Kort opsummering af forskellen mellem overstøbning og 2k-støbning

Mens injektion overstøbning and 2K injection molding (also known as 2-shot injection moulding) share many similarities, they also have some key differences. See below for the difference between those two moulding processes.

Overstøbning ved sprøjtning involves the use of a standard single-nozzle injection machine to combine two distinct types of materials into a single solid product. The overmolding manufacturing process means moving the first part (substrate part) or metal inserts to the subsequent mould (over skimmelsvamp) to create the final product. You can use this technology to add a soft-touch grip to a tool handle or to create a product with multiple colors or textures.

2K-sprøjtestøbning, also referred to as multi-shot injection molding, 2-shot injection molding, or dual-injection molding, involves using a specialized 2K injection machine to simultaneously inject two or three materials (colors) into the same mold. In fact, the 2K injection machine actually has two installed moulds. Unlike overmolding, the 2K moulding machine simultaneously injects both materials, fully bonding them together once the moulding process is complete. The 2k molding process, while complex, is characterized by its speed, efficiency, and high quality.

Compared to both manufacturing technologies, 2K injection tooling offers superior quality and production efficiency. However, due to the high cost of the 2K injection moulding machine, overstøbning sometimes serves as a substitute. On the other hand, the cost of an over-molded part is higher than that of a 2K injection-moulded part. However, for low volumes of 2-color moulding parts, injection overmolding can utilize any standard injection-moulding machine to produce the overmoulded parts.

Når man designer plastemner i flere materialer eller to farver, er det vigtigt at vælge den rigtige støbeproces baseret på emnets design og produktionsbehov. Både overstøbning og 2K-sprøjtestøbning have their own advantages and disadvantages. Some of the injection moulded prodcuts can only be created with the overstøbning process, while some of the injection-molded parts can only be made with the 2K injection molding process; this is depending on the plastic part geometry design.

If both moulding processes can produce the plastic parts, the 2K molding process will be the most effective for high-volume production.

Begge dele overstøbning and 2K injection moulding can be used to create products with multiple materials or layers, but the key difference is that in overmolding, two materials are formed separately (preloading the substrate to the second mould), while in 2K injection molding, two materials are formed together in the same process (of course, a specialized machine is needed).

Hvad er overmolding (overformning)?

Overmolding, eller over skimmelsvamp is a manufacturing process that involves molding one plastic over another material to be merged to create a single end product. In plastic overmolding, two separate moulds are required: the substrate, which is the first tool, and the overmould, which is the second mould. Typically, the second mould is made of thermoplastic elastomer (TPE) material, but this is not always the case. If the substrate is machined metal or brass components, then we normally call this insert molding, and insert moulding only needs one mould (over mould) to finish the manufacturing process.

De materialer, der oftest bruges til plast overstøbning are thermoplastic elastomer (TPE), rubber, or the same material as the substrate but in different colors. Today, we will primarily focus on the Overstøbningsteknologi der anvender TPE-materialer, som er meget udbredt i forskellige industrier. De stive substrater kan være fremstillet af en lang række materialer, herunder polyethylen (PE), polypropylen (PP), polycarbonat (PC), nylon (PA6 eller PA66), akrylonitrilbutadienstyren (ABS), polymethylmethacrylat (PMMA), polystyren (PS), slagfast polystyren (HIPS), polyphenylenoxid (PPO), acrylonitrilbutadienstyren (ABS) eller ethvert andet specialmateriale, der kan bruges som substrat.

Overstøbning bruger sprøjtestøbningsprocessen til at sprøjte et plastmateriale (Over-mold) over another material (substrate). The overmolding plastic material normally uses TPE, rubber, TPU, or the same material but in different colors. Overmoulded materials will make a strong bond with their substrates, ensuring long-term durability and optimal performance in their intended environments. The use of overmolding removes the need for adhesives when connecting thermoplastic elastomers (TPEs) to hard substrates. The overmolding teknikken forenkler støbeprocessen, sænker omkostningerne og giver mulighed for større designfleksibilitet.

Typerne af overstøbning

Types of overmolding include two-shot sequential overstøbning, insert moulding, and multi-shot injection molding (2K and 3K injection moulding, or more).

Two-shot sequential overmolding

I to-shot sekventiel Overstøbning af plastindsprøjtning, the molding machine injects the first plastic resin into the first mold cavity (substrate mould); after the material cools and forms the first plastic shape, it then opens the tool. All of those molding processes are the same as the traditional injection moulding process.

Once the first substrates are completely finished and cooled, insert the substrate into the second mold (overmold), close the tool, and then inject the second material. The process is also the same as the traditional molding process; the difference is preloading the substrate into the cavity before the manufacturing process begins.

All of those moulding processes will be done with traditional injection machines.

Inert overstøbning

Indsæt overstøbning bruger præformede indsatser eller metalindsatser, der placeres i formen, før det andet materiale sprøjtes ind; hvis indsatserne er af metal eller messing, kalder vi det metal Indsatsstøbning. This overmolding process, which we used a lot, for example, metal screw insert moulding and Støbning af filterindsatsDenne type overstøbning bruger en traditionel sprøjtestøbemaskine til at fortsætte, som sætter metalindsatserne ind i formhulrummet under den enkelte sprøjtestøbningscyklus.

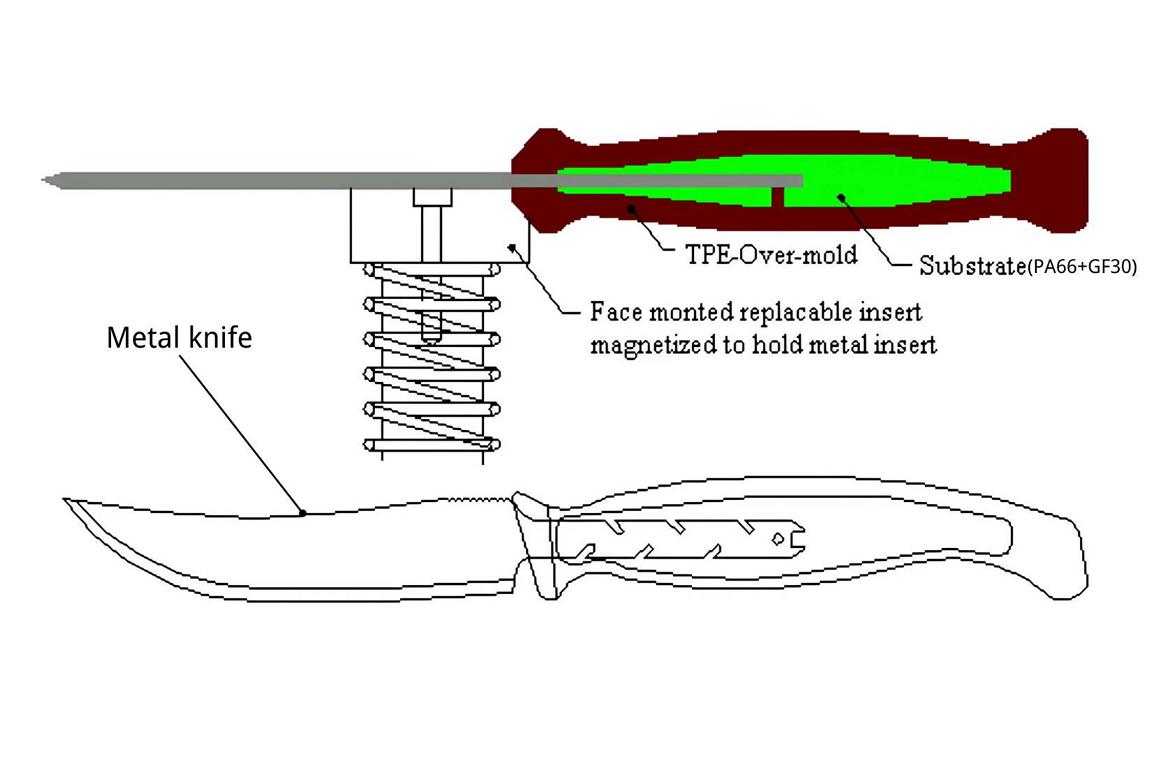

Like the below picture is showing, the insert overstøbning med inert metal. Denne type Overstøbning kræver kun én sprøjtestøbeform; men hvis den første indsats er lavet af en plastdel, skal vi bruge en ekstra form til den første plastindsatsdel.

Multi-shot injection moulding or 2k injection molding

Multi-shot injection molding, sometimes called 2-shot injection moulding, is also a type of overmolding. This molding technology requires specialized injection moulding machines, which have two injection units. The injection barrels can be parallel or perpendicular to each other. There will be two injection moulds assembled in this machine; one injection tool makes the substrate, and the other one is for the overmolding process.

The moulding machine injects the first plastic resin into the first cavity, also known as the substrate mould. Once the material cools and forms the first plastic shape, it opens the tool. This process is identical to the traditional injection manufacturing process. Once the moulds are open, the movable half rotates 180° without ejecting the substrate. Next, it closes the molds and initiates the second injection, also known as the overmold.

Simultaneously, it injects the first shot. Once the second cavity completes its molding process, it opens the tools again and ejects the overmoulded product from the overmold. During this process, a new substrate is generated for the second cycle.

Dette er en komplet støbecyklus for 2k-sprøjtestøbningsprocessen.

TPE overmoulding

TPE (termoplastisk elastomer)) plastic materials are used a lot in the injection molding field, especially for the overmolded parts. In the overstøbning market, over 80% of overmolded parts are made by TPE-overstøbning,

TPE-overstøbning is the injection moulding process where TPE (thermoplastic elastomer) is formed onto a rigid material (for example, PC, PA66, or ABS material) according to the specific requirement. The overmolded TPE will strongly bond with the first plastic and maintain its final use purpose. To prevent the TPE material from stripping off from the second material, material selection and part design are very important.

EN TPE producent af overstøbning vil overveje alle relevante faktorer, når de vælger den optimale metode til fremstilling af en sprøjtestøbt plastdel, og vælger mellem 2K-støbning og overstøbningsprocessen. Kritiske faktorer omfatter produktionskapacitet, materialevalg, tilgængeligt udstyr og lønomkostninger.

Normalt vil overstøbning process is the most popular choice when total production volumes are less than 50K. This number is only a reference and not a definitive one because it depends on the size and complexity of the part design. For higher volume production requirements (total volume over 200,000 units), a 2-shot injection moulding process will be a better option; of course, this is still dependent on the part design because some parts can only be made with an overmoulding process; for example, the below part can only be created with the overmolding process.

I hver eneste TPE overmoulding or 2K injection molding process, the number one issue is to achieve maximum adhesion between the TPE and the substrate. Some TPE overmoulding may have significantly different bond strengths between multi-shot and overmolding. Even if an excellent bond is produced with two-shot molding, the same material may have a low bond strength when using overstøbning. For at fremstille færdige produkter af høj kvalitet overmolding and 2K moulding products, a thorough understanding of TPEs, part design, engineering plastics, and the specifics of the moulding process is important.

Tips til udvælgelse af materialer til TPE-overstøbning

Som vi ved, laver vi høj kvalitet TPE overstøbt product, both TPE and substrate materials are most important, the number one factor to define the quality of overmoulded part is how good the mergeration between two matreials, if the TPE is easy to strip off from the substrate then the material will be issues, below there are some tips for meterials selestion, following thsi tips you will find the best suitable material for overmoulded part.

Tykkelse af TPE-overstøbt del

Designers frequently request the softest TPE. They don’t realize that a TPE’s soft durometer doesn’t provide much to “cushion” below a particular thickness (usually less than 0.1mm). Thinner TPE overmoulded part feel harder—the hardness impact depends on thickness. Multiple closely spaced ribs can produce the illusion of thickness without utilizing much material. Many kitchen utensil handle use this method.

Hårdhed af TPE-plastmateriale,

Der er en blødhed i TPE-materialet, som du skal vælge, når du laver TPE-overstøbningisær TPE uden tykkelse, som er mere end 0,5 mm. For at få en god berøringsfølelse kan det være nødvendigt at teste forskellige typer TPE shore A-materiale, medmindre der er særlige funktionskrav, normalt bruger vi på markedet fra TPE Shore A 40 til 60; hvis det er for lidt, kan det fjerne sig fra underlaget; hvis hårdheden er for høj, er berøringsfølelsen muligvis ikke god nok.

Tips til valg af substratmateriale

Sammenlignet med TPE-materiale vil substratmaterialer være lettere at vælge; de fleste materialer kan være substrater, herunder nylon/PA (PA66 eller PA66 GF30, PA6 eller PA6 GF30 plast), polycarbonat (PC), akrylonitril-butadien-styren (ABS, PC/ABS, acetal (POM), PMMA og så videre. Det endelige valg af substratmateriale afhænger af det endelige formål. Hvis du er i tvivl om det optimale materiale til dine TPE-overstøbte dele, kan du kontakte os, så vi kan give dig nogle anbefalinger.

Overfladefinish på substrat og TPE-overmold

Overfladefinishen på underlaget vil også påvirke vedhæftningen af TPE-gummi. Jo stærkere vedhæftning, jo mindre sandsynligt er det, at det vil stribe af, normalt vil der være god polering mellem fletningsoverfladen mellem TPE og substrat, på TPE-hulrumssiden, soemtime overfladefinish vil også påvirke TPE-overformningen, engang higi polering til TPE-hulrumsformen, vil TPE-overformningsdelen klæbe til hulrumssiden, tilføje nogle små VDI-tekstur vil forbedre dette.

Tips til design af TPE-overstøbningsdele

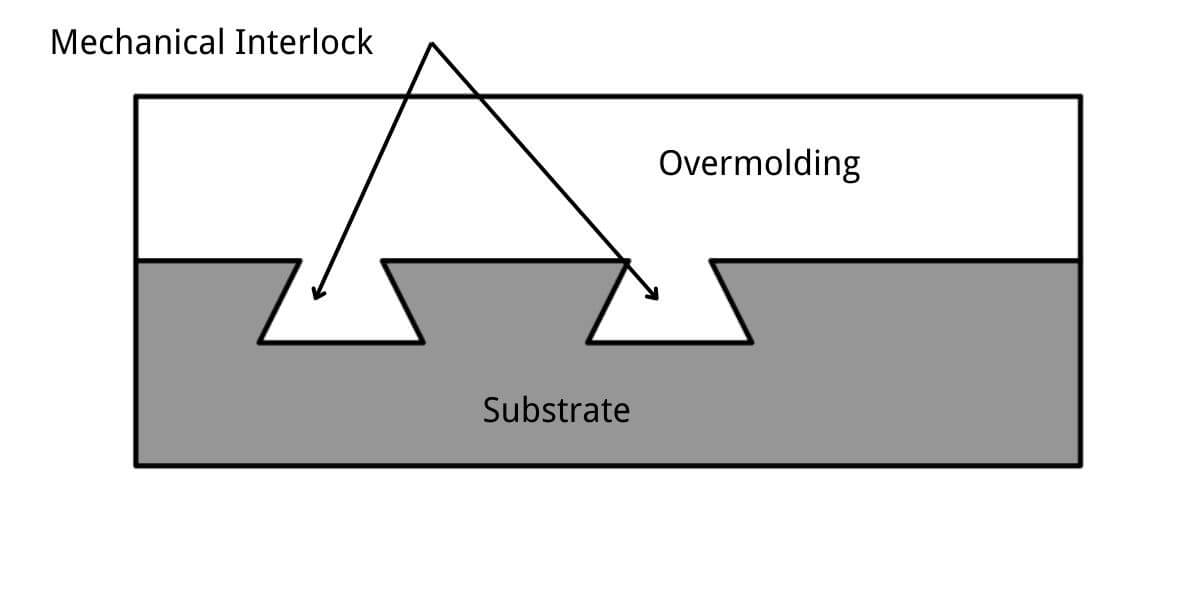

Emnedesign spiller som tidligere nævnt en afgørende rolle for at skabe en høj kvalitet. TPE-overstøbning produkt. Generelt er designet af substratdelen det samme som for andre dele til plastindsprøjtningsværktøjer. For yderligere detaljer henvises til siden om Design af plastemner til sprøjtestøbning. But there are some factors on the merge area between the substrate and TPE overmoled area; there is no standard design for this area since different parts have different geometries, but there are some key points that you need to think about when you do the overmoled part design. Those factors will be:

Sådan forsegler du TPE-overstøbningen godt og forhindrer, at den blinker, når du laver designet til overstøbningsdelen:

TPE material easily exhibits flash (0.03 mm gap), and bondable TPE materials meet more stringent criteria than standard TPE polymers. The same holds true when designing parts. Unlike traditional part design, two-component part designs must account for shrinkage from two different thermoplastic materials. Both substrate and over-moulding have their own gate and runner systems, which must be tailored to the individual material properties used.

For at opnå den bedste cyklustid, substrat og overstøbning vægtykkelsen skal være ensartet. I de fleste applikationer med overstøbning sikrer 1-3 mm vægtykkelse tilfredsstillende limning. Tykkere stykker bør udkernes for at reducere svind, vægt og cyklustid. For at undgå opfyldninger og gasfælder skal overgangen mellem vægtykkelser være gradvis. Tilføj radius til de skarpe koner for at reducere stressproblemer. Undgå dybe, utilgængelige blinde lommer eller ribber. Lange træk bør have en trækvinkel på 3-5 grader for at lette afformningen. I overstøbte forbindelser kan der laves dybe underskæringer, hvis der bruges en fremskudt kerne, når formen åbnes, delen ikke har skarpe hjørner, og elastomeren bøjes under udstødning.

Most TPE compounds have significant flow direction tool shrinkage and moderate cross-flow shrinkage. After ejection from the tool, the over-moulding compound may contract more than the substrate. This can stretch the substrate, usually in the overmolding material’s direction. This is especially true for long, thin parts or components with a low-modulus substrate or one thinner than the over skimmelsvamp. Brug substratmaterialer med højere modul og afstivningsribber for at mindske dette. Tyndere belægninger og overformningskvaliteter med lavere hårdhed hjælper. Det kan også hjælpe at flytte porten for at påvirke TPE-flowet.

Hvis du kan forbedre designet for at sikre en tættere binding mellem TPE-materialet og underlaget, f.eks. ved at øge tværsnitsarealet, uden at gå på kompromis med funktionaliteten eller udseendet, vil det være en fordel. Nedenfor er et af eksemplerne på tips til design af overstøbningsdele.

Undgå at designe for mange afgrænsede områder på TPE-overstøbningsdelda dette kan komplicere overmold fremstilling og støbeprocessen. Især mange områder er designet til skillelinjeområdet; dette vil være svært at løse flashen helt, når du designer den TPE-overstøbte del, der designer så simpelt som muligt, medmindre der er noget funktionsformål.

Tips til design af overformning:

Når vi designer sprøjtestøbning til overstøbning dele, den første form (substratværktøj) vil vi tilføje krympningshastighed i henhold til plastikkrympningshastighed, men for over mould (andet værktøj), vil vi ikke tilføje nogen shinakge-sats på indsprøjtningen over formen.

Omkostninger til overstøbning

Basisomkostningerne for en overstøbning er ikke et fast tal, der vil være det samme for alle ansøgninger. Det har en varierende værdi, der kan ligge mellem 1 og 10 dollars.

Dette er et ekstremt bredt prisinterval. Den rigtige værdi ændres baseret på flere komponenter, der er involveret i overstøbningsprocessen. Disse faktorer, der påvirker omkostningerne, er:

Udstyr til sprøjtestøbning

Startomkostningerne for udstyr til sprøjtestøbning kan variere meget afhængigt af anvendelse og type.

Der er sprøjtestøbeudstyr i lille skala, som virksomheder har i huset. Og så er der de store oversprøjtningsmaskiner, der normalt bruges af serviceudbydere og dem i den store produktionsindustri med store produktionsmængder.

Professionel industri overstøbning Udstyret koster mellem $50.000 og $200.000. Der kan være forsendelsesomkostninger involveret. Disse maskiner er ikke for amatører og hobbyfolk, da de kræver dygtige operatører.

Overmold manufacturing costs

Mens overstøbning udstyr er en engangsinvestering, der skaber over skimmelsvamp according to each custom design is an additional cost, and each single product design will require a unique over mould. It is an expense for every different part produced. over mold manufacturing costs are one of the most vital cost factors for overmoulded parts.

This over mold cost can vary depending on the part design, part size, and quality required to create the moulds. Generally, three factors are employed for this objective, which are listed below:?

Designets kompleksitet

Highly complex designs that requires complex overmold, this often include features like multiple cavities, intricate geometries, sliders, and lifters. These elements require advanced engineering, extended development time, and additional manufacturing cost, all of which increase overmolding tooling costs.

Delstørrelse

Over mold is the same as other injection moulds; a large size will require a large mouldbase and moulding machine, which will increase the over mold cost and unit moulded part cost.

Arbejdsomkostninger

Over mold is normaly hard than normal mold, because it needs perfect mold fitting, specailly is TPE overmolded on the substrate, TPE is very easy to go flash, the skilled technicians are needed to monitor machines, perform quality checks, and mold fitting operations, which adds to labor costs,

Since the the overmolding typically involves manual or robotic pre-loading the substrates into the cavity, the molding cost will be much higher than traditional molding cost.

Waste cost

Material waste from sprues, runners, and rejected parts adds to costs. Overmolding will have more reject costs than traditional costs; if one part is rejected, that means the substrate is wasted as well. Employing hot runner systems can minimize waste by eliminating runners, but these systems come with higher initial investment costs.

Final summarize for the overmoulding cost

Hvis du er på udkig efter overstøbt parts for your custom injection moulding parts, then you do not need to pay any cost on the injection molding equipment, because your supplier should have this, but you need to pay for the over mold cost, over-moulding process cost, materials cost, packing cost, and so on. If you want to know the price of your overstøbning projekt, bedes du kontakte os, så giver vi dig et tilbud inden for 24 timer.

Metal insert moulding

Sådan reducerer du omkostningerne til overstøbning

Overstøbning er den foretrukne fremstillingsproces på grund af dens omkostningseffektivitet og pålidelighed.

While the process is affordable compared to its alternatives, you can further decrease the costs. For that objective, here are some points that you need to take into account:

Optimering af CAD-designet

En enkelt del kan tilgås via forskellige CAD-designs. Alligevel er ikke alle designideer perfekte. Nogle designs til den samme del kan føre til tids- og ressourcespild. Så ved at forenkle emnets kompleksitet via effektivt CAD-design sikrer man optimal udnyttelse af ressourcerne.

Reduktion af delstørrelse

Større dele er ikke altid fremragende dele. Når størrelsen på emnerne stiger, stiger også udgifterne til de sprøjtestøbeforme, der skal bruges til emnerne. Hvis den samme proces kan opnås ved at mindske emnestørrelsen, er det en god idé at vælge det.

Resuing over forme

Make full use of the over molds by reusing them for many applications. You cannot just use the same mold for the same part but also for similar parts as well, when you design similiar part you can even use interchangeable cavity and core to save the tooling cost.

Using DFM (Design for Manufacturing) Analysis

DFM står for design til fremstilling. DFM i overstøbning refererer til at producere en del, der tjener kundens mål og er inden for deres fastsatte budget.

A thorough DFM analysis helps align the design with manufacturing capabilities, for examle, ensure the design meets functional requirements without unnecessary complexity, and use lower-cost thermoplastic elastomers (TPEs) compatible with the substrate. which can lower down costs. Go to design til fremstilling side for at få mere at vide.

Reduce Cycle Times as Much as Possible

There is a direct correlation between reducing cycle times and improving operational efficiency and costs:

Optimised Cooling Channels: better cooling linee design in the mold can reduce the amount of time needed for cooling and increase the quality of the part, this is same to traditional mold.

Decrease the amount of material waste

Efficiency in the use of materials is a primary factor in cost reduction, for high volume products requrirement, use hot runners in order to reduce the amount of scrap material resulted from sprues and runners.

Incorporating regrind material while ensuring that its percentage does not damage the quality of the item is an important step in the recycling process.

Make sure perfect mold fitting can reduce the waste as well, use stable injection molding machine can reduce the waste cost.

Begge dele overstøbning og 2k sprøjtestøbning are very similar processes, sometime both moulding processes can work on the same part, but something can only be created with single overstøbning eller 2K-sprøjtestøbningDette er helt afhængigt af delens design.

Fordele ved oversprøjtning

- Sammenlignet med 2K-sprøjtestøbning, overstøbning is easier to make. You can use a normal injection machine to make two or three different colors in one molded part or two or three different materials in one end part.

- Til nogle små mængder af tofarvede støbeprojekter behøver du ikke at invertere eller leje en 2K-sprøjtestøbemaskine; ved at bruge overstøbt processen er den bedste og mest omkostningseffektive måde at opfylde kundernes krav på.

- Det øger designdiversiteten og fremhæver også slutproduktet i mange materialesammensætninger.

- Med reducerede samleomkostninger er der færre sekundære aktiviteter eller processer, der udføres på slutprodukterne. Det reducerer omkostningerne til arbejdskraft. Efter fremstillingen er der heller ikke flere omkostninger.

- Delene har en høj grad af stabilitet og sammensætning, da de bliver til ét, efter at de har fået lov til at gribe mekanisk ind i hinanden.

- Produkter overstøbt der bruger plast, har høj modstandsdygtighed over for vibrationer og stød, fordi plastharpiksen er perfekt struktureret.

- The plastic moulded parts are more reliable because there is no bonding at the production stage.

- Slutprodukterne har den ønskede standard, som f.eks. iøjnefaldende design og solide komponenter.

Ulempe ved sprøjtestøbning frem for støbning

- Siden overliste process involves moving the first substrate part to another over mold, the tolerance is not as good as in the 2K injection molding process.

- Produktionskapaciteten er ikke så effektiv som 2K-sprøjtestøbning, da det kræver robotter eller manuelt arbejde at indsætte substratet i det omstøbte værktøj. Det tager tid, og støbeparameteren er nogle gange ikke stabil, især når der er to eller flere substrater i et værktøj. Dette vil føre til yderligere problemer og en højere spildprocent, hvilket resulterer i dobbelt så meget affald (fra substratet og det overstøbte materiale).

- Med den Overstøbningsproceser der færre valgmuligheder med hensyn til plastkompatibilitet. Nogle materialer binder måske ikke godt sammen eller kan ikke modstå de høje temperaturer og tryk i sprøjtestøbningsprocessen.

- There are no secondary practices carried out on the end products of over-moulding. When the plastic material becomes cold, activities and adjustments come to a complete halt.

- In cases where products are scarce, it is expensive to run such an operation. Sincerely, you need someone to put the substrate into over-mold, so the cycle time and production cost are increased accordingly.

- Overstøbningsprocessen kræver normalt to forme, en til substrat og en til overstøbning, så de indledende værktøjsomkostninger vil være højere.

- Overstøbning er en mere kompleks proces end traditionel sprøjtestøbning, der kræver præcis koordinering mellem de to indsprøjtningssystemer og et ordentligt formdesign.

- Hvis der er problemer med overstøbningsprocessen, kan det være sværere at fejlfinde og løse problemer med overstøbning end med traditionel sprøjtestøbning.

Hvad er 2k-sprøjtestøbning (Two-shot moulding)?

Sprøjtestøbning med to skudeller 2K-sprøjtestøbning er en fremstillingsproces, der bruges til at skabe to farver eller materialer i én plast. Denne two-shot-støbningsteknologi blander to materialer eller to forskellige materialefarver i en plastdel ved hjælp af en 2K-sprøjtestøbemaskine.

Den kemiske bindingsproces, der er involveret i denne proces, er meget vigtig, fordi den er i stand til at kombinere to eller flere materialer til en del. Når man bruger 2K-sprøjtestøbningsteknologien, vil materialevalget være en vigtig faktor for, om projektet bliver en succes eller ej.

Fordele ved 2K-sprøjtestøbning

2K-sprøjtestøbning giver en række fordele i forhold til traditionel sprøjtestøbning i ét materiale. Nogle af disse fordele indeholder:

Omkostningseffektiv

Den 2K injection molding process combines two compatible materials in a single machine cycle. It begins with the first material being injected into the primary mold. The moving half then rotates 360 degree, and close to eject the plastics for the second material to be overmolded in the secondary cavity. in the maintime the first injection is working synchronous.

The use of adhesives or further assembly is not necessary for this seamless technique, which guarantees the high quality bonding between the materials.

Because the method uses only one cycle instead of separate machine cycles, it costs less for any production run and needs fewer employees to make the end product while delivering more items per run. It also ensures a powerful bond between the materials without the need for additional assembly down the line.

Forbedret effektivitet

Støbning med to skud permits multiple components to be created with one tool, decreasing the amount of labor required to run your parts and eliminating the need to join or weld components after the molding process.

Bedre kvalitet

Two-shot is carried out within one tool, permitting lower tolerances than overmolding processes, a high level of accuracy and repeatability, and reduced scrap rates.

Solve the part design issues

Støbning med to skud gør det muligt at skabe komplekse formdesigns, der inkorporerer forskellige materialer til funktionalitet, der ikke kan opnås via efterstøbningsprocesser.

Ulemper ved 2K-sprøjtestøbning

2K-sprøjtestøbning har mange fordele, men som alt andet har det sine fordele og ulemper.

En ulempe ved 2K-sprøjtestøbning er, at formomkostningerne er højere end traditionelle sprøjtestøbeforme. fordi 2K-sprøjtestøbning kræver to forme, det første skud og det andet skud (det er derfor, vi kalder det to-skud-støbning), og det er sværere at lave 2K-sprøjtestøbeforme end at lave to separate traditionelle forme, fordi de to forme kører sammen i den samme maskine (en to-skud-sprøjtestøbemaskine). så det kræver to forme at skifte over uden problemer.

Derudover er 2K-sprøjtestøbning processen skal bruge en 2K-sprøjtemaskine, hvilket også gør maskinen dyrere og kræver en særlig teknisk operatør til at justere maskinen. Dette er også en højere omkostning end traditionelt sprøjteværktøj. I sidste ende genvinder vi 2K-sprøjtestøbning omkostninger ved at reducere arbejds- og monteringsomkostningerne, da den manuelle påføring af f.eks. en forsegling ikke længere er nødvendig. Dette eliminerer et monteringstrin.

En anden ulempe ved 2K-sprøjtestøbning er, at det gør genbrug af plastemner vanskeligt, fordi der ofte samles to forskellige plasttyper. Selv når plasten er "fra samme familie", vil kvaliteten af returstrømmene være meget lav, hvilket gør det svært at genbruge plasten til en applikation af høj standard.

Sådan vælger du overmolding og 2K-sprøjtestøbning

You may have questions about when you need to use over moulding and when you should use the 2K injection molding process. Here are some simple suggestions:

- If the quantity of the overmolding or 2K molding part is only a few thousand or ten thousand, it is recommended to use the overmolding process instead of 2k moulding process as it can significantly reduce mold costs.

- If you require more than 500,000 parts, 2K injection molding is the most cost-effective manufacturing process. This is due to the high labor costs associated with overmolding and the high initial cost associated with 2K moulds, two-shot injection moulding machines, and related equipment.

- Overstøbning er den eneste tilgængelige metode for nogle dele, mens den dobbelte sprøjtestøbningsproces er nødvendig for andre. Det afhænger af emnets designstruktur. Hvis du er i tvivl, kan du sende dine data til info@plasticmold.net. Vi kan tjekke det for dig og give dig en pris som reference.

Looking for over moulding or 2k injection molding service?

Sincere Tech er en af de bedste sprøjtestøbevirksomheder i Kina. Hvis du er på udkig efter overstøbning, insert moulding, 2K-støbningeller andre brugerdefinerede forme, send os din 3D-designtegning og dine krav; vi vil aldrig dele dine data med nogen anden. Vi er villige til at underskrive en NDA dokument for at sikre dit projekts sikkerhed.

We will offer you the most competitive price for high-quality overmoulded parts, 2K tooling and moulding, plastic tooling, and plastic parts for the long-term business relationship, and we will suggest the best injection manufacturing process for your products.

More than 18 years of experience providing plastic mold making and custom mold services in overmolding, 2K moulding, die casting, machining, and so on, plus 18 years of fluent technical English communication (technical English communication is very important to work with worldwide customers).

Små ordrer accepteres. Vigtigste eksportmarkeder: Asien, Australien, Mellem- og Sydamerika, Østeuropa, Nordamerika, Vesteuropa og resten af verden.