The important Mould Manufacturing industry -China Mould

China mould companies are now facing heavy pressure because of the high competitiveness of injection moulding companies from India and Vietnam. The reason for the heavy pressure on the Chinese plastic injection moulding company is detailed below.

- There are many plastic injection mould companies in India and Vietnam, so this will take part of China’s mould manufacturing share.

- The inflation caused the China mould manufacturer to need to pay more material costs, such as for mould steel and other materials (especially copper). Also, we need to pay a much higher salary. From 2009 to 2011, the general salary increased by 40%, but it did not increase more each year.

- Due to the global economic recession, many Chinese mould factories have experienced reduced orders. Therefore, when any purchase order is required, they all compete with each other on the mould price, leading to a continuous decrease in the price. At the same time, the quality of the mould cannot be guaranteed.

Given the aforementioned points, we are considering strategies to enable China’s mold manufacturers to endure longer, unlike the majority of European mold makers. As we know, 30 years ago, many people went to Germany, Italy, or Portugal to order moulds; 20 years ago, individuals visited China and the Taiwan area to order the moulds; and 10 years ago, individuals came to Chinese mainland mould makers to order custom ds. Now, China mould companies are wondering how long it will last for people ordering moulds from China.

href=”https://plasticmold.net/china-mould/” title=”China Mould”>China Mould

The Advantages of China Mould

As above, we explained that China mould companies face pressure in making moulds, but to compare with India mould and Vietnam mould, China mould still has its advantages. Of course, these advantages are not as big as they were 10 years ago. But even today, many Indian companies are still buying Chinese moulds for their Indian plastic injection moulding mpanies.

A simple piece of information I got from one of my Indian clients (who works for a big plastic injection moulding company in India) is that Indians cannot make good quality mould; when they have any small issues, they will hold on to the project and not do anything to solve the sue. On the other hand, Indian moulds will have big issues with quality and lead time.

Here are some advantages of using China moulds:

If you are seeking a plastic mould for your project, what is the most cost-effective option? Then a China mould is going to be the least expensive method based on quality and lead time. Going to China to have a mould made may seem a little daunting at first, but as you read further into this article, you will understand why most people choose this option. Here are a few reasons why people buy moulds from China:

Less expensive than the US

Production costs for a China mould are much lower than ordering one in the US. This is primarily due to the economic differences, specifically the lower labour costs in China. This is not something to feel bad about, as it is fairly relative to the cost of living and comparable to labour costs across many industries.

The quality is good.

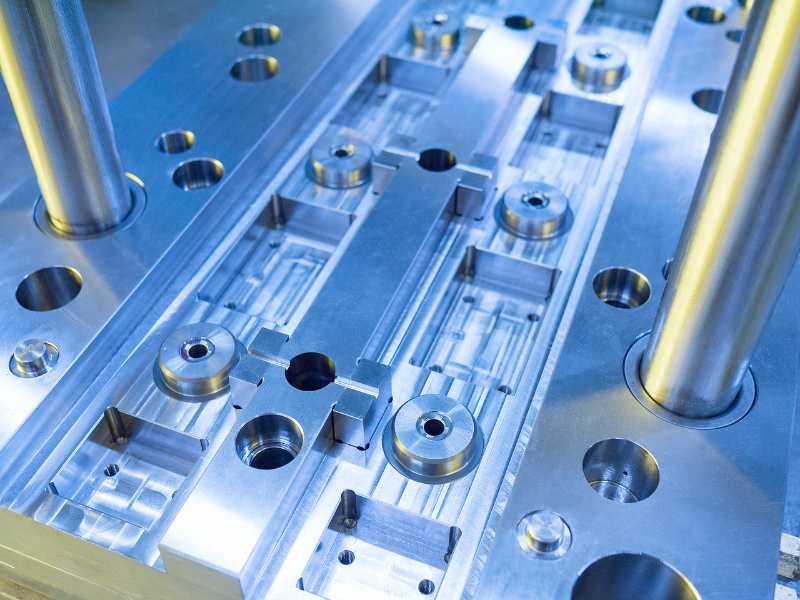

Because China has such a large industrial landscape, they specialise in plastic moulds and other industrial items. There are a number of factories you can choose from, all of which are very experienced in making moulds of high quality.

Easy to Arrange

By using the internet, it is very easy to communicate directly with Chinese plastic mould manufacturers. You will easily find a representative that speaks English, as they are used to dealing with the US, and you can work with them back and forth until you are happy.

Customisation

China mould manufacturers can produce customised moulds according to your specific requirements, ensuring that you get a mould that meets your exact needs.

Large production capacity

With a vast pool of skilled labour and state-of-the-art manufacturing facilities, China has a large production capacity for olds. This means that they can produce moulds in large quantities and deliver them quickly.

Wide range of materials

China mould manufacturers can produce moulds from a wide range of materials, including plastic, metal, and composite materials.

Taking into consideration all of the above, if you are ever interested in hiring a China mould maker to assist you with your production-related work, then you should consider a couple of important factors in order for everything to work out fine. For example, clearly identify the specific goals you hope to achieve with the assistance of a reputable company. This can either be precision or any other important thing that stands to help improve your production activities. Precision serves as a guarantee that the work you have in hand will be done exactly as ordered.

In addition to the above, as well as taking into serious consideration the demands of this fairly competitive industrial sector, punctuality is yet another important requirement that you will need. It is important because it will help ensure there is a strong turnaround in the production of your goods once the new technological developments have been taken into consideration. Simply put, the sooner you get hold of the plastic parts requested, the sooner you will be able to finish production, consequently being able to witness the much-needed cost effectiveness.

You should also take time to familiarise yourself with all the relevant plastic mould services that are relevant to your production activities. Doing so is very important because it will help you make all the right decisions and allow you to start enjoying the advantages of operating on a global scale. The best place to do plastic injection tooling is in China; hence, you should keep that in mind when looking to collaborate with any China Plastic Mould Company. Assembly and finishing should be done later, in Mexico. Simply put, these recommendations take into serious consideration the basic requirements, which are cost efficiency and speed.

It is equally worth noting that the best global company to work with should be accustomed to working with a variety of global clients. This is important because it will help make sure that all plastic moulds can easily be sent to any location across the globe. In general, in order to excel in the manufacturing industry, it is imperative that you keep up with all the latest trends linked to the industry.

Next time you need plastic injection mould work carried out, focus on making sure that you only engage companies that have a proper understanding of how to operate on a global scale. This is important because it will also help make your global expansion plans much easier.

How to Source Moulds From A China Mould Manufacturer

This process is a lot easier than you may think. You can find China mould manufacturers online, by searching or by looking for recommendations from other people. Then you can make contact and start negotiating terms. You can usually have your plans drawn up in the US then sent over for them to review, or you can work on plans directly with the mould suppliers in China.

Here are some steps to source a mould from China:

- Determine your mold specifications: Determine the type of mold you need, including its size, material, and other specifications. You should also have an idea of your budget and production volume.

- Research and select potential China mould suppliers: Use online directories, trade fairs, referrals, online research, and industry associations to identify potential mold suppliers in China. Evaluate the suppliers based on their experience, reputation, and their ability to meet your specific requirements.

- Contact the China mould makers: Reach out to the China moold makers and send them your specifications. Request quotes from each supplier and ask for samples, references, and certifications.

- Evaluate the quotes and samples: Evaluate the quotes and samples from each supplier and compare them against your budget and specifications. You should also consider factors such as the supplier’s lead time, payment terms, and quality control processes.

- Negotiate and finalize the contract: Once you have selected a supplier, negotiate the contract terms, including payment terms, lead time, and quality control. Ensure that the contract includes details such as the scope of work, specifications, and delivery dates.

- Monitor the production and quality control: Monitor the production process closely to ensure that the mold is being produced to your specifications. You can also hire a third-party quality control company to inspect the mold before shipment.

- Receive and inspect the mold: Once the mold is complete, receive it and inspect it carefully to ensure that it meets your specifications. Test the mold to ensure that it produces high-quality parts.

If it is new project, you should always make some prototype before go to order moulds. Once you are happy with the prototype you can start to order mould and wait for your shipment to be delivered. Even with packing and shipping, the overall cost will be substantially lower than it would be in the US or Europe.

Sincere Tech is one of top 10 mold manufacturers in China. we offer custom plastic mold, plastic injection molding parts to the world, we have clients from Germany, Canada, America, Spain, Thailand, Lithuania, etc

Are you looking for A professional and long partner China mold maker?

SINCERE TECH is one of top 10 Plastic injection mold companies in China that offers injection moulding service to various countries in the world with the best quality and excellent after sales services. The company which is known to be the leader of the China mould manufacturer, with all its dedication, developed and produced varieties of the injection molding parts. The optimal service, leading equipment, and advanced technology are valuable reasons for the success of the company.

Sincere tech optimize the design based on the requirements of the customer and they are very attentive while designing the mold as they can save their money, reduces the processing and mould repairing time for their customers.

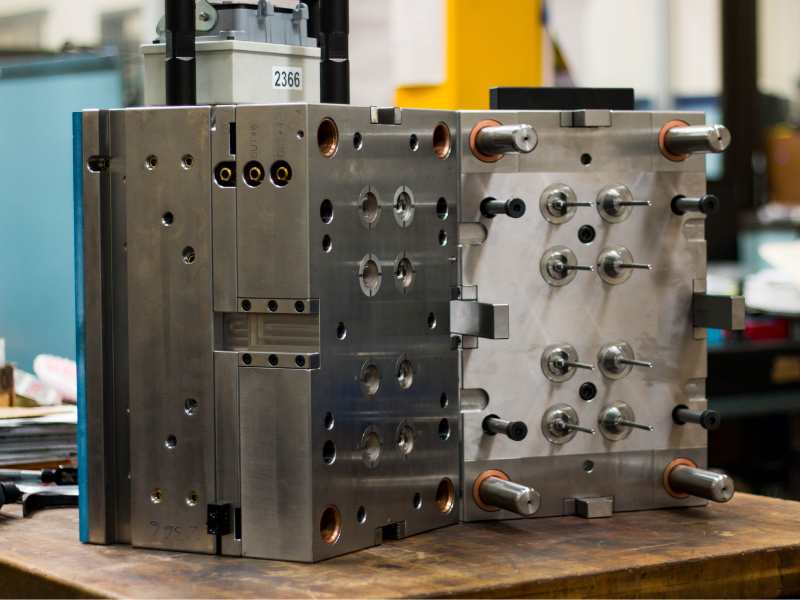

There have 15 experts plastic mold designing team in the company which is making fully complete mold design, four engineers who inspect the mold design and two technical managers to verify the mold structure before mold manufacturing. This team possesses the ability to operate UG and PRO-E software with all their efforts.

The engineers of the company have the specialization of the product so that they can provide their customers with worth able suggestions and technical supports. The design engineers will offer DFM( design for manufacturability) in two business days and within five days they supply fully mold design to the customers.

Mold developments with perfect design, the top mold manufacturing processing technologies with constant works are their key to success. The superior emphasis on design, sophisticated working devices, and ideal processing system provide their clients with more satisfaction.

Sincere Tech has launched 3 automatic production outline in the surface treatment and workshop that is dustproof which is used in surface texture, surface spray, IMD, etc. they provides its customers with injection mold making and injection molding services at low cost which could not be provided by their competitors. If you are looking for injection mold or injection molding China partner to support your business, then you could contact with our team, we will reply to you with two business days.

We have over 18 years of rich working experience plus 15 years of skilled technical English communication.

Good price, good quality, and good service is our tenet.

We guarantee your project will be successful, look at the below picture what our happy customers say.

Are you ready to start your mold project with China mould maker Now,

Send us your requirement for quotation, you won’t lose anything but will get competitive China injection mould price. Check below what is happy customer says