High volume injection molding is a critical process in manufacturing large volumes of plastic parts in a short time. It’s a straightforward process involving two key steps: acquiring the mold and then using it to make parts. This systematic approach helps cut down the cycle time and ensures that the output is standardized and, hence, is cost-effective for large projects due to economies of scale. Also, it has versatility in the choice of material since it can work with almost all types of plastics.

Quality control is also given a high priority at Sincere Tech when it comes to high-volume injection molding. The emphasis is made on the quality and accuracy of each part made of plastic. First of all, we focus on cooperation with clients to identify their requirements for the design, materials, and production. Our expert team then uses CAD models to design custom injection molds, and then we test them to ensure that they meet the required standards before the actual production process is initiated.

In this case, we use modern machines and fully automated production lines to ensure that we produce high-quality products with efficiency and accuracy. There are several quality control checks that are done at the various stages of production; this includes checking the raw materials before they are used and checking the final product before it is sold. The performance is also monitored through the use of continuous data analysis to achieve the best results at every stage of production.

High Volume Injection Molding Materials & Technologies at Sincere Tech

Our high volume plastic injection molding services at Sincere Tech involve a variety of materials, including thermoplastics like PE, PP, PS, and PVC, and thermosets like epoxy, phenolics, and melamine.

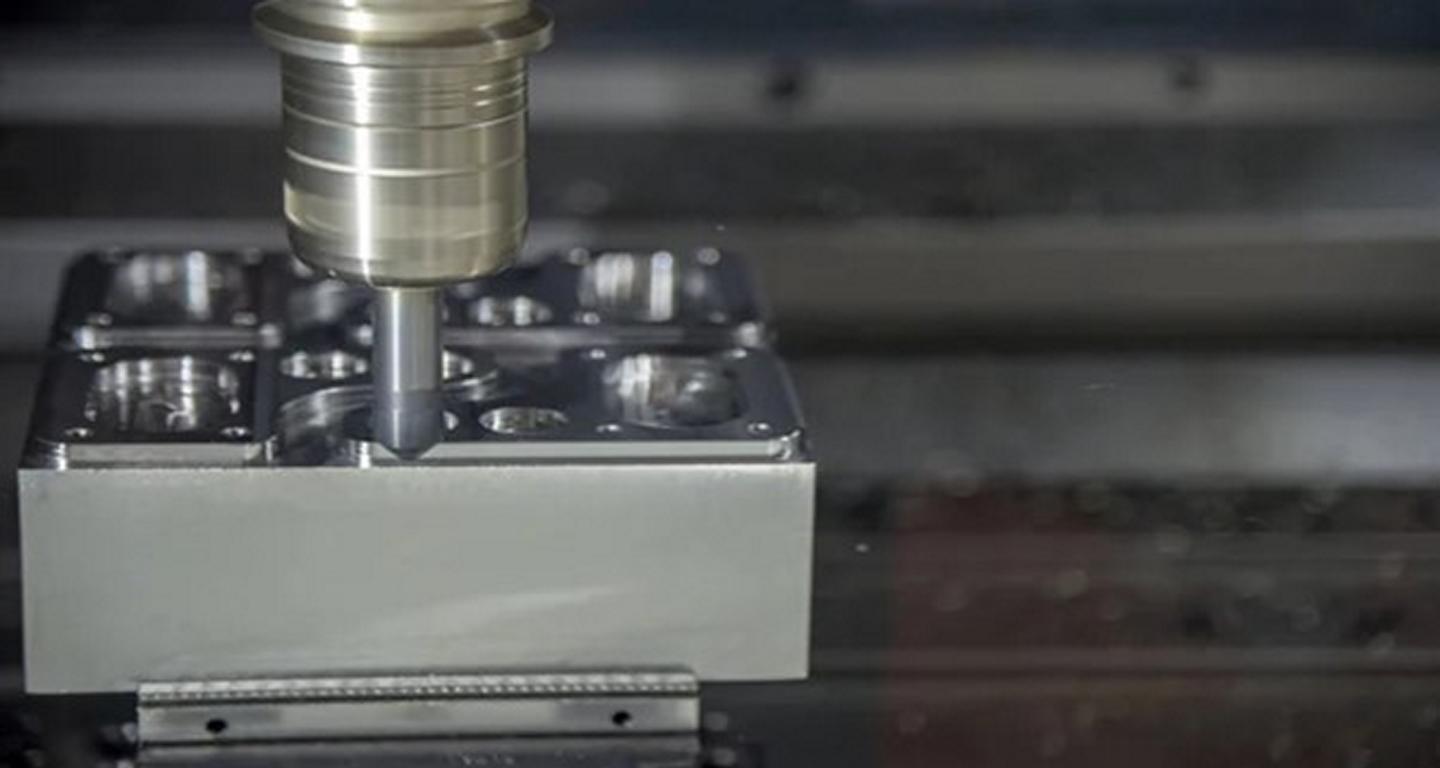

Accuracy in molds is very important when it comes to manufacturing high quality, identical injection molded parts in large quantities. We employ state-of-the-art CAD/CAM technologies to design and develop molds specific to each component’s specifications. Automation is very important in our high production injection molding process to reduce cycle time, increase productivity, and reduce manual handling for quality production.

Custom High Volume Injection molding at Sincere Tech

Sincere Tech is a company that deals with high volume custom injection molding of plastic products. Our services range from prototype to production quantity levels. We pay close attention to the management of our high-volume molds regardless of the number of shots, cavities, or the number of shots required. Such attention to detail ensures that every aspect of mold design and manufacturing is in harmony with the project objectives and schedule.

The approach that we have adopted with our clients is to design and engineer the products and, at the same time, create high volume cost effective molds. Sincere Tech provides services such as low volume molding, insert molding, and pad printing for different industries such as medical, electrical, hand tools, communications, and automotive.

We employ hi-tech computerized systems and mechanical gadgets to facilitate production and quality control. Our services range from designing to delivering the end product, thus offering a complete plastic injection molding solution for every project.

High volume injection molding at Sincere Tech also ensures that the manufacturing process of the plastic parts is fast and cheap, and the quality of the products is always high since they are all alike. This commitment to quality improvement means that no matter if an order is for a few prototypes or a million production parts, the quality is the same. For high-quality and fast, high-volume molding services, please contact our specialists at Sincere Tech.

Three Volumes of Injection Molding

Different plastic injection molding providers often focus on specific volume categories:

Small-Volume Plastic Injection Molding: These providers are most suitable for projects with less than 10,000 parts. They usually employ aluminum tooling for short time production runs. Small-volume specialists are great for; Small-volume specialists are great for:

Prototyping injection molding: Cheap and fast for determining the feasibility of designs, form, fit, and function, and for prototyping before production.

Low-volume injection molding production: It is a very efficient and economical process for applications such as specific medical devices that are not required to produce hundreds of thousands of parts.

Market testing and pilot production: Perfect for making a transition from short-run production to volume manufacturing.

Medium-Volume Plastic Injection Molding: These companies specialize in medium to high volume production of between 10,000 and 750,000 parts. They use aluminum or pre-hardened steel tooling, depending on the order size.

Large-Volume Plastic Injection Molding: These providers focus on orders over 750,000 parts and can manufacture hundreds of thousands of parts with precision and quality. They employ only the best hardened steel molds and incorporate modern technology, and they usually do not take orders below 750,000 parts. This category includes:

- High tolerance precision, low scrap loss, and low cost.

- Little post-production work is required because of the technology used and the quality of molds.

Considerations for Choosing Between Low and High-Volume Injection Molding

Choosing between low and high-volume injection molding depends on several factors that should be considered carefully:

Production Needs: If the production requirement is less than 75,000, then low-volume injection moulding is often the most suitable because of the cost advantage.

Design Complexity: In the case of special or prototype designs, low-cycle injection molding is useful in the economical testing and development of the tool.

Production Cost: When costs increase during production, prototyping, and automation can be advantageous to a business. High volume injection molding becomes more possible in such cases as it greatly cuts the cost of per unit production.

Set-Up Budget: It is possible to begin with low volume injection molding, especially if there is a limitation on the amount of capital to be invested in the molding process since high-volume molding calls for a huge investment at the initial stage. Also, high-volume processes using steel tools will result in long cycle times and high material costs.

Advantages of High-Volume Injection Molding:

- Cost-Effective Production: Flexible and fast, which reduces labor and material expenses.

- High-Production Output: Can manufacture many parts at once to address the variations in demand.

- Consistent Quality: This guarantees that the parts are accurate and similar, with very small variations and complex features.

- Versatility in Part Design: It can produce various designs and shapes and work with different geometries.

- Reduced Waste: Reduces the amount of scrap and waste since injection parameters are well controlled and the molds used are of high quality.

- Increased Production Efficiency: Very low level of manual intervention and is mostly operated through computer systems.

Disadvantages of High-Volume Injection Molding:

- High Initial Investment: This involves a high initial cost for mold design and construction.

- Long Lead Times: The creation of molds can take a long time since the design and production of molds require time.

- Limited Material Choices: Some plastic resins may not be ideal for high-volume manufacturing.

- Limited Design Flexibility: Accurate process that restricts the geometry of the part, especially for intricate shapes.

- High Maintenance and Repair Costs: Maintenance and repairs of molds are often costly and may require frequent replacements.

Material Types Used In High Volume Injection Molding

High volume injection molding requires careful consideration of the type of material to be used to get the best results. Polypropylene (PP) is the most popular type due to its low cost, high strength-to-weight ratio, and high impact resistance. It is used in the automotive, packaging, and consumer goods industries. On the other hand, Acrylonitrile Butadiene Styrene (ABS) has the properties of being tough, impact resistant and smooth finish used in toys, automotive parts and electronic devices.

Polycarbonate (PC) is highly valued for its ability to withstand impact, transparency, and heat stability, which makes it suitable for the automotive, aerospace, and electronics industries. Polyethylene (PE), which is flexible, hard, and chemically resistant, is used in packaging, plastic bags, and agricultural films because it is light and can be molded in many ways.

Polyethylene Terephthalate (PET) excels with its strength, transparency and barrier properties, making it suitable for use in beverage bottles, food packaging and protective packaging. Finally, Polystyrene (PS) is cheap, lightweight and insulating, which makes it ideal for use in disposable cups, packaging and insulation. Each of them meets certain requirements, which guarantees the quality of the final product in large-scale injection molding.

Machine Types Used for High volume Injection Molding

Injection molding machines are used in high-production processes, where the plastic material is injected into a mold to produce different parts.

Hydraulic Injection Molding Machines are machines that use hydraulic pressure to operate and are characterized by high production rates but slow cycle rates, thus appropriate for high production volume but low cycle time applications. Electric Injection Molding Machines, which are driven by electric servo motors are very accurate and fast and are suitable for applications in areas such as the production of medical equipment and electronics.

Hybrid injection molding machines are a combination of hydraulic and electric machines, which are efficient, fast and offer high production rates, thus suitable for high production requirements.

Two-Shot Injection Molding Machines are used to make parts of two different materials or two different colours and are suitable for making parts with high complexity.

Multi-Material Injection Molding Machines have multiple injection units for the processing of different materials at once to meet the requirements of parts with different properties such as strength, durability, and flexibility. Liquid Injection Molding Machines are specifically designed for producing LSR parts, and the parts are very accurate and strong, making them ideal for applications such as medical equipment and automotive parts. These machines are used to meet particular production needs and help achieve high-quality and fast high-volume molding.

Design Considerations For High Volume Injection Molding

Several factors need to be taken into account when designing a plastic part for high-volume injection molding.

First, the wall thickness should be uniform so that the cooling process will not be a problem and the part will not warp. Thin walls are suitable for mass production as they use less material and time as compared to thick-walled parts that provide extra strength where required.

This is also true in the size and shape of the part, as it determines the time taken in production. Shapes that are large or complex may take longer cycles or specialized equipment which increases the cost. The more complex the design, the more difficult it is to produce many items; therefore, geometric patterns are preferred. Draft angles should also be incorporated into the design to enable easy removal of the parts and to prevent problems such as cracking or deformation during production.

The location and size of gates are very important. Gates should be positioned so that they will not compromise the structure of the building and be of the right size so that they do not interfere with the flow of materials that are to be transported. Material selection should take into account the requirement of the part to be manufactured in terms of strength, durability, and flexibility.

Surface finish matters too. The surfaces of parts should be polished and should not contain any imperfections such as warping or sink marks. Some of the factors that help in attaining a smooth surface include proper gate placement, mold design, and the choice of material. Lastly, tolerance, which is the permissible deviation in the dimensions of the parts, should be given due consideration right from the design stage so that the parts can be manufactured accurately and with a high degree of precision.

Common defects In High Volume Injection molding

In high volume injection molding, there are several types of defects that may affect the quality of the end product. Sink marks are those marks which are formed due to the uneven distribution of material during the cooling process and can be avoided by redesigning the part and ensuring that the wall thickness is uniform. Distortion, which results in part distortion, can be prevented by regulating the temperature of the mold and by including features that reduce stress.

Flash excess material that protrudes from mold joints is caused by misalignment or lack of clamping force and can be avoided by correct alignment of the mold and sufficient clamping pressure. Short shots and incomplete filling of the mold cavity due to problems such as low injection pressure or blocked gates can be solved by adjusting the injection parameters and gate design.

Finally, weld lines, which are apparent signs of meeting flow fronts, can be avoided with proper design of the mold and injection parameters to ensure equal material distribution. These strategies assist in ensuring that the quality of the products produced by the high volume injection molding is high.

Tips To Maximize the Productivity of High-Volume Injection Molding

Problem-solving in high volume injection molding is crucial to ensure the quality of the end products. Here are some practical tips for addressing common issues:

Check Machine Settings: Start the problem-solving process by checking the injection molding machine parameters. Ensure that the temperature, pressure, and cycle time are correctly set depending on the material to be processed.

Address Material Flow Problems: Pay particular attention to any problems that may arise in the field of material flow. Defective settings of the machines or the presence of barriers in the flow of materials can also be a hindrance. Make sure that the material does not jam in the machine during the process.

Combat Warping and Shrinkage: Distortion and shrinkage are typical issues in large-volume injection molding because of non-uniform cooling. Reduce the cooling time depending on the material properties to prevent warping and shrinking of the part.

Prevent Air Traps: Air locks are formed when air is locked in the mold cavity, and this results to the formation of voids or bubbles. Make sure that there are no trapped air pockets in the mold so that they do not influence the final product.

Monitor the Process: Ensure that you monitor the whole injection molding process very closely. The following are some of the best practices that can be followed to ensure that the problems are detected early: This proactive approach enables one to prevent possible issues that may affect the quality of the products.

Conclusion

If you are still unsure of which molding process to use, you should consider seeking the help of a professional. However, to get the best results, it is imperative that the selected injection molding process is in sync with the production requirements. Any difference can lead to an interruption of the production process, and this, on its own, increases the cost greatly.

They may cause disruptions that hinder production, and this, in turn, has an impact on your ability to produce quality products at reasonable prices. This can, in the long run, affect your customer relations and their satisfaction levels.

Sincere Tech is one of the leading China high volume injection molding companies in the Plastic Injection Molding industry, and it has always been appreciated for its good communication with customers and clients from all over the world. They can advise you on what you need to do and how to do it to lead you to the right decision concerning your production needs.

What is plastic injection mold press

Plastic injection mold press is simple called press. Plastic injection mold press holds the plastic mold in which the components are shaped. Mold press is rated by tonnage, which expresses the amount of clamping force that the machine can generate. This pressure keeps the mold closed during the injection process. Tonnage can vary from less than 5 tons and big than 5000 tons, with the higher figures used in comparatively few manufacturing operations.

Plastic injection mold press is simple called press. Plastic injection mold press holds the plastic mold in which the components are shaped. Mold press is rated by tonnage, which expresses the amount of clamping force that the machine can generate. This pressure keeps the mold closed during the injection process. Tonnage can vary from less than 5 tons and big than 5000 tons, with the higher figures used in comparatively few manufacturing operations.

Plastic injection mold press can fasten the plastic molds in either a horizontal or vertical position. The majority is horizontally oriented, but vertical machines are used in some niche applications such as insert molding ( click here to know more about insert molding) allowing the machine to take advantage of gravity.

Plastic injection mold press is used to create many things such as milk cartons, packaging, bottle caps, automotive dashboards, pocket combs, and most other plastic products available today. It is known that injection molding is the most common method of part manufacturing. It is ideal for producing high volumes of the same object. Go to injection molding page to know more about injection moulding.

Basic Components of a Plastic Injection Mold Press

The basic components of a Plastic Injection Mold Press are integral to its functionality, contributing to the precision and efficiency of the injection molding process. Sincere Tech China Mold Maker, a prominent player in the industry, understands the significance of each component in delivering top-notch manufacturing solutions. Let’s delve into the essential elements that constitute a Plastic Injection Mold Press:

1. Injection Unit:

- Hopper:

- The hopper serves as the reservoir for raw plastic material. Sincere Tech ensures that the hopper design facilitates efficient material loading and prevents contamination.

- Barrel:

- Within the barrel, the plastic material is subjected to controlled heating and pressurization. Sincere Tech’s barrels are designed for optimal heat transfer and durability, ensuring uniform melting of the plastic.

- Screw or Plunger:

- The screw or plunger is responsible for conveying the molten plastic material from the barrel to the mold. Sincere Tech’s precision-engineered screws and plungers ensure a consistent and reliable injection process.

2. Clamping Unit:

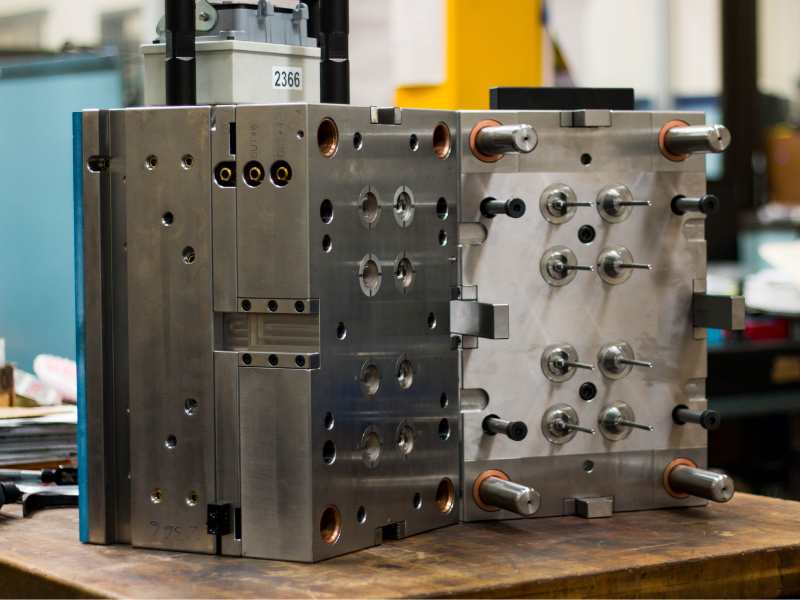

- Mold:

- The mold defines the shape and features of the final product. Sincere Tech specializes in custom mold designs, tailored to the specific requirements of clients across diverse industries.

- Clamping Mechanism:

- The clamping mechanism ensures that the mold remains securely closed during the injection process. Sincere Tech’s robust clamping systems guarantee stability and accuracy in the molding process.

- Cooling System:

- Efficient temperature control is critical for the solidification of the plastic within the mold. Sincere Tech integrates advanced cooling systems to maintain precise temperature levels, contributing to the overall quality of the molded products.

These components work seamlessly together during the injection molding process, reflecting Sincere Tech’s commitment to excellence in every facet of Plastic Injection Mold Press technology. Their attention to detail in the design and manufacturing of these components ensures that clients receive reliable and high-performance machinery for their production needs.

Advantages of Plastic Injection Mold Press

Sincere Tech China Mold Maker’s Plastic Injection Mold Press technology comes with a multitude of advantages, positioning it as a preferred choice for manufacturers seeking precision, efficiency, and versatility. Here are the key advantages associated with Plastic Injection Mold Press:

1. High Precision and Accuracy:

- Sincere Tech’s Plastic Injection Mold Press technology excels in producing intricate and complex designs with exceptional precision. The advanced control systems and precise engineering contribute to the consistent replication of detailed molds, meeting the strictest quality standards.

2. Efficient Production Rates:

- The efficiency of Sincere Tech’s Plastic Injection Mold Press technology translates into high production rates. Rapid injection cycles, coupled with reliable and durable components, ensure that manufacturers can meet demanding production schedules and reduce time-to-market for their products.

3. Versatility in Material Usage:

- Sincere Tech understands the importance of material flexibility in manufacturing. Their Plastic Injection Mold Press technology accommodates a wide range of materials, from traditional polymers to advanced engineering plastics. This versatility enables clients to choose the most suitable material for their specific application.

4. Reduced Material Waste:

- Precision control over the injection process minimizes material waste. Sincere Tech’s technology ensures that the right amount of material is injected into the mold, reducing excess and optimizing resource utilization. This commitment to sustainability aligns with global environmental goals.

5. Cost-Effectiveness:

- The efficiency and accuracy of Sincere Tech’s Plastic Injection Mold Press technology contribute to cost-effectiveness in manufacturing. Reduced waste, faster production cycles, and reliable operation result in overall cost savings for clients.

6. Scalability:

- Whether dealing with small-scale production or large-volume manufacturing, Sincere Tech’s Plastic Injection Mold Press technology is scalable to meet varying production needs. This scalability is crucial for adapting to market demands and business growth.

7. Consistent Quality Control:

- Sincere Tech places a strong emphasis on quality control throughout the manufacturing process. The precise control mechanisms in their Plastic Injection Mold Press technology ensure consistent product quality, minimizing defects and rejections.

8. Tailored Solutions for Diverse Industries:

- Sincere Tech’s expertise allows them to provide tailored solutions for diverse industries, including automotive, consumer goods, medical devices, and packaging. Their understanding of industry-specific requirements ensures that clients receive customized solutions that align with their unique needs.

In essence, Sincere Tech China Mold Maker’s Plastic Injection Mold Press technology offers a comprehensive package of advantages, making it a reliable and efficient choice for manufacturers seeking excellence in plastic injection molding processes.

Types of Plastic Injection Mold Press

Sincere Tech China Mold Maker offers a range of Plastic Injection Mold Press technologies, each catering to specific needs and preferences. Here are the primary types of Plastic Injection Mold Press provided by Sincere Tech:

1. Hydraulic Injection Mold Press:

- Description: Hydraulic injection mold presses utilize hydraulic systems to power the various components of the machine. These systems provide high force and are known for their robustness.

- Advantages:

- High clamping force suitable for large molds.

- Versatility in handling a variety of materials.

- Reliable and durable, with lower maintenance requirements.

2. Electric Injection Mold Press:

- Description: Electric injection mold presses rely on electric servo motors to drive the machine’s components. This type is appreciated for its precision, energy efficiency, and accuracy.

- Advantages:

- Higher energy efficiency and reduced operating costs.

- Enhanced precision and control over the injection process.

- Quieter operation compared to hydraulic counterparts.

3. Hybrid Injection Mold Press:

- Description: Hybrid injection mold presses combine hydraulic and electric systems to optimize performance. They often use electric motors for plasticizing and hydraulic systems for clamping.

- Advantages:

- Balances the energy efficiency of electric systems with the power of hydraulic systems.

- Provides flexibility in adapting to different production requirements.

- Offers improved precision in injection molding processes.

Sincere Tech China Mold Maker excels in delivering these types of Plastic Injection Mold Press machines, ensuring that clients have the flexibility to choose the technology that best suits their specific production needs. The company’s commitment to innovation and customization enables them to stay at the forefront of the industry, meeting the evolving demands of various manufacturing sectors.

If you are a plastic mold manufacturing company that produces anything from plastic molding toys to car parts and you are not using Plastic injection mold press to produce your parts, you will spend too much money. Indeed, using Plastic injection mold press provides additional savings to manufacturers because plastic is less expensive than metal and manufacturers pay for fewer parts. As a result, they are widely used because of the high quality of the end product.

One of Plastic injection mold press you can choose in the market is Plastic Injection Molder (YS-1180). This machine has moving platen featuring box type bridge structure and full-connected rear high-rigidity mold platen. Through finite element analysis, it can prevent deforming of mold platen, resist against fatigue, have high repetition accuracy, distribute mold closing force uniformly, greatly increase mold’s service life and reduce injection molding cost.

Another option of Plastic injection mold press is HDT-200 200ton plastic injection molder. This machine comes in two series; HDT series and HDF series. The HDT machines’ clamping force is from 80 tons to 2200 tons and the shot weight is from 80g to 2kg. These machines have strong locking force and a very good injection precise also a stable performance etc.

Meanwhile, the HDF machines are a type of high-speed Plastic injection mold press. The machine’s cycle time is very short (2.6 seconds-3.6 seconds) with a high injection pressure (to be possible to reach 240MPA) and a high-speed injection (to be possible to reach 600MM/S). This machine can be used to produce the thin-wall products, especially the thin-wall snack boxes and containers (with the wall thickness of 0.4mm).

Or you can choose another option among other Plastic injection mold press available in the market. Just choose the one based on your needs and budget, and you will surely find the one you are looking for.

Related Info to Plastic injection mold press

Plastic Injection Molding Machine

Plastic injection molding machine, also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. Plastic injection molding … read more

Plastic Injection Molding Process

Plastic injection molding process requires the use of an injection molding machine, raw plastic material, and a plastic mold. In this process, the plastic is melted …read more

Blow Molding Machine

Blow molding machine is a machine used in blow forming jobs that become a multibillion-dollar business. It is a manufacturing process in which hollow … read more

Is your project ready for molding? Send us your requirement for quotation, we will send you the price in 24 hours, you will not lose anything but have our competitive price for reference.

Plastic Injection Molding Service

Looking for plastic injection molding service?

Contact us to get quote, we are A Custom injection mold maker in China that offers plastic injection molding services.

The excellent quality of our plastic molds and molded parts, coupled with our experience and the performance of our services give us today a high international recognition. Indeed, the company is specialized in International Business and has customers all over the world. SINCERE TECH has very high standards of quality control and always runs long tests to make sure that our Plastic Injection Molding Service reaches all the expectations of our customers. We believe that the quality of a company and its products are seen through time and this is why we like to build strong long-term partnerships with our customer

What is plastic injection molding process?

Plastic injection molding is a manufacturing process in which melted plastic is injected into a mold and then cooled to form a solid part. The mold is created from a metal or plastic tool (1.2344, H13, NDK80, etc.) and is typically made in two halves that are clamped together. The plastic material is heated in a barrel and then forced into the mold under high pressure where it cools and solidifies into the desired shape. This process is used to produce large quantities of identical parts with high precision and repeatability.

When do you need plastic injection molding service?

You may need plastic injection molding service when you require mass production of plastic parts with consistent quality and high precision. This process is ideal for producing large quantities of the same part, as the mold can be used multiple times to produce identical pieces. Additionally, plastic injection molding is well-suited for producing complex and intricate shapes that would be difficult or impossible to achieve with other manufacturing methods. This process is often used in various industries such as automotive, consumer goods, medical devices, and electronics.

plastic molding services

Benefits of plastic injection molding service

The benefits of plastic injection molding service include:

- High volume production: Plastic injection molding is ideal for high volume production of identical parts, as the mold can be used multiple times.

- Consistent quality: The process is highly repeatable, which leads to consistent quality of parts produced.

- Complex shapes: Plastic injection molding can produce complex and intricate shapes that would be difficult or impossible to achieve with other manufacturing methods.

- Material flexibility: A wide variety of plastic materials can be used in the injection molding process, including thermoplastics, thermosets, and elastomers.

- Cost-effective: The process is efficient and cost-effective for producing large quantities of parts, as the cost of the mold can be spread over many parts.

- Precision: The process can produce parts with high dimensional accuracy and minimal tolerance variation.

- Automation: Plastic injection molding machines can be automated for increased productivity and reduced labor costs.

Plastic injection molding is a versatile and reliable manufacturing process that can provide significant benefits for producing large quantities of complex and high-precision plastic parts.

Plastic Injection Molding Service in China

We are the manufacturer of our own moulds (toolmaker or plastic injection tooling) and support the production of Injection molded parts allowing reducing your numbers of suppliers. Our injection machines have clamping forces going from 60 to 1050 Tons (2000 Tons outside). Plastic injection molding is the process of producing parts from thermosetting and thermoplastic materials.

Our qualified teams of Designers, Quality controllers and our Research and Development Department allow us to complete our policy: achieving Customer Satisfaction through Improvement and Innovation. The quality of our products and organization permits us to obtain quality certifications (ISO 9001, ) and be awarded numerous times of “Quality Supplier” from different customers. We integrate constantly new resources into our process in order to anticipate any future need of the plastic injection molds market and we became one of the most innovative companies in the sector. The modernity and the organization of our facilities allow us to adapt very quickly to the customer’s needs.

SINCERE TECH has always the objective to stay one of the innovative leaders of the sector and play an important role in our customer’s development. The firm can now propose a total solution from mould design to the semi-finished product (All in-house). SINCERE TECH is always willing to integrate new processes to the solution proposed by staying aware of new technologies. If a customer has a special requirement, we will do everything to fulfill its needs.

Plastic Materials /Commodities

We are used to working with all the classic and less classic plastic materials except PVC (PP, PE, PC, ABS, PC+ABS, PA 6, PA 6.6, PBT, PMMA, TPU, PC+GF, AS, PTFE, POM, PEHD, PEEK…). Our main suppliers are Sabic, Bayer, and Chimei.

About the steel used for our moulds, for export plastic molds we work only with the best steel suppliers like Assab (Sweden), Buderus (Germany), Daido Steel (Japan) LKM( the biggest one in China). For our standard component suppliers, we work with Hasco and DME.

We are used to working with our suppliers the same way we work with our customers. It means good long-term relationships with high-quality policy.

Complex moulds: SINCERE TECH has a rich experience in difficult plastic mould and parts, complex moulds and is an expert in finding solutions to your issues. SINCERE TECH is a real specialist in difficult tooling. To give a classic example: many design companies create plastic products without thinking about mould construction. Then, when the designs are sent to toolmakers, it can be hard for them to make the exact parts (Difficult design, many sliders, many lifters, double injection with materials non-bonding well together, many details in awkward places…).

Most of the classic toolmakers will accept the parts and say that they are able to do it. And then, they will have problems with the plastic injection mould construction, the lead time will be extended and the quality of the tool will not be as expected. Often, these companies have to contact SINCERE TECH to help them to resolve their problems. If you are not sure about the complexity of your part, be sure about your mould maker’s professionalism. SINCERE TECH works closely with its customers in order to resolve any issues.

Thin Wall injection molding: it permits a precise, very accurate molding of plastics and gives better details to the product. This is the name referring to products with a wall thickness lower than 2mm. Usually, the flow is quick, permits a short cycle time and a cost-saving.

Hot runner mold: the special process of injection of plastics where the plastic is kept hot when going through cavities of the mould while the rest of the mould is getting cold to solidify the plastic part and create the molded part: this permits to save plastic material. This is mainly used for parts with medium or large sizes. We are used to working with all popular companies like Yudo, INCOE, Synventive, Husky, HRS… We also have the technology to make our own hot runner systems if the production of the parts (Molding) is made in-house. This again allows our customers to save costs.

Optical Lens Molding: precision molding for glass plastic. This is the technique to produce transparent plastic molded parts (For example Security cameras parts such as the dome cover or also phone frames).

Gas-assist Injection Molding: the plastic parts are gas-assisted molded which means that gas (Most often is nitrogen) is injected at the final stage of the part creation process. It permits to reduce the cycle time, the product weight, the risk of deformation and also the pressure tons injection needed. Moreover, it makes the part’s structure stronger with a better look.

LED/LCD frame molding: injection of plastics used for example to manufacture television screen monitors, computer back-light modules, GPS frames…

IMD, IMF, IML, IMR Molding: In-mold decoration. The decoration of the part is made inside the mould through a film. The film is printed before the molding with the designs wanted. It permits better productivity and extends the decoration’s lifetime. If the customer wants to change the design/decoration of the part, it is not necessary to make another mould but only to change the film. SINCERE TECH is experienced with In-mould forming, in-mold-labeling, and in-mold by roller.

Overmolding: this technique permits to join several components together with a thermoplastic material. This reduces assembly and labor costs. Because the parts are made together, this allows less risk of improper termination or misalignment and increases the design flexibility. Moreover, thermoplastic provides better resistance to vibration or shocks. This technique permits to increase resistance, reduce costs and weights.

Insert Molding: this is a technique where a small part (Stamping part, optical part…) is added or inserted to the Injection molded part.

Two-Shot Molding: 2 independent injection units using 2 different materials and/or colors. The first material is injected; then, the mould rotates and the second material is injected to make 1 part. It permits a 2-colour-molding or also called double injection, 2 shot molding, two-shot injection, overmolding, 2K injection, two colour injection, bi-injection, dual shot molding or multi-component molding.

CNC Technology. CNC is an abbreviation for Computer Numerical Control. This is a machine extremely accurately controlled by computer programs permitting a CAM (Computer-aided Manufacturing) through a CAD (Computer-Aided Design). Any plastic injection tool manufacturer uses it but the value-added of SINCERE TECH is the experience, professionalism, and training of the staff.

FMMS Molding or can be called RHCM (Rapid Heat Cycle Molding): excellence surface appearance: permits to take off the welding line. This process is integrated into the molding to save time. It is used for example for clear plastic parts.

US Welding: Ultrasonic Welding: process to weld/ join/ assemble plastic parts thanks to ultra-sounds.

Silk-Screen Printing: this is to print logos or designs on parts.

Dip-Coating: this is the process of putting the component inside a liquid solution to apply a thin film on it. It permits to manage, change the hardness, the strength of the part by protecting it and expanding the lifetime of the product. Then, the excess liquid has to be drained and evaporation of the solvent is done to create the thin layer.

Laser Etching: this process is made for cutting a shape, a pattern, an image on the plastic part. It is also called laser graving.

Sputtering coating: this is the process of creating a very thin layer of conducting material on the component. It is also called Plasma Enhanced Chemical Vapor Deposition (PECVD) and can be done with most metals like aluminum, stainless steel, copper…

EMI shielding: protect parts from electromagnetic interferences. It is used to protect electrical signals from the outside world. For instance, we use it with marine radars for Garmin.

Waterproof technology: SINCERE TECH has the experience to make water-resistant parts and is able to ensure in-house tests thanks to the IP68 tests.

Sub-assembly: this is the pre-assembly of a component who will be later on being assembled in a larger product.

R&D: SINCERE TECH has its own Research and Development department in order to work with the customers on their projects, advise them on designs, resolve issues and study the feasibility of those.

Quality Control: We have very high standards of quality control in order to respect any requirements from our customers. We have a 100% quality control on our plastic molded parts, it means we control any part coming out of our production.

At Sincere Tech China mold maker, our unwavering commitment to staying at the forefront of the plastic mold industry drives us to embrace advancements and anticipate future trends. We continuously explore innovative materials and composites that offer enhanced performance and promote sustainability. By investing in ongoing research and development, we consistently deliver cutting-edge solutions that meet the evolving needs of our valued customers. As a trusted injection mold supplier in China, we take pride in our unwavering dedication to excellence.

Aligned with our sustainability goals, we place a high priority on environmentally friendly practices. We actively seek out sustainable alternatives, such as biodegradable polymers, and implement recycling initiatives to minimize the environmental impact of our manufacturing processes. By choosing our custom injection molding services, you can align your brand with sustainable manufacturing practices and contribute to a greener future.

Ensuring quality is our topmost priority, and we maintain rigorous quality control measures throughout the entire manufacturing process. Equipped with state-of-the-art facilities and staffed by skilled technicians, we subject each product to thorough inspection and testing. This guarantees exceptional performance, reliability, and customer satisfaction.

When you choose Sincere Tech as plastic injection molding service partner in China, you can expect the highest level of professionalism, expertise, and innovation. Our dedicated team is committed to helping you bring your ideas to life, delivering superior products that excel in performance, durability, and cost-effectiveness.

Partner with Sincere Tech Mould suppliers for your custom plastic injection molding service, and benefit from our comprehensive capabilities, unwavering commitment to quality and sustainability, and our drive to exceed your expectations at every step of the process. Together, let’s bring your innovative ideas to life.

Sincere Tech specializes in custom injection-molded parts fabrication technology. Our engineers design and manufacture individual parts with our high-wear engineering-grade plastic materials, self-lubricating, wear-resistive, and maintenance-free plastic injection molded parts. Each material is designed to perform to the particular needs of your intended use application and can adore harsh conditions, such as chemicals, dirt, or heat resistance.

Our fast line service provides injection-molded plastic parts and prototypes in just 2-3 weeks in short leads. Furthermore, our injection molding techniques are perfect for small to extensive prototyping because we employ cutting-edge 3D-printed injection molds. This enables us to design, fabricate, and bring parts to market with minimal turnaround without compromising quality.

Why Choose Us for Your Custom Injection Molding Needs?

We set ourselves apart because our services comprise as;

- Perfect for Large Order Quantities: Suitable for large orders likely above 1000s pieces of prototypes.

- Most diminutive or maintenance-free parts with Longer Service Life: Our components provide longer serviceability without requiring maintenance.

- Rapid turnaround: Up to 70% faster than comparable injection molding methods.

- Extensive material options: Select from our diverse high-performance materials to meet your specified requirements.

Custom Injection Molding: An Overview

Custom injection molding or injection molding mold parts is a plastic part fabrication process that involves injecting stringent quality material into a mold die or cavity designed specifically for intended applications. This process allows design manufacturers to produce parts in low volumes to bulk. Generally, it’s also known as injection molding of plastics, as this process is carried out in the following manner.

The process starts by forcing molten polymer into a mold designed to match the shape of the desired product. The polymer is then cooled and solidified to form the required part released from the mold. The custom injection-molded parts or products manufacturing process provides flexibility and can be used for medium production for about a few 100s to manufacture 1000s of identical molded components at a large scale. The process is widely favored for its economic production and helps industries like automotive, aerospace, and electronics to fabricate prototypes for functional testing and enhance the aesthetics of intended products or end-use parts.

Custom Plastic Injection Molding Materials

The types of plastics used in custom injection molding are diverse, with different melting points and peculiar characteristics that can be adjusted to suit a specific application. Here are some commonly employed thermoplastic materials for manufacturing high-quality injection molded parts.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a widely used thermoplastic material that offers flexibility, low density, and good impact strength. It is unsuitable for applications requiring chemical, electrical, or UV resistance. Because of its strength,

ABS injection molding is widely used in products such as children’s toys, household appliances, and car parts.

Low Density Polyethylene (LDPE) & High Density Polyethylene (HDPE)

These versatile thermoplastics provide high tensile and impact strength and resistance to moisture. HDPE injection molding is used in consumer and industrial products, while LDPE, which is softer, is also used in similar applications. Both materials are appreciated for their high degree of durability and ability to be bent.

Polycarbonate (PC)

PC is a crystal clear, high-gloss matte, lightweight, and yet strong substitute for glass. It is highly resistant and has high impact and mechanical strength, PC injection molding parts aer good ideal for use in applications like bulletproof glass.

Polyamide (Nylon)

Nylon injection molding part is a popular thermoplastic known for its electrical properties, mechanical strength, heat, wear, and chemical resistance. Because of its durability and high functional performance, it is commonly used in the medical and automotive industries for injection molded mold parts.

High Impact Polystyrene (HIPS)

HIPS is an inexpensive, impact-modified crystalline styrene-rubber copolymer widely used in producing disposable cutlery and toys. It is non-toxic, suitable for use in food-contact applications, and appreciated for its flexibility and low price.

Polypropylene (PP)

PP injection molding part is a tough plastic with good chemical and stress resistance and high impact strength. Due to its high melting point, it is ideal for use in the food industry, where equipment must be durable and safe for use with food products.

These materials are chosen according to the application’s needs to provide the best performance and long life of custom injection-molded parts.

Tool Design and Engineering

In injection molding, the tool is the mold or die that forms the material into the intended part. It’s in fact a negative cavity that recreates the part’s shape with the correct dimensions to allow for the material to behave as desired during injection and cooling. In the production of custom molded plastic parts, it may be necessary to use one or several tools depending on the need. Although using more tools initially raises the cost a little, it greatly reduces the cost per piece in the long run, making it economical for mass production.

These tools are located in a mold base and are a single component of injection molding machines. Mold bases are costly, so we use insert tooling that can be fitted into existing polymer molding mold bases.

Our real engineers consider the details by analyzing DFM analysis to material, and technique selection when creating custom-molded plastic components, including tool design and process optimization. They incorporate the right manifold and runner systems, molding processes, and functionalities without extraneous features, thus cutting costs on your budget. The high-tech software helps uniformly transition from virtual technical 2D or 3D g-code to m-codes to accurate tooling in the tool room.

Tool Building

Sincere Tech has a functional tool building and mold maintenance department with experienced professional tool makers. By selecting the right steel grade tool to correspond to the particular process, our skilled engineers and manufacturers create and design accurate tools to meet the required standard. We employ CNC machines, precision optical laser engraving machines, laser and tig welders, EDM, heat treating, grinding, polishing, and plating capabilities, which allow us to build and sustain tools for maximum performance.

Lean Molding

Our on-site production unit uses advanced feature machines and presses which offer high-speed production and fast tooling changeovers for every batch. These standard, efficient machines, manufacture millions of molded plastic parts daily with quality, and low cost.

Tool Maintenance

Our value-added customer services ensure rigorous quality for your custom tools during manufacturing. Our mold changeover department cleans and inspects tools regularly after every use, re-plating or repairing them where necessary before storing them for use in the next production cycle.

Benefits of Custom Injection Molded parts

Custom injection molded aprt is a flexible manufacturing process that is suitable for creating intricate parts with small dimensions and strict specifications. It is suitable for high-volume production of identical parts, which makes it an economical solution. It is relatively faster and more effective than other plastic forming techniques such as machining or additive manufacturing. In addition, it has a high degree of design freedom, which means it is possible to shape and produce parts of different shapes, sizes, and colors. Depending on the desired rigidity and ductility of the end product, the materials can be polypropylene and ABS, nylon, and polycarbonate, thus meeting the requirements of a particular application.

Who Should Use Custom Injection Molded parts

Custom injection molding is the most suitable for companies that want to produce complex parts, whether in large or small quantities. This process benefits industries like the automotive, electronics, and medical sectors, where customized components are required quickly and accurately.

Custom injection molding is a versatile process that can produce intricate detailed parts in a short time frame, ranging from hours to days, depending on the complexity and size of the part. This is particularly useful for creating a prototype and transitioning to mass production in a short turnaround.

In the context of cost, custom injection molding is more advantageous than traditional machining or 3D printing if the part design meets the requirements of injection molding. In addition, the parts produced by injection molding are of better quality and uniform surface finish than those produced by machining.

Customers also benefit from shorter lead times and a wide range of materials, including thermoplastics such as ABS, polypropylene, nylon, and PEEK. This versatility guarantees that the final product is produced to the required standards and performance characteristics.

Our Expanded Customers’ Support Services

Sincere Tech molding holds an ISO 9001:2015 certification, which proves our dedication to quality control and assurance.

Adherence to ISO standards guarantees our services have the best business processes and quality management systems to meet the needs of its customers and provide high levels of satisfaction.

Our quality department utilizes state-of-the-art technology, a four-step inspection system, and Statistical Process Control (SPC) to guarantee compliance throughout the manufacturing process. By using advanced measuring instruments that obtain specific measurement values instead of relying on the naked eye, we guarantee that the dimensions are uniform regardless of the complicated designs to ensure parts meet exact dimensions and specifications. This approach does not only increase efficiency but also allows for more frequent and accurate inspections.

It starts from mold setup to production runs, and our quality assurance process is very strict. The first parts after mold setup are inspected to ensure the product is of the right quality before proceeding with the production process. During production, the machine operators are responsible for the visual inspection of the products and during production, the in-process inspectors conduct the visual, dimensional and functional inspection periodically. The last step before packaging is a visual check to confirm the labels’ quality, quantity, and correctness.

Statistical Process Control (SPC) enables us to control quality by collecting and analyzing statistical data from processes, product measurements, and machines. This approach enables us to improve efficiency, increase productivity, and reduce the likelihood of producing off-standard products and scrap, thus reducing the cost to our customers.

At Dong Guan Sincere Tech, we understand the importance of product quality. Our experienced professional team of engineers is always available to help with certifications and reports such as PPAP, ISIR, FAIR, IMDS, Reach, RoHS, and others.

Our company is one of the leading plastic injection molding companies in China, specializing in custom plastic injection molding and delivering billions of high-quality parts and components to numerous industries. Furthermore, Our facility offers a wide range of injection molding molds, and we are one of the largest family-owned plastic injection molders in the country.

With a wealth of knowledge and experience, our company offers comprehensive capabilities that span from concept to completion: With engineering speciality of knowledge and experience, we offer comprehensive capabilities that span from concept to completion:

Design Expertise: We have a highly experienced design team with over 30 years of experience in the industry. We use the latest technology, such as Solid Works, to design and modify molds. We pay special attention to the specifics of the part’s operation and the conditions necessary for it to work as designed.

Comprehensive Approach: We pride ourselves on taking a comprehensive approach to the manufacturing process, starting with the mold design and ending with the injection molding process. This concept-to-completion approach guarantees the highest quality from the design stage to the final product, incorporating practical and technical knowledge of plastic injection molding.

Toolmaking and Precision Tooling: Creating effective tools is not easy; it takes time, effort, and focus. Our company is dedicated to providing you with precision tooling that will ensure the success of your project. Advantages include a warranty on our tools, high-quality tools that ensure tight tolerances and optimized cycle time, and the ability to mold parts with varying wall thickness and complex geometries. Although we focus on small parts, we can handle up to 10” square sizes.

We have a state-of-the-art factory with 125 fully automated presses that run seven days a week, 24 hours a day, almost the whole year.

Facility and Equipment: Both presses come equipped with self-diagnostic and microprocessor-controlled functions, and the clamping forces range from 46 to 720 tons and fractional to 107 ounces. We also have a Class 8 cleanroom environment that can be modified to fit different projects depending on the client’s needs. This is especially beneficial for the pharmaceutical, medical, food, and beverage sectors and others requiring high safety measures.

Automation and Inventory Management: Sincere Tech keeps safety stock to meet unexpected client demand. Our real-time inventory tracking helps forecast future requirements, and we have a robust MRP system that monitors jobs from end to end. Our understanding of the properties of the resin, the demand for the part, and the cycle time helps us achieve a 99% customer satisfaction rating.

Choose Sincere Tech Group for Your Next Injection Molding Project

The Sincere Tech is one of top 10 mold manufacturers in China that offers custom plastic injection molding services. Our certifications in ISO 9001:2015 and ISO 13485 ensure the highest quality, and our broad expertise addresses various fields. Our team provides the best solution if you need high-accuracy components or components with small tolerances. Contact us today to learn more about our state-of-the-art plastic injection molding solutions. Get a quote to work on your next custom injection molding project, and let us meet your desired requirements without compromising premier standards.

About Us

Sincere Tech is Contract mould supplier in China that offers electronic new product research and development services as well as assembly company services. Contact us for more information.

All in one service for new product development from part design, PCB design, prototyping, testing, mold/die/tooling making, massive production, assembly, inspection, and packing.

Contact Info

Building 1, No. 30 Huan Zhen Rd, Shang Dong village, Qi Shi Town, Dongguan City, Guangdong province China, 523000

Mobile: +86 135 30801277

Weichat/whatsup No.: + 86 135 3080 1277

Email: info@plasticmold.net

Web: https://plasticmold.net

Our Customers feedback

“Hi Steve, Molds work very well good job, I hope you are doing well, as son as I have new project will come to you”

Customer from Hansaplastic in USA————–

“We are very happy with your management & English communication, you are outstanding in issue solving and fast replier, frankly say you are the best plastic mold maker and the molding company I have been working up to know”

Customer from Canada—————–

What is injection molding manufacturing?21/12/2024 - pm4:28

What is injection molding manufacturing?21/12/2024 - pm4:28 What is advanced Plastic Injection Molding Manufacturing?20/12/2024 - pm5:05

What is advanced Plastic Injection Molding Manufacturing?20/12/2024 - pm5:05 Top 10 Plastic Injection Molding Services in China and USA19/12/2024 - am4:42

Top 10 Plastic Injection Molding Services in China and USA19/12/2024 - am4:42- Custom Injection Molding Services: A Complete Guide to Precision Manufacturing17/12/2024 - pm12:40

Top plastic injection molding companies15/12/2024 - am11:50

Top plastic injection molding companies15/12/2024 - am11:50