Prototype Injection Molding

Some people think that plastic injection molding is only for the mass production of end products; most people think that steel molds are for high-volume production molding and aluminum molds are for lower-volume injection molding but expensive production. However, it is high time that these assumptions were challenged. Thus, injection molding, which is usually considered a process suitable for high-volume production, can be effectively used in prototyping and low-volume production as well.

Yes, prototype injection molds do have some costs, but these are not very high in the current world. Unlike in the past, where mold-making was said to take months, a competent manufacturing partner can now create molds in weeks.

When speaking of prototype injection molding, one must take into consideration the big picture. This entails the design of the part, the type of material to be used, the cost of the tools, and the time taken in the production process. When you are able to look at the big picture, you can avoid making decisions that are costly and time-consuming. Therefore, if someone has informed you that injection molding is not suitable for prototyping, it is high time you change your mind.

Exploring Prototype Injection Molding

In the last few years, the technology of 3D printing has changed the meaning of the term rapid prototyping and is now a feasible option for traditional manufacturing. With the advancement in printing technology, the sintering of material and the finishing process, and the availability of more materials for use, new opportunities have been created. One of the major developments is the ability to use 3D printing in developing injection molded prototype tools for short-run prototyping and production. This technique is gradually being incorporated by product developers, tool makers, and contract manufacturers because of the following benefits.

Conventional injection molding prototype is widely known to be very efficient in high-volume production runs. Aluminum molds are capable of making thousands of parts, while steel molds offer the highest mass production capacity. However, these conventional processes are often bureaucratic and expensive especially when there are mistakes in the process. Applying 3D printed tools in prototype injection molding is cheaper than when one has to go to full-scale production, and it also reduces the chances of having to fix mistakes in tooling.

Pros of Injection Molding in Prototyping

Prototype injection molding is one of the useful techniques that can be employed in the process of product development to minimize the risk of mass production. Here are the benefits that are likely to be realized:

Affordable Prototyping

The use of 3D printing in the development of injection mold prototypes can be of great assistance in cutting down the cost as well as the time taken in the prototyping process. Traditional molds are made from aluminum or steel; they are expensive and cannot be easily changed once made, which becomes a challenge if changes are required. However, 3D-printed molds are cheaper and faster in making modifications, as highlighted in the cost comparison and time analysis of tooling.

Realistic Functional Testing

Prototype injection molding is also relatively cheap and allows testing a product with the material it will be made of. 3D printed molds are usually plastic and can be reinforced with ceramic fibers; they can handle the pressure of working with different thermoplastics such as polycarbonate, nylon 66, ABS, POM, Ultem, and GF Ultem. This makes it possible to come up with more than twenty prototypes that are almost similar to the final product for testing and assessment.

Fast Feedback Cycles

It is imperative to note that feedback is an essential aspect in the development of products, and therefore, it should be as fast as possible. Prototype injection molding enables the production of small quantities of parts that can be easily provided to beta testers and engineering departments. This short lead time is especially useful for customer satisfaction and for organizations with branches or facilities, to ensure that they do not run out of spare parts.

Preventing Late-Stage Issues

It is not normal to achieve perfection in the first attempt at designing. The biggest issues are the time and money that is wasted on the errors that occur in the later phases of the project. If the idea of prototype injection molding is applied at the early stages of development, then it is possible to avoid some production issues because they will be identified and addressed before they worsen.

Therefore, by the application of prototype injection molding, the product developers are in a position to come up with a better and more efficient way of developing the product that will assist in bridging the gap between the concept and the actual production of the product.

Comparing Prototype Molding and Mass Molding

The classification of plastic injection molding is mainly done with regard to the number of parts that are being manufactured; this is done between the production of prototypes and the production of end-use parts. While both methods are similar in the techniques used to produce the part, both methods are designed to be cost-effective, functional, and mechanically strong for the specific part. The main difference is in the type of mold that is employed.

In prototype molding, the process entails the use of a CNC machined mold to inject molten thermoplastic and then cool it. What makes this process unique is that aluminum molds are used instead of conventional steel molds. Aluminum molds not only increase the rate of manufacturing but also decrease the cost of manufacturing, and therefore, are appropriate for manufacturing parts that are fit for use.

Different types of plastic engineering materials can be used, which gives a wide range of options even if the mold is made of one material. The main purpose of prototype molding is to shorten the time required in manufacturing and the total cost of manufacturing.

When To Opt for Prototype Injection Molding?

The following are some of the factors that help in determining when to use prototype molding. First of all, it is effective during the design stage and when testing the materials as it provides a real-life approach to cost and possibility analysis. Secondly, when checking the functionality of parts that are to be produced in large numbers, prototype molding offers an excellent opportunity to test the parts before going to large-scale production.

Also, prototype molding can increase R&D efficiency and shorten the time to market, which is why it is popular among companies that strive to enter the market quickly. Another factor that needs to be taken into account is prototype molding, which is suitable when the production is required to be around 10,000 units, and the cost of molding is relatively high.

On the other hand, mass-production molding entails the use of molds that are made from steel materials for long-term use in the manufacturing of large numbers of parts. These molds are also able to accommodate more intricate part geometries and are designed to endure long production runs. The costs of manufacturing mass-production molds are relatively higher than that of prototype molds because of the use of high-quality steel and time-consuming processes; however, the cost per piece is relatively low for large quantities. However, mass-production molds take longer to make and require more money at the start, but they are cheaper per piece and are ideal for large production runs.

Advantages of Plastic Injection Molding

Rapid injection molding of plastic parts through prototyping has numerous benefits that are very important in product development. This method not only enables engineers and designers to confirm the quality of the parts but also enables them to use real parts for market testing before finalizing the designs. Apart from design verification and structural validation, the rapid prototype injection molding helps in optimizing the tooling designs for the production runs.

It proves most useful for products that have high aesthetic standards and performance during the early stages of the product life cycle. It is wise to consult MSI Mold for a rapid prototype injection molding quote before investing in expensive production tooling. Here are some other significant benefits of prototyping plastic parts before full-scale manufacturing:

- Accelerated and Reliable Product Launch: Prototyping and market testing can help to overcome a number of issues that are the root cause of many product failures, including inaccurate cost estimation and inadequate understanding of the market. This approach makes the process of bringing a product to the market less problematic and more effective.

- Enhanced Product Functionality and Appearance: It is easier to evaluate the performance and appearance of the prototype samples in the real world as compared to evaluating the same from the engineering drawings or even visualizations.

- Streamlined Design Process: Prototyping is useful in shortening the total time spent on engineering and design review since it offers physical proof of a product’s feasibility. This is because when one has a prototype plastic injection molding part in his or her hand, it is easier to convince the stakeholders.

- Cost Savings on Tooling: Rapid prototype injection molding is useful in revealing any issues that may be present before they are incorporated into the production tooling hence minimizing the chances of having to redo the tooling. This approach is proactive and results in a lot of savings in the long run as compared to the reactive approach.

Thus, the use of rapid prototype injection molding for the production of plastic parts not only guarantees the quality of the product and its marketability but also helps in the improvement of the product development process in terms of time and cost.

Material Selection Considerations in Injection Molding

Selecting the right material is very important in both prototype injection molding and production injection molding. However, they are allowed to use the same plastics provided they meet some factors. For example, glass-filled nylon material is good for production, but it wears out the prototype injection molds faster because it is abrasive. However, when it comes to the prototyping of a set of approximately 100 parts, wear is not as critical as when making 10,000 parts.

There is a difference between what is known as commodity plastics and engineering plastics in terms of the material used. Commodity plastics are cheaper than engineering plastics, but they may not have the same mechanical characteristics. For example, PEEK injectino molding, an engineering plastic material used in medical devices, is relatively expensive and may be available in low MOQs, especially if bought in large quantities.

If you are going to make a prototype that works like a real one, then you may use a cheaper material such as polyphenylsulfone (PPSU). However, it is worth mentioning that PPSU may be sufficient, but it may not challenge the moldability of your part to the extent that the intended production material is PEEK. Another option could be applying the method of additive manufacturing with the help of 3D-printing filaments of materials such as PPSU or PEEK. This method can be useful in cutting down tooling costs and enables the use of the preferred plastic material.

Thus, material selection is one of the most important factors that determine the success of the prototype and production injection molding processes and the cost of the final parts while meeting their mechanical requirements and moldability.

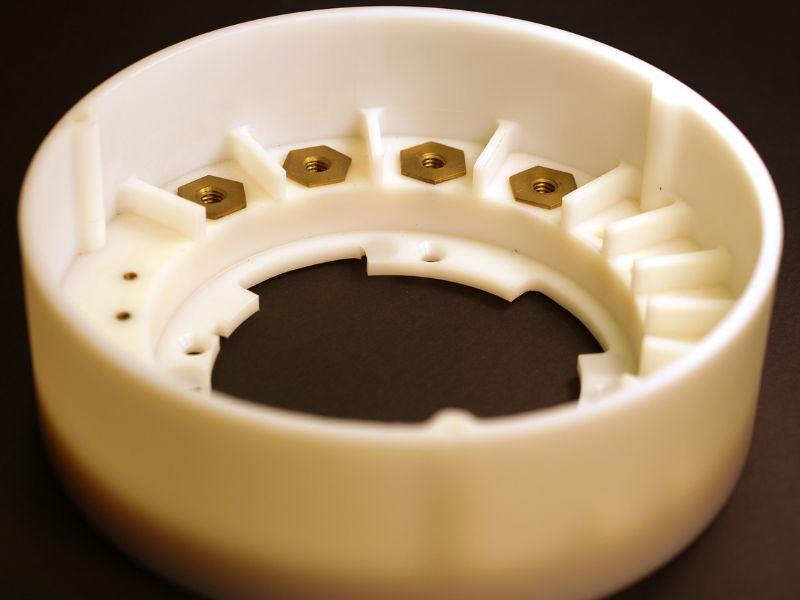

Comparing the Features of Prototype and Production Injection Molds: Steel Vs. Aluminum

The difference between prototype and production injection molds does not stop at the selection of metal only. Both of them can be made from aluminum or steel, but they differ in a number of significant parameters. One of them is the SPI (Society of Plastics Industry) mold class, with Class 105 designed for prototype production, which usually does not exceed 500 pieces. This classification system defines mold finish standards that are instrumental in mold performance and part quality.

In prototype injection molding, the emphasis is placed on the quality of the part rather than the durability of the tool. This is particularly important during FAIs to check if the parts have the required characteristics or not. While production injection molds focus on cycle time and tooling life, prototype molds focus on getting the best part quality even if it means losing some cycle time optimization.

On the other hand, production injection molds’ design and construction focus on such aspects as cycle time, part quality, and tooling life (cycles). These molds are designed to be used in high volume production with high-quality parts and little or no need for frequent replacement.

The decision on which injection mold to use, prototype or production, depends on several factors such as the application, quantity of parts needed, and quality. Every type of mold has its strengths and weaknesses, and it is important to understand these differences when choosing a mold for injection molding.

Contact SIncere Tech For Your Prototype Project

If you are seeking professional services in prototype injection molding, you can turn to Sinceretech. They have reliable manufacturing partners worldwide that focus on injection molding and provide services from concept to production. Sinceretech offers many services, such as 3D printing and injection molding, so you can select the appropriate process depending on the development phase. This integrated approach leads to efficiency in the production process since it can be used to create complex parts, for instance, prototypes, with a lot of speed.

Leave a Reply

Want to join the discussion?Feel free to contribute!