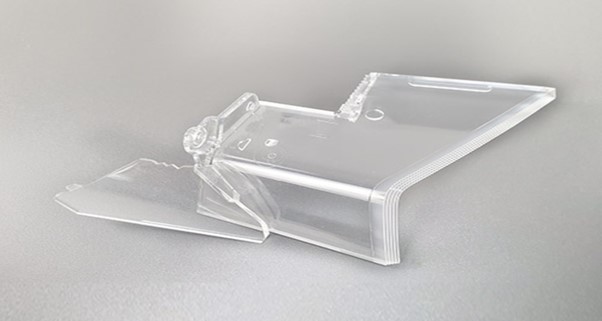

Clear plastic injection molding

Creating clear plastic injection molding parts involves complex tasks that differ from those involved in injection molding with non-transparent materials. Selection of materials affects their properties, production process, and final product. Working with non-transparent materials can cover some defects to a certain extent, but for transparent injection molding, the precision of the design and manufacturing processes must be impeccable.

However, it is important to note that planning and preparation are crucial in the clear plastic injection molding process before going into the details of the materials used. This entails proper preparation of raw materials, special injection molding machine, proper calibration of equipment, proper clear plastic injection mold, and proper molding procedures, which are crucial in the production of clear plastic injection molded parts.

When practicing clear injection molding, the first criterion is the ability to see the particles. Unlike opaque plastics, clear plastics do not conceal potential molding defects. Hence, it is crucial to keep every area of the production cycle as clean as possible to achieve the best quality of the final clear plastic product. Proper storage of materials is crucial to prevent contamination and ensure high-quality raw materials.

After the production of clear plastic injection-molded products, packing plays a crucial role in protecting the clear parts from scratches or surface fogging.

Material Selection For Clear Plastic Injection Molding Process

When it comes to selecting materials for translucent and clear injection molding, several options offer distinct advantages:

Acrylic (PMMA)

This versatile material allows for the injection molding of both clear and colored products. Outdoor equipment, lighting fixtures, and decorative items widely use acrylic due to its nontoxicity, scratch resistance, and UV resistance. However, the rigidity of acrylic and its brittle nature require proper drying to avoid moisture, which affects the molding process and the final product. Go to the Acrylic Injection Molding page to learn more about PMMA molding.

High-density Polyethylene (HDPE)

An advantage of HDPE is its UV resistance and its ability to mold into translucent parts. It is more resistant to breakage than acrylic and is relatively cheaper; hence, it is suitable for use in containers, bottles, and pipes, among others. However, due to its relatively low impact strength, we do not recommend HDPE for high-pressure applications.

Polycarbonate (PC)

Polycarbonate is clear, resistant to UV light, and more resistant to impact than acrylic. Safety clothing, windows, containers, and other applications demanding high-impact strength and transparency extensively utilize polycarbonate (PC). Similar to acrylic, PC also requires drying prior to injection molding for optimal performance. Learn more about polycarbonate injection molding.

Polyetherimide (PEI)

PEI is a high-performance material that exhibits excellent resistance to UV, heat, and chemical environments. High-performance applications, such as medical instruments, automotive parts, and aerospace components, widely use it, desiring its high mechanical performance and thermal characteristics. However, due to its high cost and the requirement for specialized manufacturing processes, such as the use of steel molds, PEI is most appropriate for applications that require high performance.

Polypropylene (PP)

PP is a very useful material that is characterized by flexibility, electrical conductivity, and chemical stability. Numerous industries use it for applications such as fabrics, packaging, electronics, and chemical uses. Because of its hinge-like characteristic, PP excels in applications that demand flexibility and resilience, without the expectation of bearing any load.

Liquid Silicone Rubber (LSR)

LSR is a biocompatible material with excellent thermal, chemical, and electrical stability. Medical equipment, electrical parts, and automobile manufacturing industries widely apply it where strength and efficiency are crucial. Due to its flexibility and enhanced characteristics, LSR is well suited for applications where high-accuracy molding and high performance are required.

Optical silicone rubber (OLSR)

This is an advanced material that is used for improving the light transmission and clarity of optical parts. OLSR exhibits superior non-yielding characteristics, making it a suitable choice for outdoor fixtures and other applications subjected to extreme weather conditions. Due to its good optical transmittance stability over time, OLSR is suitable for clear optical parts where light transmission is important.

All these materials have their own benefits and challenges when it comes to clear injection molding, and they are suitable for use in different applications across various industries. To produce clear molded parts of high quality, performance, and appearance, we carefully consider and implement the choice of materials, design, and manufacturing techniques.

Polyethylene (PE)

Petroleum undergoes heat and pressure exposure to create HDPE, a type of thermoplastic. While acrylic has its advantages, HDPE has UV resistance, is incredibly versatile, and is simple to mold. Large-scale production of products like bottles, pipes, and containers commonly uses HDPE due to its advantages and relatively lower manufacturing costs.

Elastomeric Resins

TPR, an elastomeric resin, is a blend of plastic and rubber, easily processed through injection molding. TPR has uses in products such as fluid dispensers, flexible hoses, catheters, and equipment that need to have resistance to liquids such as acids. Due to its flexibility and ability to withstand tough conditions, these applications prefer TPR.

Thermoplastic Polyurethane (TPU)

Thermoplastic polyurethane (TPU) is characterized by high tensile and tear strength, softness, and elasticity. This makes TPU suitable for use in the development of products that need to have a firm handle while at the same time being comfortable to hold. Despite its higher cost compared to other resins, manufacturers widely use TPU to create parts with rubber-like attributes.

Common Issue With clear injection Injection molds

Some of the common defects that are evident in clear plastic injection molding parts and the possible solutions include the following:

Plastic parts that are transparent are vulnerable to different kinds of defects during the molding process. It is important to understand these defects and how to avoid them in order to manufacture high-quality transparent products. Here are some of the most common defects and their respective solutions:

1. Air Traps

Air pockets frequently lock into the resin during molding, a phenomenon that will be visible in the final product. This is usually a result of poor venting or low pressure during injection of the material.

Solution: By enhancing the mold design to incorporate the correct venting channels and increasing the injection pressure, we can reduce the air traps and increase the product transparency.

2. Flow Lines

Flow lines, also known as streaks, form on the surface of clear plastic parts due to variations in material flow during the injection molding process. These lines can mar the beauty of the product.

Solution: To minimize flow lines and improve the overall surface finish of the clear plastic injection molding part, adjust the injection speed, pressure, and gate design.

3. Sink Marks

Sink marks, which are tiny indentations on the plastic part’s surface, typically result from variations in the cooling rate or incorrect resin filling during the solidification process.

Solution: Reducing cooling time, controlling packing pressure, and applying proper mold temperature control measures can go a long way in reducing sink marks and enhancing the quality of the part.

4. Surface Scratches

Surface defects like scratches or marks from handling or ejecting molded parts affect the transparency and surface finish of clear injection-molded products.

Solution: Proper handling and ejection procedures, mold release agents, or surface treatments can help avoid surface scratches and ensure product clarity.

5. Haze or cloudiness.

Several factors, such as inadequate drying of the raw material, contamination, or high moisture content during the molding process, can cause misting or clouding of clear plastic injection molding components.

Solution: To avoid hazing and obtain clear, transparent parts, it is necessary to pay attention to the correct handling and storage of materials, the use of dry resins, and the correct processing conditions.

Manufacturers can produce clear plastic parts with excellent clarity and aesthetic value if they correct these defects and apply the right solution.

Surface Finishing Selection and Design Tips For Clear Injection Molds

In as much as the clarity of the plastic parts is concerned, choosing the right surface finish is very important. Manual sanding and polishing are useful for rougher designs that do not have fine details, but they are not efficient for creating clear products. If the production run is low or the prototype or project is a one-off, the SPI-A2 finish may be sufficient, particularly if surface finish is not taken into account when evaluating a prototype. We also observed that deferring the concept of surface finish to the production level could result in significant time and cost savings.

For flat or nearly flat transparent parts such as windows or lenses, the best surface finish is the resin coating. Be aware that release agents damage the part’s surface and should not be used. It is important to note that lead times and costs of surface finishing may differ depending on the project.

Several aspects should be considered when designing clear or translucent plastic injection molded parts. Maintaining constant wall thicknesses throughout the part is crucial to maintain consistency in clarity. Other considerations include designing gate runners that are wide enough and placing gates in such a way that they will accommodate the contraction process. The lack of sharp corners, especially for PC products, helps to avoid gaps and make the transitions clearer.

Furthermore, maintaining a smooth surface of the mold and proper cooling will reduce the surface defects and the decline in the clarity of the plastic in clear plastic injection molding. We suggest reading more about transparent injection molding to obtain more specific design recommendations.

If You Require Clear Plastic Injection Molding, Then Sincere Tech is The Company To Turn To.

Transparent injection molding is more critical and needs more attention than non-transparent molding when it comes to the production of clear plastic parts through injection molding. Clear polymers have different characteristics, such as different strengths, temperature limits, and chemical resistance. Therefore, these factors should guide the selection of the most suitable clear plastic material for a given project.

Sincere Tech is one of the top 10 plastic injection molding companies in China that focuses on helping clients determine the best clear plastic material for their parts. Whether you require help with the creation of a prototype or have questions about clear plastic resins and injection molding, our team is ready to help. Please get in touch with us now to share your project specifications with us.