Information about PA6/PA66 (Nylon) Injection Molding

Basically, there are PA6 AND PA66(Nylon 6 or Nylon 66), Nylon has tenacious and wearable, self-lubricious and smooth characteristics with non-toxic and antibiosis and high water absorbability. In addition, its tensile strength and stiffness will be sharply decreased with the moisture-absorbing. Then, the size of finished pieces changes greatly. If in the high-temperature environment for a long time, it will be resolved.

It will not soften gradually with increasing high temperature until closing to the extent of melting-point. Once reaching the proper temperature, it will flow. It is soluble in many chemicals. However, gas, lubricating oil, developer, detergent and grease have no effect on nylon.

Advantages Nylon Injection Molding :

It has high mechanical strength, good tenacity and high press resistance and strength of extension. Its strength of extension is close to yielding strength, which is twice stronger than ABS injection molding parts.

Nylon Injection molding parts have excellent fatigue durability with the smooth surface and minor friction coefficient and good wear resistance. It also has corrosion resistance and remarkable resistance to alkali (acid) and most of the salt solution, non-toxic, presenting inertia to biological erosion and good anti-mildew ability, heat resistance and excellent electrical features.

Its product has a lightweight and is easy to dye and molding.

Disadvantages of PA injection molding:

It is easy to absorb water and has poor light resistance. It requires more strict plastic molding technology. It can absorb water and becomes swelling in alcohol but has no resistance to strong acid and oxidizer.

Therefore, it cannot be used as acid-resisting material.

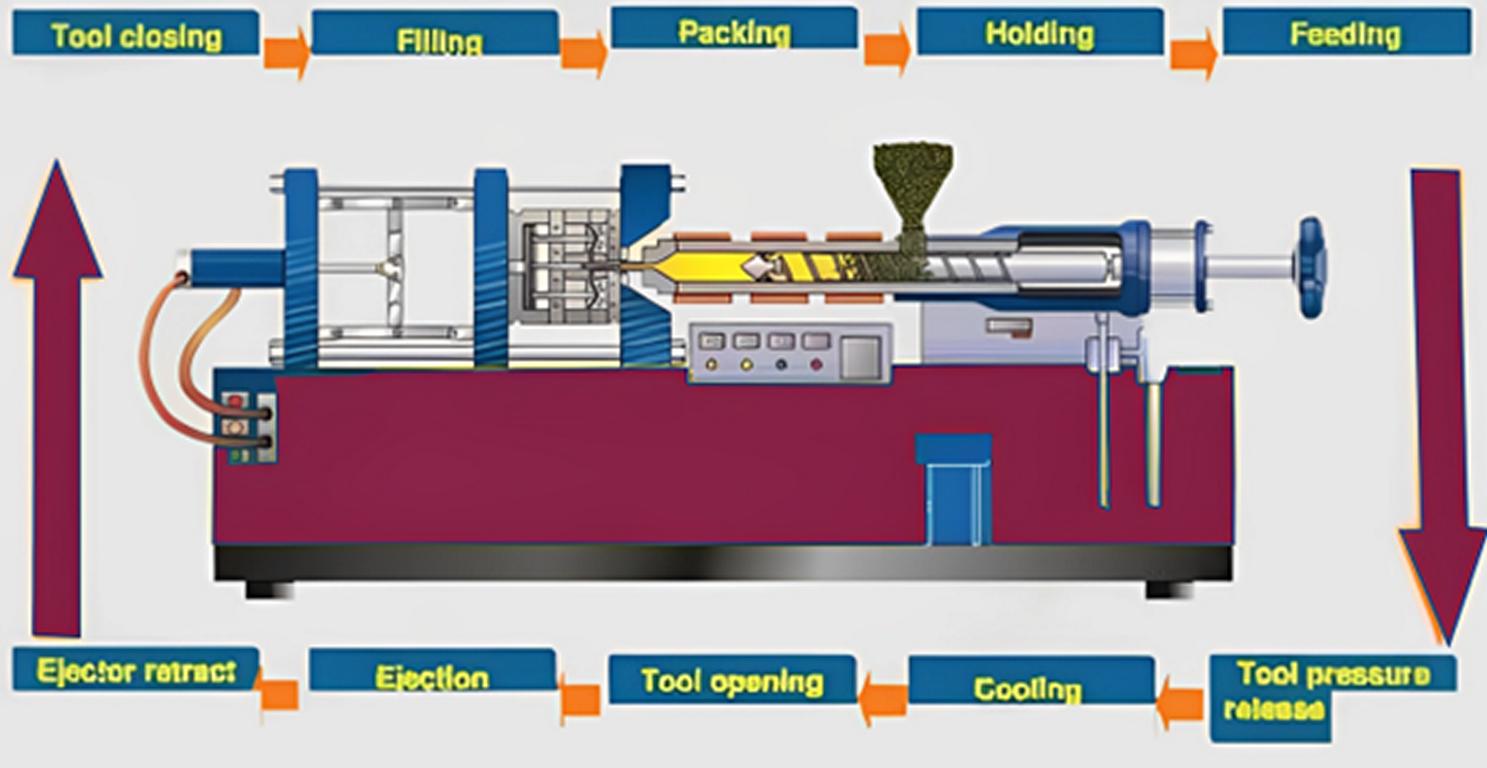

Nylon Injection Molding process:

We should exactly control the injection molding process to prevent problems like flashing. Meanwhile, as the faster speed of condensation quick releasing for melt, we should keep off the insufficient production caused by material blocking in orifice runner and gate (temperature and pressure increase liquidity firstly).

As the poor thermal stability, the temperature should not be too high so as not to cause yellowing of material.

The proper injection pressure can be judged by the appearance of the products. If it has higher injection pressure, products will appear the problems such as flashing; the too low temperature will bring about defects like a ripple, flow mark, weld line or insufficient producing. Therefore, the higher holding pressure should be avoided in order to prevent increasing the internal stress for products generally.

It is advisable that injection should be done with speed so as to avoid problems such as ripple or insufficient mold filling caused by the rapid cooling rate.

PA Nylon injection molding Technique

1, Preparation of Original Materials

PA (polyamides) absorbs humidity easily, which has an effect on the course of working, like decreasing viscosity of the melt and appearing bubbles and crazing on the surface, etc. And force property of product will also decrease obviously. Therefore, the drying process must be done before shaping up. Besides, PA is easily oxidized and color changed as well as decomposition under hot temperature, so it will be better with vacuum drying. But if there is no vacuum drying condition, atmospheric hot air drying can also be adopted.

The temperature of vacuum drying is 85-95 Celsius degrees and the lasting time is 4-6H; while the temperature of hot air drying is 90-100 Celsius degrees and the lasting time is 8-10H. PA materials after being dried are not fit for locating in the air (not more than 1-3H).

2, Melting Temperature

The choice of the machine barrel is mainly based on the melting point of PA Material. At the same time, it is also related to the type of injection molding machine, type of product and size. Generally, under 220-320 Celsius degrees, PA6: 220-300 Celsius degrees; PA66: 260-320 Celsius degrees, as the processing temperature of PA is narrow, so the temperature of machine barrel must be controlled strictly, in order to avoid decomposition of melt thus to make the product go bad. The setting of the machine barrel has a large effect on plasticizing and speed of melt.

The temperature of the middle section of the machine barrel should be higher than the melting point of 20–40 Celsius degrees and lower than the decomposition of 20-30 Celsius degrees. The temperature of the front section is lower than the middle section of 5-10 Celsius degrees. The temperature of back-end (loading section) is lower than the middle section of 20-50 Celsius degrees. Cooling of the charging hole must be effective. If the temperature of the middle section is too low and the screw changes its speed too fast, then jamming phenomenon will appear. If the temperature of the posterior section is too high, then the delivering capacity will be affected. A lower speed of screw will affect production efficiency.

3, Injection Pressure

Injection pressure has a small effect on the force of PA. Choosing of injection pressure mainly depends on the type of injection molding machine, machine barrel temperature, type and size of the product, and mold structure. And there are also some factors like injection speed, injection time and injection time, etc.

4, Injection Speed

Choosing of injection speed is related to the thickness of the product, the temperature of the melt, the size of the gate, etc. The injection speed cannot be so fast. Otherwise, the excess temperature will be caused due to over cutting thus to create decomposition, causing color changing of product and decrease of force property. Too fast injection speed will also create defects like bubble and scorching, etc.

5, Revolving Speed of Screw

Intermediate speed should be adopted. The too-fast speed may cause decomposition of plastic due to excessive cutting, causing color changing and decrease of property and too slow of revolving speed, which may affect the quality of melt and production efficiency due to a long period of melting.

6, Back-pressure

On the premise to guarantee the quality of the product that the lower of the back-pressure is the better. High back-pressure may decompose due to the excessive cutting of melting.

7, Mold temperature for PA injection molding

The high temperature of mold improves hardness, density, tensile strength and modulus of elasticity of the product. Mold temperature is related to the property of the product. As to those thin products which require elongation and good transparency, it will be better with lower mold temperature; while as to those thick molds which require high strength, good abrasion resistance and transformation less, and then higher temperature of mold temperature is better. The specific is as follows.

The thickness of product temperature of mold: Less than 3mm, mold temperature use 50 -70 Celsius degrees, 3-6mm, mold temperature use 70-90 Celsius degrees, 6-10mm, mold temperature use 80-100 Celsius degrees, and wall thickness is more than 10mm, 100 Celsius degrees Mold temperature has a big effect on contractibility rate of product. The higher of the mold temperature, the bigger of the contractibility, otherwise, the smaller of the contractibility rate.

8, Molding Cycle

It mainly depends on the thickness of the product. As to thin wall product, the injection time, pressure maintaining time and cooling time can all be shorter; while as for thick wall product, in order to avoid the appearance like shrinkage transformation, sink mark and bubbles, etc., then injection time and pressure maintaining time should be lengthened and high mold temperature should be adopted. The cooling time should be longer.

9, Post-processing of Product

Crystallization of the process of molecular orientation and cooling process while in the process of cooling creates some internal stress in the product. The size and shape of the product will change while in the future storage and using process. Therefore, annealing and humidifying processing are required.

10, Annealing

It adopts a product that is 80 Celsius degrees higher of the temperature and accurate precision. The product is taken out after being demoulded, putting in oil or paraffin for annealing. The temperature of annealing is higher than the usage temperature of 10-20 Celsius degrees and time is 10-60 minutes. (Depending on the thickness of product)

11, Humidifying

While in the process of shaping up, a product that is used in humanity or aqueous solution must be put into boiling water or potassium acetate solution for 1-2 days after taken out.

12, Residence Time

While in the process of manufacturing, if the temperature of glue is above 300 Celsius degrees, then the long residence time of melting in the machine barrel must be avoided (20 minutes), otherwise decomposition will be caused due to overheating, causing the color change of product or brittleness. If a temporary stoppage for more than 20 minutes is required, then the temperature of the machine barrel can be lowered to 200 Celsius degrees. When in a long time of residence, polymer with higher viscosity must be used to clean the machine barrel. For example, HDPE or PP can be used for cleaning.

Contact us to get a price for your PA injection molding (PA6, PA66, PA12) or any other custom injection molding projects.