Caja acrílica personalizada y contenedores han recibido mucha atención en las actividades de almacenamiento, exposición y transporte. La capacidad de ajustarse en tamaño, forma y color es una característica que hace que las soluciones sean únicas para sus usuarios.

¿Cuál es el beneficio de tener una caja de acrílico diseñada más específicamente para su artículo en lugar de comprar una caja de stock o una caja hecha de un material diferente? En este artículo se analizan las ventajas del acrílico personalizado y cómo se puede utilizar, es muy duradero, muy bonito y relativamente barato. Descubra por qué el acrílico a medida suele ser superior a materiales como la madera, el metal o el plástico, deje que nuestros expertos se lo expliquen.

Durabilidad y versatilidad: Características clave de las cajas acrílicas

La alta durabilidad es una de las razones por las que las cajas expositoras acrílicas personalizadas

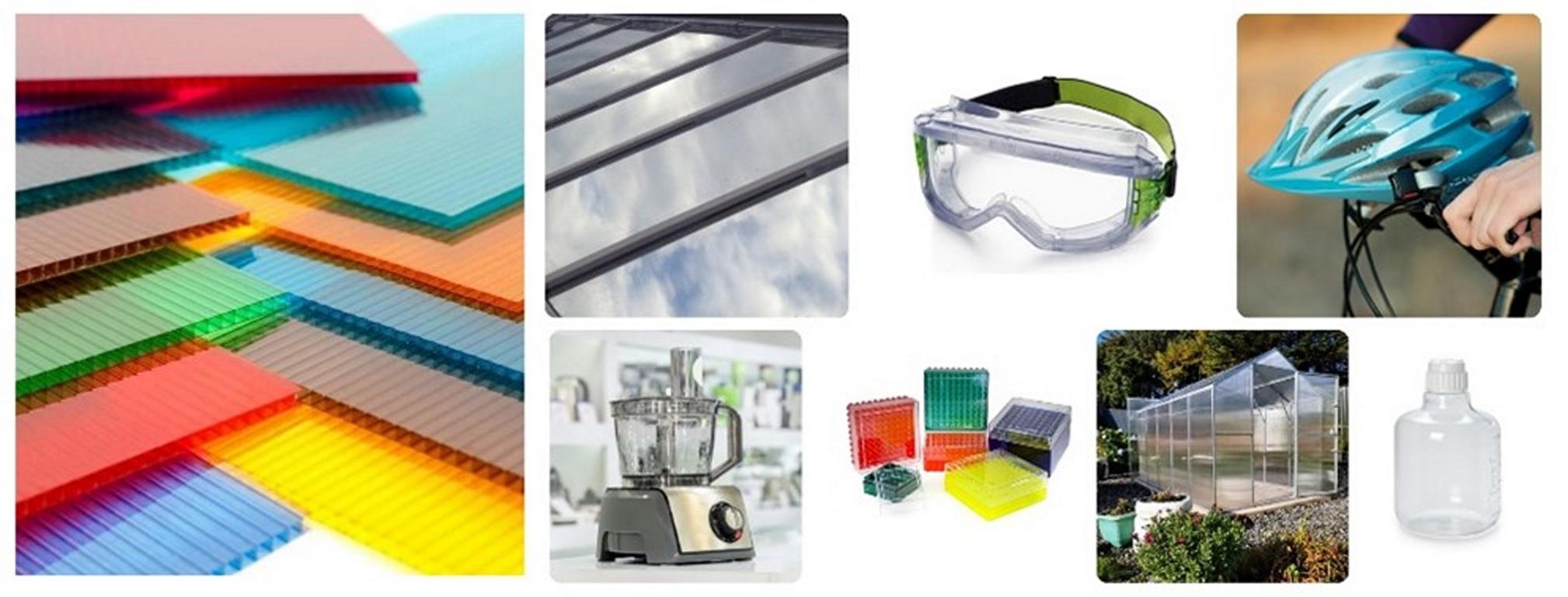

son cada vez más populares. Fabricado con metacrilato de metilo (PMMA), el acrílico es muy resistente a roturas y arañazos. Esta propiedad lo hace adecuado para proteger objetos de valor durante mucho tiempo.

En comparación con las construcciones de madera, cartón o vidrio, el acrílico es menos sensible a los impactos y golpes. Empotradas, las cajas acrílicas a medida fabricadas a partir de láminas fundidas son prácticamente invulnerables, por lo que su contenido está a salvo de roturas. Cuando se necesitan contenedores resistentes pero transparentes, las cajas a medida de acrílico son ideales.

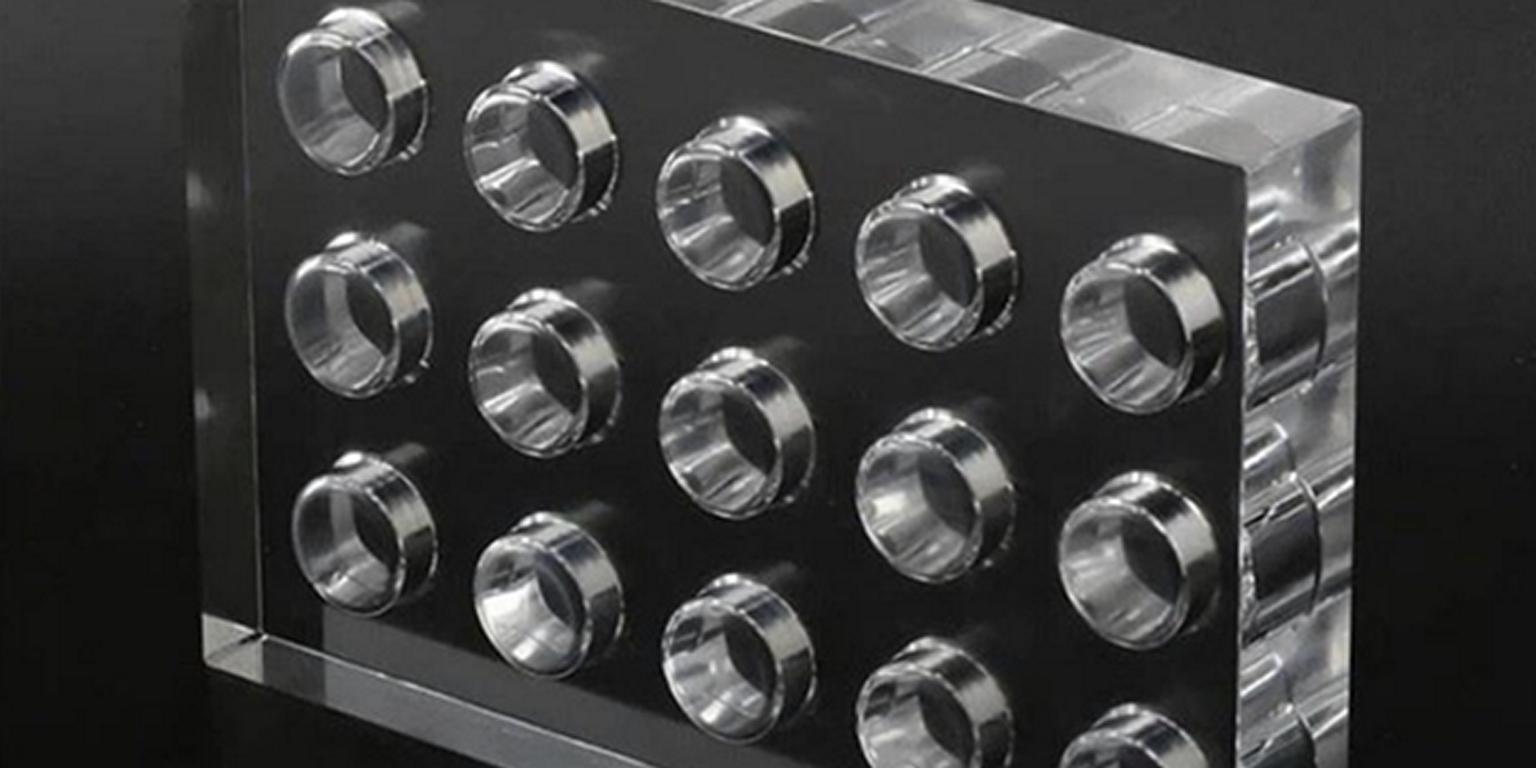

Además de la resistencia, la flexibilidad subraya el papel que desempeña el acrílico en la personalización de productos. Puede moldearse en una gran variedad de formas, tamaños y figuras con mucha facilidad. Tanto en cajas pequeñas como en grandes contenedores, el acrílico es adecuado para diversas aplicaciones de almacenamiento o exposición de artículos.

Tienen muchos usos, como la venta al por menor, los regalos, los escaparates, los museos y los laboratorios, entre otros. Los usuarios pueden cambiar el nivel de opacidad, los colores y el tipo de tapas y separaciones dentro del envase. Esta adaptabilidad también se ajusta a la estética personal o de marca.

Opciones de diseño a medida: Caja acrílica Diseño a medida

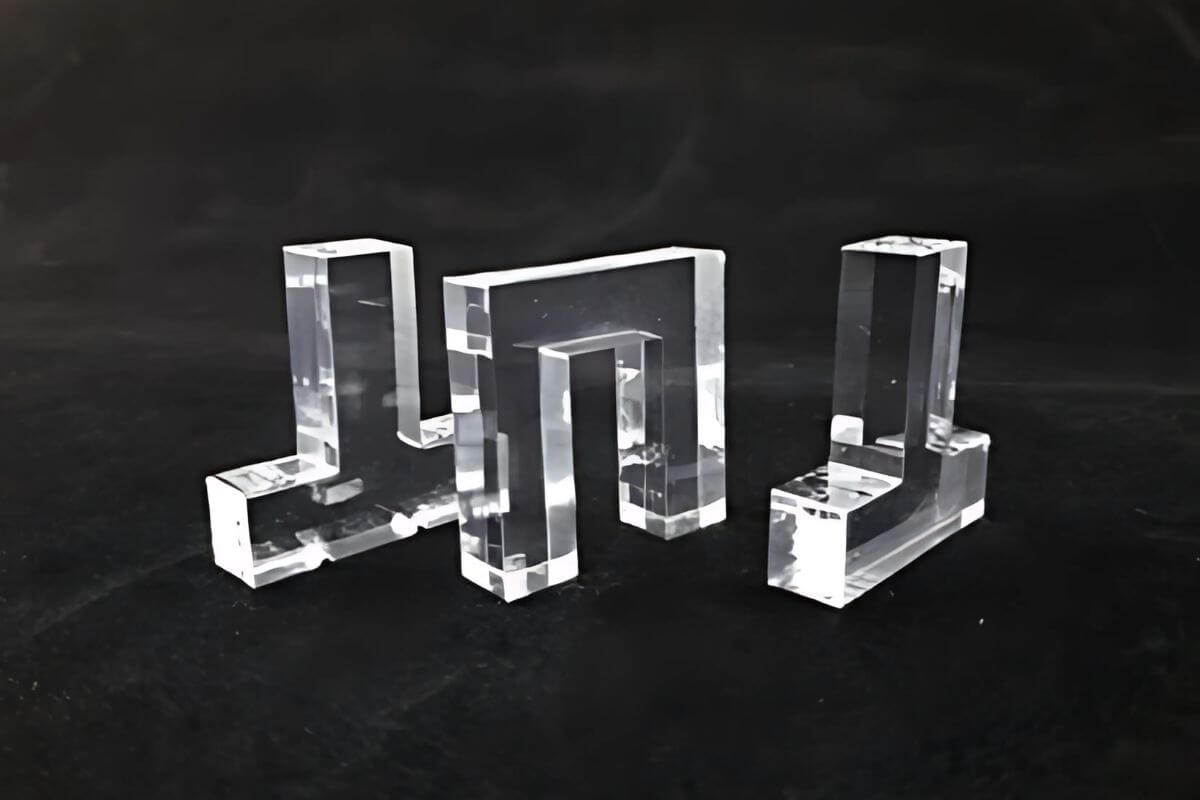

Una ventaja notable de estos cajas acrílicas personalizadas es que hay muchas opciones de diseño. Los clientes pueden elegir la forma, el tamaño, el color, el nivel de transparencia, el tipo de tapa y el propio diseño.

Además, las empresas pueden crear cajas acrílicas personalizadas con sus colores y logotipos que pueden utilizarse para ferias o publicidad. Una caja transparente con un logotipo grabado ofrece una solución de regalo corporativo profesional. En la aplicación personal, la personalización de los productos permite a los usuarios hacer recipientes para sus intereses, joyas o recuerdos, dando un aspecto personalizado.

Tapas a medida: Cree diseños únicos para sus cajas acrílicas

Hay muchas formas de personalizar las tapas de los recipientes acrílicos. Puede ser transparente o tener un color sólido, o también pueden hacerse diseños tallados en la tapa. Las cajas acrílicas personalizadas pueden mejorar aún más su aspecto añadiendo elementos como gráficos llamativos, diseños en 3D o grabados con láser. Los usuarios también idean insertos especiales que contienen bandejas, ranuras y rampas, dentro de los contenedores.

A partir de la rica variedad de opciones ofrecidas, los usuarios pueden construir cajas acrílicas únicas que encarnen a la perfección la marca específica y la visión personal del propietario.

Rentabilidad: Maximizar el valor

El acrílico es más económico que la madera o el metal para cajas y estuches. Seleccionar envases a medida hace que los costes del acrílico sean aún más asequibles.

Las cajas acrílicas a medida precisas no contienen dimensiones ni características adicionales. Los envases se diseñan para ajustarse al tamaño de la aplicación, de modo que no haya material ni costes innecesarios. Los diseños gráficos, incluidos los logotipos, cuestan menos cuando se hacen a medida que cuando se producen en serie.

El material utilizado en la fabricación del acrílico también aumenta su durabilidad, lo que se traduce en un mayor tiempo de servicio. Con un buen mantenimiento, estas cajas acrílicas personalizadas pueden durar hasta 20 años antes de ser sustituidas, a diferencia del plástico o el cartón.

Además, si se tiene en cuenta el ciclo de vida de las cajas acrílicas personalizadas, son relativamente baratas y ofrecen un valor excelente. Son más baratas que comprar puertas a medida de madera o cristal. Por lo tanto, para los usuarios preocupados por el precio, las soluciones acrílicas a medida presentan el equilibrio necesario entre rendimiento y coste.

Ventajas del acrílico: Mucho más que estética

El acrílico tiene innumerables posibilidades de diseño, por lo que supera a otros materiales en cuanto a estética. Sin embargo, no es solo la ventaja estética lo que ofrece.

Muy apreciado por su transparencia, el acrílico permite acceder cómodamente al contenido de la caja. A diferencia del uso de madera o plástico translúcido, que mejora la visibilidad del producto dentro de la caja.

Sin embargo, no es muy pesado para su robustez. Esta característica hace posible desarrollar contenedores personalizados grandes y portátiles para diferentes propósitos y usos, incluidos los kits de viaje. El acrílico también es menos propenso a agrietarse por las gotas en comparación con el vidrio.

Es un material versátil que se puede moldear fácilmente, lo que facilita hacer cambios que los metales o las piedras no permiten. Además, el acrílico es fácil de cuidar y no se raya con facilidad ni se oscurece con el paso del tiempo. Estas ventajas inherentes hacen que el acrílico sea el material preferido para los envases personalizados.

Aplicaciones reales: Cajas acrílicas personalizadas: Historia de éxito

La eficacia de cualquier solución reside en garantizar un rendimiento superior sobre el terreno. Las cajas acrílicas personalizadas demuestran sus ventajas prácticas a través de diversos casos de éxito:

Embalaje de regalo premium

Una marca de joyería había creado unas preciosas cajas de regalo de acrílico fundido transparente con su logotipo grabado en la tapa. Estas cajas se utilizaron para empaquetar sus collares de diamantes, especialmente su collar de diamantes más famoso, haciéndolo más lujoso y elegante para regalar.

Vitrinas de museo

Un museo de ciencias para niños tenía incluso cubos acrílicos transparentes de distintos tamaños para exponer las rocas minerales. Estas cajas acrílicas permitían ver los especímenes, pero también protegían los delicados artefactos del tacto de la gente.

Exposición de productos

Un minorista de electrónica ha revitalizado su oferta de teléfonos inteligentes con la incorporación de modernos soportes acrílicos hechos a medida tanto para los últimos modelos de teléfonos como para sus soportes. Las paredes transparentes y al mismo tiempo seguras hicieron que los clientes se engancharan fácilmente a los productos.

Diseño de envases para cosméticos

Una empresa emergente de cosméticos ideó unos envases acrílicos opacos de bonitos colores para contener su línea de lociones y bálsamos ecológicos. Este tipo de envase acrílico era adecuado para una marca centrada en lo natural y mejoraba el atractivo general.

Estos ejemplos muestran cómo pueden aplicarse las cajas acrílicas personalizadas en diversos contextos, ya que el objetivo principal es mostrar lo versátiles que son estas cajas. El número de aplicaciones que se han destacado demuestra lo versátil que es el acrílico.

Acrílico: La primera opción de la empresa para productos especializados

Entre las cajas, estuches y expositores acrílicos a medida, el acrílico se perfila como la opción más popular. Tiene las ventajas añadidas de unos costes más bajos y una adaptabilidad exquisita en comparación con sus equivalentes.

La selección de contenedores acrílicos personalizados permite a marcas y particulares satisfacer satisfactoriamente tanto los requisitos estéticos como los funcionales. Si busca estanterías especializadas para almacenamiento o productos de exposición, tiene sentido buscar soluciones acrílicas personalizadas.

Trabajar con un proveedor de acrílicos adecuado permite diseñar envases atractivos y muy utilitarios que representan la personalidad de las personas. Cuando se trate de estuches o cajas transparentes con el logotipo de una marca, deje que muestre un universo de oportunidades.

Las ventajas de las cajas expositoras acrílicas

Hay muchas razones por las que las cajas expositoras acrílicas son cada vez más utilizadas. Aunque cada característica es bastante obvia y fácilmente comprensible, aporta algo único. Ahora es esencial discutir estos aspectos con más detalle.

Exponga sus productos en cajas transparentes

Presenta tus cosas bonitas en recipientes de plástico transparente. Estos versátiles recipientes pueden contener piedras brillantes, flores, joyas y telas. Para darle un toque especial, puedes darle la vuelta a la caja y convertirla en un elegante expositor. Utilizadas sobre todo en eventos o ferias, estas cajas ayudan a mejorar la exposición de sus productos. Pueden utilizarse como un jarrón chic para las flores; basta con poner sus flores/velas favoritas en agua para realzar la belleza del espacio. Disponen de dimensiones personalizadas para que sus preciados artículos quepan de la mejor manera posible.

Cómo crear un elegante expositor apilable

Mejore su organización con modernas y bonitas cajas acrílicas. Apilar estas cajas unas sobre otras forma una bonita estructura cuando se exponen en mesas o estanterías. Este método no solo ayuda a exponer los objetos, sino que también aprovecha el espacio de forma ineficaz.

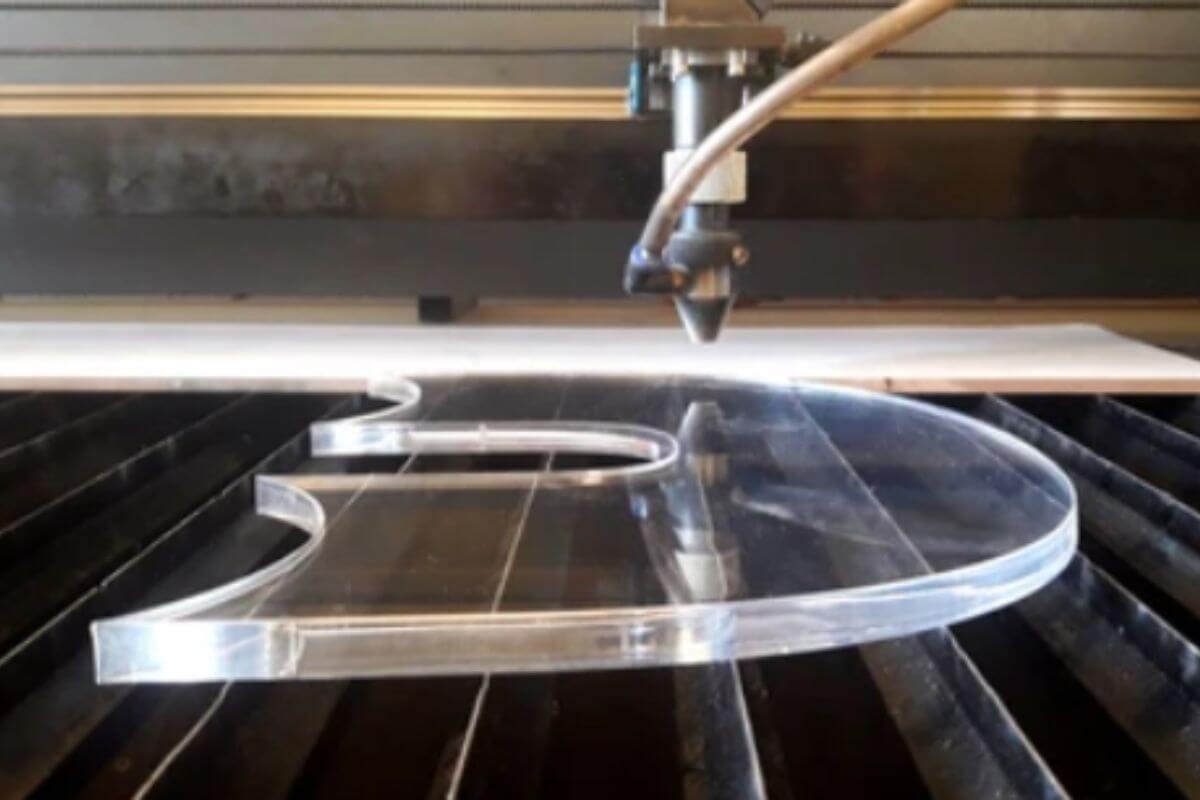

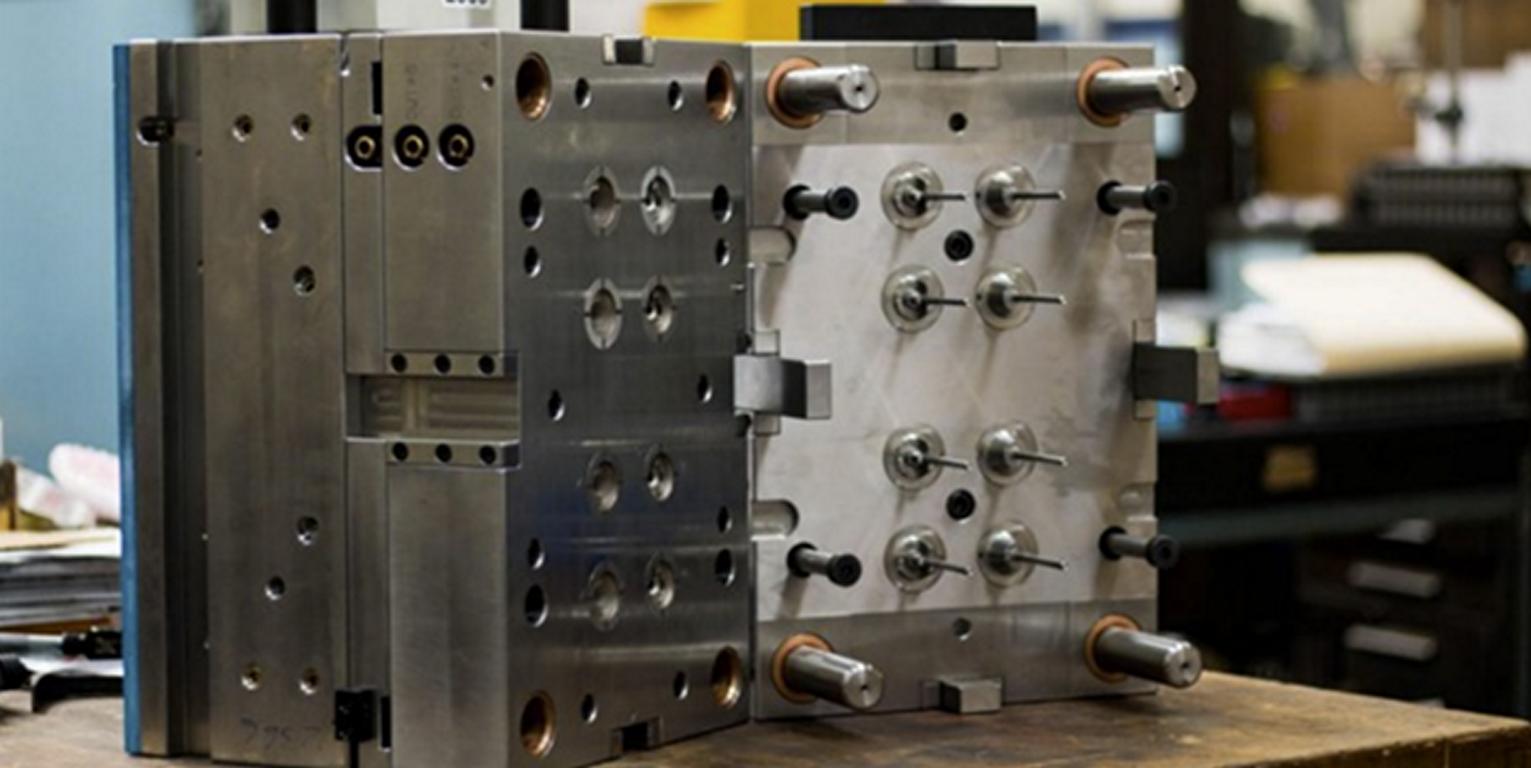

Hay muchas formas de hacer una caja acrílica, como por ejemplo moldeo por inyección de acrílico proceso, el proceso de corte por láser, corte más proceso de soldadura, blisting proceso de moldeo, moldeo por extrusión proceso de moldeo y así sucesivamente, cada proceso tiene sus propias ventajas y desventajas, es en función de su diseño de la pieza para seleccionar el priocess fabricación adecuada, si no está seguro de cuál es el mejor proceso para su parte de acrílico, que son bienvenidos a ponerse en contacto con nosotros, vamos a revisar su dibujo o muestra para ofrecerle la mejor solución.

Proteja sus objetos de valor

Además del valor estético de las cajas acrílicas, ofrecen el máximo nivel de seguridad para sus valiosos objetos. Independientemente de que las piezas se guarden en casa, estas cajas protegen el contenido del polvo y la suciedad, así como de los golpes que puedan producirse de camino a la galería o durante la venta.

Personalice su diseño

Es crucial hacer realidad sus visiones expositivas y crear el rótulo perfecto. Una de las tendencias más comunes es aplicar imágenes gráficas brillantes sobre la superficie acrílica mediante el método de la impresión. Con la ayuda de las modernas soluciones de impresión, todos los logotipos y gráficos que desee colocar en sus cajas impresas a medida llamarán la atención.

Soluciones a medida

Tanto si sus artículos son grandes como pequeños, podemos fabricar cajas acrílicas en las que quepan fácilmente. Estas cajas duraderas y cajas acrílicas transparentes y contenedores hacen que sus mercancías estén visibles y seguras al mismo tiempo. Fabricados con un material ligero, son baratos y puedes hacerlos de diferentes tamaños para adaptarlos a tu equipo o empresa.

Consideraciones sobre el coste de las cajas acrílicas a medida

Adquirir cajas acrílicas personalizadas supone un reto: el reto de ofrecer productos y servicios de calidad al mismo tiempo que asequibles. Este equilibrio garantiza que la inversión satisfaga las necesidades de la empresa al tiempo que se tiene en cuenta el aspecto de los costes. Analicemos cómo abordar estos costes.

Comprender los factores de fijación de precios

Varios factores definen el coste de las cajas acrílicas a medida. Son las dimensiones, el grosor del material utilizado, la posibilidad de personalización y la complejidad del diseño. Identificar estos elementos ayuda a los agentes de compras a tomar las decisiones correctas a la hora de obtener presupuestos. La comunicación con los proveedores evita la necesidad de adquirir productos caros que, en principio, no eran los que se pretendía comprar.

Ventajas de los pedidos al por mayor

También es posible encontrar un precio razonable para un gran número de productos en función de la calidad. Se ha comprobado que los fabricantes ofrecen mejores precios unitarios para cantidades mayores, al repartir los costes de producción entre muchas unidades. Evaluar las necesidades a largo plazo ayuda a los agentes de compras a agrupar los pedidos para conseguir el mejor trato. Pero es importante conseguir un equilibrio adecuado entre los beneficios de la agrupación y el riesgo proporcional de exceso de existencias.

Calidad frente a cantidad: Encontrar el equilibrio adecuado

La compra de acrílico de mejor calidad se traduce en una mejor calidad que puede soportar un uso más prolongado, una mejor transmisión de la luz y un mejor aspecto. Los siguientes factores contribuyen a la noción de valor añadido de los artículos expuestos. Es fundamental decidir si merece la pena invertir en materiales de primera calidad. Por ejemplo, cuando se requiere acrílico de calidad superior en artículos de valor o para su exposición al público, entonces resulta vital en este caso, pero no tanto en el caso del almacenaje.

Negociar con los proveedores

No hay forma de lograr una combinación óptima de calidad y precio sin unas negociaciones adecuadas. En sus actividades de aprovisionamiento, los agentes de compras deben poder expresarse sobre cuestiones de precios, pedir descuentos por volumen y considerar opciones más baratas. También descubrieron que los proveedores podían ofrecer consejos adicionales para ahorrar costes, por lo que es importante establecer buenas relaciones con los proveedores.

Medidas del coste total de propiedad

Por lo tanto, es importante tener en cuenta el coste total de propiedad, en la adquisición de cajas acrílicas a medida. Esto abarca desde el coste de adquisición del producto en el primer uso, la durabilidad del producto y el coste de mantenimiento del producto. Una caja acrílica ligeramente más cara que tenga una vida útil más larga puede resultar más barata a largo plazo que una caja más barata que deba sustituirse constantemente.

La cuestión de los costes de las cajas acrílicas personalizadas es compleja y requiere una estrategia adecuada. Si se tienen en cuenta los factores de fijación de precios, se aprovechan los descuentos por cantidad, se regatea y se evalúa el coste total de propiedad del artículo, los agentes de compras estarán en condiciones de tomar las decisiones correctas. Esto maximiza la calidad y el gasto al nivel más bajo posible.

El proceso de personalización: Cómo diseñar su caja acrílica

El proceso de fabricación de una caja acrílica personalizada perfecta no es muy complicado y puede dividirse en varias etapas. Gracias a este proceso, todo puede ajustarse a las necesidades del cliente. Todas las etapas garantizan que el producto final satisfaga las necesidades funcionales y la estética de los clientes. Ahora, resulta pertinente examinar cómo se realiza la personalización de principio a fin. Por lo general, puede fabricar eficazmente sus cajas acrílicas personalizadas siguiendo estos pasos.

Etapa 1 Elección de dimensiones y grosores

A la hora de diseñar su caja acrílica, el primer paso consiste en determinar las dimensiones. Determine la longitud, anchura y altura específicas más adecuadas en función de lo que vaya a contener o presentar. Ya sea para vender productos o para un simple almacenamiento, el tamaño desempeña un papel fundamental en la practicidad y el aspecto de las cosas.

Después, piense en el grosor de la sustancia acrílica en la que se va a fabricar el producto o la instalación. El grosor elegido para cada caja depende de las funciones que vaya a desempeñar y del grado de protección que deba ofrecer el material. El acrílico más transparente y grueso es más rígido y, por tanto, más adecuado para cajas grandes o para cajas que contengan artículos caros.

Paso 2. Elección de acabados y colores Elegir acabados y colores

La personalización implica elegir los acabados y los colores que responden a la imagen de la empresa o a las preferencias de un particular. El acrílico está disponible en una gran variedad de brillos, desde alto brillo hasta cáscara de huevo, lo que afecta al aspecto final. El acrílico está disponible en prácticamente cualquier tono, lo que ofrece una variedad casi ilimitada de opciones de apariencia. Como ya se ha dicho, el color y el acabado pueden contribuir a dar un aspecto más elegante a una caja corriente.

Paso 3. Añadir más opciones Añadir más opciones

Adición de otras características a su caja acrílica personalizada para aumentar su funcionalidad. Por ejemplo, cuando es probable que un artículo esté expuesto a la luz, la protección contra este aspecto es importante para conservar el color y la resistencia.

Otro proceso es el grabado, útil para personalizar o añadir el logotipo de una marca. Rotular su caja con logotipos, texto o dibujos puede mejorar su aspecto y también establecer la identidad de la caja.

Algunas de las características incluyen manillas en las puertas para cerrarlas, tiradores para abrirlas y luces para iluminar el contenido. Estos elementos pueden generar una solución única que satisfaga todos sus requisitos y necesidades.

Paso 4. Finalización del diseño

Una vez elegidas las dimensiones, el grosor, los acabados, los colores y otras características adicionales, el último paso es decidir el aspecto de su producto. En muchos casos, es esencial trabajar con un fabricante para obtener una consulta y hacer cambios. El proceso global de diseño y el asesoramiento profesional garantizan que el resultado final se ajuste a sus expectativas.

El proceso de elección de su caja acrílica perfecta es único e implica trabajar en él junto con los expertos. Dependiendo de cada aspecto, desde las medidas básicas hasta los detalles más refinados, podrá obtener una solución adaptada a sus necesidades. Investigue sus posibilidades y comuníquese con los expertos para aprender a hacer realidad la caja acrílica de sus sueños.

Reflexiones finales

Mejore su presencia en exposiciones con estas modernas cajas expositoras de acrílico transparente. Estas cajas dan una imagen profesional y de empresa en muchos tipos de productos. Se ofrecen tarifas atractivas, y los servicios gratuitos incluyen cajas expositoras con revestimientos de PVC para hacerlas más atractivas a la vista. Los clientes pueden mejorar económicamente la exposición de sus productos comprando grandes cantidades de cajas acrílicas transparentes. cajas de presentación. Póngase en contacto con nosotros hoy mismo para hacer realidad sus ideas.

Preguntas frecuentes - Fabricación de cajas acrílicas a medida

Q1. ¿Qué son las cajas acrílicas personalizadas?

Las cajas acrílicas individualizadas son soluciones específicas de almacenamiento o exposición creadas a partir de acrílico. Pueden fabricarse en distintos tamaños, formas y colores, y pueden equiparse con características relevantes para el uso previsto.

Q2. ¿Son las cajas expositoras acrílicas resistentes y duraderas?

Las cajas expositoras acrílicas son extremadamente duras, resistentes a los productos químicos y a los arañazos, y casi imposibles de romper. Están diseñadas para ofrecer la protección necesaria a los objetos de valor durante mucho tiempo, pero el acrílico no es el material más resistente, si necesita algo más fuerte que el acrílico, puede elegir moldeo por inyección de policarbonato caja u otra fabricación de caja de policarbonato para satisfacer sus necesidades.

Q3. ¿Puedo personalizar el diseño de mi caja acrílica?

Por supuesto. Las cajas acrílicas personalizadas se pueden grabar, están disponibles en colores y acabados precisos, y se pueden mejorar con otras funciones que se adapten a su marca o gusto personal.

Q4. ¿Son más baratas si se piden en grandes cantidades?

Sí, es posible que al encargar muchas cajas acrílicas a la vez el precio baje considerablemente. Los minoristas suelen reducir sus precios porque los costes de producción se reparten entre varias unidades.

Q5. ¿Cuál es el procedimiento correcto para limpiar mis cajas acrílicas?

Limpiar las cajas acrílicas es fácil; se utiliza un paño suave y una solución jabonosa. No utilice limpiadores agresivos, ya que dañarían la claridad y el acabado de los espejos.