Custom Plastic Injection Molding China Service – Affordable Custom Parts

Sincere Tech is a well-established custom plastic injection molding company in China that provides high-quality custom tooling and molding solutions. We provide solutions for manufacturing services such as raw material testing, tool manufacturing, molding, surface finishing, and product testing to suit the various needs of customers. Our team of engineers is highly qualified and can ensure the professional execution of orders of any size and complexity.

Our Custom Plastic Injection Molding Services Include:

Custom Rapid Prototype Tooling and Low Volume Injection Molding.

- Perfect for prototyping or creating a few pieces of the product at a time.

- They can range from simple machines capable of producing between 50 to 5,000+ parts.

Custom Bridge Tooling and Medium Volume Rapid Injection Molding

- Ideal for market entry strategies.

- Manufactures 5000 to 100000+ components.

Custom Production Tooling and High Volume injection Molding.

- It was created for the mass production of bicycles.

- Produces 100,000+ parts.

With over a decade of experience in On-demand manufacturing solutions, we have helped many of our customers produce their parts using custom plastic injection molding. We are excited to work with you and bring your products to life accurately and quickly.

What is Custom Plastic Injection Molding?

Custom Plastic Injection molding is an efficient process of manufacturing custom plastic parts in any quantity, small, medium, or large. This involves the use of molds where the molten plastic material is poured and allowed to cool and harden to the required shape. This cycle is repeated hundreds or even thousands of times, which enables the production of several custom plastic parts at once. The cost of the custom mold is distributed over the number of parts manufactured, which makes the price per unit only a few $$s or even less. Custom plastic injection molding guarantees uniformity of the parts produced and has more material, color, cosmetic, polish, and surface finishing possibilities than 3D printing or CNC machining.

Sincere Tech is a specialized custom plastic injection molding company that provides prototypes and short-run and volume-run custom molding services. We offer custom plastic parts that meet your exact design requirements while being affordable. Our professional engineering department consults with every injection molding quote offered to customers to facilitate an easy transition from design to production.

Types of Custom Injection Molding Services at Sincere Tech

Sincere Tech is a prestigious custom plastic injection molding services company in China that specializes in providing different types of molding services for low to high-volume production requirements. Here’s a brief overview of the types of injection molding services we provide:

1. Custom Clear Injection Molding

Process: This is a process that involves the use of plastic materials that are transparent to produce parts that need to be precise or semi-clear.

Applications: Suitable for products such as lenses, light covers, and other translucent parts.

Normal material: PC, PMMA, PS, ABS, etc.

2. Custom Insert Molding

Process: Insert molding is a technique in which metal or other parts are placed inside the plastic during injection molding.

Applications: Typically used for manufacturing components with metallic inserts, including threaded bolts, bearings, or electrical contacts.

Normal material: ABS, PC,PP,PA66, PMMA, PE, PET, PPT, etc

3. Custom Over Molding

Process: Overmolding is a two-shot process in which a second material is molded over an existing part or base material.

Applications: Ideal for manufacturing components made of several materials, for instance, handles with soft grips or cases with seals.

Normal materials: TPE, TPU, ect.

4. Custom Thread Molding

Process: This technique involves the formation of internal or external threads in the molded plastic part without the need for subsequent screw cutting.

Applications: Applicable to parts that require screwing or joining, for instance, caps, closures, and threaded inserts.

Normal material: ABS, PC,PP,PA66, PMMA, PE, PET, PPS, etc

5. Custom Rubber Molding

Process: Rubber molding entails using elastomers to create flexible, strong parts and components.

Applications: It is recommended for use in gaskets, seals, o-rings, and other components that need to be flexible and have high recoverable elasticity.

Normal material: Rubber.

6. Custom Silicone Rubber Molding

Process: Silicone rubber molding uses silicone to create parts that are thermally stable and able to withstand weathering.

Applications: Applicable for use in medical devices, kitchenware, seals, and gaskets.

Normal material: Silicone, rubber.

Our technical experts are committed to delivering the best molding services that meet your precise needs. From prototypes to short runs and total production runs, our team of engineers will help make your project successful. Explore China’s best custom injection molding services today, or discuss your injection molding requirements directly with our representative.

Customized Injection Molding Costs

The price of customized injection molding is not standard and depends on how you engage our services and your project specifications. Generally, the cost can be broken down into two main components: the total cost of production and the price of the mold or the tools that are used in the production process.

Tooling Cost/Injection Mold Cost/Rapid Tooling Cost

Making the custom mold entails other costs that are not included in the total cost of production. The custom mold cost is paid at the beginning of the injection molding process and depends on the blueprint design of the mold. The time it takes to create a mold depends on the mold’s design and its intricacy. Plastic parts production is initiated only after the mold has been made or finalized. There are two types of manufacturing processes for mold creation: rapid manufacturing and conventional manufacturing, with different prices and production approaches.

If you want to know more about custom mold cost, pleae go to injection molding cost and how much does an injection mold cost page to know more.

Key Factors Influencing Customized Injection Molding Cost

The following steps are involved in customizing injection molding molds.

Design Blueprint and Complexity

The level of preparedness and the level of complexity of the product design is a key factor that influences the costs. The complex designs require more complex molds and take more time to make.

Raw Materials

The cost is determined by the type and quality of the material used on both the plastic products and the mold. In general, it can be stated that the acquisition of higher-grade materials is more costly than that of lower-grade ones.

Manufacturing Technology

The choice between rapid manufacturing and traditional manufacturing technologies is based on cost. Although rapid manufacturing is faster, it is expensive.

Tooling Process

The following are some of the factors that can be associated with the tooling cost: the design of the mold, its features, and the material used to construct it.

Project Requirements

The cost may also be affected by schedules and certain specifications of the project. This may force the client to order rush services which are usually costly.

Additional Processes

Other operations such as branding, pad printing or any other special operations will also add to the price.

The cost of injection molding is determined by the design of the product, the quality of the material used, the technology used in production, and other factors of the project. At Sincere Tech, we offer tailor-made solutions to your needs, whether it is a one-off or a batch run. For more information and to get an online quote for your project, please do not hesitate to contact us.

Custom Plastic Injection Molding Method

Custom plastic injection molding entails the use of injection molds, and the quality of the final products depends on the molds and their design. In addition to the molds, technical know-how and experience are crucial in arriving at the structure and design of the injection products and the molds.

Mold-making is one of the core departments in our company, equipped with the most modern tools and employing highly qualified and scientifically oriented staff. This makes it possible for us to have good quality molds and also makes it possible to offer the molds at an affordable possible price and within the shortest time possible.

We also provide technical consulting services for selecting appropriate plastic materials for products. When our customers use large plastic molds for their products, they can benefit from our experience in different engineering plastics. We deal with all types of engineered plastics, including conventional plastics and high-performance thermoplastics, to ensure that we select the right material for the particular application.

Our competencies include all types of large plastic molds and materials, and it has been realized to incorporate high-performance thermoplastics into the large plastic molding.

In addition to the general categories of thermoplastic injection molding services available today, our company provides several particular injection molding services to meet our client’s requirements. These are specific processes designed for specific uses, needs, and problems.

Thermoplastics Materials We Processed

At our In-house set-up, we process the following custom molded plastic products;

ABS (Acrylonitrile Butadiene Styrene)

ABS is a general-purpose thermoplastic with good impact strength and a high degree of hardness. Its tensile yield strength is 6,500 psi, suitable for many engineering applications that demand strength and durability. Go to ABS injection molding to know more.

Polypropylene (PP)

Polypropylene is a thermoplastic polymer widely used in many applications because of its flexibility and strength. It has a tensile yield strength of 4,900 psi and is used where good chemical resistance and processability are needed. Go to PP injection molding to know more.

Polyoxymethylene (POM):

POM, also known as acetal, is a thermoplastic material with low friction, high stiffness, and good dimensional stability. With a tensile yield strength of 10,000 psi, it is suitable for applications that require high accuracy and mechanical strength of the parts. Go to POM injection molding to know more.

Polycarbonate:

Polycarbonate is a thermoplastic polymer with high heat resistance and impact resistance. It has a tensile yield strength of 9000 psi and is used in applications that demand clarity and strength like eyeglasses and electronics. Go to Polycarbonate injection molding to know more about PC molding.

Polycarbonate/ABS Blend:

This is a combination of polycarbonate and ABS that results in the formation of strong and durable parts. It has a tensile yield strength of 8000 psi and is mainly used in automotive and electronic housing industries. Go to PC/ABS injection molding to know more.

PVC (Polyvinyl Chloride):

PVC is a polymer that has good electrical insulating property, high hardness, and good mechanical property. It has a tensile yield strength of 4,500 psi and this makes it suitable for use in many industries and construction activities.

Nylon:

Nylon is a strong polymer material with high elongation and relatively good wear resistance. It has a tensile yield strength of 8,400 psi and is applied to gears, bearings, and wear-resistant components. Go to Nylon injection molding to know more.

Nylon 30% Glass Fiber:

This nylon composite has enhanced mechanical strength and thermal stability, and the tensile yield strength is 18,000 psi. It is applied in areas where high strength and stiffness of the structure are required. Go to Glass filled Nylon injection molding to know more.

Acrylic (PMMA):

Acrylic is quite popular for its strength, which makes it ideal for use in areas likely to be exposed to pressure. It is commonly used in applications that need to be transparent. It has a tensile yield strength of 9400 psi and is used for lenses, displays, and light guides. Go to PMMA plastic injection molding to check more.

Styrene:

Styrene is another type of plastic that is lightweight and has high impact strength and toughness. It has a tensile yield strength of 6,530 psi and is employed for packaging, disposable cutlery, and modeling.

Polyether Imide (PEI):

PEI is a thermoplastic with high temperature tolerance and good mechanical properties. Its tensile yield strength of 16,000 psi makes it suitable for aerospace, automotive, and medical applications.

Quality Assurance & Surface Finishing Options For Custom Injection Molded Parts

At Sincere Tech, we know how vital it is to produce high-quality and accurately shaped custom molded parts. When you request an injection molding quote, we provide a variety of quality inspections and finishing options depending on your application’s needs.

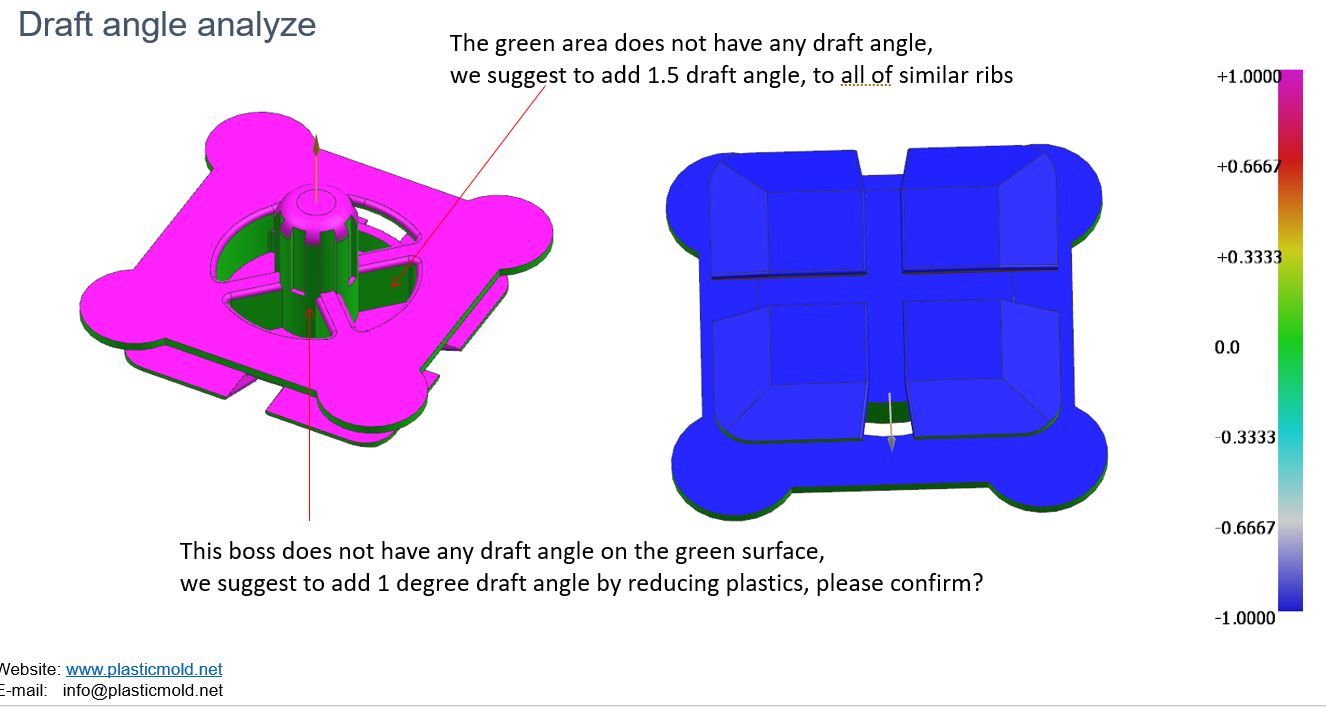

- Designing for Manufacturability Feedback (DFM): Our specialists give detailed comments on your design to make sure that your product is suitable for manufacturing without possible problems, which could slow down the process.

- Scientific Molding Process Development Report: Our scientific molding reports cover the development process and guarantee that the mold will perform as intended and that the quality of the parts will not deteriorate over time.

- In-Process CMM Inspection and Machine Monitoring: Our CMM checks and real-time monitoring of the machines ensure that the molding process is accurate and high-quality.

- First Article Inspection (FAI) and Process Capability Report with GD&T: Our FAI and process capability reports, inclusive of GD&T, assure you that the first set of molded parts meets all the required standards and tolerances.

Wrapping Up

In conclusion, it’s economical and effective to get custom plastic molded parts made in China. China is a preferred destination for manufacturing high-quality plastic components because of its skilled workforce, competitive prices, and advanced manufacturing capabilities. Understanding the factors we have discussed and using the tips for collaboration, you can successfully apply the potential of custom plastic injection molding china industry to introduce new developments and high quality in your production.

FAQs

Q1. What is Plastic Injection Molding?

Injection molding is a manufacturing process that involves using injection to force molten material into a mold. The plastic cools and hardens into the intended shape; each round is known as a molding cycle or molding shot.

Q2. How Much Does Plastic Injection Molding Cost?

The cost of injection molding varies from $100 to over $ 100,000. The cost factors that are considered include the type of material used, size of the part, quantity ordered, complexity of the part, number of cavities, cycle time, and labor costs.

Q3. How Much Does Injection Molds Cost?

Injection Mold Cost varies depending on the complexity of the mold and the material used in its construction. Injection Mold costs are estimated to be between $1,000 and $100,000+ or even more. The cost of molds is also influenced by the complexity of the mold and its size, where simple and small molds are cheaper than complex and large molds with multiple cavities and features.