Blog about buying plastic mold, plastic injection molding parts from China Plastic Injection mold and molding companies, advantages and disadvantages buying plastic molds and plastic molding parts from China.

PPSU LSG artificial knee joint components.

Advanced knee injuries or arthritis cause knee tissue damage, inflammation and terrifying pain. These conditions can disable you from flexing or extending your knees. As time proceeds, the damage on your knee joint and knee tissue can make it challenging to perform day to day activities. Knee joints damage can inhibit you from sitting or lying down. This calls for a knee replacement surgery to replace knee joints. One of the available artificial knee joint components is PPSU LSG.

PPSU, a plastics for medical plastic parts, is basically an abbreviation for polyphenylsulfone which is an amorphous high-performance thermoplastic. The medical grade PPSU is bone white in color and thus suitable for knee implant design. This material is used to manufacture artificial knee joint spacer components. LSG is also an abbreviation. It refers to laparoscopic sleeve gastrectomy, a bariatric procedure which involves removing outer margins of an organ leaving a sleeve. This is a procedure undertaken to replace your knee with an artificial joint.

When it comes to choosing an artificial knee joint for your knee problem, you have to choose right. PPSU LSG knee joint components should be your first choice. Crafted from sterilized PPSU polymers, these joints are available in various knee implants designs. These will fit perfectly with your knee. Their durability and high impact resistance will ensure a strong knee after the knee joint is replaced.

This material possesses unlimited steam sterilization capabilities. This makes its sterilization easy and with these artificial knee joint spacer components, you will never acquire a bacterial infection. This is essential as other artificial knee joints have been associated with bacterial infections. Instead of improving your knee problem, it worsens. This can be completely averted by choosing PPSU knee joint spacer components.

You may ask yourself the advantages of using PPSUinjection molding parts as an artificial knee joint spacer component. Ask no more. This product has myriad advantages. These include:

High resistance against high energy radiation: This product has a very good resistance against high energy radiation. This includes gamma and x-rays. This property makes it possible for one to undergo x-ray examination. This will be undertaken without fear of damaging the knee joint and the artificial knee joint adoption by the knee can be monitored. This guarantees your safety when you use this artificial joints.

High operating temperature: Medical grade implants have to be heavily sterilized. PPSU has a high operating temperature that is 180 degrees. This allows it to be sterilized easily by repetitive steam sterilization. This is possible without deforming these artificial knee joints or shrinking them.

Highly rigid over a range of temperatures: This material has high rigidity over a wide range of temperatures. It is therefore durable and provides better functionality as compared to other knee implants.

Compatible with body tissue. This is crucial for knee joints. This material will not prevent regeneration of your body’s tissue. It also has a smooth design and will not scrape off regenerating tissue.

Other advantages include very high impact strength. This is important to prevent breakage of the knee joint implants. Good chemical compatibility will reduce the wear and tear caused by chemicals during the manufacture of this product. Good electrical insulating properties is key in avoiding lightning and other charge related complications.

If you need PPSU injection molding parts for your medical devices, we recommend you go to our medical plastic parts area, If you need some PPUS LSG artificial knee joint spacer components, please contact with us, we have over 40 version of this components to meet every size requirement.

What is Weld Line Defects in injection molding

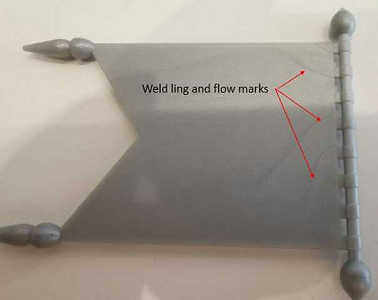

When plastic flows around an obstruction (for example a hole) in a mold cavity the point where the material comes back together is called a weld line defects. If two more more plastics material flow together after coming together it will become a weld line. Weld lines defects will always have when two or more melt flows meet together. we call knit lines defects as well.

Weld line defects in injection molding is a line or lines on the part surface that caused the part looking ugly or cuased part lifetime, or even broken easily. These weld lines occur usually around holes or at the material flow joint area in the injeciton molded part, some welding lins is very small, specially if the molded part made in firber glass material, must be very carfully in the massive production.

Welding line

Weld lines defects issues and troubleshooting skill

Weld lines defects are formed when two flow fronts are merged together. An obstruction such as a core pin or holes will split the material flow and cause a weld line issue to form on the other side.

Weld lines defects can also form when the flow fronts from two gates merge or when thick and thin sections in a part cause a flow to split and merge. Since plastic cools as it flows, the separate flow fronts are partially solidified when they meet and form the weld line.

This can lead to quality issues. Weld lines issues are usually a visible line on the part surface and can be an appearance issue. Weld lines may also reduce the part strength by 10% – 20% potentially creating a structural issue depending on their location. The strength reduction is worse in glass filled materials because the fibers do not cross the weld line.

The below image is a weld line plot. The black line on the part represent welding line. On this part there are two major weld lines. The weld line in the side of the part is created when the flow fronts from the two separate gates meet. The weld lines at the end of the flow are formed when the flow front travels around the pin that forms the hole and meets up on the other side.

To avoid problematic weld lines issues, it is critical to know where weld lines will form on appearance or strength critical parts. Mold flow analysis provides a weld line plot that details the location of weld lines. Note that the analysis can only be used to predict weld line location, not weld line strength or appearance. However, weld lines can be moved to low stress areas or to higher packing pressure areas of the part by changing the gate location.

If a plastic injection mold is built without considering the impacts of the number and position of weld lines, the mould may not produce an acceptable part,

Welding lines defects troubleshooting skills

Once the mold have been made and the weld lines defects in injection molding appear, to solve this welding line issue by using below troubleshooting skill will improve this issue.

- Increase injection pressure

- Increase melt temperature

- Increase mold temperature

- Enlarge vents

- Change gate location

- Increase runner diameter

If mold flow analysis is not used to fix these problems before the mold is built, the plastic mold company will be forced to use one of the above costly solutions!

Case study weldline in injection moulding

Several years ago a customer transferred an old single cavity mold to our facility. The part was a very simple rectangular ring. It had two sub-gates, one at each end of the part on the short side of the rectangle. The material was glass-filled and made a very strong part.

We made our first sample submission and were approved for production immediately. The next day we delivered the first parts for their order. A couple of weeks after the plastic parts were delivered I received an email from our customers General Manager thanking us for the very fast service, then he went on to say none of the parts were usable because they did not pass “the hammer test”.

The first words out of my mouth were “what is the hammer test? And why wasn’t this test requirement talked about before this”. after communication I observed the hammer test. It was quite simple; the part was set on a metal table so it stood up resting on its long axis. A technician then proceeded to beat the daylights out of the part with the pointy end of a steel masonry hammer.

The part broke in the very middle of the long side. I examined the part and asked if they had this problem before. The general manager said this happens all the time and it is a major problem. As it turned out the hammer was used to seat a metal piece between two of the plastic parts to make the assembly. The metal pieces were too stiff to assemble by hand so the hammer was used.

My further examination showed that the failure had occurred at one of the weld lines in the part. Weld lines occur when plastic flows around a core and then joins back together, maybe sometimes you can not see this by eyes, but if the part has a function requirement, like this case the part need load some power, so even the weld lines does not existing still will be broken, because there is still joint line that that filling joint area.

The solution was very simple, the problem was that no one looked at the way the part was gated and how the part would be assembled. I told the Custom that we will slightly change the mold a little and send you the new samples that would not break.

I had one of our mold that have weld line issue on the molded part and we simply blocked off one of the two gates. This meant that all the material would flow through one gate and the single weld line that resulted from the new flow pattern would be on the short axis. The old flow pattern produced a weld line in the middle of both of the long sides. We tested the parts with our own hammer and could not produce a failure. I immediately sent the newly re-gated parts to the customer and asked them to test them with their hammer.

They could not break the parts either, we took the first parts back and scrapped them and we delivered the new parts the next two days.

Sincere Tech is one of top 10 plastic injection molding companies in China that offer custom injection molding and delvier to the worldwide, we have rich experience to solve all of molding defects, all of our molding parts will be 100% meet your requirement, if you have any project that needs plastic injection molding service from China, welcome to contact us.

What is Injection molding cleanroom

Injection molding cleanroom refers to a controlled environment specifically designed and maintained for the manufacturing of plastic components using injection molding processes. These cleanrooms are essential for industries that require high levels of cleanliness and precision, such as medical, pharmaceutical, electronics, and aerospace sectors.

Key characteristics and features of an injection molding cleanroom include:

- Cleanroom Classification: Medical Injection molding cleanroom adhere to specific cleanliness classifications based on international standards, such as ISO 14644-1. These classifications determine the allowable limits of airborne particles per cubic meter of air, ensuring a controlled environment with low levels of contamination. Cleanrooms are typically classified as ISO Class 5 or higher for injection molding applications.

- Environmental Control: Injection molding cleanrooms incorporate advanced environmental control systems to maintain the desired cleanliness levels. These systems typically include high-efficiency particulate air (HEPA) filters, air pressure differentials, and temperature and humidity control to minimize the presence of airborne particles and ensure optimal manufacturing conditions.

- Gowning and Personnel Hygiene: Strict gowning procedures and personnel hygiene practices are enforced within injection molding cleanrooms to prevent contamination. Cleanroom personnel are required to wear specialized garments, including cleanroom suits, gloves, masks, hairnets, and shoe covers. Handwashing and sanitization protocols are rigorously followed to maintain cleanliness.

- Material Handling and Preparation: Raw materials used in injection molding are handled and prepared within the cleanroom environment to prevent contamination. Controlled storage and transportation of materials are implemented, and specific protocols are followed to maintain material cleanliness. Material drying, conditioning, and mixing may also be conducted in dedicated cleanroom areas.

- Cleanroom Equipment and Machinery: Injection molding machines used in cleanroom environments are designed and maintained to meet the cleanliness requirements. These machines may feature additional enclosures, laminar flow hoods, or barrier systems to minimize the risk of particle generation during the molding process. Regular cleaning and maintenance of the equipment are essential to uphold cleanliness standards.

- Mold and Tooling Preparation: Molds and tooling used in injection molding are prepared and maintained within the cleanroom environment. Proper cleaning procedures, including solvent cleaning, ultrasonic cleaning, or specialized cleaning agents, are employed to eliminate contaminants. Mold storage and handling are carefully managed to prevent particle accumulation.

- Process Control and Quality Assurance: Injection molding cleanrooms implement stringent process control measures to ensure consistent quality and minimize defects. Critical process parameters, such as temperature, pressure, injection speed, and cooling time, are closely monitored and controlled. In-process inspections, dimensional measurements, and quality checks are performed to verify product quality and compliance with specifications.

Injection molding cleanrooms are crucial for industries that demand high-quality, precision-molded components. By providing a controlled and clean environment, these cleanrooms minimize contamination risks, ensure product integrity, and meet stringent regulatory and industry standards. The combination of environmental control, personnel hygiene, material handling, and process control measures in an injection molding cleanroom contributes to the production of reliable and high-quality plastic components.

Sometimes a Plastic mold company is looking for good niche products that related their business and they could earn more profits. Such was the case for SINCERE TECH a well-known plastic mold manufacturer that is now inverted molding shop in a 5,000 -sq Class 10,000 injection molding cleanroom which is especially for medical injection molding service.

injection molding cleanroom

Located in Dong Guan China, a small town in the Dong Guan City of China near the Shenzhen airport, SINCERE TECH has a reputation for complicated, high-precision molds, medical molding, automobile mold and a particular specialty in multi-component molds. After 2000 China has become mold manufacturing country on the world and lots of tool-making companies started their mold business, in 2005 the SINCERE TECH started plastic mold manufacturing business to make export molds, primarily of shorter runs for customers of its tool-making business.

Staying with what worked, when SINCERE TECH was set up as a plastic molding facility by a wall divided from the plastic mold making shop, it was designed around what the mold customers were doing. That way it could handle customers’ short lead time, benefits for mold maintaining, and so on. Since molds were mostly made for technical and multi-material or colored parts, the molding company configured with high-precision injection molding machines and multi-component technologies. Molding presses range from 60 to 2000 tons and include two-shot injection molding machines. you can go to our double injection molding parts page.

Medical Plastic Injection Molding Products Needs Injection Molding Cleanroom

Several of our customers were in medical equipment which needs medical molding parts, automotive industry, health care industry and pharmaceutical manufacturers. to provide a custom solution for all of our customers, ST decided to set up an injection molding cleanroom manufacturing (for medical injection molding service) operation at a Class 10,000 level with turbulent airflow. Plastic molding parts made include dialysis machine components, medical machinery components, closures for PE infusion bottles, and medical plastic caps and some of other medical injection molding parts

medical plastic parts

The ways of using injection molding machines in a cleanroom environment are too numerous to count. There are hoods over individual machines, machines completely in the cleanroom environment, and machines partially in the molding cleanroom itself.

ST decided to put only the clamp end of the machine in the clean room injection molding, “We considered the particular characteristics of the machines in all our planning.” ST chose some of the high precision Series injection machines, including 65-, 80-, and 110-ton machines to cover its product range, this machines seems working perfectly as we thought at the beginning,

Full-service Plastic mold making, normally molding and Cleanroom

ST did not set up the injection molding cleanroom to simply molded parts. That would not have fit with the level of service expected by the medical plastic molding requirement of customers. Such customers generally specify medical degree for all of the molding equipment, packing, assembly, and shipments, to complete this task, ST operates an assembly room within the Class 10,000 cleanroom so that the finished product leaves in hermetically sealed packages ready for shipping.

For normal requirements, we have a range of machines from 80 tons to 2000 tons to produce a wide range of products for our customers.

This quality and service have led the business more growth, in both the cleanroom business and the rest of the molding operation referred to as the Technology Center. Today our plastic molding company area increased from 6,000 sq to 12,000 sq. The cleanroom is expanded from 2050 sq to 4400 sq

At Sincere Tech China mold manufacturer, we understand the importance of custom injection molding and its role in achieving manufacturing excellence. With our expertise in the field, we offer top-quality custom injection molding services that meet the highest industry standards. Our team of skilled professionals, state-of-the-art equipment, and commitment to innovation ensure that we deliver exceptional results for your specific needs.

When you partner with us, you can expect a seamless and efficient manufacturing process. From the initial design phase to the final production, we pay meticulous attention to detail, ensuring that every product meets your exact specifications. Our experienced engineers work closely with you, providing valuable insights and recommendations to optimize the design for injection molding, resulting in cost-effective solutions without compromising on quality.

We leverage the properties of plastics material to create products that are not only good surface finish but also tight tolerance. This translates to reduced waste rate costs, improved energy efficiency, and enhanced user experience. Whether you require consumer goods, automotive components, electrical enclosures, medical devices, or industrial parts, our custom injection molding capabilities cater to a wide range of industries and applications.

At Sincere Tech Plastic Mold company, we are committed to staying at the forefront of the industry and embracing future trends and innovations. We constantly explore advanced materials and composites that offer enhanced performance and sustainability. Our continuous investment in research and development enables us to offer cutting-edge solutions that meet the evolving needs of our customers. We are one of the best mould suppliers in China.

Furthermore, we are dedicated to environmentally friendly practices. We actively seek out sustainable alternatives, such as biodegradable polymers and recycling initiatives, to minimize the environmental impact of our manufacturing processes. By choosing our custom injection molding services, you can align your brand with sustainable manufacturing practices and contribute to a greener future.

Quality is our utmost priority, and we adhere to stringent quality control measures throughout the entire manufacturing process. Our state-of-the-art facilities and skilled technicians ensure that each product undergoes rigorous inspection and testing, guaranteeing exceptional performance, reliability, and customer satisfaction.

Partner with Sincere Tech China mold maker for your custom injection molding needs, and experience the highest level of professionalism, expertise, and innovation. We are dedicated to helping you bring your ideas to life, delivering superior products that excel in performance, durability, and cost-effectiveness.

Contact us today to discuss your project requirements and discover how our polypropylene injection molding services can elevate your manufacturing processes to new heights. Together, let’s unlock the full potential of polypropylene and create exceptional products that shape the world around us.

Still have a question? Welcome to contact us and send us an email.

The Plastic collapsible crate molds (folding crate molds) we made for our customers offer superior value to the market. the plastic collapsible crate offers two powerful advantages for lowering materials handling costs. First is the plastic collapsible crates are lightweight which lowers shipping and material costs, especially for the disposable crate parts which can save lots of material. Unlike aluminum collapsible crate with the high cost and heavyweight, second is the transportation cost is very low comparing to unfolding crate, the foldable crate made from foldable crate mold can save lots of place during the transportation.

folding crate mould

The plastic collapsible crate containers have some other advantages

- Collapsible crate containers collapsed in 20 – 30 seconds without tools by one person

- Ideal for closed-loop and automated storage-retrieval systems

- Stackable to store 3 collapsed containers in the same height as one upright, assembled crate container

Today, many industries are using plastic collapsible crate containers to save money, including:

- Food processing plants

- Pharmaceutical production facilities

- Nuclear energy plants

- Hospitals

- Kitchens

- Laboratories

- Petrochemical facilities

- Chemical Plants

- Automotive

If you have any plastic collapsible crate project that needs collapsible crate mold manufacturer, go to find a China mold company will be the best option to save your money, of course, find a reliable plastic mold manufacturer is not easy. We would be delighted to assist you with your collapsible crate mould, we are one of the best top ten mold manufacturing companies in China, we offer custom molds for the world customers, we can share you some of our customers and you could verify our quality and service, this will be the simplest way to help you to make your collapsible crate mold or any custom plastic injection mold, send us an email to get a price.

At Sincere Tech, we are dedicated to maintaining our position as a leading plastic mold company by embracing industry advancements and anticipating future trends. We actively explore innovative materials and composites that offer improved performance and sustainability. Through ongoing investments in research and development, we deliver cutting-edge solutions that address the evolving needs of our customers. As one of the best injection mold suppliers in China, we pride ourselves on our commitment to excellence.

In line with our commitment to sustainability, we prioritize environmentally friendly practices. We proactively seek sustainable alternatives, such as biodegradable polymers, and implement recycling initiatives to minimize the environmental impact of our manufacturing processes. By choosing our custom injection molding services, you can align your brand with sustainable manufacturing practices and contribute to a greener future.

Quality is of the utmost importance to us, and we maintain stringent quality control measures throughout the entire manufacturing process. Our state-of-the-art facilities and skilled technicians ensure that each product undergoes rigorous inspection and testing, guaranteeing exceptional performance, reliability, and customer satisfaction.

When you partner with Sincere Tech as your preferred China mold maker, you can expect the highest level of professionalism, expertise, and innovation. We are dedicated to helping you bring your ideas to life, delivering superior products that excel in performance, durability, and cost-effectiveness.

Our expanded capabilities include:

- Rapid Prototyping: We offer rapid prototyping services to quickly transform your concepts into tangible prototypes, allowing for iterative design improvements and accelerated product development.

- Precision Tooling: Our advanced tooling capabilities enable us to create high-quality molds with tight tolerances, ensuring consistency and precision in your injection-molded products.

- Overmolding: We specialize in overmolding, which allows for the combination of multiple materials or components, resulting in enhanced functionality, aesthetics, and durability.

- Insert Molding: Our expertise in insert molding enables us to securely encapsulate inserts within the molded parts, facilitating efficient assembly and enhancing product performance.

- Two-Shot Molding: With two-shot molding, we can produce complex, multi-material components in a single operation, reducing assembly requirements and enhancing design possibilities.

- Value-Added Services: In addition to injection molding, we offer a range of value-added services, including product assembly, packaging, and logistics support, streamlining your supply chain and reducing costs.

Partner with Sincere Tech Mould suppliers for your custom injection molding needs, and benefit from our comprehensive capabilities, unwavering commitment to quality and sustainability, and our drive to exceed your expectations at every step of the process. Together, let’s bring your innovative ideas to life.

What is TPU Injection Molding

TPU injection molding refers to the process of injecting Thermoplastic Polyurethane (TPU) into a mold to produce a finished product. TPU is a type of material that exhibits the properties of both thermoplastics and elastomers. It is often used to produce products that require flexibility, durability, and resistance to abrasion.

TPU injection molding is a versatile process that can be used to produce a wide variety of products, including footwear, industrial parts, medical devices, and more. It offers many benefits over traditional manufacturing methods, including lower costs, faster production times, and greater design flexibility. TPU materials are also recyclable, making them a more sustainable option for manufacturers.

TPU (Thermoplastic polyurethane) injection molding process has many methods, including injection molding, blow molding, compression molding, extrusion molding, etc., among which injection molding is most commonly used. use the injection molding process to mold TPU into required TPU injection molding parts, which are divided into three stages: pre plasticizing, injection, and ejecting out. The injection machine is divided into plunger type and screw type. Screw type injection machine is recommended because it provides uniform speed, plasticization, and melting.

TPU phone cover molding

1. Design of injection machine

The barrel of the injection machine is lined with copper-aluminum alloy, and the screw is chrome plated to prevent wear. The length diameter ratio of screw L / D = 16 ~ 20 is better, at least 15; the compression ratio is 2.5/1 ~ 3.0/1. The length of the feeding section is 0.5L, the compression section is 0.3L, and the metering section is 0.2L. The check ring shall be installed near the top of the screw to prevent backflow and maintain the maximum pressure.

The TPU should be processed with a self flow nozzle, the outlet is an inverted cone, the nozzle diameter is more than 4mm, less than 0.68mm of the main channel collar inlet, and the nozzle should be equipped with a controllable heating belt to prevent material solidification.

From an economic point of view, the injection volume should be 40% – 80% of the quantitative amount. The screw speed is 20-50 R / min.

2. Mold design for TPU injection molding

Mold design should pay attention to the following points when molding with tpu material injection molding:

(1) shrinkage of molded TPU molding parts

Shrinkage is affected by the hardness of raw materials, thickness, shape, molding temperature, mold temperature, and other molding conditions. Generally, the shrinkage range is 0.005-0.020cm/cm. For example, a 100 x 10 × 2mm rectangular test piece shrinks in the length direction of the gate and the flow direction, and the hardness of 75A is 2-3 times larger than that of 60 shore degree. The effect of hardness and thickness of TPU on shrinkage is shown in Figure 1. It can be seen that when the hardness of TPU is between 78a and 90a, the shrinkage decreases with the increase of thickness; when the hardness is between 95A and 74d, the shrinkage slightly increases with the increase of thickness.

(2) Runner and cold slot well

The main runner is a section of the runner connecting the injector nozzle to the shunt channel or cavity in the mold. The diameter should be expanded inward, with an angle of more than 2 degree, so as to facilitate the removal of flow channel vegetations. The shunt channel is the channel connecting the main channel and each cavity in the multi-groove mold, and its arrangement on the mold should be symmetrical and equidistant. The flow channel can be circular, semi-circular and rectangular, with a diameter of 6-9mm. The runner surface must be polished like the cavity to reduce flow resistance and provide a faster filling speed.

A cold well is an empty place (extra extend runner) at the end of the main runner, which is used to catch the cold material produced between the two injections at the end of the nozzle, so as to prevent the diversion runner or gate from blocking by cold material. When the cold material is mixed into the mold cavity, the internal stress of the product is easy to occur. The diameter of the cold material hole is 8-10 mm, and the size is about 6 mm long.

(3) gate and vent

The gate is the runner connecting the main flow channel or the shunt channel and the cavity. Its cross-sectional area is usually smaller than the runner passage, which is the smallest part of the runner system, and its length should be short. The gate shape is rectangular or circular, and the size increases with the thickness of the product.

The thickness of the product is less than 4mm, with a diameter of 1mm; the thickness of the gate is 4-8mm, with a diameter of 1.4mm; the thickness of the gate is more than 8mm, with a diameter of 2.0-2.7mm. The gate position is generally selected at the thickest part of the product, which does not affect the appearance and use, and is at right angles to the mold, so as to prevent shrinkage and avoid spiral pattern.

Exhaust or venting slot is a kind of slot type air outlet opened in the mold, which is used to prevent the molten material from entering the mold from getting involved in the gas and to discharge the gas from the mold cavity.

Otherwise, the products will have air holes, poor fusion, insufficient filling or air trap, and even burn the products due to high temperatures caused by air compression, resulting in internal stress of the products. The exhaust port can be set at the end of the melt flow in the mold cavity or on the parting line of the plastic mold, which is a 0.15mm deep and 6mm wide pouring slot.

It is necessary to control the TPU mold temperature as evenly as possible to avoid warping and twisting of the parts, below are some TPU injection molding products we made before. If you have any requirement for TPU or TPE injection molding products, welcome to contact us.

TPU injection molding

3 Molding conditions

The most important molding condition of TPU (Thermoplastic polyurethane) is the temperature, pressure and time that affect the flow and cooling of plasticization. These parameters will affect the appearance and performance of TPU injection molding parts. Good processing conditions should be able to obtain even white to beige parts.

(1) Temperature

The temperature to be controlled in the TPU plastic injection molding process includes barrel temperature, nozzle temperature, and mold temperature. The first two temperatures mainly affect the plasticization and flow of TPU, and the second one affects the flow and cooling of the TPU injection molding part.

- Barrel temperature – the selection of barrel temperature is related to the hardness of TPU material. The melting temperature of TPU with high hardness is high, and the highest temperature at the end of the barrel is also high. The temperature range of the barrel used for processing TPU is 177 ~ 232 ℃. The temperature distribution of the barrel is generally from one side (rear end) of the hopper to the nozzle (front end), gradually increasing, so as to make the TPU temperature rise steadily and achieve the purpose of uniform plasticization.

- Nozzle temperature – the nozzle temperature is usually slightly lower than the maximum temperature of the barrel to prevent the possible salivation of molten material in the straight-through the nozzle. If the self-locking nozzle is used to prevent salivation, the nozzle temperature can also be controlled within the maximum temperature range of the barrel.

- Mold temperature – mold temperature has a great influence on the internal performance and apparent quality of TPU products. It depends on the crystallinity of TPU and the size of products. Mold temperature is usually controlled by constant temperature cooling medium such as machine water.

TPU has high hardness, high crystallinity, and high mold temperature. For example, Texin, hardness 480A, mold temperature 20-30 ℃; hardness 591A, mold temperature 30-50 ℃; hardness 355d, mold temperature 40-65 ℃. The mold temperature of TPU products is generally 10-60 ℃. Mold temperature is low, melting material is frozen too early and streamline is produced, which is not conducive to the growth of spherulites, so that the crystalline of products is low, and late crystallization process will occur, which will cause post shrinkage and performance change of products. - Pressure – the injection process is pressure including plasticizing pressure (back pressure) and injection pressure. When the screw retreats, the pressure on the top of the melt is the backpressure, which is regulated by the overflow valve. Increasing the back pressure will increase the melt temperature, reduce the plasticizing speed, make the melt temperature uniform and the color mixture uniform, and discharge the melt gas, but will extend the molding cycle. The backpressure of TPU is usually 0. 3 ~ 4MPa. Injection pressure is the pressure exerted on TPU by the top of the screw. Its function is to overcome the flow resistance of TPU from the barrel to the cavity, to fill the mold with molten material, and to compact the molten material.

The flow resistance and filling rate of TPU are closely related to the melt viscosity, while the melt viscosity is directly related to TPU hardness and melt temperature, that is, the melt viscosity is not only determined by temperature and pressure, but also by TPU hardness and deformation rate. The higher the shear rate is, the lower the viscosity is; the higher the hardness of TPU is, the higher the viscosity is.

Relationship between viscosity and shear rate of resin with different hardness (240℃). At the same shear rate, the viscosity decreases with the increase of temperature, but at the high shear rate, the viscosity is not affected as much by temperature as at a low shear rate. The injection pressure of TPU is generally 20 ~ 110MPa. The holding pressure is about half of the injection pressure, and the backpressure should be 1. Below 4MPa to make TPU plasticized evenly. - Cycle time – the cycle time required to complete an injection process is called the molding cycle time. Cycle time includes filling time, holding time, cooling time and other times (opening, demoulding, closing, etc.), which directly affects labor productivity and equipment utilization. The forming cycle of TPU is usually determined by hardness, thickness, and configuration. The high hardness cycle of TPU is short, the thick cycle of the plastic part is long, the complex cycle of plastic part configuration is long, and the forming cycle is also related to mold temperature. The TPU molding cycle is generally between 20-60s.

- Injection speed – the injection speed mainly depends on the configuration of TPU injection molding products. Products with thick end face need lower injection speed, while products with thin end face need faster injection speed.

- Screw speed – The processing of TPU injection molding products usually requires a low shear rate, so a lower screw speed is appropriate. The screw speed of TPU is generally 20-80r / min, so it is preferred to be 20-40r / min.

(2) Shutdown treatment

As TPU (Thermoplastic polyurethane) may degrade in extended time under high temperature, PS, PE, acrylate plastic or ABS should be used for cleaning after shutdown; if the shutdown lasts for more than 1 hour, heating should be turned off.

TPU plastic molding

(3) Post-treatment of products

Due to the uneven plasticization of TPU in the barrel or the different cooling rates in the die cavity, it often produces uneven crystallization, orientation, and contraction, which leads to the existence of internal stress in products, which is more prominent in thick-walled products or products with metal inserts. The mechanical properties of products with internal stress are often reduced, and the surface of products is craze or even deformed and cracked. The way to solve these problems in production is to anneal the products.

The annealing temperature depends on the hardness of TPU injection molding products. Products with high hardness have higher annealing temperatures and lower hardness temperatures. Too high temperatures may cause warpage or deformation of products, and too low temperatures cannot eliminate internal stress. TPU should be annealed at low temperature for a long time, and the products with lower hardness can be placed at room temperature for several weeks to achieve the best performance. The hardness can be annealed 80 ℃× 20h under shore A85, and 100 ℃× 20h above A85. Annealing can be carried out in the hot air oven, pay attention to the position not to locally overheat and deform the products.

Annealing can not only eliminate internal stress but also improve the mechanical properties. Because TPU is a two-phase form, phase mixing occurs during TPU hot working. When the TPU injection molding product is cooled rapidly, due to its high viscosity and slow phase separation, it must have enough time to separate and form a micro area, so as to obtain the best performance.

(4) Inlaid injection molding

In order to meet the needs of assembly and service strength, TPU injection molding parts need to be embedded with metal inserts. The metal insert is first placed in a predetermined position in the mold and then injected into a whole product. Because of the great difference of thermal properties and shrinkage between the metal insert and TPU, the TPU products with insert are not firmly bonded.

The solution is to preheat the metal insert because the temperature difference of the melt is reduced after preheating so that the melt around the insert can be cooled slowly and the shrinkage is relatively uniform during the injection process, and a certain amount of hot material feeding effect can occur to prevent excessive internal stress around the insert.

TPU is easy to inlay and the shape of inlay is not limited. Only after the inlay is degreased, it is heated at 200-230 ℃ for 1. The peel strength can reach 6-9kg / 25mm in 5-2min. In order to obtain a stronger bonding, the insert can be coated with adhesive, then heated at 120 ℃, and then injected. In addition, it should be noted that the TPU used should not contain lubricants.

(5) Recycling of recycled materials

In the process of TPU injection molding processing, wastes such as the main flow channel, shunt channel and unqualified products can be recycled. According to the experimental results, 100% recycled material can be fully utilized without adding new material, and the mechanical properties are not seriously reduced.

However, in order to keep the physical and mechanical properties and injection conditions at the best level, it is recommended that the proportion of recycled material be 25% ~ 30%. It should be noted that the type and specification of recycled materials and new materials should be the same.

The polluted or annealed recycled materials should not be used. The recycled materials should not be stored for too long. It is better to granulate and dry them immediately. Generally, the melt viscosity of recycled materials should be reduced and the forming conditions should be adjusted.

Check more TPU injection molding information or to contact us.

Procedure Engineering alludes to the nature of electrical contact focuses in an electrical framework, and unwavering quality is the most significant angle for the general framework. So how might you characterize unwavering quality in an electrical framework? Some may state that it is in the PLC (Programmable Logic Controller), the DCS (Distributed Control System), or the drives framework. Be that as it may, you can quantify the unwavering quality of an electrical framework by the point wherein the wires meet. To the normal individual, this is otherwise called an electrical connector. From a modern application outlook, these are likewise alluded to as terminal blocks.

Elements that impact an electrical framework

There are numerous things that impact an electrical framework, however extraordinary conditions, for example, warmth and cold have the greatest effect. Different interesting points incorporate combustibility, and this is particularly significant in the petrochemical business and nourishment industry. In Northern America, the ATEX 100a (94/9/EC) has been applied to the defensive frameworks and gear in touchy environment. National electrical codes and Canadian electrical codes are utilized in these situations.

Recorded underneath are the key necessities for particular terminal blocks:

Should be verified and should never come free at the terminal point.

Should be fitted with a flexible part on the off chance that they were initially implied for multi wire channels

The protecting parts must not experience the weight point.

These prerequisites must be tried by an outsider testing focus and should be ensured with the endorsement of plan endorsement.

In process building, you should know about the consistent changes in temperature. This test affirms that the terminal focuses have reliably high contact quality even with the consistent changes in temperature. Measured terminal blocks can be appended to the fixing backing and wired to a channel for testing. The testing utilizes a two chamber strategy, which test the particular terminal blocks to temperatures near their higher and lower limits. These cutoff points run from short 50 degree C to more than 105 degree C. They are generally tried in these temperatures for 60 minutes, and the temperature can change on various occasions inside a moment. This procedure proceeds with two or three dozen times, and on the off chance that the parts are not harmed after the test, at that point the necessities have been met.

Voltage Drop Test for Modular Terminal Blocks

So as to keep up a solid electrical connection, their contact focuses ought to be liberated from erosion. The voltage drop test is otherwise called a consumption test, and the terminal blocks should past a test where they bear sulphuric corrosive. The terminal blocks are exposed to sulphuric corrosive for a couple of hours and afterward left out to attempt. They are physically assessed a while later to guarantee that the contact focuses are as yet solid.

It might appear to be extremely straightforward, however all of them experience these thorough tests to guarantee their quality and strength. Basically, if your terminal square bombs your whole framework comes up short and generation is deferred. From a business point of view this is unsatisfactory and can cost tens and thousands of dollars. So the exercise here is to ensure you do your exploration and go with quality for your business.

Terminal square housing

Light circuits are wired in an outspread circuit setup, not at all like attachment outlets that can be wired in either spiral or ring arrangement. A spiral circuit doesn’t circle back to the MCB in the Consumer Unit or circulation board. The best cable to use in a local dwelling for a standard light circuit is 1.5mm square twin and earth PVC cable, provided from commonly a 5A, 10A or 16A MCB relying upon the heap and measure of lights on the circuit. 16A MCB’s for lighting is progressively utilized in business homes where bigger and all the more light fittings are utilized. This article will concentrate on a standard light circuit utilizing 1.5mm PVC “twin and earth”. Its normal to utilize 1.0mm(square) cable for shorter circuits with littler burdens to get a good deal on cable. By computing the most extreme circuit length and burden you will have the option to settle on what cable size the best is to utilize. Utilizing 1.0mm(square) cable may be somewhat less expensive however considering future adjustments its in every case better to utilize a 1.5mm for later expansions and including of heavier burdens. A 1.5mm square cable would regularly be encouraged from a 5A,6A or 10A MCB and have a most extreme cable length of 108, 90 and 52 meters individually. 108 meters sound exceptionally long yet once the cable is steered through your home’s canvis will turn out not to be that long.

When the spiral circuit is sustained through your home by means of each space to each light point, feed a cable(Twin and Earth) from each light point to the switch in that room.

From your outspread circuit at the lighting point, you need to associate the Live (which is the cable nourished to your switch) with the spiral Lives on a similar connector square. Interface the opposite finish of your Live cable at the change to the terminal in the switch set apart with L1. The other two cables in your twin and earth are blue and an exposed copper cable. Make a point to put Yellow/Green sleeving over the exposed copper cable at the switch end and light fitting and do associate it to the earth terminals gave in the fittings. Make sure to interface the metal pit box to earth in the light switch. The blue cable is utilized as the arrival live associated in the change to the terminal set apart as C (normal). You need to check the blue cable (ordinarily utilized as unbiased) with a dark colored sleeving to demonstrate that its now a Live and do likewise at the opposite finish of the cable in the pendant connector square. The dark colored sleeved blue cable is currently associated with a similar terminal square as the cable to the light holder cable. Rehash this entire expositions at each light point. Recollect before turning your circuit on that it should be tried for extremity, protection, progression, earth coherence lastly once livened up a circle impedance test must be completed.

Flower pots have different uses, from beginning new seeds, moving plants to new areas, indoor development plants improve garden, or beguiling your stay with magnificent flowers. Flower pots have been utilized since antiquated occasions, the Egyptians were among the first to utilize pots to move plants starting with one area then onto the next, later the Romans brought pruned plants inside during chilly climate. In current periods, they can be utilized as an individual blessing, kitchen improvement, room beautification, and workmanship object.

Plant pots can be effectively found in garden supply stores, markets, home improvement stores, and online nursery stores. There are various types of plant compartments, from mud flower pots, plastic, clay, fiberglass, hanging pots, window box planters, sandstone urns, and some increasingly; every one of them has their own upsides and downsides. Out of all these, plastic flower pot considered one of the most mainstream kinds of pot. In the course of recent years, plastic pots have gotten a moderate and non-brittle other option,

Before picking which sort of pot you need, you have to figure out where would you like to put the pots. OK prefer to lay the pot in your nursery? Or on the other hand, do you like to put within your home? Regardless of whether in the lounge room, kitchen or window design in a private room, you should design and choose the arrangement of your pots.

With the impeccable situations and match with the environment, it will improve the wonder of home just as your nursery. Kind of plants, sizes of flower, weight, characteristics, and costs likewise significant contemplations before picking the correct pot for you. Growing your very own flowers unquestionably brings extreme joy, an intriguing movement that enlightens your days.

You ought to set up your peat pots and seedling plate on the off chance that you are preparing for the following growing season. You additionally need to have a reserve of plastic flower pots that will get your transplants. The humble plastic pot is intended for this exhausting however fundamental cultivating and planting task. Notwithstanding, there are some fresh employments of the modest plastic pot that can be utilized as a blessing to a planting companion.

You can likewise make a solitary houseplant stand apart with a painted plastic pot. A plant that is hanging in the restroom will look significantly greater in a hand-painted plastic flower pot of your own structure. A plain old plastic pot can make a unique blessing out of a standard house plant with the expansion of a hand-painted, unique structure. Utilizing a violet theme on the humble plastic flower pot separates the plant from the regular flower specialist’s advertising.

Another interpretation of the plastic flower pot is only a brush stroke away. It is shrewd, to begin with a little undertaking and see where it takes you. In the event that you utilize your imagination and put a portion of your time in it, at that point painting the plastic pot can turn into a fulfilling and fascinating diversion.

Simple Tips for Taking Care of Plastic Flowers pots at Home

Numerous property holders incline toward designing their homes with plastic flowers. They’re minimal effort and low-upkeep, in addition to they will keep going quite a while. Some plastic flowers resemble the genuine article yet the vast majority of them simply look like modest impersonations – let it out, on the off chance that you got them for P200 at some retail establishment deal, you can’t anticipate a lot.

Then again, a few mortgage holders incline toward growing genuine flowers in their homes rather if making do with plastic ones. Genuine flowers give the house a progressively normal and individual mood which is once in a while accomplished with plastic impersonations. Other than that, flowers assimilate carbon dioxide noticeable all around to deliver oxygen, in this way cleaning the air in your home. Growing flowers may require a ton of exertion however by the day’s end when you see them sitting pleasantly on the windowsill or giving a bit of class on your feasting table, it merits the time.

Dealing with flowers at home shouldn’t be excessively hard on the off chance that you realize the best possible approach to do it. Here are a few hints to assist you with thinking about your houseplants:

- Water them day by day.

Make a point not to make the soil spongy by directing the measure of water, sitting tight for it to retain and sift through at the base of the pot (pots generally have openings for this) to the sink, saucer or pail. Over-watering plants may slaughter them. A few indications of over-watering are yellowing leaves that in the long run tumble off, withering, hindered growth and shape growth in the plant. At the point when you see these signs, promptly diminish the water you pour in.

- Lighting.

Some flowering plants require splendid, medium or low lighting, Make sure to look into the light prerequisites of your plant so as to expand their growth.

- Sunlight.

Contingent upon the kind of flowering plant you have in your home, their necessary introduction to sunlight can be four as long as eight hours every day. For increasingly touchy plants, don’t place them in direct sunlight. They would do well in the shade.

- Expel dead flowers and leaves.

Doing this will keep your flowers from decaying or infection. Additionally, nuisances won’t be pulled in to the plant.

- Wipe the leaves with delicate, clammy fabric.

Your flowering plant will look shinier and more advantageous with this progression. Gathered residue can make your flower look messy and not well kept.

Remember these tips and your flower will grow more beneficial and increasingly wonderful.

Advantages of plastic flower pots

- Plastic flower pots are the pots comprised of plastic material which is light in weight and simple to deal with and move starting with one spot then onto the next spot. It gives an astounding look to your nursery in minimal effort and support costs. They are perfect for little nursery and to grow plants and flowers to satisfy the propensity for cultivating and home stylistic theme. It’s one of the most favored planters in India which can be found in house, showroom, shopping centers, open spots, and different spots.

- Plastic Flowerpots can be utilized to balance the pots outside a house in a gallery. And furthermore, use as indoor planting. Plastic flower pots come in various sizes, plans, and structures which gives an outstanding motion to space where you place plastic flower pots. In this cutting edge method for cultivating and individuals’ get-up-and-go about growing flowers, plastic flower pots rise as best pots to fulfill and meet your planting needs.

- Plastic flower pots are helpful to deal with and you don’t have to make a fuss over moving the pots at the hour of moving. This gives plastic flower pots extraordinary highlights on the grounds that typically individuals don’t remain in a specific spot for long and furthermore keep changes the segment of their nursery, so it turns out to be anything but difficult to move pots in light of its lightweight.

- More affordable

Plastic flower pots are more affordable in contrast with different kinds of pots at your nursery. You don’t have to cost bunches of cash on its support and don’t to go through a lot of cash in purchasing flower pots for your nursery. Plastic flower pots request less cost and come at a sensible cost in the commercial center and online store. Plastic flower pots are extremely more affordable and simple to manage.

- Adaptability

Plastic flower pots are adaptable in nature as you can utilize them for various reasons and places. It tends to be utilized at indoor and outside without worrying about its harm. Plastic flower pots can be utilized for cultivating and enrichment reasons. It’s one of the most flexible pots among the flower pots.

How to make your custom plastic flower pots

Stage 1: Prepare Some Concrete Materials

- Prepare some solid materials, a wide range of plastic compartments, containing plastic jugs, lunchroom plastic bowl, can be reused and reused. Need two holders of various sizes in concrete poured before you can begin orchestrated by the shape and size.

Stage 2: Put the Mixed Concrete in the Large Containers

- Put the blended cement in the huge compartments and afterward put the littler holders in Central, drill gap as the waste gaps in the bottom. Stay totally dry, the plastic compartment can be expelled, the surface harshness of coarse sandpaper can be utilized.

Stage 3: Layered With Plants, Done

- Layered with plants, done! During the time spent characteristic drying, botanical examples on the outside of follows and practically difficult to control, so I won’t rehash, truly is excessively cool. Was intending to purchase the proprietor of flower pots.

How To Find Plastic Flower Pots Wholesale

At the point when web-based looking for plastic flower pots, we sell plastic flower pots at volume in various value ranges. We accept that you can depend on us as we give you very palatable plastic flower pots with the best quality at most aggressive cost on the planet.

We are a perceived wholesale for plastic flower pots on a special stage and have a lot of experience selling wholesale on the web. We offer a wide assortment of plastic flower pots, custom plastic flower pots. Peruse our best worth things and shop our most noteworthy reviewed stock at modest costs. Purchase plastic flower pots wholesale from us and get a fair cost on all wholesale plastic flower, custom plastic flower pots!

Shop for plastic flower pots from at sensible cost!

What is precision plastic injection molding?

Precision Plastic Injection Molding is tight tolerance requirement plastic injection molding parts. Normally tolerance on the plastic molding part is around 0.05-0.1mm, if the part tolerance requirement is about 0.01-0.03mm, that means this is precision plastic injection molding, to make high precision plastic injection molding parts, the first thing is making the precision injection mold, all of the mold components must have tolerance within 0.005-0.01mm.

This is min requirement for high precision plastic injection mold after mold is completed finished, then take mold trial to verify the dimension according to 2D drawing requirement, to trial the mold and make stable tolerance.

High Precision plastic injection mold is number one key point to making high precision plastic injection molding parts, but not limited to this, you still need use high precision injection molding machine to produce the part, by this two min requirement we can make sure that we can make precision injection molded plastics continually, there are few issues that we make still need to know for the high precision plastic injection molding.

Plastic precision Connector-overmolding

Question I:

The determination of the structure of the precision plastic mold is the key, and the overall structure is the embodiment of the final effect of the product: the determination of the overall structure of the mold, the determination of the gate system, the determination of the ejection system and the determination of the water transportation system, and others should be conducive to the post-processing orientation of the product.

Question II:

What about the feeding problem? First of all, we will choose a reasonable injection scheme according to the structure, weight, volume, and cost of the product, which can meet the requirements of customers as well as the requirements of quality.

Second, we will design in strict accordance with the injection design standards: the layout of the runner should be uniform, especially the size of the cross load surface of the main and sub runner, the shape and size of the gate.

Question III:

What about the ejection problem? Firstly, we will determine the ejection mode according to product orientation and structure. Secondly, we will evaluate the ejection balance and coexist with other systems, such as interference with water transportation and recycling marks, date clock, etc.

Question IV:

The design of the water channel system is based on four requirements (the cooling line should be as balanced as possible. The water cooling line shall not interfere with other mechanisms. The water channel equipment shall meet the customer’s standards and be easy to install. Each water channel line shall be displayed with identification numbers or marks (in and out).

Question V:

How to ensure the manufacturing accuracy of the mold and the accuracy of the molding products to get precision injection molding, this mainly depends on the manufacturing accuracy of the mold cavity, the insert, and the mold core size. The accuracy of the mold cavity number or the accuracy of the parting line will directly affect the size of the product. Firstly, we need to make the manufacturing process plan and flow chart.

Each completed manufacturing process must be fully inspected and the data inspection list must be recorded in the datasheet. After the manufacturing is completed, the workpiece shall be processed and maintained.

The design of the parting line of plastic mold is also an important part. If the design is not reasonable, the part is not easy to demoulding or even damage the mold. Here are the design principles for the parting line of mold

It is convenient to eject out the plastic part and simplify the structure of the plastic mold. After the demoulding direction is selected, the position of the parting line should make the plastic part fall done without any interference, like sliders, etc.

For the plastic part with high coaxiality accuracy, the parting line should be selected at the position where two diameters can be placed on the lower mold or upper mold at the same time.

When the precision plastic injection molding along the height direction is required to be high, the half overflow cavity should be used. If the transverse flash is formed at the parting line, it is easy to ensure the height precision, while the non-overflow cavity is not easy to ensure.

When the radial dimension accuracy is high, the influence of flash thickness on the accuracy of the plastic part should be considered, as shown in the figure. If the vertical parting of plastic parts is easy to ensure, the horizontal profile is difficult to control due to the thickness of the flash, which affects the accuracy of plastic parts.

Ensure the appearance of the plastic part, it shall be easy to clean the flash and not easy to damage the appearance. The flash produced by the parting surface as shown in the figure shall be easy to clean and not easy to damage the appearance of the plastic part.

It is convenient for the manufacture of plastic mold and the processing of forming parts. The improved parting surface makes the processing concentricity of plastic mold low, easy to manufacture and the flash does not damage the appearance of plastic parts.

Ensure the strength of the formed parts, for example, when determining the parting surface, avoid the thin wall and sharp corner of the formed parts.

In addition to the design elements of general molds, the following points should also be considered in the design of precision injection molds:

- Adopt proper mold dimension tolerance;

- Prevent forming shrinkage error;

- Prevent deformation of injection part;

- Prevent the deformation of demoulding;

- The manufacturing error of the die/mold is minimized;

- Prevent the error of mould precision;

- Maintain mold accuracy.

Prevent the error of mold precision; classification of processing molds in plastic mold factory and requirements of various points for attention

There are many kinds of plastic injection molds, which can be roughly divided into ten categories. According to different requirements of a part material, physical and chemical properties, mechanical strength, dimensional accuracy, surface finish, service life, economy, etc, different types of injection mold are selected.

The plastic mould with high precision needs to be processed by a high precision CNC machine, and the material and molding process of the mould have strict requirements. Mould technology is also needed to design and analyze.

Some of the parts have special requirements during molding, so advanced technologies such as hot runner, gas-assisted injection molding, nitrogen cylinder, etc. are needed for plastic mold.

Plastic mold manufacturers shall have CNC machine tools, EDM machine tools, wire cutting machine tools, and CNC profiling milling equipment, high-precision grinder, high-precision three coordinate measuring instruments, computer design, and related software, etc.

In general, large metal stamping dies (such as automobile cover part die) should consider whether the machine tool has a blank holder mechanism, even edge lubricant, multi-position progressive, etc. In addition to the punching tonnage, the punching times, feeding device, machine tool and die protection device should be considered.

The plastic mold manufacturing capacity and process of the above are not possessed and mastered by every enterprise. When choosing a cooperative plastic mold manufacturer, we must know its processing ability, not only look at the hardware equipment, but also combine the management level, manufacturing experience, and technical force.

For the same set of mould, there is sometimes a big gap in the quotation of different mould manufacturers. You should not pay more than the value of the mold, but also should not be less than the cost of the mold. Plastic mold manufacturers, like you, want to make a reasonable profit in business, ordering a set of molds with a much lower price will be the beginning of trouble. You should start with your own requirements and measure them comprehensively.

If you have a plastic parts that needs precision injection molding manufacturing services, you are welcome to contact us, Sincere Tech is customized precision plastic injection molding company in China. We offer precision injection molds and molding services to customers all over the world.

About Us

Sincere Tech is Contract mould supplier in China that offers electronic new product research and development services as well as assembly company services. Contact us for more information.

All in one service for new product development from part design, PCB design, prototyping, testing, mold/die/tooling making, massive production, assembly, inspection, and packing.

Contact Info

Building 1, No. 30 Huan Zhen Rd, Shang Dong village, Qi Shi Town, Dongguan City, Guangdong province China, 523000

Mobile: +86 135 30801277

Weichat/whatsup No.: + 86 135 3080 1277

Email: info@plasticmold.net

Web: https://plasticmold.net

Our Customers feedback

“Hi Steve, Molds work very well good job, I hope you are doing well, as son as I have new project will come to you”

Customer from Hansaplastic in USA————–

“We are very happy with your management & English communication, you are outstanding in issue solving and fast replier, frankly say you are the best plastic mold maker and the molding company I have been working up to know”

Customer from Canada—————–

Top 10 Injection Molding Companies in Indiana2024年11月20日 - pm1:02

Top 10 Injection Molding Companies in Indiana2024年11月20日 - pm1:02 Top 10 Plastic Injection Molding Companies In Michigan2024年11月20日 - pm12:43

Top 10 Plastic Injection Molding Companies In Michigan2024年11月20日 - pm12:43 Top 9 Plastic Injection Molding Companies in Chicago2024年11月16日 - pm3:29

Top 9 Plastic Injection Molding Companies in Chicago2024年11月16日 - pm3:29 Top 9 Injection Molding Companies In Wisconsin2024年11月10日 - pm1:03

Top 9 Injection Molding Companies In Wisconsin2024年11月10日 - pm1:03 Top 10 Injection Molding Companies in Ohio2024年11月10日 - am9:44

Top 10 Injection Molding Companies in Ohio2024年11月10日 - am9:44