PEEK Plastic Injection Molding

PEEK Plastic Injection Molding: Applications, Advantages, and Your Trusted Partner

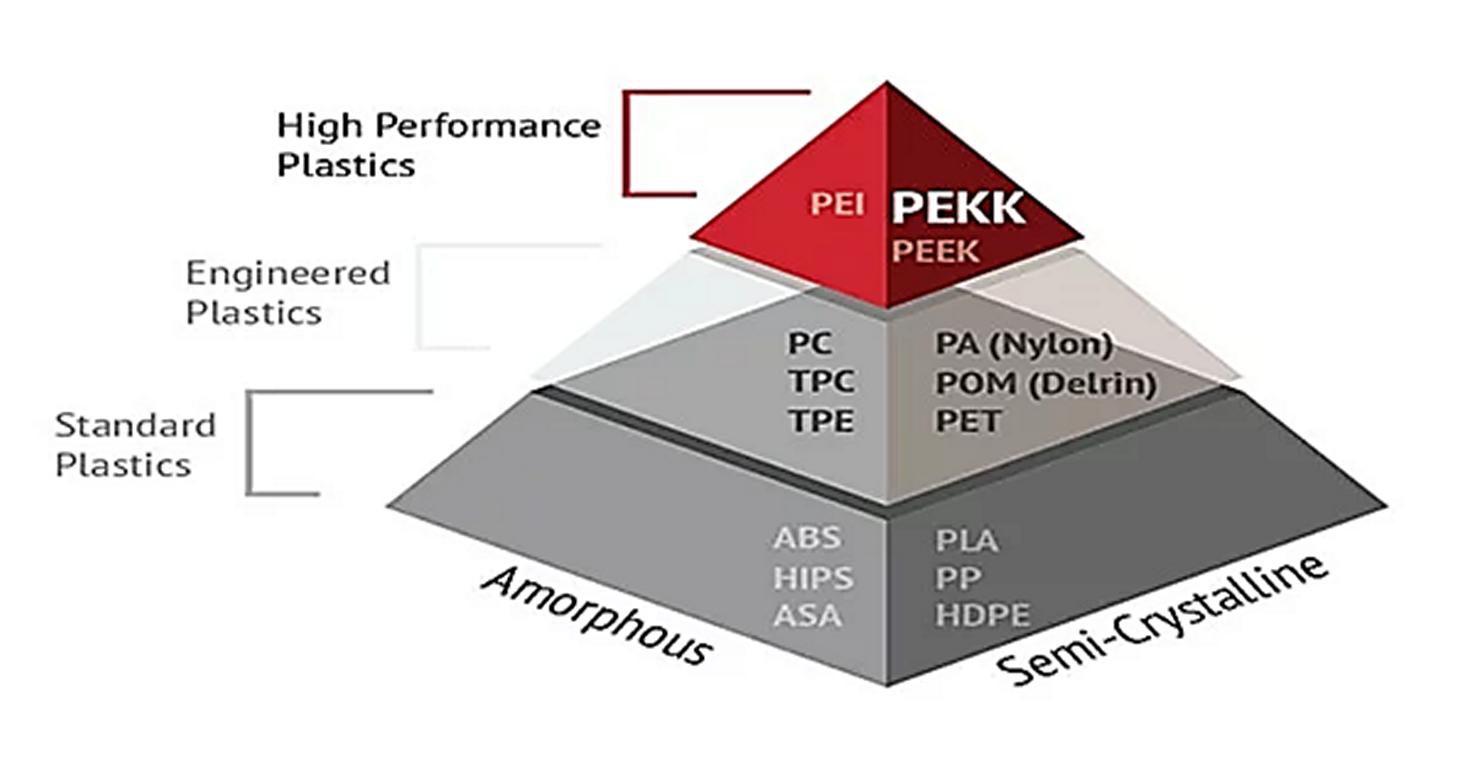

Without any doubt, PEEK (polyether ether ketones) is the best plastic on the market right now. PEEK platic injection molding is unique because it is powerful and able to stand up to high temperatures and harsh chemicals. Another thing is that PEEK injection molding part does not break into any kind of dimension stability. With its unique and connecting semicrystalline thermoplastic structure,

PEEK outperforms all other organic materials when it comes to making parts that can withstand extreme circumstances. The people who want to use PEEK injection molding technology in their next initiative. Plasticmold.net has a counseling service tool that we made as a way to work together on our injection molding PEEK skills. Learn more about this amazing material, find new ways to fill in the gaps, and enjoy the progress you make with your products as you use the power of PEEK injection molding.

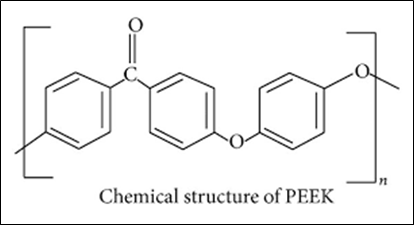

What is PEEK Plastic?

Since PEEK plastic (melting point: 343 °C) is a semicrystalline thermoplastic well known for its strength, high-temperature resistance, and chemical inertness with the chemical formula (C36H26O11), which makes it an ideal material for the production of implantable medical PEEK injection molded devices. The molecule can be described by the intriguing molecular structure that has alternating ether and ketone groups, which account for all the marvelous properties. As a general-purpose universal material with high strength and temperature ranges from -196° C to 260° C. PEEK injection molding part is widely used in aerospace & mining and the oil & gas industry.

PEEK’s History and Development

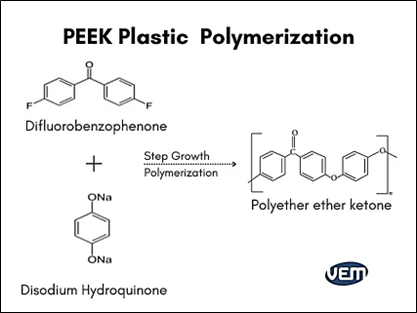

In 1970s, Victrex plc made PEEK a plastic that was capable of holding up to high temperatures and harsh conditions. Since then, there have been huge improvements in how PEEK is made that leads to several steps with unstable properties. PEEK plastic material is made by Step growth polymerization which changes the chemical structure of bisphenol’s salts by alkylating them with alkali carbonates. This process gives PEEK plastic its unique qualities, which make it a useful material for many applications.

Categories OF PEEK material At a Glance:

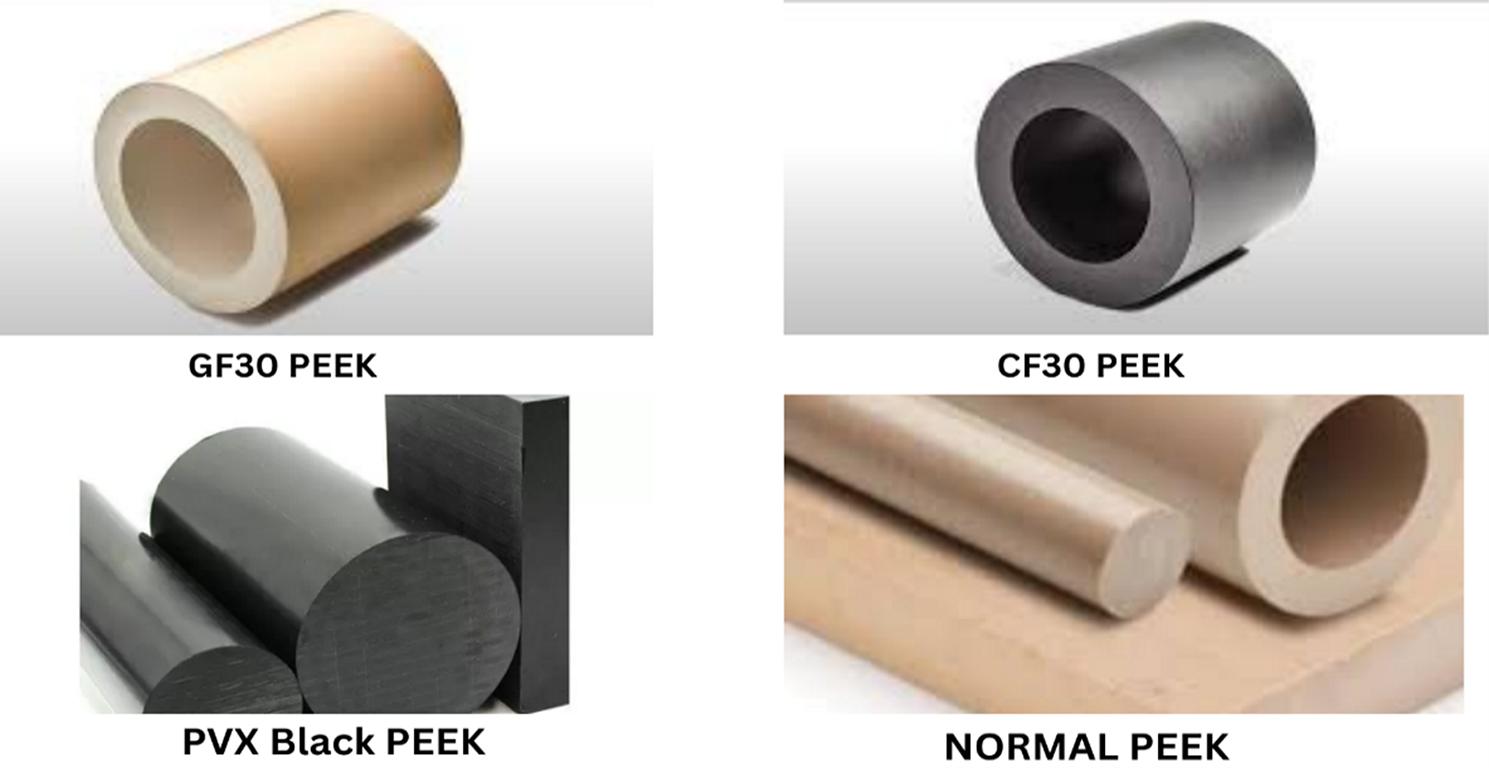

These are several variations of PEEK material:

Normal PEEK:

It is made from solid and heat-resistant materials that resist corrosion agents. Its exceptional properties will work best for surge parts such as brake drums.

GF30 PEEK:

plastic molding part made in PEEK reinforced with 30% glass fibers increases strength, stiffness properties and dimensional stability. It is best for cases that require high resistance to loading. (It is slightly less chemically resistant than the others and has more abrasiveness.)

CF30 PEEK:

PEEK with 30% carbon fibers supports joints with higher strength, excellent stiffness and overall light weight. It is appropriate for demanding load bearing applications that will perform well with the best that engineering can achieve at a slight exchange in brittleness (more expensive but less ductile).

PVX Black PEEK:

Probably a PEEK-PTFE-graphite-carbon fiber, this material shows excellent bearing performance with low friction and durability.

Introduction to PEEK plastic Injection Molding

PEEK plastic injection molding is a manufacturing process that combines heat and pressure to transform PEEK resin into components of highly durable precision and complexity. Under a controlled set of temperatures, PEEK granules reach the melting point, which is then cooled and solidified into a mold cavity. The temperatures in injection molding PEEK produce perfect pieces that, besides good dimensional stability, have excellent properties.

Advantages of PEEK Injection Molding

PEEK injection molding has many advantages over conventional thermoplastics as far as these materials are concerned, and you will understand its value once you see its application in different fields. Let’s explore some key benefits:

Strong and durable:

PEEK plastic injection molding part is solid and durable. Its strength allows it to bear the loads in high-stress conditions.

Chemical Resistance:

The high-impact PEEK molded part is known for its superb chemical stability and is usually used in applications that deal with harsh conditions such as solvents, acids and bases.

High-Temperature Performance:

PEEK injection molding product is heat stable and it may be tested at temperatures as high as 500°F (260°C) for a short amount of time.

Biocompatibility:

PEEK molded part is defined to be biocompatible, which is why it is used a lot when manufacturing medical devices and implants that usually come into close contact with human body cells.

Dimensional Stability:

Because PEEK injection molding parts do not shrink or bend much during processing. It is possible to make very precise and high-quality injection molded parts that remain exactly the same size.

Lightweight:

PEEK molded part has a unique weight-to-strength ratio that lets manufacturers make parts that are lighter than similar products without reducing their quality. This is the main reason why PEEK is the best choice for businesses that want to make their projects lighter.

Versatility:

PEEK can be used for a variety of purposes due to its wide range of qualities that are specific for different applications. To cover a wide range of uses it can also be polished, colored and CNC-ed.

Cost-Effectiveness:

Initially, PEEK resin may be more costly than other conventional materials, but its long lifespan, low maintenance cost and outstanding durability later contribute significantly to the overall cost savings.

Applications of PEEK Plastic Molding

A lot of different types of businesses use PEEK injection molding as their main source because it has a lot of different properties. Some well-known ways to use PEEK are listed below:

Aerospace Components:

The PEEK material is light, does not melt at high temperatures and does not catch fire. It can be used in rocket engine parts, space suits and other space related applications.

Automotive Parts:

The main things that make PEEK injection molding the best material for vehicle parts like bearings, pistons and seals are that it does not break down easily and does not change temperature easily, there are lot of parts made by PEEK CNC machining process.

Medical Devices:

Medical grade PEEK injection molding is safe for all medical devices, surgical tools, and sterilization plates because it has good qualities like not being biocompatible, being resistant to chemicals and being able to be sterilized.

Oil and Gas Equipment:

PEEK Plastic Molding is known for not changing its shape when working with harsh chemicals and high temperatures. These qualities make it a good material for creating parts for machines used in oil and gas.

Electronics and Electrical Components:

PEEK plastic injection molding is beneficial for electrical links and high-performance circuit boards because it is electrically insulating and also does not change size or shape.

Industrial Machinery Parts:

PEEK injection molding process is used in gears, bearings, and other industrial parts because it does not break down easily and can handle high temperatures.

Food Processing Equipment:

Chemical resistance and heat tolerance for particular grades of PEEK meet the food contact legislative standards and therefore some grades are generally used to produce injection molding parts for food processing equipment.

Semiconductor Manufacturing:

PEEK is commonly used in the electronics industry because it stays the same size and does not melt at high temperatures, making it ideal for jigs and fixtures.

PEEK Injection molding: Considerations for Success

Several factors need to be considered before PEEK plastic injection molding can be successful:

- Controlling the temperature is important for making sure that things last and prevent anything from going bad.

- Molds must be made of materials and designs that resist high temperatures and work well during the process of filling, cooling, and ejection.

- Injection molding tools need high-pressure injections, a lot of impact strength and a lot of heat energy.

- Injection molding tools need high-pressure injections, a lot of impact strength and a lot of heat energy.

- Before drying PEEK granules, make sure the joints are smooth, the parts don’t make noise and the cleaning processes are complete.

- Post Molding operations machining, polishing and metalizing improve the finish and usefulness of a surface.

- Quality control is very important for important designs because it makes sure that measurements are correct, and that the product works well and is safe.

The Right PEEK Injection Molding Partner

If you want success in your PEEK molding plan, you have to choose the right partner. Here are some factors to consider:

Evaluate Experience and Expertise:

Your potential partner should understand the material you use, you should not just rely on how well he has done in the past with PEEK plastic molding.

Assess Quality Control Measures:

If you have a partner who helps with the designs and prototyping for injection casting you can be a part of the whole process. Because it takes less time to sell to end users.

Consider Design Assistance and Prototyping Capabilities:

If you have a partner who helps with the designs and prototyping for injection molding, you can be a part of the whole process. Because it takes less time to sell to end users.

Compare Pricing and Turnaround Times:

You should call a lot of possible partners and ask them for their prices. Then make a chart comparison of their prices and response times to help you find a solution or partner that you can afford and that fits your project schedule.

Customer Service and Communication:

Find a partner who values good conversation and is aware of all of your concerns and questions.

PEEK Molding with Plasticmold.net

Plasticmold.net fulfills more than just product specifications. We provide a wide range of services to guarantee the success of your project:

Dedicated to Quality:

We never give up on our goal of making precise PEEK molded parts. We do this by putting our products through strict quality checks and using the most up-to-date inspection tools.

Advanced Technology and Expertise:

To achieve the best performance our lineup of cutting-edge injection molding tools can handle all kinds of PEEK processing.

Design and Prototyping Support:

Our service includes helping you create the best injection molding method for PEEK molding and testing prototypes to make sure the final product works before full-scale production starts.

Timely Delivery and Competitive Pricing:

We are able to meet the project delivery deadline and our pricing models are unbeatable.

Exceptional Customer Service:

Plasticmold.net is trying to make a change that will have an impact on our world and on future generations. During this process, we always keep conversation at the top and are open and honest with our clients.

When you use PEEK plastic molding, you can do a huge number of high-performance things. Plasticmold.net wants to give you the tools and information you need to get the most out of PEEK. Our engineers do a wide range of work including tilting parts for aerospace, medical equipment and industrial equipment. We use PEEK injection molding technology for design, testing and mass production. Our high-precision service makes sure that the quality of the injection molded parts is always the same. Contact us at Plasticmold.net.

The Future of PEEK Injection Molding Technology

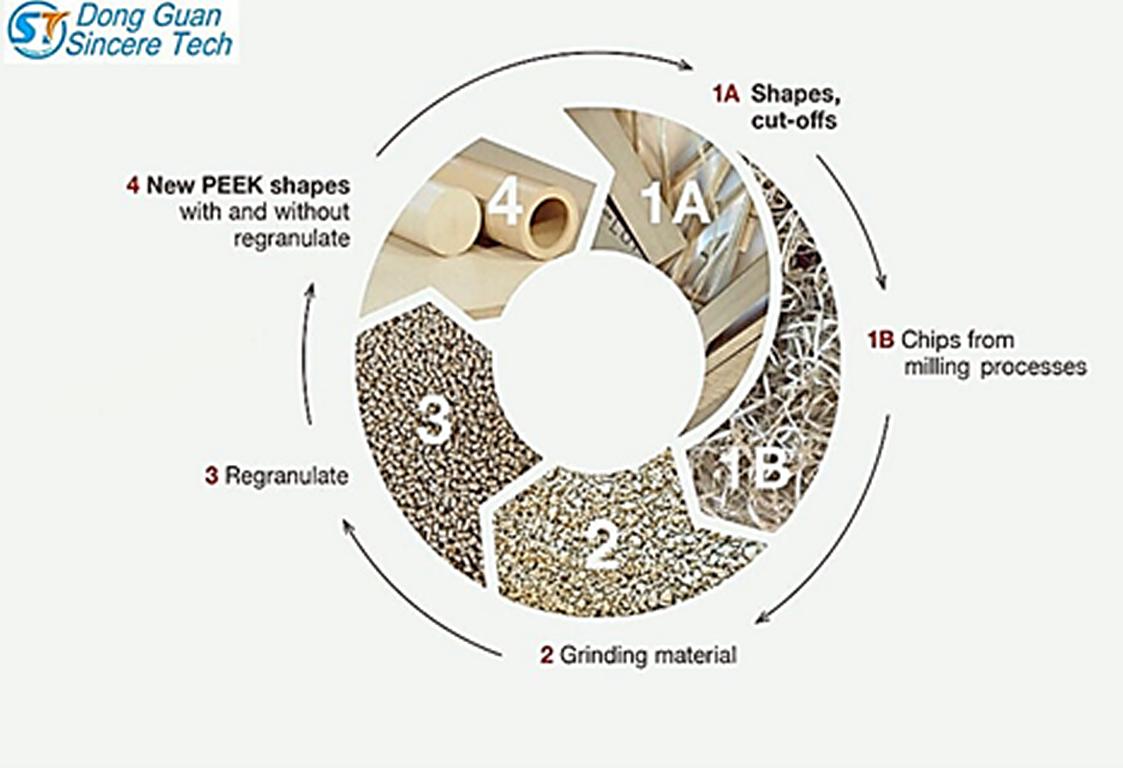

PEEK injection molding is going to do very well in the future! New and better materials, hot new techniques (like multi-material molding and conformal cooling), a focus on sustainability (like bio-based PEEK and efficient recycling) and even the addition of 3D printing will all lead to great results in injection molding design.

FAQ’s:

1. Why Plasticmold.net for PEEK Injection Molding?

Ans: Top-quality PEEK parts, expert team, design & prototyping support, competitive pricing and exceptional service. Contact us for a successful PEEK injection molding experience

2. In which instance does the injection molding PEEK possess some limitations?

Ans: PEEK has got a number of benefits, but it also has some limitations. For example, its initial cost is usually higher when compared to some types of conventional plastics, and it implements a special processing machine and expert molding to be successful at the process.

3. Is there any substitute for PEEK injection molding available?

Ans: The alternatively used materials such as a high- performance grade nylon, PEI (polyetherimide) and PPS (polyphenylene sulfide) might also be considered depending on the application requirements. On the other hand, these materials may not be able to sustain such outstandingly high characteristics of the PEEK material.

4. What is the minimum time required for PEEK injection molding?

Ans: The PEEK molding lead time may differ for each part, following the complexity, requirements of mold design and production volume. Usually, the line of a mold is followed by a sequence of masses production.

Conclusion:

PEEK injection molding is a new choice that solves problems in tough situations. The combination of toughness, chemical resistance, rough wear resistance, and high-temperature resistance makes this type of material unbeatable. Plasticmold.net provides the necessary information to study PEEK’s properties and to be processed in a complicated way. Additionally, we provide a full range of services to make things out of PEEK, including help with creation and small- and medium-sized production runs.

Our team of experts uses cutting-edge technologies and provides reliable quality assurance to make sure that all of our PEEK plastic injection molding parts meet your specific needs. You are already imagining yourself working with PEEK. Contact us right away at Plasticmold.net.