1,8 | 2,1 |

| 1,0 | 2,9 | 3,8 | 4,5 | 3,5 | 4,5 | 2,9 | 3,3 |

| 1,3 | 4,1 | 5,3 | 6,2 | 4,9 | 6,2 | 4,1 | 4,6 |

| 1,5 | 5,7 | 7,0 | 8,0 | 6,6 | 8,0 | 5,7 | 6,3 |

| 1.8 | 7,4 | 8,9 | 10,0 | 8,4 | 10,0 | 7,4 | 8,1 |

| 2,0 | 9,3 | 11,2 | 12,5 | 10,6 | 12,5 | 9,3 | 10,1 |

| 2,3 | 11,5 | 13,4 | 14,7 | 12,8 | 14,7 | 11,5 | 12,3 |

| 2,5 | 13,7 | 15,9 | 17,5 | 15,2 | 17,5 | 13,7 | 14,7 |

| 3,2 | 20,5 | 23,4 | 25,5 | 22,5 | 25,5 | 20,5 | 21,7 |

| 3,8 | 28,5 | 32,0 | 34,5 | 30,9 | 34,5 | 28,5 | 30,0 |

| 4,4 | 38,5 | 42,0 | 45,0 | 40,8 | 45,0 | 38,0 | 39,8 |

| 5,1 | 49,0 | 53,9 | 57,5 | 52,4 | 57,5 | 49,0 | 51,1 |

| 5,7 | 61,0 | 66,8 | 71,0 | 65,0 | 71,0 | 61,0 | 63,5 |

| 6,3 | 75,0 | 80.8 | 85,0 | 79,0 | 85,0 | 75,0 | 77,5 |