Metal Injection Molding China

How Metal Injection Molding Transforms Manufacturing?

The equilibrium of Metal Injection Molding turns manufacturing process into another thing altogether. It’s a game-changer. This blog focuses on its effects on efficiency, accuracy, or even the expenses involved. Expect insights and opinions. Ready to transform? Let’s begin.

What is Metal Injection Molding?

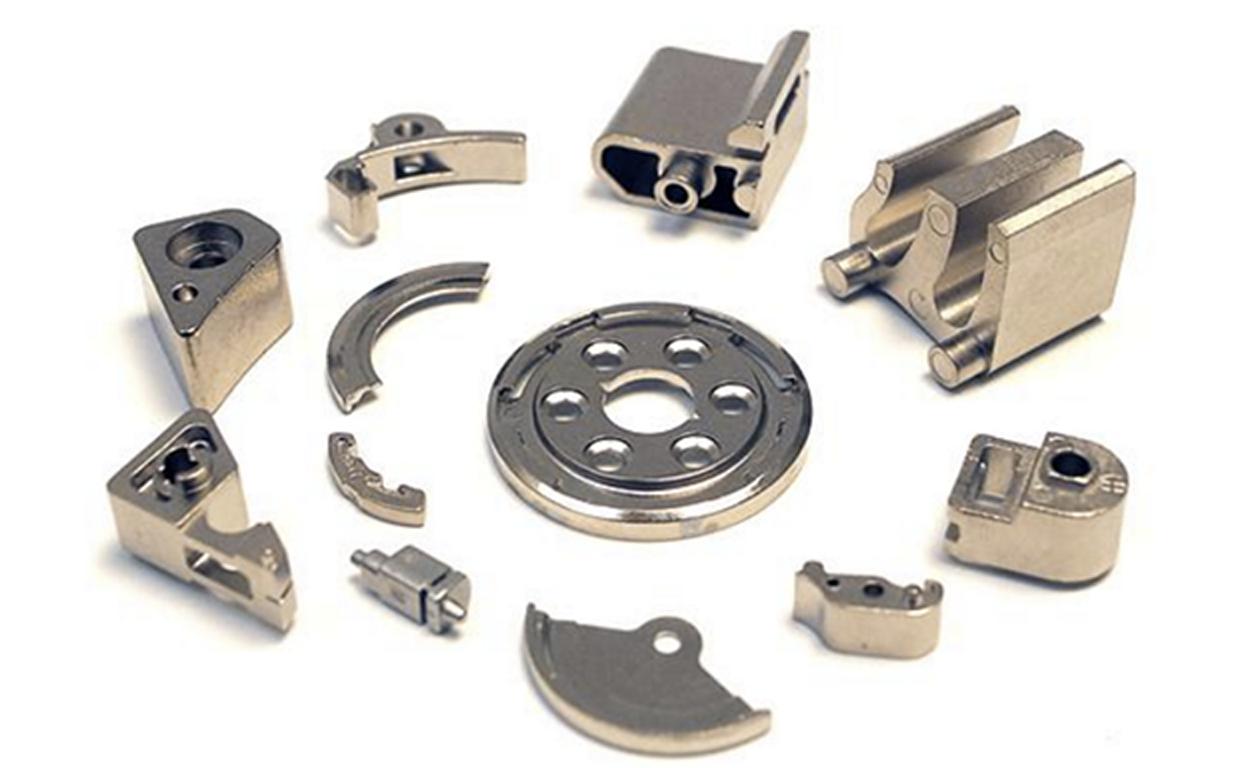

Metal Injection Molding (MIM) is a process of combining metal powder and binding material. The mixture is injected into a specific mold to take the desired shape.

Following molding, the binder is eliminated by a process known as debinding. The debound part is sintered at a high temperature. This means that one gets a highly compact and strong metal part. MIM is suitable for complex shapes such as gears, connectors, and housing components that are made in metal alloys.

Conventional powder size usually varies between 2 and 20 microns. Metal injection molding components can have high tensile strengths and complicated shapes.

How Does the Metal Injection Molding Process Work?

Mixing

Metal Injection Molding process involves the blending of fine metal powders and polymer binders. The blend achieves homogeneity. Common particle range is between 2 and 20 microns.

The binders are waxes and thermoplastics. This combination results in a molding feedstock. The feedstock viscosity is especially important when molding.

Uniform particle distribution is beneficial as it ensures the properties possess consistent characteristics. The mix is then subjected to granulation to enable injection. Each process leads to an equal end result.

Injection Molding Processing

In Metal Injection Molding, the metal feedstock is first heated and then injected into the metal injection mold cavity. This is because the mold cavity defines the shape of the metal part.

They are optimized for the flow and fill injection pressures. This process creates green parts. Mold temperature management is critical in determining precise solidification.

The green part maintains the geometry that is intended. The design of the mold plays a significant role in the quality of the part. It is linked to further processing through metal injection mold technology.

Debinding

In Metal Injection Molding, debinding eliminates polymer binders from green parts. Two popular techniques for debinding are thermal and solvent methods, which efficiently remove the polymer binders from the green parts. The process makes certain that the distortion margin is kept to the bare minimum. If debinding is done correctly, there will be no flaws in sintering.

It was observed that the binder removal rate affects the achieved density. Debound parts, known as brown parts, still retain their delicate nature. This step prepares parts for sintering. All steps preserve dimensional homogeneity.

Sintering

In Metal Injection Molding, sintering is the process of densifying brown parts with the use of temperatures. Humidity levels come close to those of melting.

Controlled atmospheres prevent oxidation. The process results in high tensile strength.

Shrinkage is generalized, preserving some measure of precision. In general, grain growth improves the characteristics of mechanical properties in metals. This step cements the shape of the final part. All the process stages are linked to quality.

Quality Control

In the context of Metal Injection Molding, quality control is a process that aims to guarantee that parts are manufactured to the required standard. Dimensional checks verify accuracy.

Mechanical tests determine tensile and yield strengths. Microstructure analysis examines presence and size of grains. Surface inspections detect defects. They all go through the extremely critical scrutiny.

Statistical process control ensures that there is a set pattern. This step is critical in ensuring that the final product is reliable and performs optimally. There is one common thread that links all process stages: China metal injection molding quality.

| Process Step | Temperature (°C) | Pressure (MPa) | Key Materials Used | Typical Time (mins) |

| Mixing | Room Temp (25) | 0 | Metal powders, Binders | 30 |

| Injection Molding | 120-200 | 50-100 | Feedstock | 2-5 |

| Debinding | 200-400 | 0 | Solvents, Thermal energy | 600-1440 (10-24 hrs) |

| Sintering | 1100-1400 | 0 | Inert gas, Vacuum, Hydrogen | 240-720 (4-12 hrs) |

| Quality Control | Room Temp (25) | 0 | Testing equipment | Variable |

Table on How the Metal Injection Molding Process works!

Why Choose Metal Injection Molding Over Traditional Methods?

Precision

Metal injection molding (MIM) provides dimensional accuracy in the range of ±0.005 mm. This makes it possible to produce very delicate gear shafts. It helps in manufacturing complicated valve parts.

MIM (metal injection molding) produces miniature medical plastic parts. The accuracy of dental braces cannot be paralleled by any other device in the market. Connectors are used in aerospace need to meet certain standards.

Metal injection molding creates identical metal parts for electronic devices’ shells. All the components conform to automotive specifications. Precision watch components are created. MIM always provides quality surgical instruments.

Cost-Efficiency

Metal injection molding is very advantageous in terms of waste minimization as compared to other conventional techniques. This method enables the manufacturing of fuel injector nozzles effectively. It reduces the need for further processing of turbine blades.

MIM reduces the cost of small mechanical gears. Large quantities of electrical contacts are relatively cheap. It reduces cost for housing of advanced sensors.

Metal injection molding improves material utilization concerning pistons. The process reduces the overall cost of manufacturing dental brackets. It saves on complex hinge parts.

To save more cost with metal injection molding parts, find metal injection molding China partner will be one of the best option to support your project, if you are looking for China metal injection molding manufacturer, you are welcome to contact us, we will send you a price in 24 hours.

Material Versatility

Metal injection molding is a process that involves the utilization of stainless steel. It is capable of processing tungsten carbide effectively. Cobalt-chromium alloys are not a problem for MIM.

Titanium components can be easily manufactured. This method shapes superalloys. It forms intricate forms of magnesium. MIM can handle a wide range of aluminum alloys.

It produces precision zirconia ceramics through the process. MIM produces Inconel parts with superior functionality. Various materials improve flexibility in aerospace in different ways.

Strength

The process of metal injection molding further improves the strength of the components. It manufactures tough firearm parts. MIM is used to produce long-lasting turbine blades. This method ensures the production of strong and durable automotive gears.

Durable medical implants are created. MIM produces high tensile watch parts. Safety and integrity of structures in aerospace parts are maintained. MIM produces hard precision tools.

Components withstand significant stress. MIM provides remarkable strength in the electronic connectors.

What Are the Key Applications of Metal Injection Molding?

Automotive

Metal injection molding accurately creates gear parts. It produces turbocharger vanes. MIM components include fuel injector nozzles. It also provides good mechanical properties. MIM provides complex geometries for sensors components. It allows for high-density transmission elements.

Metal injection molding can support complex design for ABS housings. It provides for high accuracy in the production of valve seats. The use of MIM improves the fatigue strength of the engine parts. It produces highly specialized locking devices.

Medical Devices

Surgical instruments are made by metal injection molding. MIM forms orthodontic brackets. It manufactures endoscopic instruments with precision. The Metal injection molding allows complex geometries in implantable devices to be realized. It can help to control the biocompatibility of bone screws.

High strength dental tools are provided by Metal injection molding. It manufactures accurate catheter tips. MIM can accommodate detailed work in orthopedic pinning. It helps to have fine detail in the microsurgical instruments. MIM holds high levels of precision for stent parts.

Consumer Electronics

Metal injection molding produces Smartphone hinges. MIM fabricates camera lens lids. It offers high precision with regard to the components that are used in the wearable device.

MIM forms intricate connectors. It provides rigidity to the laptop hinges. MIM has the potential to create complex shapes in gaming consoles. It gives high detail in the earbuds casings.

Metal injection molding accurately produces SIM card trays. It improves wear resistance in smartwatch components. MIM enables tight tolerances in battery connectors.

Aerospace

Turbine blades are made from metal injection molding. MIM produces fuel nozzles. It provides reinforcement to structural members. MIM creates geometrically accurate actuator parts. It delivers high-performance fasteners. Metal injection molding offers intricate shapes in sensor housing applications.

It can accommodate complex geometries for heat exchangers. MIM fabricates lightweight brackets. It improves the anti-fatigue performance of landing gear parts. Metal injection molding guarantees accuracy in navigation systems.

Defense

Metal injection molding produces firearm parts. MIM manufactures delicate trigger assemblies. It provides strength in weapon housings. MIM manufactures accurate optical sight components.

It delivers high-performance connectors. MIM is capable of handling intricate structures in missile components. It offers precision for radar components. MIM produces lightweight armor components.

It also improves reliability in communication appliances. Metal injection molding enhances accuracy in targeting systems.

How Does Metal Injection Molding Improve Product Design?

Design Flexibility

One of the features of metal injection molding is the possibility of molding complex shapes. MIM provides the ability to achieve high levels of accuracy for complicated contours. It supports innovative design features. MIM also provides fine surface finishes in terms of high details.

It enables undercuts and thin walls. MIM offers the ability to create lightweight structures that are strong. It also increases the complexity of multi-functional part designs.

MIM combines different sections into a single unit. It supports the downsizing of parts. MIM allows for a more accurate reproduction of designs.

Prototyping

Metal injection molding helps to get more prototypes in a shorter time. MIM has high accuracy for producing sample parts. It can accommodate constant changes of design. Metal injection molding also helps to minimize material wastage when it comes to the process of prototyping.

It guarantees the feature replication down to the finer details. By using MIM, functional testing of prototypes is made possible. It shortens development cycles.

MIM makes it possible to produce samples at a relatively low cost. It also guarantees proper assessment of the performance of different employees in the organization. MIM can help with design verification.

Customization

In metal injection molding, the part designs can be customized as per the requirement. MIM supports particular requirements of the application. It offers special geometrical properties. MIM offers the opportunity to control mechanical properties.

It also ensures that those complex assemblies are accurately fitted. MIM enables customization of individual parts. It accommodates varying material needs.

MIM caters for specific surface finish requirements. It can achieve desired thermal characteristics. MIM incorporates particular design components smoothly.

Performance

Metal injection molding contributes to improved part performance. MIM results in high strength-to-weight ratios. It guarantees enhanced mechanical characteristics. Metal injection molding is characterized by high fatigue strength. It can provide high-precision control in terms of dimensionality.

MIM enhances wear resistance. It keeps the material properties uniform. Metal injection molding improves thermal stability. It enables the creation of complex cooling channels.

MIM can support the best stress bearing. It improves the reliability of each part that is incorporated in the construction of a given product.

Durability

Through metal injection molding, durable parts are produced. MIM increases wear resistance to a substantial degree. It enhances corrosion resistance. Metal injection molding provides better mechanical properties. It supports high-stress applications. MIM also maintains constant material density.

It reduces failure rates. MIM enhances impact resistance. It supports extreme environmental conditions. MIM improves surface hardness. It increases part lifecycle by a large margin.

How Does Metal Injection Molding Enhance Efficiency in Manufacturing?

Streamlining Processes

Metal injection molding in fact combines several processes into one. MIM simplifies complex assemblies. It also has a potential to lowering machining needs greatly. In this case, MIM has the ability to achieve high levels of precision during the initial molding process.

It supports automated production. Metal injection molding realizes fine details without requiring secondary operations and manufacturing. It minimizes manual interventions. MIM assures the production of high quality of parts.

One of its benefits is that it brings down production cycle times. Thus, MIM optimizes manufacturing effectiveness in general terms.

Reducing Waste

Metal injection molding has a high material efficiency. MIM minimizes scrap generation. It produces near net shape parts. MIM reduces post-processing waste. It maximizes feedstock utilization. MIM assists with effective reuse of powder. It enhances environmental sustainability.

This way, Metal injection molding guarantees an adequate distribution of material in the process. It also reduces the amount of material, which has to be removed to achieve the desired shape. MIM lowers total cost of waste management.

Optimizing Time

They also reduce the production cycles through metal injection molding techniques. MIM also shortened lead times for intricate parts. It can effectively support the change of mold tools.

Making changes is easy with MIM. It minimizes setup times. MIM has fast production rates. It reduces waiting periods. MIM enables quick transfers of material. It enhances workflow efficiency. MIM enhances the total timeframe of manufacturing processes.

Labor Costs

Metal injection molding eliminates the need for hiring many workers during the production process. MIM does not support automated production lines. It minimizes assembly labor. MIM simplifies manufacturing processes. It brings down the need for skilled labor.

MIM enhances worker productivity. It decreases labor-intensive operations. MIM provides quality without having to inspect the part manually. It also fosters proper organization of manpower. MIM reduces total costs of direct labor in production.

How to Ensure Quality in Metal Injection Molding?

Quality Assurance

A material injection molding requires a high degree of quality assurance measures. MIM controls powder blend more accurately. It requires uniform feedstock properties. MIM employs sophisticated monitoring systems. It helps to set and maintain proper temperatures of the mold.

Metal injection molding can deliver high levels of dimensional tolerances. It employs statistical process control (SPC). MIM has stringent controls in its production process. It implements enhanced defect detection processes. MIM guarantees high-quality finished parts.

Testing

Metal injection molding goes through various phases of testing. Tensile strength tests are conducted by MIM. It performs hardness assessments. MIM utilizes X-ray fluorescence (XRF). It also helps in checking the composition of the material that is used. MIM conducts porosity analysis.

It checks for dimensional consistency. Thermal conductivity measurements are conducted at MIM. It evaluates fatigue resistance. MIM uses ultrasonic testing. It makes it possible to check the overall quality.

Inspection Methods

Generally, metal injection molding involves several inspection methods. MIM has adopted the use of coordinate measuring machines (CMM). It applies optical microscopy. MIM helps to produce parts with accurate measurements. It uses laser scanning. MIM engages in non-destructive testing (NDT).

It uses methods of visual examination. Automated inspection systems are used at MIM. It guarantees the surface finish. MIM performs batch sampling. It ensures quality is kept constant.

Certifications

Metal injection molding gets different certifications. MIM meets ISO standards. It obtains ASTM compliance. MIM follows FDA regulation for medical parts. It ensures RoHS compliance.

Metal injection molding complies with aerospace industry quality standard AS9100. It secures automotive IATF certification. It is important to state that MIM acts in accordance with environmental legislation.

It is for obtaining CE marking for European markets. MIM secures NADCAP accreditation for defense. It adheres to rigorous certification standards.

Industry Standards

Metal injection molding complies with the best practices of the industry. MIM follows MPIF standards. It meets ISO/TS requirements. MIM follows SAE standards to the letter. It maintains ASTM compliance. MIM follows stringent DIN norms. It guarantees JIS standards for Japanese markets.

Metal injection molding conforms to MIL-SPECs for defense. It complies with certain customer specifications. MIM identifies with international standards and practices. It retains high industry standing.

Why You Should Work with China Metal Injection Molding Manufacturers

China has emerged as a global hub for metal injection molding (MIM) manufacturing, and for good reasons. Businesses across the globe are increasingly choosing Chinese manufacturers for their expertise, cost-effectiveness, and state-of-the-art facilities. Here’s why working with metal injection molding China manufacturers can benefit your projects and bottom line.

1. Cost Efficiency

One of the most compelling reasons to collaborate with China metal injection molding manufacturers is cost efficiency. The country’s streamlined supply chains, lower labor costs, and competitive material pricing enable manufacturers to offer high-quality products at lower prices compared to many Western counterparts. These savings allow companies to allocate resources to other critical areas such as product development and marketing.

2. Advanced Manufacturing Capabilities

China has heavily invested in advanced manufacturing technologies, making its MIM sector highly competitive. Metal injection molding China manufacturers are equipped with cutting-edge machinery and automation systems that ensure precision and consistency in metal parts production. Many companies also have robust quality control processes that meet or exceed international standards, ensuring your products are reliable and durable.

3. Scalability and Capacity

China metal injection molding manufacturing ecosystem is designed for scalability. Whether you need a small batch of prototypes or mass production of millions of parts, MIM China manufacturers can handle varying levels of demand. Their ability to scale production quickly helps businesses meet market demands without compromising on timelines or quality.

4. Expertise and Experience

Over the years, China has developed a strong talent pool in MIM technology. Many China MIM manufacturers have decades of experience, producing complex and intricate metal parts for industries such as automotive, aerospace, medical devices, and consumer electronics. This expertise translates into optimized designs, improved functionality, and superior product performance.

5. Comprehensive Solutions

Chinese MIM manufacturers often provide end-to-end solutions, from design and prototyping to production and post-processing. Many companies also offer services like material selection, finishing, and assembly, reducing the need to work with multiple vendors. This integrated approach streamlines the production process and minimizes logistical complexities.

6. Compliance with Global Standards

Reputable Chinese manufacturers adhere to international quality standards such as ISO 9001, ISO 13485, and IATF 16949. Their compliance ensures that the products meet global requirements, making them suitable for export and use in regulated industries.

7. Shorter Lead Times

Despite geographical distance, many Chinese MIM manufacturers have optimized their logistics and production schedules to offer competitive lead times. With advancements in global shipping and supply chain management, businesses can receive their orders promptly without sacrificing quality.

8. Innovative Materials and Techniques

China’s MIM industry is at the forefront of material innovation. Manufacturers work with a wide range of metal powders and binders to meet specific application requirements, from stainless steel and titanium to exotic alloys. Their ability to adapt to emerging trends and technologies makes them an excellent choice for cutting-edge projects.

9. Partnership Opportunities

Collaborating with Chinese manufacturers often goes beyond a transactional relationship. Many companies focus on building long-term partnerships, offering flexible contracts and support for continuous improvement. This collaborative approach can drive innovation and foster mutual growth.

10. fast lead time

Working with China metal injection molding companies will make your project fast and high quality, becauaes the low labour cost so that makes Chines manufacutrers can work fast, we can make your metal injection molding project as fast as 3 weeks.

Working with China metal injection molding manufacturers can provide a host of benefits, including cost savings, advanced technology, and scalable production capabilities. Their expertise, commitment to quality, and integrated solutions make them an ideal choice for businesses looking to stay competitive in today’s global market. By leveraging their strengths, you can ensure high-quality, efficient, and innovative production for your metal components.

Conclusion

Metal Injection Molding revolutionaries the manufacturing. It is effective, accurate, and affordable compared to the traditional methods of data collection. We’ve explored its impact. Ready to innovate? Visit PLASTICMOLD. Learn how the manufacturing industry will evolve.