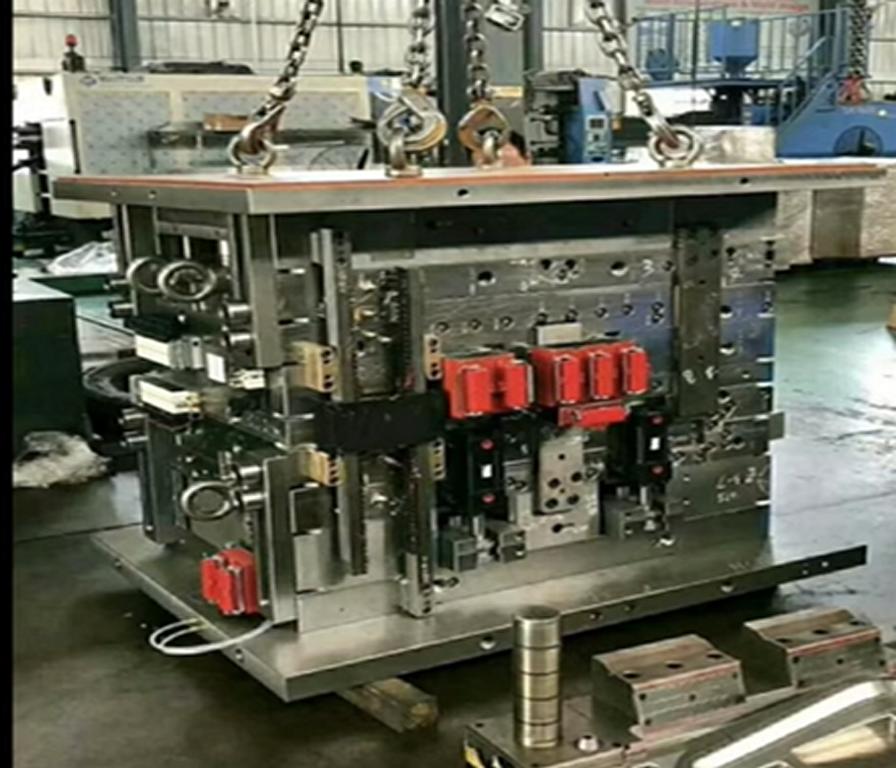

Stack Mold

Stack Molding: Everything You Should Know

Stack molding is an outright revolution within the injection molding industry because it boosts production speed. In stack molds, at least two or more compacted cavities mean that different parts are molded in one go to increase efficiency. But for now, what is stack molding, and how does it work, especially, when compared to its counterparts? In this article, we will define stack molding, a brief overview of its benefits as well as how it is quickly reshaping high-volume production is provided. Besides this, we will learn about the stack mold injection molding process including the materials, design guidelines, and everything in between.

What is Stack Injection Mold?

A stack injection mold has multiple parting lines, or “tiers” of cavities, produced by stacking more than one mold cavity over. Every level in the mold contains another set of cavities which simultaneously increases the overall output of the machines. It does not invest in additional tools or the real estate required to accommodate them. Compared with the ordinary mold which can only form a part in one plane, stack molds configured in the vertical plane to more than one plane making the part, hence having higher productivity.

How is stacked molding performed?

Here’s a step-by-step outline of how the stacked molding process is performed:

1. Mold Closing

The stack mold has a series of cavities, and they are in a standing position by arranging the Cavities in vertical order. The mold closes as the machine’s platen oscillates, so the cavity and core of each stage are aligned at the same time.

2. Injection of Material

After it is closed, molten plastic is injected into the mold cavities through a single sprue or hot runner. The material enters every cavity at every stage of the multiple-tiered mold. The layout of the hot-runner systems guarantees that the material will be uniformly distributed over all the cavity grades.

3. Cooling and Solidification

Once the molten plastic has entered the cavities it starts to cool and get solidified. Each level of the mold enables the part to cool at a time. So, the cycle time does not have to be extended because cooling can be done for each cavity set concurrently.

4. Mold Opening

When the polymer is sufficiently cooled a system opens the mold. Mold is intended to remove each level of the stack at a time. Some features guarantee that the cavities are open to facilitate easy and smooth removal of parts from the mold.

5. Ejection

The mold’s ejection system then throws away the solidified parts from the cavities leaving a cavity-free mold ready for the next cycle. The difference is that each level of the mold launches its parts all at once, thus achieving high turnover in one full cycle. Additional or more complex parts can be easily ejected using collapsible cores or special ejector systems.

6. Recycling the Process

But once ejected the mold closes again and goes for another round of operation until the cycle is complete. Since stacked molds incorporate more cavity levels, the manufacturers can make more parts per cycle. So, they can make them more efficient without calling for greater size or tonnage.

Suitable Material for Stack Mold Injection Molding

In particular, the right material is important for stack mold injection molding. The material should be flowable to ensure it enters all the spaces in a structure well. So, the common materials used include:

| Material | Tensile Strength | Melting Point | Mold Shrinkage | Common Applications | Properties |

| Polypropylene (PP) | 25-40 MPa | 160-170°C | 1.0-2.5% | Packaging, automotive parts, household items | Good chemical resistance, suitable for high-speed molding |

| Acrylonitrile Butadiene Styrene (ABS) | 40-60 MPa | 200-260°C | 0.4-0.8% | Consumer goods, electronics, automotive parts | Tough, impact-resistant, good dimensional stability |

| Polyethylene (PE) | 10-30 MPa | 110-130°C | 1.5-3.5% | Bottles, containers, packaging film | Low density, flexible, ideal for lightweight applications |

| Nylon (PA) | 60-80 MPa | 220-260°C | 0.5-1.5% | Automotive parts, industrial components | With high strength and toughness, moisture absorption is a factor |

| Polycarbonate (PC) | 55-75 MPa | 260-270°C | 0.5-0.7% | Optical disks, electronics, automotive lenses | Excellent transparency, impact resistance, expensive |

| Polyethylene Terephthalate (PET) | 50-80 MPa | 250-260°C | 1.2-2.5% | Bottles, packaging, industrial components | High strength, clarity, good for recyclable applications |

| Polystyrene (PS) | 30-50 MPa | 210-250°C | 0.4-0.8% | Disposable containers, insulation, packaging | Low-cost, rigid, but brittle |

Types of Stack Molds

Here are some common types of stack molds we can use in different applications;

1. Two-Level Stack Mold

It has two cavity levels that produce double the number of single-level molds. So, they help fit the need for a raise in production without extra machines. It is cost-effective for mid-range production quantity range and effectively controls the usage of the machines.

2. Three-Level Stack Mold

It has three cavity levels, which increases output by three times and is effective for use in industries where productivity is all important. Besides this, it minimizes idle time and optimizes the end product throughput without enlarging the effective area of the machine.

3. Four-Level Stack Mold

This mold is created for parts with an extremely high demand; and features four cavities which multiply production four times per cycle. It is ideal for use where large quantities of goods are produced with a need to achieve very close tolerances.

4. Rotating Stack Mold

Of course, multiple sets of platens are configured to perform molding and cooling in various tiers to increase production rates and shorten the cycle time. This system is more efficient in its function since it accomplishes several tasks in a single cycle.

5. Index Plate Stack Mold

Through the cycle, each level shifts to a new position that allows multiple-stage operations in a single mold. It is useful for fabricating contractual parts that may need different operations at various cycles.

6. Collapsible Core Stack Mold

It is ideal for expelling objects with intricately compact sections such as threads or undercuts. It works perfectly for producing complex plastic parts which may be hard to demould without causing an effect on the part. So, the cores reduce the chances of the layers sticking together or the core dragging in the layer above during ejection.

7. Hybrid Stack Mold

Stack molds are special molds that consist of two or more molds sometimes known as tandem or rotating molds and hybrid stack molds with other molding techniques. This design makes it possible to produce parts since the molding processes are done in one mold. Doing so yields a multifunctional system, that can fashion complex components with diverse characteristics in one cycle.

Comparison Between Stack Molds vs. Tandem Molds

Here is a brief table to compare the stack molds with tandem molds;

| Feature | Stack Molds | Tandem Molds |

| Mold Structure | Multiple levels of cavities stacked vertically. | Two molds operating in tandem, side by side. |

| Operation | All cavity levels are filled and ejected simultaneously. | Molds alternate operation, one fills while the other cools. |

| Cycle Time | ~20-30% shorter cycle time compared to single molds. | ~10-20% longer due to alternating mold operations. |

| Production Output | High output (2x, 3x, 4x depending on mold levels). | Moderate output increase (1.5x to 2x compared to a single mold). |

| Part Complexity | Best for simple to moderately complex parts. | Suited for more complex parts or multi-stage operations. |

| Material Usage | Single runner system shared across all cavity levels. | Separate runner systems may be required for each mold. |

| Energy Efficiency | More efficient (~10-15% energy savings due to simultaneous operations). | Slightly less efficient due to alternating operations. |

| Ideal Use Case | High-volume production of identical parts. | Producing complex parts requires different molding stages. |

Selecting the Right Manifold System for Your Stack Molds

Here are some ways you can opt to select the right system for stack molds;

- Multiple Cavities: Enables manufacturing similar items to reduce unit injection molding cost and increase yield.

- Compact Design: Allocating cavities in vertical columns reduces the floor space, especially in a facility with limited space.

- Enhanced Cooling Efficiency: Conventional and coupled cooling structures with counterflow provide efficient cooling in all cavities. Besides this, it has a reduced cycle time and better parts quality.

- Simplified Ejection Mechanism: Advanced ejection methods help to snap off parts without causing any harm to those parts.

- Hot-Runner Technology: Reduces Styrofoam material waste and guarantees equal filling since plastic is retained at its molten state before entering cavities.

Selection of manifold system for stack molds

- Material Compatibility: Check whether the structure and functionality of the manifold system meet the flow characteristics and thermal properties of those specific materials used in the fabrication of the circuit board.

- Flow Distribution: Choose a cavity with a design that would allow for even distribution of the material to all levels to prevent pressure loss

- Temperature Control: Select the system that controls the temperature to affect the part’s viscosity or material quality.

- Ease of Maintenance: Select a design that disassembly since products need regular maintenance and cleaning.

- Scalability: Research for a manifold system that could be promptly changed or added to correspond to future production.

Applications of Stack Molds

Stack molds are commonly used in industries requiring high-volume production, such as:

- Vehicle structure and interiors or car components and casings.

- Consumer products (packaging, caps)

- Other (syringes, caps)

- Electronics (housing, connection)

Advantages of Stack Molds

- Increase in production capacity by thousands of percent

- Efficient material usage

- Reduced labor costs

- This usually results in minimized thereby minimizing floor space requirements of the varied facilities.

- High return on investment

Disadvantages of Stack Molds

- Higher upfront cost

- Complicated mold design and need for frequent repair

- These call for a higher method that is more precise and controlled by more advanced machinery.

- Possible case to get part quality wrong if not balanced appropriately

Misconceptions Regarding Stack Molding.

- Myth: Stack molds are too expensive for small businesses. Fact: This is always a costly affair in the initial procedure but it also helps in saving a lot of consumable material and time of production in the long term.

- Myth: Stack molds are the disadvantage of part quality. Fact: Good design dictates that a particular part should be of the same quality regardless of its cavity level.

Ideal Use Cases for Stack Molds

Stack molds are ideal in settings that require frequent changes in the heated mold, where the load is relatively large relative to the mold size, and in applications where the mold is to be periodically replaced with a cooled mold.

Stack molds are best suited to situations where large quantities of one part are required especially in production runs. These are particularly important in industries that require great accuracy such as the packaging industry, especially the manufacturing of consumer packaging products and the medical device industry.

Conclusion

In conclusion, Stack molding is one of the most effective production techniques that can greatly improve the production rate of many products in the production line, particularly in the high production line industry. Yet, stack molds can increase the density of cavings without enlarging the size of the machinery to help realize the high production value at a lower injection molding unit cost. So, know the types, materials, and design considerations. So, you can maximize the advantages of stack molding.

Frequently Asked Questions

What is Stack mold injection molding?

It’s a method that employs several cavities to manufacture several molding parts at once per cycle.

What materials can be used in stack molds?

PP, ABS, and Nylon are some of the available polished materials.

What is the difference between stack molds and tandem molds?

While stack molds make parts that are similar to each other at the same time, the second type of molds, the tandem molds create parts in different stages.

In which sectors are stack molding useful?

Almost every type of manufacturer such as automotive, packaging, medical, and electronics manufacturers among others.

How does hot-runner technology improve stack molding?

It cuts down the wastage of material and proper completion of wall cavities.

Are stack molds expensive?

Their cost is initially higher than other machines, but, the production efficiency is much higher.