Thermoplastic molding Ultrasonic Welding Process, Fast, Computer-Controlled Accuracy, Chemical / Adhesive Free, Low Cost, High Speed

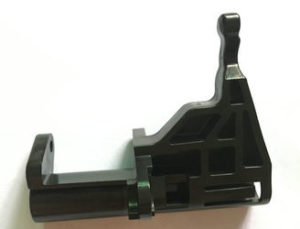

SINCERE TECH is an injection mold china company that provides a variety of services to the world, including custom plastic mold making, custom injection molding service, printing, silk-screen, and molding ultrasonic Welding, one step to complete your project. Molding Ultrasonic Welding is used to bond two pieces of plastic together.

Molding Ultrasonic welding is probably the most commonly used thermoplastic molding welding process because it is very fast (fractions to a few seconds) and usually produces welds that are relatively free of flash. In addition, Thermoplastic molding ultrasonic welding is suitable for high volume production.

Molding Ultrasonic Welding: A Brief Explanation

molding Ultrasonic welding uses the potential energy within the plastic itself, converting it to heat and sound. In plastic ultrasonic welding the parts are vibrated toward and away from each other. This heats and softens them. The continued motion heats and softens the plastics, then mixes the softened surfaces of the plastic together. This forms both a physical, and if the plastics are selected correctly, a chemical bond between the parts.

A sonic horn oscillates vertically, contacting the plastic part at a variable distance from the projection point, depending on the application, delivering the energy where it’s needed. The part on the other side of the joint area rests on an energy-dampening anvil, ensuring the sonic energy remains in the weld zone.

Tongue & groove joint design and location is very important in ultrasonic welding. Interference, or shear types of joints, involve welding a slightly larger part into a smaller one. Shear joint designs are commonly used for semi-crystalline polymers, or when watertight seals or high joint strengths are needed.

Molding Ultrasonic Welding: Benefits & Advantages

Rapid development of the ultrasonic welding machine has occurred in the last ten years. Basic functions are now computer-controlle

d for greater accuracy and reliability, such as:

- Weld energy

- Collapse

- Trigger force

- Pressure

Ultrasonic welding of plastics has many advantages over other plastic-joining processes, including:

- Lower cost – eliminates the costs of consumables, produces repeatable, error-free results

- Higher speed – welding usually occurs in less than a second.

- Cleaner process – no consumables required, less risk of contamination

- Greater reliability – adaptable to clean-room environments as well as high-volume production situations

Unlike most other methods of plastics joining, ultrasonic welding uses no caustic chemicals and produces few fumes. The only restriction on welding plastics is that the parts must have relatively close melting points, or else one will melt completely before the other begins to soften.

Molding Ultrasonic Welding: Applications & Uses

Ultrasonic assembly is ideal for assembling all types of medical products, such as:

- Filters

- Instruments

- Fluid vials

- Masks

- Surgical garments

Molding Ultrasonic welding has a wide variety of additional uses and applications, including:

- Sealing containers and bags

- Attaching plastic components

- Inserting metal components into plastics (see Ultrasonic Insertion)

- Corrugated containers – eliminates the need for staples or adhesives

- Plastic Tubes and pumps – will not contaminate contents

SINCERE TECH provides a variety of value-added services, including Plastic mold Manufacturing, plastic molding service, Ultrasonic Insertion, to help complete your project. Ultrasonic insertion is used to bond metal and plastic parts together without the need for glues, adhesives or additional heating or processes.

When a metal part needs to be attached to a plastic part,conventional insertion methods include:

- Mold the metal component into part during production

- Glue the metal part to the plastic

- Heat

- Melt the plastic component at insertion point

- Insert metal piece into molten area

- Allow part to cool and solidify

Ultrasonic Insertion: Benefits and Applications

This technology is an alternative to gluing or heating. Ultrasonic Insertion of metal to plastic offers distinct advantages over other bonding processes. Although this process is similar to locally melting the area with another heat source, it has the advantages of::

- Heating a far smaller area to lower temperatures

- Reducing energy costs

- Decreasing cooling time

- Reducing the possibility of defects due to thermal effects

Ultrasonic insertion works by using the ultrasonic head to vibrate the metal component against the plastic one. The Welding Horn couples directly with either the insert or the thermoplastic part. Ultrasonic vibrations heat and soften the plastic part, allowing the metal part to be inserted. As the plastic cools, a very strong bond is made.

Applications for ultrasonically inserted components include:

- Threaded inserts or studs

- Metallic webs or grills (speaker covers, etc.)

- Permanent magnets

- Electric contacts

If you have a project that need metal staping and plastic molding service and ultrasonic Insertion, you are welcome to send us, if your project needs molding Ultrasonic Welding servcie, contact us as well, we will quote your complete price for you.