Promotional plastic cups are perfect given that we get to design cups according to our events, businesses, or marketing needs. Custom plastic cups can be used for branding and usability issues, i.e. branding your company’s name at a party, taking orders at a restaurant, or providing a takeaway menu. But what are these highly specified products, and how much do they cost to make custom plastic cups? So, in this article, we will study the possible material, design, and concepts to consider when embarking on a custom plastic cup project.

What are Custom Plastic Cups?

Custom plastic cups are disposable beverage containers manufactured from versatile plastics. These plastics can be polypropylene or PET with a facility for imprinting company logos, messages, images, or customized design plastic cups. Besides this, these are mostly present in restaurants, occasions, and firms to enhance the company’s identity, and celebrations to customize customer experiences.

Production Process for Customized Plastic Cups

The examined and identified production process for customized plastic cups is as follows:

1. Custom Plastic cups Design or Custom LOGO design

The first is designing or painting the image you want on your cups before printing them. LOGS are logos messages or patterns generated by clients or designers. So, these have to fit into specific patterns of perception or rebranding. The design must be digital to ensure that the final product’s printing process is easily met.

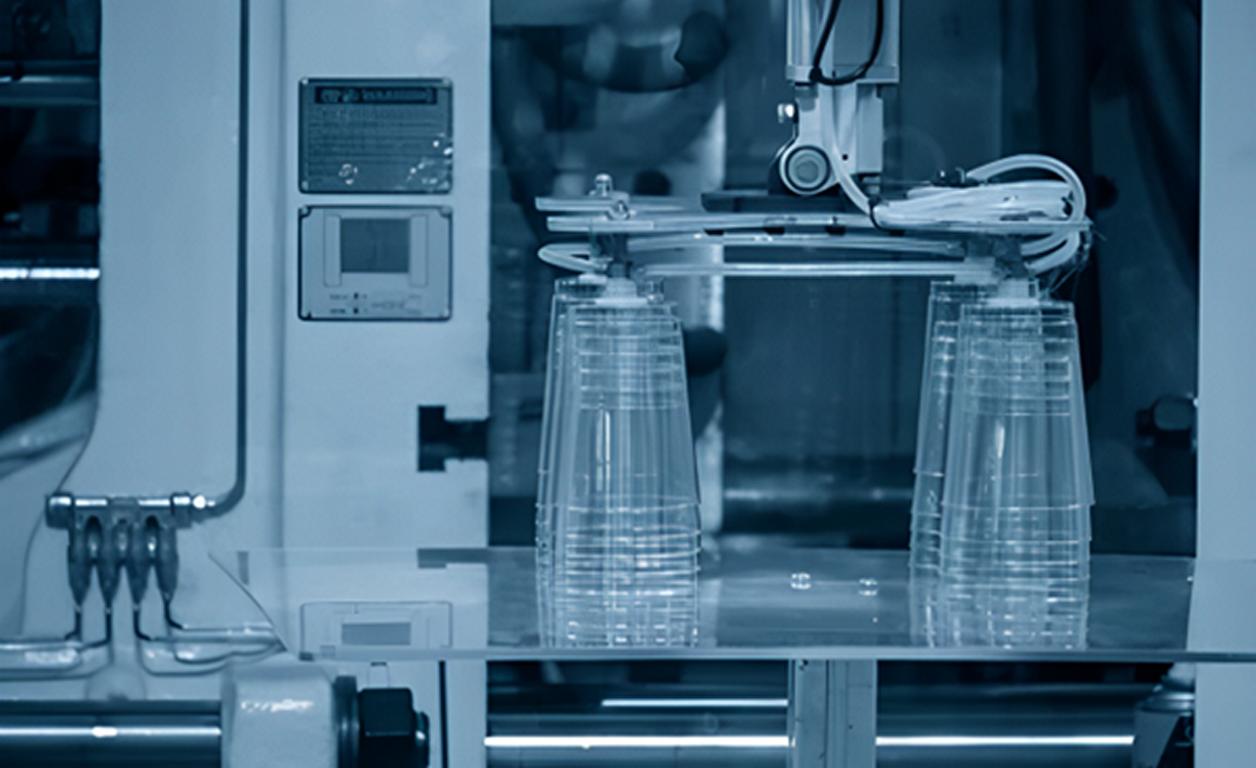

2. Plastic Cups Molding manufacturing

In this stage, the cups made of plastic are shaped using either injection molding or the forming process. Injection molding entails the injection of molten plastic into injection plastic mold while thermoforming involves heat to shape a sheet to the desired cup shape. They ensure the cups have the right size measurement, and thickness and are as durable as is required.

3. Customization

After the cups have been molded, the customization process then starts. Graphics include logos, label designs, or message printing techniques, i.e. screen printing, offset printing, or digital printing. Each method is chosen depending on the order’s size, complexity, and finishing degree which should complement the artwork on the cup.

4. Finishing

In the printing process, the cups are taken through several rigorous tests to ensure that the prints are clear, lasting, and to the client’s desire. Conditions on the cups are treated and removed before the cups are taken through the packaging process. So, the end product has the right appearance and is of the right quality.

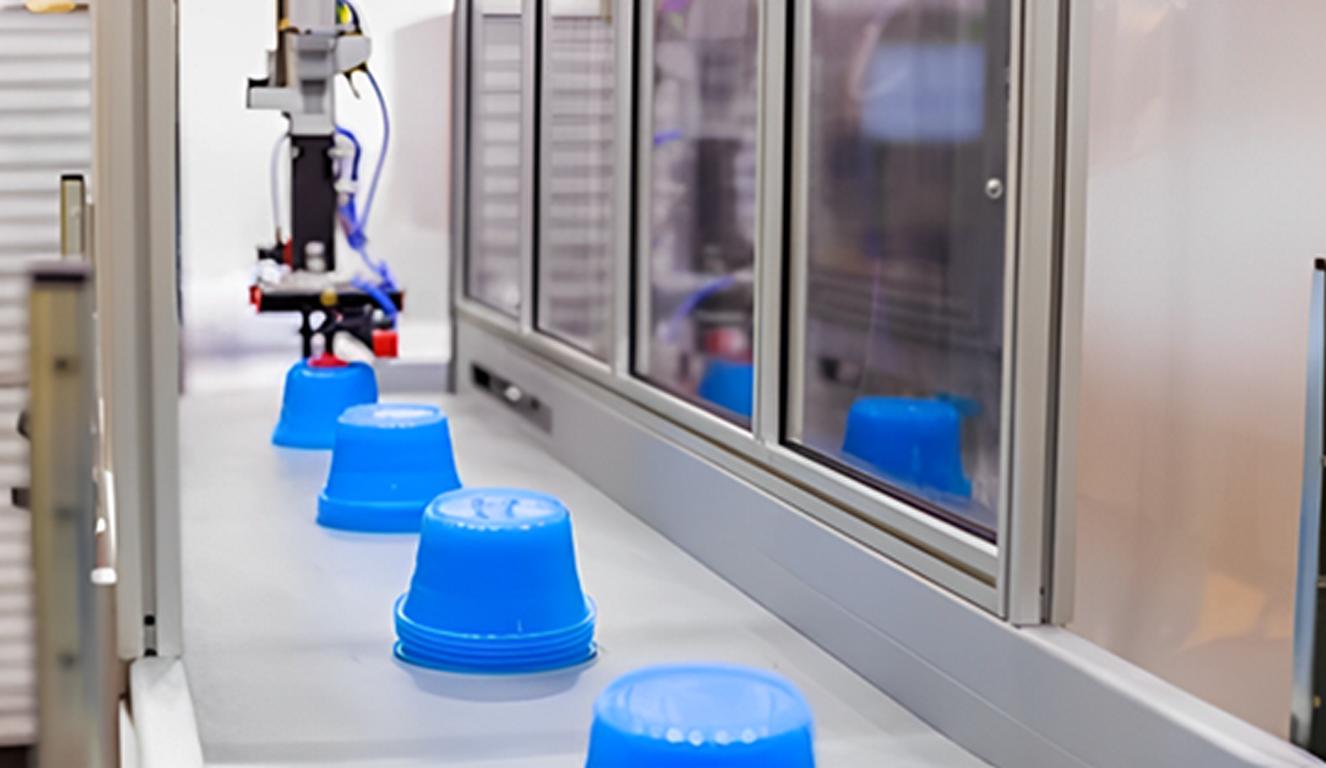

5. Packaging and Shipping

The last is organizing the cups according to the client’s order before packaging them for delivery. The cups are packed in a way that protects them when in transit and labeled with the client’s details. The cups are then packed in oral pouches and sent to the client thus achieving the manufacturing process.

Choose Suitable Materials for Your Customized Plastic Cups

Here is a detailed table to explain the materials we can use to make custom plastic cups. Besides this, it gives us an estimate of how much it costs to make custom plastic cups.

| Material | Characteristics | Benefits | Typical Applications | Cost |

| Polypropylene (PP) | Lightweight, flexible, durable, heat-resistant | Affordable, microwave-safe, recyclable | Hot drinks, food-safe applications | Low |

| Polystyrene (PS) | Rigid, brittle, clear, lightweight | Cost-effective, high clarity | Cold drinks, disposable applications | Very Low |

| Polyethylene Terephthalate (PET) | Clear, glossy finish, durable, recyclable | High transparency, strong, eco-friendly | Cold beverages, juices, reusable cups | Moderate |

| Polycarbonate (PC) | Rigid, impact-resistant, heat-resistant | Durable, long-lasting, dishwasher-safe | Reusable cups, premium designs | High |

| High-Density Polyethylene (HDPE) | Opaque, rigid, chemical-resistant | Strong, resistant to impact and chemicals | Industrial uses, large beverage cups | Moderate |

| Low-Density Polyethylene (LDPE) | Soft, flexible, lightweight | Affordable, flexible, chemical-resistant | Thin cups, disposable drinkware | Low |

| Biodegradable Plastics (PLA) | Compostable, made from renewable resources (corn, etc.) | Environmentally friendly, compostable after use | Eco-friendly cups, single-use | Moderate to High |

Types of Customization Options for Plastic Cups

So, here are some important types of customization options for custom plastic cups;

- Logo or Branding: You can also paint it with your company’s logo or design for events to increase brand awareness or use it for occasions.

- Colors: It comes in different colors and is available in transparent ones too so you can put on any color related to the brand or event of the day.

- Size and Shape: Get cups in various sizes and with designs to fit different capacities and design requirements.

- Print Area: Contemplate full-wrap designs or special logo placements to decide how much of a cup is covered.

- Special Effects: Increase cups with this metallic finishing, embossing, or UV coating to give a very appealing and strong outlook.

Printing Methods for Customized Plastic Cups

Here are some important methods we can use to make customized plastic cups;

1. Screen Printing

Among all kinds of printing, screen printing is most suitable for producing simple images in large quantities. It helps make ink through a mesh screen on the cup to make it a cost-effective and perfectly sturdy machine but restricts the range of colors that can be printed. This method yields highly striking and durable prints suitable for repeated uses. Moreover, it is for simple logos, texts, and artworks that need a high reproduction at a cheap price. So, eventually, you can get custom-printed plastic cups wholesale.

2. Digital Printing

Digital printing as the name suggests prints intricate full colors print directly on the cup. It has an advantage for small quantities and detailed designs but may be costly in large production. It does not need screens or plates, i.e. it is highly suitable for bespoke patterns. This method enables high-quality images and bright color yield.

3. Offset Printing

Offset printing involves; the ink being transferred from the plate through a rubber blanket and finally on the cup. Most suitable for engraving large quantities of massively detailed cuts. Besides this, it is economical in the long run after tooling. It may be used largely for full-wrap designs and intricate motifs. One of the best for mass production jobs especially when finesse and vivid colors must match.

4. Pad Printing

Pad printing employs a silicone pad to apply ink to small or hard-to-reach surfaces/areas. Moreover, it is best suited for fine-tuning logos and intricate designs. Especially in small tight-knit spaces capable of holding multiple color densities. This method yields ease of printing where there are curved or uneven surfaces. Although versatile, it is suitable for small and localized designs, i.e. brand logos, and fine and detailed text.

How Much Does It Cost To Make Custom Plastic Cups?

Our major concern is how much it costs to make custom plastic cups, let’s discuss the different prices. This price can vary from manufacturer to manufacturer, the materials types we use, the design of the cup, and the quantity of cups you want to make. But the following table will help you get an average estimate of the cost of custom plastic cups;

| Cost Factor | Details | Estimated Cost per Cup |

| Material | – Polypropylene (PP), Polystyrene (PS) | $0.05 – $0.15 |

| – Polyethylene Terephthalate (PET) | $0.10 – $0.25 | |

| – Biodegradable Plastics (PLA) | $0.20 – $0.50 | |

| Design Complexity | – Simple Logo/One-Color Print | $0.05 – $0.10 |

| – Full-Color/Intricate Designs | $0.15 – $0.30+ | |

| Quantity Ordered | – Small Orders (under 500 units) | $1.00 – $1.50 |

| – Large Orders (5,000+ units) | $0.20 – $0.50 | |

| Printing Methods | – Screen Printing | $0.05 – $0.15 |

| – Digital Printing | $0.20 – $0.50 | |

| – Offset Printing | $0.10 – $0.30 | |

| Special Customization | – Metallic finishes, embossing, UV coatings | +$0.10 – $0.25 |

Strategies for a Successful Customization Project

The following points will help you understand different strategies you can opt for a successful customized project of plastic cups;

- Define Your Purpose: First, you must understand your goals and audience before creating any design.

- Choose High-Quality Artwork: Don’t forget to check that the image you use as a custom logo plastic cup or in your design is in ample resolution for print.

- Select the Right Printing Method: Sync the printing style to the cost and density of the artwork to be printed.

- Plan for Quantity: Large quantities are purchased on credit to reduce the expenditure costs.

- Communicate with Manufacturers: When conveying your needs avoid making a disaster in manufacturing.

Applications of Custom Plastic Cups

Here are some applications of custom plastic cups;

- Corporate Events: Branding and promotions.

- Restaurants & Cafes: Drink dispense with containers and logos.

- Weddings & Parties: Purchasing designs made to match the occasion.

- Sporting Events: Attendees receive custom souvenir cups.

- Festivals & Concerts: Advertising gadgets or cups for a big occasion.

Advantages of Customized Plastic Cups

The following are some benefits of custom plastic cups;

- Brand Recognition: This adds to your branding as you can engage your trustworthy designer when using custom designs.

- Reusable Options: Most articles encourage reusability in many contexts thus the call to save the environment through recycled materials.

- Cost-Effective: Budget branding and marketing instrument for events or business ventures.

- Customizable: There are numerous chances of color combinations, shapes, and designs in the crafts made on leather.

- Durable: Constructed from durable materials that last through daily use.

Drawbacks of Customised Plastic Cups

Here are some limitations of custom plastic cups;

- Environmental Impact: Plastic cups that can only be used once are a problem in waste management unless their material is biodegradable.

- Cost: Complex materials or more sophisticated designs might increase prices.

- Limited Reusability: Not all plastic cups can be used many times.

- Setup Fees: Additional costs comprise charges a manufacturer masters to create a mold or preparations for a certain type of printing.

- Design Restrictions: Integrated circuits and certain materials may restrict versatility and promote designs of particular complexity.

Challenges Faced During Manufacturing Customized Plastic Cups

The following are certain challenges we can face while manufacturing custom plastic cups;

- Design Complexities: Thorough work may not adopt complex designs on the body of plastics.

- Material Shortages: One risk in manufacturing is that raw materials might be out of stock for some time.

- Environmental Concerns: Restrictions on the use of plastics:

- Cost of Specialty Materials: Greater quality or organic material cause overall cost to rise.

- Print Durability: Preserving the print when it is being washed, or ironed several more times.

Conclusion

In conclusion, How Much Does It Cost To Make Custom Plastic Cups? From the above points, it is evident that custom plastic cups are a great concept when advertising your company’s brand or spicing up an event. This means you’re not limited to the traditional cups or cups designed in a specific way. So, you can get well-designed cups with the right materials, design, and printing that meet the intended purpose in the right price range.

Nonetheless, it is possible to report several disadvantages of custom plastic cups, which are still overshadowed by the numerous advantages of using this idea. So, when planning your custom project, and effectively communicating your vision with manufacturers and suppliers, have a positive experience. It improves the look and feel of your brand or event.

Frequently Asked Questions

What is the minimum order for custom plastic cups?

The average ordering is dependent on the manufacturers, the average order required by most of the manufacturers is 500-1000 units.

Are custom plastic cups recyclable?

Absolutely Yes! the lids are recyclable if made from materials like PET or polypropylene.

How long does the production of custom plastic cups take?

This may take 2-4 weeks depending on how big and complex the order is.

Are there eco-friendly options for custom plastic cups?

Yes, PLA (biodegradable plastic) among other options provides the green option in product manufacturing.

Can I get a sample before placing a bulk order?

Many manufacturers were said to give test cups for inspection before mass production is made.

What influences the cost of custom plastic cups?

They may include the material, the level of design put in place, the method we use by the printer to print, and the number of cups printed in one round.