Unveiling the Organized World of Plastic Crate Mould

You always see plastic crates no matter where you go. After all, these seemingly simple containers offer a robust and versatile storage solution, from the crisp vegetables in the supermarket to the tools in the garage,. But have you ever wondered how these plastic workhorses are born? The answer lies in a specialized yet fascinating realm: plastic crate moulds.

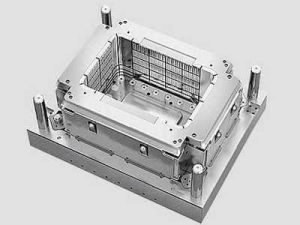

What is Plastic Crate Mould

Plastic crate mould, also known as a plastic crate injection mold, is a specific type of mold used in the manufacturing of plastic crates. Plastic crates are widely used in various industries for storage, transportation, and organization purposes. They are durable, lightweight, and stackable, making them ideal for applications such as logistics, agriculture, retail, and more.

The plastic crate mould is designed to create the cavity and shape required for manufacturing plastic crates through the injection molding process. It consists of two main parts: the core and the cavity. The core forms the internal shape of the crate, while the cavity defines the outer shape and surface details.

The plastic crate mold is typically made of high-quality steel or aluminum to withstand the pressures and temperatures involved in the injection molding process. It is precision-machined to ensure dimensional accuracy and repeatability.

The process of plastic crate molding involves injecting molten plastic material, usually polypropylene (PP) or high-density polyethylene (HDPE), into the mold cavity. The molten plastic material fills the mold under high pressure, conforming to the shape and details of the mold. After cooling and solidification, the mold is opened, and the molded plastic crate is ejected.

Plastic crate molds can be designed with various features to meet specific requirements, such as handles, interlocking mechanisms, labeling areas, or ventilation holes. The design of the mold depends on factors like the desired crate size, load capacity, aesthetics, and functionality.

Manufacturers or mold makers with expertise in plastic crate mold design and manufacturing can provide custom mold solutions tailored to specific crate designs and production requirements. These molds are typically produced using advanced computer-aided design (CAD) software and precision machining techniques to ensure high-quality and efficient production of plastic crates.

Sincere Tech is the leading plastic crate mold manufacturer in China. We manufactured custom plastic mold around 200 sets of different types of molds for our customers, around 20 percent of plastic crate molds for our customers. After many crate mold cooperation with German and Italian customers, Sincere Tech has accumulated and updated many times for advanced crate mold design and crate mold tooling.

We have been made a different type of plastic crate moulds such as plastic industrial crate mould, plastic vegetable crate mould, Plastic beer bottle crate mould, plastic fish crate mold, bread crate mould, plastic foldable crate mould (Collapsible crate mold), plastic storage crate molds, etc.

Plastic Big Crate Mould

The Magic of Moulding Process

You can think of a plastic crate mould as something similar to a giant cookie cutter. However, the only difference is that it is for molten plastic rather than dough. A plastic crate mold is made from high-grade steel machined to perfection to produce the exact shape and features of the desired crate.

Try to think of a mind-boggling puzzle with numerous interlocking components. The core of the plastic crate mould forms the crate’s base, while cavity blocks produce the hollow interior and any intricate details such as handles or stacking ridges.

Building the Strength: Mould Design Considerations

There is an intricate process involved in the creation of plastic crate mould that strikes the perfect balance between functionality and cost-effectiveness of plastic crate mould price. Several factors such as the size, weight capacity, and stacking ability of the crate all affect the final design of the mould.

- Ejection Mechanisms

Efficient removal of the finished crate from the mould is paramount. Ejector pins, strategically placed within the mould, push the crate out after it cools. Sometimes, sliders or cores are incorporated for more complex designs with deep undercuts.

- Gate Placement

The gate is the crucial entry point for molten plastic into the mould cavity. Its location significantly impacts the final product’s quality and aesthetics. A strategically placed gate ensures even flow of plastic, minimizing imperfections and optimizing material usage.

- Strength and Durability

The mould steel needs to withstand the immense pressure and heat of molten plastic during injection moulding. Special emphasis is placed on designing ribs and support structures within the mould to ensure it maintains its shape over countless production cycles.

Beyond the Basics: Mould Innovations

The world of plastic crate moulds is constantly evolving. Here are some exciting advancements:

- Hot Runner Systems

These ingenious systems keep the plastic molten only at the injection point, reducing energy consumption and minimizing material waste.

- Multi-cavity Moulds

These moulds create multiple crates simultaneously, boosting production efficiency.

- Textured Surfaces

A plastic crate mould can be designed to give crates their textured surfaces that can improve their grip and lower the risk of items slipping during transportation.

The Moulding Symphony: Collaboration is Key

Creating a successful plastic crate mould requires a collaborative effort. Mould designers work closely with crate end-users to understand their specific needs.

The material engineers in charge of the project double-check the chosen steel to determine its ability to endure the moulding process and the demands of the final product.

Plastic crate mold makers put their expertise into use during machining and fabrication to breathe life to the vision of the designer.

A Future of Sustainability

The sustainability drive affects the design of plastic crate mould as well. Many of these moulds are now built using recycled steel. The possibility of creating crates using eco-friendly recycled plastics is now under serious consideration.

How to start the crate molding production business?

To start the factory for crate molding production, you need a professional plastic mold company for technical support from crate part design, plastic crate molds manufacturing, injection molding machine choose and supplying and other detail technology. please contact us that we can offer you our best support for your plastic crate molding solution from design to a real plastic crate mold, below are some of the plastic crate molds we made before.

- Custom plastic Crate mold

- small crate mold

- Plastic crate mold

- Crate mould

- Collapsible crate mould

- 2 cavity crate mold

When you have done the plastic crate molds then you need to have molding equipment, like injection molding machine, material drying equipment, hot runner controller, cooling system like water chiller, cooling tower for the plastic molding shop, basically, all of those crate molding production equipment you should buy at the same time when you make the plastic crate mold, you need to select the injection molding machine that suites of this crate mould which you make for, like the shot weight, loading size, tonnage, etc,

Considering the different crate size and crate mould structure, the injection machine size is ranged from 380T to 1250T. For example, the 280x340x110mm crate with one cavity mould only needs 350 tonnage machines. When you make a folding crate which extended with mold size 1100x700mm to folding crate size 600x400x110mm of fruit crate molding, you ‘d better order 1250 tonnage injection machine.

Which is the most popular crate product in the market?

There are many popular crate molding products on the market, each country has its own popular crate molding products. When we talk about Europe’s standard there are fruit crate molding parts, vegetable crate part, plastic milk crate part, and thin-wall bottle crate, plastic folding crate, bulk crate containers, collapsible crate, Europe pool crate, nestable cate containers, etc.

We suggest you start your crate molding production one by one, choose the easy one but the most popular one to start at first. We offer you any custom plastic crate molds, such as fruit crate mold, vegetable crate mold, milk crate mold, plastic folding crate mold manufacturing services with competitive price and long lifetime.