When choosing between the material types for a certain usage, it is significant to distinct between Thermoplastic Elastomers (TPE) and Thermoplastic Polyurethane (TPU). Both are versatile polymers and have some special characteristics. They allow them to be applied in many fields. TPEs are famous for their flexibility, their readiness for processing, and their low cost. So, this makes TPEs suitable for those applications where only moderate performance is needed. Unlike TPUs, provide improved toughness, wearing, and chemical properties to serve challenging applications as well as higher performance requirements. So, in this article, we will explore TPE vs TPU, their differences, similarities, and properties.

What is TPE?

TPEs are the short form of Thermoplastic Elastomers. It’s a type of polymer that has characteristics of rubber with recyclable thermoplastic material. It is as flexible as rubber but at the same time as manageable as thermoplastics. TPEs are mostly used in those areas in which flexibility, strength, as well as ease of formulating, are considered vital. Go to is TPE safe to know more about TPE.

What is TPU?

Thermoplastic Polyurethane (TPU) is described as a thermoplastic elastomer with very high resilience, strength, and abrasion, chemical, and oil resistance. TPU is notable for the features of both plastic and elastomeric materials and exhibits outstanding performance in many severe applications. Got to is TPU safe to know more about TPU.

Complete Process of the Manufacturing of TPE and TPU?

Let’s discuss the complete process of manufacturing both TPE and TPU.

1. Manufacturing Process of TPE

The following is the step-by-step process of Thermoplastic Elastomers manufacturing.

1. Blending

In the case of TPEs like Styrenic Block Copolymers (SBCs), the method of manufacture is by compounding the polystyrene with elastomeric polymers, i.e. polybutadiene. The composition is heated to melt it and then the solidification process is carried out to obtain the final product.

2. Polymerization

In the formation of TPEs, the propylene must be reacted with other monomers in a controlled manner. So, it can produce a thermoplastic elastomer. This process can be done through some techniques including bulk or solution polymerization.

3. Vulcanization

Concerning the production of Thermoplastic Vulcanizates (TPVs), the method used during the formation is called dynamic vulcanization. During the melt processing of this thermoplastic polymer, a cross-linking agent, i.e. sulfur is added in this process. The end product is a blend where the elastomeric part is at least partially cross-linked. Then it helps improve the material’s elasticity and mechanical characteristics.

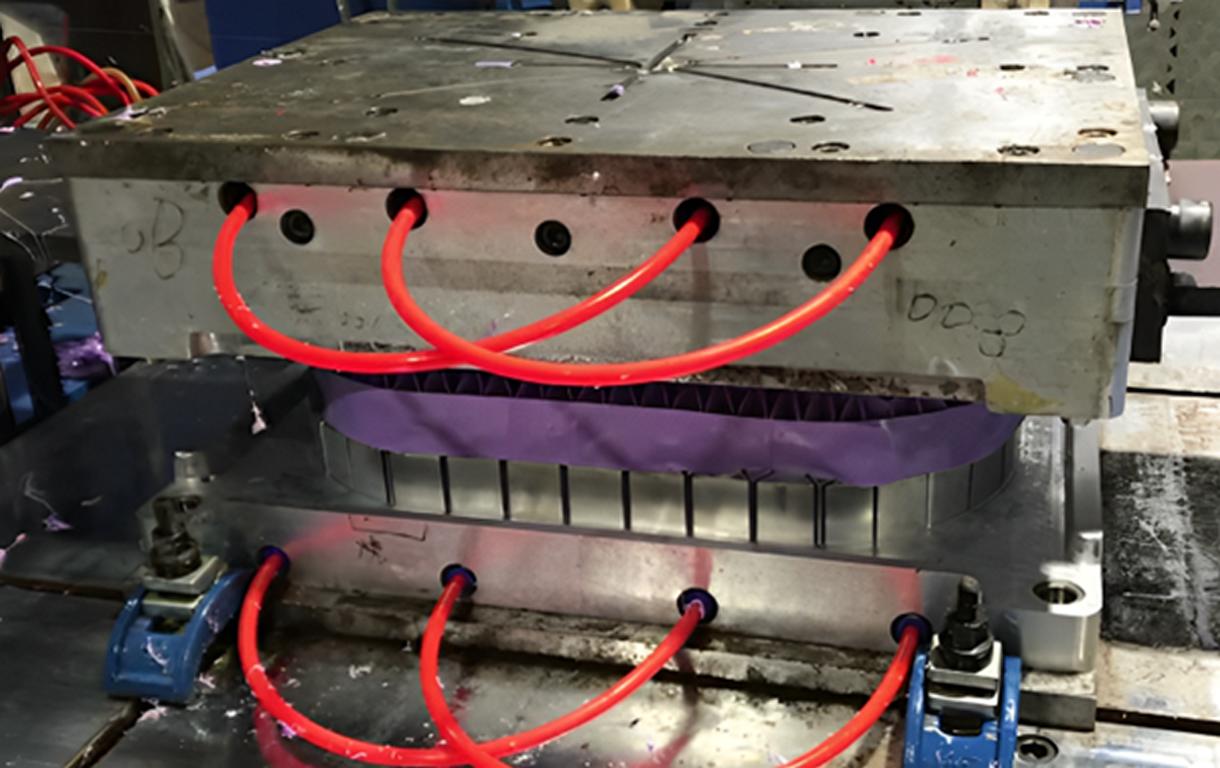

4. Extrusion and Molding

Following the blending or polymerization, TPEs then need to be processed through extrusion or injection molding. Extrusion on the other hand involves the use of a die to extrude continuous shapes of the molten TPE. Whereas injection molding is carried out by injecting the molten material into molds to make desired shapes and products.

2. Manufacturing Process of TPU

Here is the step-by-step process of Thermoplastic Polyurethane (TPU) manufacturing.

1. Polymerization

We make TPU using diisocyanates (for instance methylene diphenyl diisocyanate or toluene diisocyanate) and diols (e.g. polyether or polyester diols). So, this reaction is carried out in a controlled manner to produce the polyurethane polymer.

2. Compounding

After polymerization, the TPU polymer is mixed with fillers such as plasticizers, stabilizers, and colorants, to facilitate it to develop the required characteristics. In this process, melt mixing is carried out using an extruder. Although other methods may be involved at this stage.

3. Extrusion and Injection Molding

TPU like any other thermoplastic elastomer is processed by extrusion or injection molding. Although more advanced methods are used in the processing of TPU as compared to TPEs. Extrusion is the process, in which TPU is forced through a die and shaped into long profiles. While injection molding is the process of injecting the TPU into a mold to make certain parts.

4. Calendering and Casting

For some applications, TPU can also be processed through the calendering process in which TPU is turned into very thin sheets through rolling or casting. Here TPU is poured directly into films or sheets.

Properties of TPU

- Flexibility: TPU provides great flexibility and elasticity for the analyses.

- Durability: Referred for quality features such as abrasion, wear and tear resistance.

- Chemical Resistance: Withstands oil, grease, and chemicals moderately well.

- Temperature Range: Since they can work at high speeds, this design of UV LED can be used in a broad temperature range of -40°C to +80°C.

- Transparency: It is possible to make TPU transparent which can be advantageous in some uses.

Properties of TPE

- Elasticity: Exhibits rubber-like elasticity.

- Processability: They are easy to process as well as mold with good flow characteristics.

- Flexibility: Usually has moderate workability but can be specially compounded to give it low or high hardness.

- Recyclability: It can be recycled which makes it an environmentally friendly mattress.

- Cost-Effectiveness: Usually cheaper as compared to some of the other elastomers.

Material characteristics of TPE and TPU

- TPE Materials: TPEs are based on several polymers, i.e. styrene block copolymers, polyolefins, and thermoplastic vulcanizates. They are regularly compounded with additives like plasticizers, stabilizers, fillers, and colorants to obtain desired characteristics. The other two are the processing help and the specialty additives which can also be utilized to improve the performance and workability.

- TPU Materials: TPUs are produced either from polyester or polyether diols together with diisocyanates. They contain plasticizers, stabilizers, fillers, and colors. While the others have cross-linking agents for better performance. Functional additives which are also referred to as processing resources and specialty additives are intended for altering physical characteristics and performance.

What is the difference between TPE vs TPU?

Let’s discuss the major differences between TPE and TPU in depth

1. Chemical Composition

- TPE: This is a generic classification that contains a range of polymers falling under this category including SBCs, TPOs, and TPVs. These are a polymer that exhibits both elasticity and thermoplastic characteristics. So, they may be either blends or copolymers.

- TPU: More precisely they are produced by polyurethanes, which are formed by the action of diisocyanates and diols. TPUs are examples of thermoplastic elastomers, however, they are chemically different from other thermoplastic elastomers. Besides this, they are made from polyurethane.

2. Material Characteristics

- TPE: Provides softness and flexibility of the product. TPEs can be made to have moderate elasticity or high elasticity depending on the requirement of the application it will be used. These cause them to be generally more easily processed and shaped because of lower processing temperatures and viscosities.

- TPU: This material has a notable excellent abrasion resistance, and high mechanical strength and it is chemically and oil resistant. TPUs do not lose their performance when exposed to low or high temperatures.

3. Processing and Manufacturing

- TPE: Faster to decompose, or having lower melt viscosity. It is easier to process and therefore, cheaper to manufacture. Products made from TPE mostly undergo injection molding, extrusion as well as blow molding.

- TPU: Needs to be processed at higher temperatures and the melt viscosity to be higher makes the processing more challenging. Nonetheless, TPU can be processed in the same manner with popular tactics such as injection mold and extrusion.

4. Performance Properties

- TPE: Has poor abrasion resistance and mechanical strength in comparison to TPU. It may also not withstand severe chemical or high/low temperatures better than the other types.

- TPU: It demonstrates very high tensile strength, superior abrasive characteristics, and satisfying results in low and high-temperature ranges. It offers better chemical resistance as it can handle difficult chemical environments.

5. Cost and Recyclability

- TPE: Usually cheaper than TPU and it is easier to recycle as well. Compared to metals, its processing and material costs are usually lower. So, it is suitable for most uses.

- TPU: Has a lower cost than TPE because it offers better performance characteristics. TPU can be tougher to recycle. So, its environmental impact might be influenced.

6. Applications

- TPE: Found in consumer products, automotive applications, sealing applications, gaskets, and medical devices. It is selected for applications where flexibility and costs are key requirements rather than looking for a high degree of durability.

- TPU: Common in applications demanding high performance, i.e. manufacturing of car parts, industrial parts, sports shoe soles, and medical apparatus among others. It is best suited for products that require or want high-level abrasion, evidently chemical, and high degrees of utterance.

| Characteristic | TPE (Thermoplastic Elastomers) | TPU (Thermoplastic Polyurethane) |

| Chemical Composition | It is generally made of various polymers (e.g., SBCs, TPOs, TPVs) | It is a composition of Polyurethanes (diisocyanates + diols) |

| Material Characteristics | Relatively flexible, soft, and can be rigid or flexible | Shows high abrasion resistance, strong, and chemical-resistant |

| Processing | Quite Easier, needs lower temperatures, and requires simpler molding | It might require Higher temperatures and have more complex processing |

| Performance Properties | Generally have a lower abrasion and mechanical strength. Besides this, it has limited chemical resistance | Have superior abrasion resistance, high strength, and extreme temperature performance |

| Cost and Recyclability | Generally lower cost, easier to recycle | Have a Higher cost and is more challenging to recycle |

| Applications | Wide applications in consumer goods, automotive parts, seals, and medical devices | Many uses in industrial parts, footwear, automotive components, and medical devices |

What are the similarities between TPE vs TPU?

Both TPE and TPU belong to the thermoplastic family. So, they have many things in common. Let’s discuss these common features in detail.

- Thermoplastic Nature: Both can be reused and recycled several times by heating the process.

- Elastic Properties: They also get deformed, but these two materials are flexible, and they regain their original state once they are released from the deforming force.

- Processing Methods: All three processing methods, namely injection molding, extrusion, and blow molding are used for both.

- Customizable: Both can be of different hardness, flexibility, and strength depending on the engineering requirements.

- Consumer Products: Both of them can be applied in car components, clinical devices, and home appliances.

- Overlapping Use Cases: They are good for use when there is a need for flexibility and toughness for the required product.

- Recyclability: Both are recyclable in most cases although the process of recycling may be different.

- Environmental Resistance: They provide some extent of barrier against moisture and Ultra Violet light, depending on the formulation.

TPE injection mold

What Are the Mutual Alternatives to TPE and TPU?

| Material | Description | Advantages | Disadvantages |

| Silicone Rubber | It is an elastomer with high flexibility and temperature resistance. | Excellent temperature stability and chemical resistance. | Typically more expensive, and harder to process. |

| EPDM Rubber | Mainly a synthetic rubber with good weather and ozone resistance. | Shows high durability, good for outdoor use. | It has lower flexibility than TPE and TPU. |

| Neoprene | It is also a synthetic rubber known for flexibility and weather resistance. | Have good chemical resistance and flexibility. | It has less tensile strength and abrasion resistance. |

| Viton (FKM) | It is a fluoroelastomer with high chemical resistance. | Have superior chemical and temperature resistance. | Have high cost and rigidity. |

| Polyolefin Elastomers (POE) | Flexible and versatile material similar to TPE. | Has good flexibility and low density. | It has limited chemical resistance compared to TPU. |

What Are the Benefits of TPE Compared to TPU?

- Cost-Effective: Usually there is a higher production cost when manufacturing solid foods but the cost is generally lower.

- Ease of Processing: Reduced temperatures at which the articles can be processed, and easier molding of the material.

- Flexibility and Softness: A comprehensive parameter of the softness and flexibility of surgical staplers is available.

- Recyclability: Recyclability or reusability in form and material is the fourth criterion and states that an object should be easy to recycle or reprocess.

- Versatile Formulations: Exists in different forms to meet specific properties of the specific application.

What Are the Drawbacks of TPE Compared to TPU?

- Lower Abrasion Resistance: Leaves a lot to be preferred in high-wear applications.

- Chemical Resistance: In general, more susceptible to chemical, oil, and solvent attacks.

- Temperature Tolerance: Reduced performance where the temperatures are either high or low.

- Mechanical Strength: Generally it exhibits lower tensile strength and tear strength.

What Are the Benefits of TPU Compared to TPE?

- Superior Abrasion Resistance: Extreme wear nature provides a very good performance in applications that are likely to wear out quickly.

- Chemical and Oil Resistance: Not easily decomposed by chemical solvents and other chemicals.

- High Performance at Extremes: Resistant to high and low temperatures of both ambient and dry ice.

- Strong Mechanical Properties: Superior tend strength and increased impact qualities.

- Customizable: Comesity of hardness and elasticity, options.

What Are the Drawbacks of TPU Compared to TPE?

- Higher Cost: As a homemade product, it will be more expensive to produce than traditional consumer products.

- Processing Complexity: It needs high temperatures and specific apparatus or instruments.

- Recycling Challenges: When it comes to recycling it is more difficult to do so compared to the TPE.

- Limited Formulations: There are fewer types compared to TPE as a result of development.

When to Choose TPE?

- Cost-Efficiency: When budget is an issue, as with TPE, the use of this form can be less costly.

- Simple Processing: For applications wherein easy molding is required and the molding temperature is comparatively low.

- Flexibility: When the application of the rubber products involves elements that require softness and flexibility such as grips or seals.

- Recyclability: While for production that is environmentally friendly with relation to its impact and easy to recycle.

- General Use: These are the applications that do not require high-level performance from the brushes.

When to Choose TPU?

- Durability: Where there is going to be high wear and friction and high abrasiveness is required.

- Chemical Resistance: When working with chemicals, oils or solvents are to be encountered Individuals that have to wear gloves include those when working with.

- Temperature Extremes: When it comes to high temperatures and even for low temperature application could also be attained.

- Mechanical Strength: If high tensile and impact strength applications are required.

- Special Performance Needs: for such specific needs to be met by various built environments, one can refer to customized properties like

TPU injection mold

Conclusion

In conclusion, TPE Vs. TPU, despite the similarities, TPE and TPU are different materials with their notable features and drawbacks in the aspects of usage. TPEs are relatively cheaper, and their processing is also easier as compared to other elastomer. This makes it versatile to use. At the same time, TPUs are designed for the highest loads and requirements in terms of wear, heat, and chemical resistance. As for the differences in properties of TPE and TPU, it is possible to state the following: The superiority or inferiority of TPE as compared to TPU depends on the special demands of the material, cost considerations, and technological capabilities of further processing of the product.

Frequently Asked Questions

Q1. What is the primary difference between TPE and TPU?

The most significant distinction is that TPU is a particular kind of TPE. However, it has higher potential regarding its strength, resistance to chemicals or solvents, and adapted temperature segments.

Q2. Are TPU and TPE recyclable?

Recycling of TPE and TPU is possible although the options that are available for recycling are limited as compared to other thermoplastic elastomers.

Yes, TPE is recyclable; the same case applies to TPU materials as well.

Q3. Which of the two is cheaper, TPE or TPU?

TPE has a slightly lower cost as compared to TPU.

Q4. How does TPU differ from TPE concerning their applications

TPU is suitable where reinforcement is necessary, the application is exposed to chemicals or harsh environments, and the application also needs to withstand high heat.

Q5. Can TPE be used in regions with extraordinary climate conditions?

There are some disadvantages related to TPE. Due to this, it may not be as equally effective as TPU specifically in severe conditions.