Mold Flow Analysis Report

What is mold flow analysis report?

Mold Flow Analysis (MFA) is a simulation tool that is used to predict and optimize the flow of plastic resin in a mold during the injection molding process. The simulation takes into account the properties of the resin and the geometry of the mold, and predicts the behavior of the plastic as it fills the mold and cools.

Mold Flow Analysis report can help to identify and solve potential issues with the injection molding process, such as short shots, warping, weld lines, air traps, sink marks, etc. Mold Flow Analysis report can also be used to optimize the injection molding process by identifying the best location for gates and runners, determining the optimal injection speed, and predicting the best cooling time and temperature. This can help to reduce cycle time, improve part quality, and increase production efficiency.

Mold flow analysis report

Mold Flow Analysis Results Summary

Once we have finish the mold design, before starting mold manufacturing, to make sure that everything is no problem, we need to do the mold flow analysis to check potential issues, this is safety way to avoid mistake, specially for the big molds. below are some point that we need to check when doing mold-flow analysis report.

Mold Fill Time – Fill time is the time required to fill the part cavity. The fill time plot also provides an animation of the mold cavity filling. The fill time can also be controlled during the analysis to resolve quality issues such as high shear stresses.

Injection Pressure – A standard injection molding machine is capable of pressurizing the melt flow to 20,000 psi (2,000 psi hydraulic gage pressure). A portion of the pressure is used to push the plastic through the runner system, some of the pressure is used to push the plastic into the mold cavity, and a portion of the pressure is used to “pack out” the part after it is filled. If the part and runner system require more pressure than the machine is capable, than the part will be a short shot or have deep sink marks.

Weld Lines Defects – Weld lines are formed when two flow fronts meet and “weld” together. Weld lines are usually a visible line on the part and can be an appearance issue. Weld lines may also reduce the part strength by 10% – 20% potentially creating a structural issue depending on their location. If mold flow analysis is not used to fix these problems before the tool is built, the molder will be forced to: increase injection pressure, increase melt temperature, increase mold temperature, enlarge vents, change the gate location and/or alter the thickness of the part. All of these “solutions” take time and money to implement and/or increase the cost of the part.

Air Traps Defects – Air traps are formed when the molten plastic traps air in the part cavity as it fills. If these air traps are not vented, they can lead to quality problems such as burn marks, short shots, pronounced weld lines and incomplete fill. Our air trap plots allow the toolmaker to know exactly where the vents need to be placed when the tool is built. Air traps that are in locations that are difficult to vent can be moved to better locations by moving the gate. Doing this work before the tool is built can save on the amount of debug and mold changes that are required.

Quality – The definition of a quality molded part is not only that the part filled completely. A quality molded part must also be free of material degradation and low in molded in stress. The quality plot shows the severity and areas that are suffering from quality problems. The problems detected include excessive shear stress and shear rate, and hard to pack areas. Suggestions like thickness adjustments, processing condition changes and fill time adjustments can be tried to eliminate the quality issues.

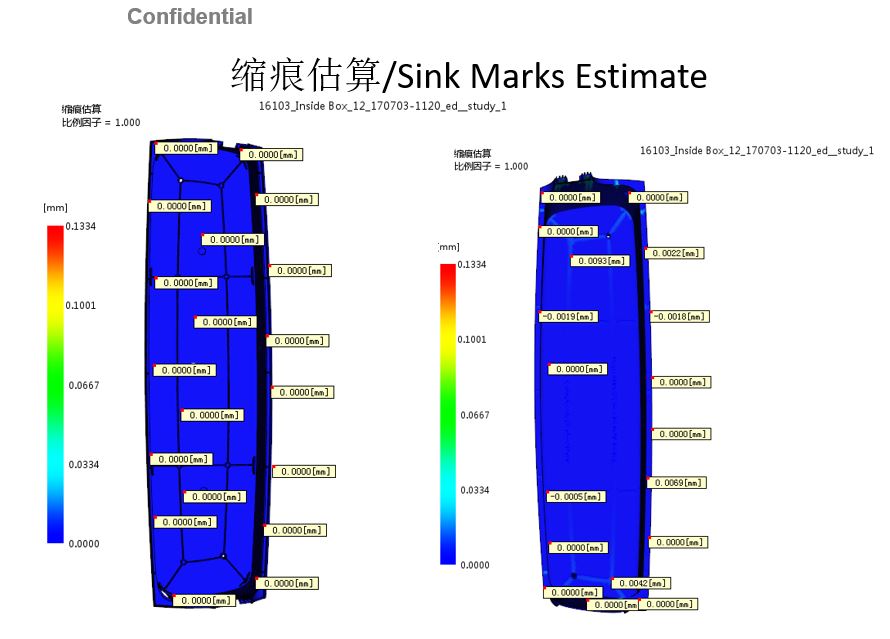

Sink marks Defects – Sink marks are localized depressions in the surface of injection molded parts caused by a non uniform shrinking of the plastic during the cooling. In cosmetically critical parts, they can be a serious problem. Sink marks often come as a surprise when the tool is complete. If the sink marks are objectionable to the customer, the molder is often tasked with “eliminating them”. This usually means running the molding machine at the extremes of the process window, which can lengthen cycle times and increase the amount of molded in stresses and material degrade.

Cooling Time – It has been shown that cooling time averages about 50% of the molding cycle. If the material in use is a commodity resin, the molding cost far outweighs the material cost. In this case, a reduction in cooling time has a big reduction in the part cost. Our Cooling Analysis can reduce your cooling cycle and optimize your cooling system eliminate hot spots and warpage.

MFA is a powerful tool that can help to improve the efficiency and quality of the injection molding process, by simulating the behavior of plastic resin as it flows through the mold and cools. It helps identify potential issues and optimize the process to minimize defects and improve the final product quality.

We do mold-flow analysis for your project

If you have a project that have many worries, please contact us, we will check all of your part drawing and make DFM report and moldflow analysis for you, and summarize all of possible issue in the datasheet and sent back to you.