Hvad er en mold flow-analyserapport?

Analyse af formflow (MFA) er et simuleringsværktøj, der bruges til at forudsige og optimere flowet af plastharpiks i en form under sprøjtestøbningsprocessen. Simuleringen tager højde for harpiksens egenskaber og formens geometri og forudsiger plastens opførsel, når den fylder formen og afkøles.

Rapport om analyse af formflow kan hjælpe med at identificere og løse potentielle problemer med sprøjtestøbningsprocessen, f.eks. korte skud, skævheder, svejselinjer, luftfælder, synkemærker osv. Rapport om analyse af formflow kan også bruges til at optimere sprøjtestøbningsprocessen ved at identificere den bedste placering af porte og medbringere, bestemme den optimale indsprøjtningshastighed og forudsige den bedste køletid og -temperatur. Det kan hjælpe med at reducere cyklustiden, forbedre emnets kvalitet og øge produktionseffektiviteten.

Rapport om analyse af formflow

Resumé af resultaterne af Mold Flow-analysen

Når vi er færdige med formdesignet, skal vi, inden vi begynder at fremstille formen, sørge for, at alt er i orden. analyse af formflow for at kontrollere potentielle problemer, er det en sikker måde at undgå fejl på, især for de store støbeforme. Nedenfor er nogle punkter, som vi skal kontrollere, når vi laver en rapport om analyse af støbeformsflow.

Formfyldningstid – Fyldetiden er den tid, det tager at fylde emnets hulrum. Fyldetidsplottet giver også en animation af formhulrummets fyldning. Fyldetiden kan også styres under analysen for at løse kvalitetsproblemer som f.eks. høje forskydningsspændinger.

Indsprøjtningstryk – A standard injection molding machine is capable of pressurizing the melt flow to 20,000 psi (2,000 psi hydraulic gage pressure). A portion of the pressure is used to push the plastic through the runner system, some of the pressure is used to push the plastic into the Formhulrum, and a portion of the pressure is used to “pack out” the part after it is filled. If the part and runner system require more pressure than the machine is capable, than the part will be a short shot or have deep synkemærker.

Svejselinjer Fejl og mangler – Weld lines are formed when two flow fronts meet and “weld” together. Weld lines are usually a visible line on the part and can be an appearance issue. Weld lines may also reduce the part strength by 10% – 20% potentially creating a structural issue depending on their location. If mold flow analysis is not used to fix these problems before the tool is built, the molder will be forced to: increase injection pressure, increase melt temperature, increase mold temperature, enlarge vents, change the gate location and/or alter the thickness of the part. All of these “solutions” take time and money to implement and/or increase the cost of the part.

Luftfælder Fejl og mangler – Air traps are formed when the molten plastic traps air in the part cavity as it fills. If these air traps are not vented, they can lead to quality problems such as burn marks, short shots, pronounced weld lines and incomplete fill. Our air trap plots allow the toolmaker to know exactly where the vents need to be placed when the tool is built. Air traps that are in locations that are difficult to vent can be moved to better locations by moving the gate. Doing this work before the tool is built can save on the amount of debug and mold changes that are required.

Kvalitet – The definition of a quality molded part is not only that the part filled completely. A quality molded part must also be free of material degradation and low in molded in stress. The quality plot shows the severity and areas that are suffering from quality problems. The problems detected include excessive shear stress and shear rate, and hard to pack areas. Suggestions like thickness adjustments, processing condition changes and fill time adjustments can be tried to eliminate the quality issues.

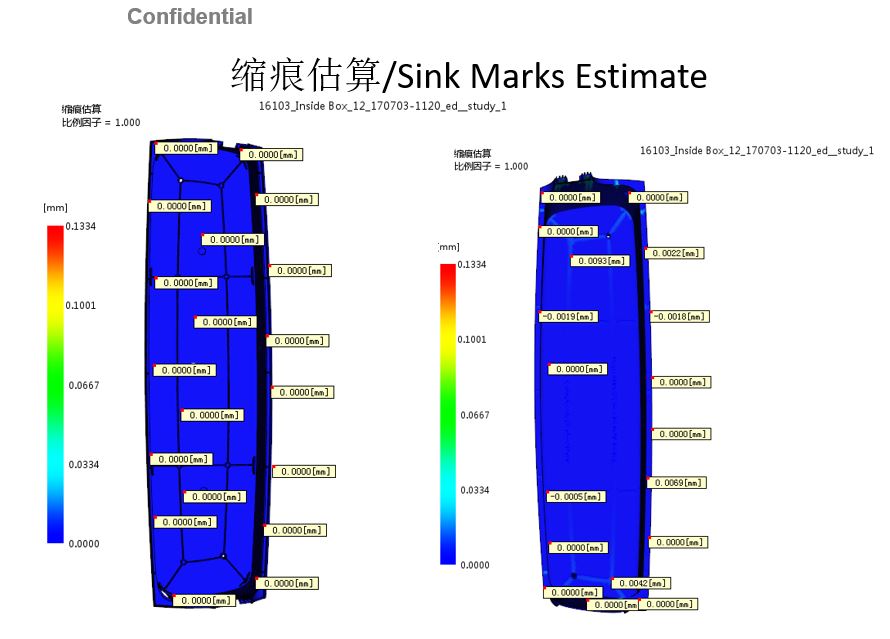

Vaskemærker Defekter – Sink marks are localized depressions in the surface of injection molded parts caused by a non uniform shrinking of the plastic during the cooling. In cosmetically critical parts, they can be a serious problem. Sink marks often come as a surprise when the tool is complete. If the sink marks are objectionable to the customer, the molder is often tasked with “eliminating them”. This usually means running the molding machine at the extremes of the process window, which can lengthen cycle times and increase the amount of molded in stresses and material degrade.

Køletid – It has been shown that cooling time averages about 50% of the molding cycle. If the material in use is a commodity resin, the molding cost far outweighs the material cost. In this case, a reduction in cooling time has a big reduction in the part cost. Our Cooling Analysis can reduce your cooling cycle and optimize your cooling system eliminate hot spots and warpage.

MFA er et kraftfuldt værktøj, der kan hjælpe med at forbedre effektiviteten og kvaliteten af sprøjtestøbningsprocessen ved at simulere plastharpiksens opførsel, når den flyder gennem formen og afkøles. Det hjælper med at identificere potentielle problemer og optimere processen for at minimere fejl og forbedre den endelige produktkvalitet.

Vi laver mold-flow-analyse til dit projekt

Hvis du har et projekt, der har mange bekymringer, så kontakt os, så tjekker vi alle dine deltegninger og laver... DFM-rapport og Formflow analyse for dig og opsummere alle mulige problemer i databladet og sende det tilbage til dig.