What is Custom injection molding?

The first question that comes to mind on hearing is what is Custom injection molding?

Custom injection molding refers to the making of plastic parts for specific applications i.e. customizing the plastic injection components as per the customer’s requirements.

Customized injection molding parts

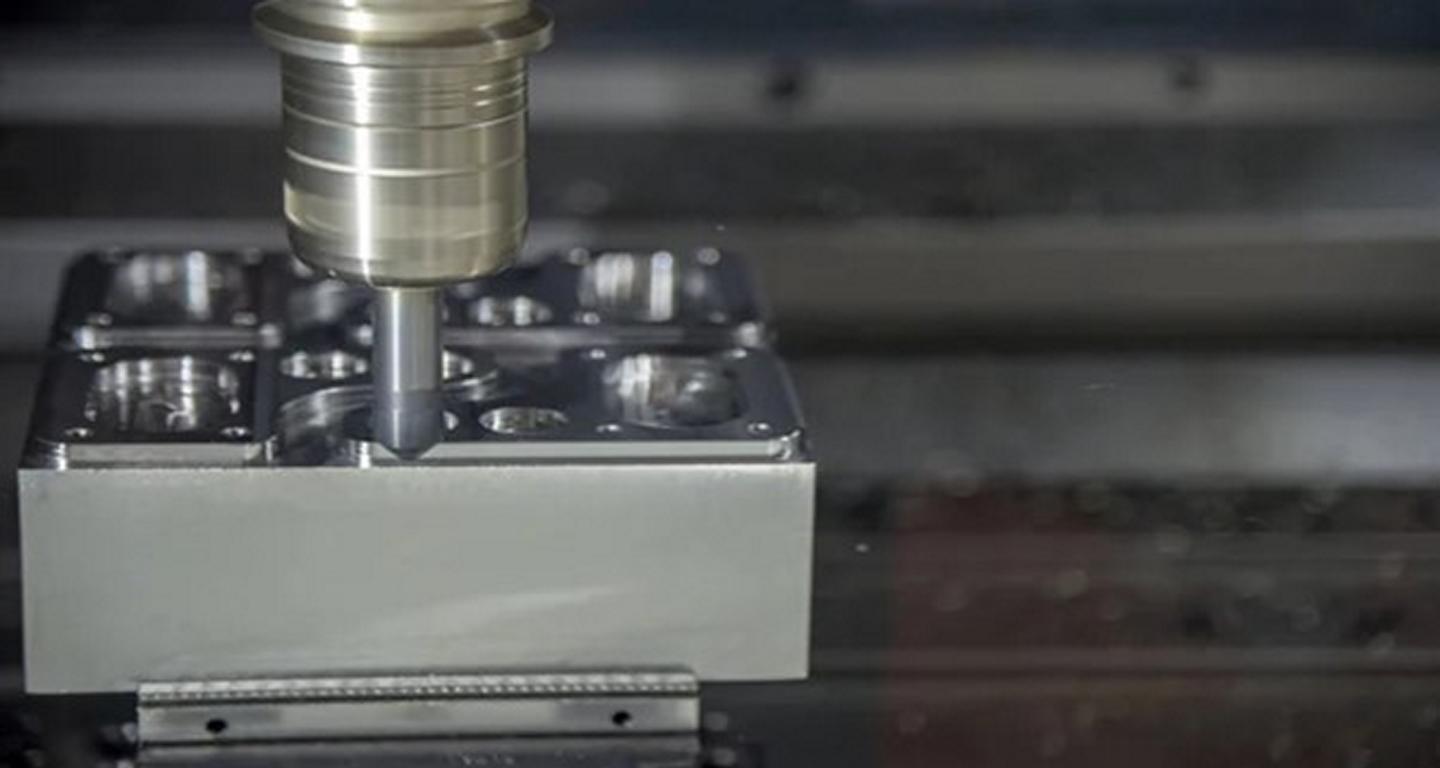

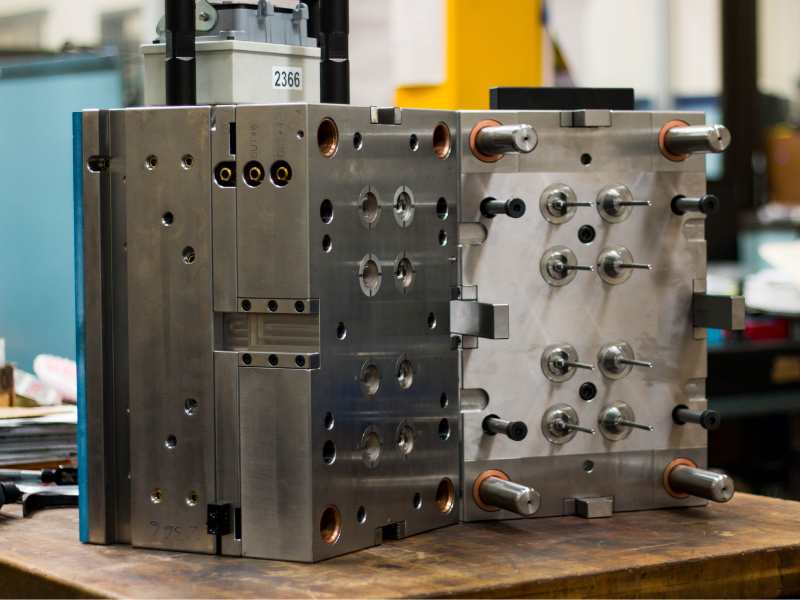

Injection molding is a process in which plastic pellets are melted and injected under high pressure into a mold cavity. The molded parts are then ejected, and the process repeated. The finished products can then be used as is, or as a component of other products. To do so requires an injection molding machine and tooling (often called a mold or die). The molding machine consists of a clamping unit to open and close the mold automatically, and an injection unit to heat and inject the material into the closed mold.

Injection molding utilizes very high pressures and typically the machine is hydraulic or, increasingly, electric. Tooling for production injection molding applications must be able to survive under high pressure and is made from steel or aluminum. The potential high cost of tooling often drives the economics of a plastic molding application. Injection molding is an effective way to make custom parts.

Bascially, most of injection molding parts are customized injection mold, because every single design need its own custom injection mold, onless you buy the ready parts from the market, otherwise you need to make your own custom injection mold for your customized design.

Injection Molding Process:Plastic Processing, Make Parts From Plastic Material

Finding the right source for your custom injection molding thermoplastic parts is as easy as selecting DONGGUAN SINCERE TECH CO.LTD. With SINERE TECH, you are guaranteed professional quality assurance standards, the latest in technological equipment, and innovative, cost-efficient manufacturing techniques.

Injection Molding Process: A Brief Description

There are three main components in the injection molding process. The injection apparatus itself which melts and then transmits the plastic, the mold, which is custom designed, and clamping to provide controlled pressure. The plastic mold is a specially designed tool with a base and one or more cavities that will eventually be filled with resin. The injection unit melts the plastic granules and then injects them into the mold by either a reciprocating screw or a ram injector.

The reciprocating screw offers the ability to inject smaller amounts of resin in the total shots, which is better for producing smaller parts. After injection, the mold is cooled constantly until the resin reaches a temperature that allows it to solidify.

Complications with Injection Molding

Injection molding complications are few and can be easily avoided by paying close attention to the design of the plastic mold, the process itself and caring for your equipment. Parts can be burned or scorched when the temperature is too high, which is sometimes caused by the length of the cycle time which may be too long. This causes the resin to overheat. Warping of parts happens when there is an uneven surface temperature for the molds.

Surface imperfections (commonly known as bubbles) happen when the melt temperature is too high, which causes the resin to break down and produce gas. This can also be caused by moisture in the resin. Another complication is incomplete cavity filling, which occurs when there isn’t enough resin released into the mold or if the injection speed is too slow, which results in the resin freezing.

Running a Custom Injection Molding Business

Custom plastic injection molding business is a competitive business and to survive you should find your niche market. Most custom molders in business today have found a niche. Through experience, the molder became good at molding a particular type of part or at molding a particular kind of material, or in working in a specific segment of the marketplace. In other words, he acquired an expertise and stuck with it.

Thermoplastic injection molding is the most widely used of all plastic processing methods. Injection molding is a manufacturing technique for making parts from plastic material. Molten plastic is injected at high pressure into a mold, which is the inverse of the desired shape.

Thermoplastics are those which, once formed, can be heated and reformed over and over again.

The mold is made from metal, usually either steel or aluminum, and precision-machined to form the features of the desired part. SINCERE TECH provides the highest quality economical plastic molds available today, with less moving parts to reduce maintenance and repair costs.

The injection molding machine reduces pelletized resins and coloring agents into a hot liquid. This slurry, or “melt”, is forced into a cooled mold under tremendous pressure. After the material solidifies, the mold is unclamped and a finished part is ejected.

An injection-molding machine performs the entire process of plastic molding. These machines serve to both heat the plastic material and form it. Using different molds the shape of the produced components may be changed.

Injection molding machines have two basic parts, the injection unit, which melts the plastic and then injects or moves it into the mold, and the clamping unit, which holds the mold shut during filling. The unit clamps the mold in a closed position during injection, opens the mold after cooling, and ejects the finished part.

Custom Injection Molded Plastic Parts:

High-Quality Parts, Guaranteed to Specification, Extended Warranty, Retain Mold Integrity, Advanced Design, Quality Assurance

Finding the right source for your custom molded plastic products is as easy as selecting https://plasticmold.net/. One of top 10 mold manufacturers in China that services custom injection mold and plastic molded parts to the world.

With SINCERE TECH, you are guaranteed professional quality assurance standards, the latest in technological equipment, and innovative, cost-efficient manufacturing techniques.

Custom Injection Molding Parts: SINCERE TECCH’s Advantage

The injection molding process offers the lowest piece prices available, but tooling (plastic mold making) prices are generally the highest. That is why we need to make all of the molds in-house to create top quality plastic mold and the lowest price for our customers, our custom mold cost as low as $500. contact to get price for your own custom plastic injection molding.

And they stand behind their word. They offer their customers the option of joining their Extended Warranty Program guaranteeing the plastic mold we design and builds for you will retain its integrity throughout a specific number of cycles, if we store the molds for you we will do the free mold maintenance for you.

For more information, see the home page.

Customized Injection Molded Applications

Injection molding is widely used for manufacturing a variety of parts, from the smallest component to entire body panels of cars. It is the most common method of production, with some commonly made items including bottle caps and outdoor furniture.

We have the ability to produce a wide variety of custom injection molding parts and components, for industries of all types, including:

|

|

|

To provide the best process for your project, you are welcome to send us email, we will offer you the best solution for your custom plastic injection molding project.