What is electrical discharge machining and how does it work?

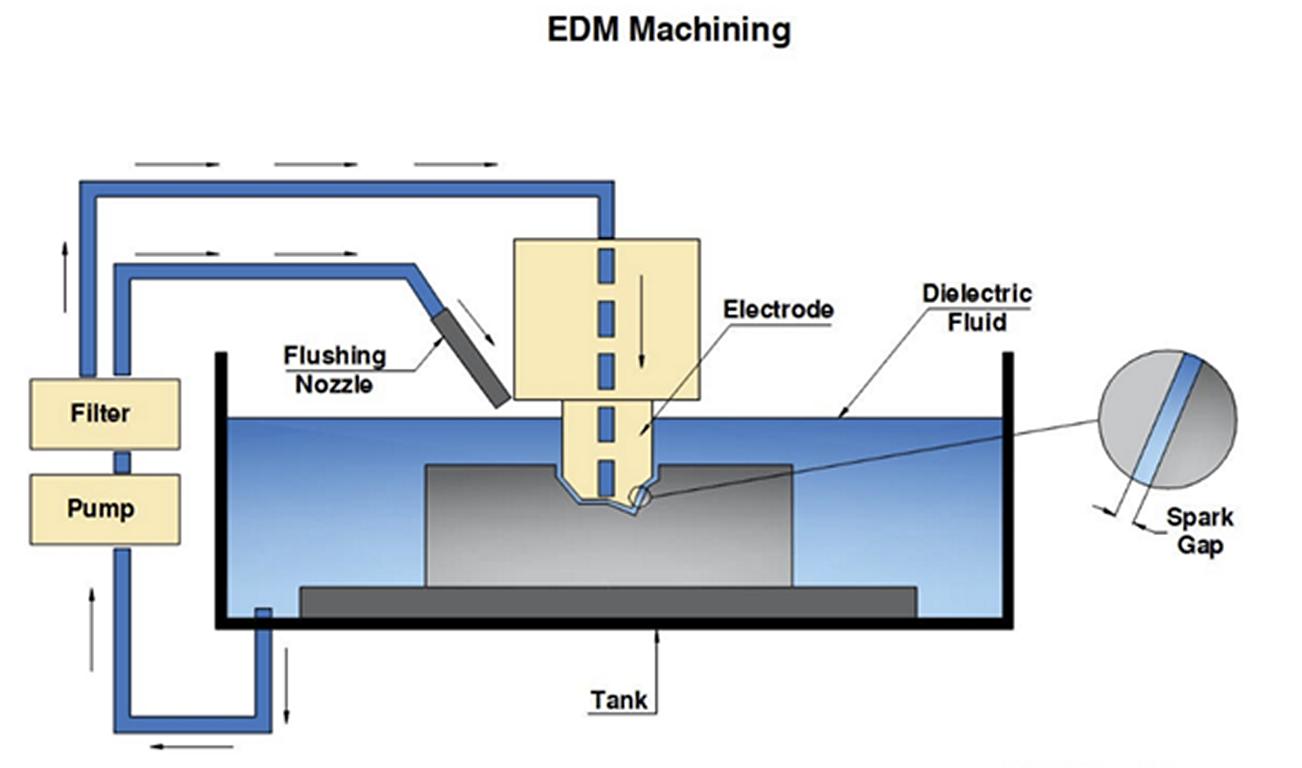

Electrical discharge machining or EDM employs electrical discharge and sparks to remove metal. Sometimes referred to as spark machining or spark eroding, EDM is a method of removing material by a series of electric discharges using copper electrodes or Graphite electrodes, rapidly arcing between an electrode acting as the cutting tool and the workpiece, in the presence of a dielectric fluid.

EDM is used to burn material away from the metal mold component, to add:

- Intricate detail

- Sharp corners

- Patterns

The EDM cutting tool is computer-guided along the desired path very close to the work but does not come in physical contact with the piece, preventing plastic injection tooling marks.

A continuous sparking action produces a series of micro-craters on the workpiece and removes excess material by melting and vaporization. The particles are then washed away by a continuous stream of dielectric fluid.

SINCERE TECH’s EDM services can give your design potential a boost. You will be able to place intricate designs and logos in a wide variety of components with top quality results. This process can be used to produce:

- Faceplates

- Nameplates

- Bezels

- Buttons

- Switches

- Gears

- And much more!

EDM can also be used in fabrication, for tapping holes into parts, and similar procedures.

This guide will show how EDM works. Some of the components include the CNC machines, the dielectric fluid, and the electrodes. It is used in cutting hard materials such as steel and carbide. Get to know the classification of EDM, its applications, and major components.

How Does Electrical Discharge Machining Work?

Principle

Electric sparks assist in the formation of metals. This is called EDM. They use a CNC machine to cut the material. This machine requires careful manipulation. Dielectric fluid is used in its cooling system.

This fluid keeps sparks from jumping. Other parts such as the tool electrode aid in forming the metal. This process employs high frequency. It can even cut through any hard material.

EDM is precise and non-intermittent. They manufacture car parts and implement tools. It includes technical aspects such as the spark gap and feed rate.

Spark

Tiny sparks cut metal. They create heat. This is called EDM. This causes heat to melt the metal. The tool electrode is significant. It is the component that is cutting. Spark gap regulates the spark.

This gap has to be negligible. The process employs a dielectric fluid. It cools the sparks. This makes sure it works well. They use it for accurate geometrical forms. EDM can make complex parts. This process involves the use of high voltage.

Erosion

Metal is lost through the process of erosion. This happens in EDM. Little flashes are enough. The process requires a dielectric fluid. It prevents the sparks from flying around. The tool electrode also determines the shape of the metal. This metal transforms into small fragments. This is called erosion.

EDM uses high frequency. They employ it in order to accurately create parts. The wear is very systematic. This makes EDM very accurate. This process is utilized in various industries.

Gap Voltage

The gap voltage plays an important role in EDM. It controls the spark. This voltage must be precise. The distance between the tool electrode and the workpiece should be very small. This is where the magic happens. The dielectric fluid is used to cool the area.

That fluid also prevents short circuits. The process involves high frequency. It ensures accuracy. They use EDM for hard metals. This method is very efficient. It provides a polished surface on the parts.

Pulse Frequency

EDM uses pulse frequency. This regulates the spark timing. The tool electrode molds the metal. It relies on dielectric fluid in the process of cooling. This fluid prevents electrical leaps.

The process requires accurate synchronization. This is the pulse frequency. They use it to make accurate cuts. EDM can work on hard metals. This process is very accurate. It entails many technical processes. EDM has application in many fields. This makes complex shapes easily.

What Are the Types of Electrical Discharge Machining?

Die-sinking

It draws shapes with sparks. This employs an electrode to sever metal. The electrode has the same shape as the intended piece. This piece gets the right shape by sparking. Die-sinking uses high frequency. They apply voltage and amperage to regulate the process.

A special fluid is used to cool and filter particles of dirt and other contaminants. CNC machines assist in managing it. It can create shapes; simple and complex. It is clear and accurate. Die-sinking is utilized in numerous industries.

Wire

It has a thin wire which is used to cut. This uses electrical sparks. The wire is made of brass or copper. They use high voltage. This wire is indeed fast, slicing through the material. Wire moves through guides.

CNC machines assist in regulating it. The process is cooled with special fluid. It makes precise cuts. Various thickness of wire is used. What is electrical discharge machining? The process is suitable for close work. It is used in many places. Wire cutting is accurate.

Hole Drilling

It drills small holes. This uses electrical sparks. The holes are made by a tubular electrode. It requires high voltage and current in the process. They employ a specific dielectric fluid. That fluid is useful for cooling and washing. The drilling is guided by CNC machines.

Various sizes of holes are created. The process is fast. It makes very deep holes. It is used in aerospace and medical applications. Drilling a hole is accurate and fast. It is widely used.

Sinker

It embeds shapes into metal. This uses an electrode. The electrode has the shape of the final product. It involves the application of high voltage. They use dielectric fluid for cooling. CNC machines assist in the process. The method constructs complicated forms. It is useful for fine work.

Electrodes are made of different materials. It is used in mold-making. Sinker EDM is a very effective and accurate process. It makes intricate designs. The process is widely used in many organizations.

EDM

It cuts with sparks. This process uses electrodes. The electrodes are made to replicate the shape of the particular part. The method applies high voltage. Dielectric fluid assists in cooling and cleaning. CNC machines lead the way. Various geometries and forms can be achieved.

What is electrical discharge machining? It is beneficial especially for accurate tasks. Various industries use it. EDM is reliable. The process is stringently regulated. It is flexible and effective. EDM cuts and forms metal with a high degree of accuracy.

Rotary EDM

It employs a rotating electrode. This process creates shapes with sparks. Cutting takes place while the electrode is in rotation. High voltage is used. They cool it with dielectric fluid.

CNC machines control the rotation. Different shapes are made. The process is precise. It is good for complicated designs. Rotating electrodes assist in cutting. Rotary EDM has many applications in many industries. It is effective and dependable. This process is used in most cases.

Small Hole EDM

It makes tiny holes. This uses electrical sparks. The holes are made by a small electrode. The process employs high voltage. Dielectric fluid also has the ability to cool as well as clean. CNC machines control the drilling process. It is possible to make holes of different sizes.

What is electrical discharge machining? The process is quick. It is used to make deep and very small holes. It is used in aerospace and medical industry. Small Hole EDM is accurate. It is fine when used to accomplish delicate tasks. The method is very effective.

| EDM | Tool Type | Accuracy (µm) | Material Removed | Electrode Wear Rate | Cost |

| Die-Sinking | Electrode | ±2-10 | Hard Metals | Medium | High |

| Wire EDM | Wire | ±1-3 | Conductive Materials | Low | Moderate |

| Hole Drilling | Tubular Electrode | ±5-15 | Any Conductive | High | Moderate |

| Sinker EDM | Shaped Tool | ±3-8 | Tough Materials | Medium | High |

| Rotary EDM | Rotating Electrode | ±4-12 | Hard Alloys | Medium | High |

| Small Hole EDM | Tubular Electrode | ±3-10 | Conductive Substances | High | Moderate |

Table on the Types of Electrical Discharge Machining!

What Are the Key Components of EDM Machines?

Power Supply

The power supply is significant. It is useful in Electrical Discharge Machining (EDM). This makes sparks. They are required for cutting metals. They are voltage, current, and frequency.

That makes the machine work. The transformer is used in changing voltage levels. It keeps everything safe. A rectifier converts AC to DC. The power supply has cables. They carry electricity. This is like magic!

Electrodes

In EDM, electrodes produce sparks. This cuts metal. They are available in various forms. They are made of copper or graphite. That makes them strong. Here, the distance between them is not very vast.

It is measured in microns. They need precise control. This is called the pulse duration. What is electrical discharge machining? Electrodes move with motors. They use CNC. This is very accurate!

Dielectric Fluid

EDM machines are cooled with dielectric fluid. It stops sparks. This is very important. The fluid also cleans. It removes small particles of metal. They are called particles. The fluid moves in pipes.

Pumps move it around. They have high pressure. This fluid is also an electrical insulator. That means it is an insulator of electricity. The filter purifies the fluid.

Filters

In EDM machines, filters clean dielectric fluid. They remove particles. This keeps the fluid pure. Filters have small pores. The size is expressed in microns. They function just like a sieve.

That is very precise. The filters need changing. It assists the machine to work properly. Filters are located in a container. This is easy to open. They keep everything clean!

Workpiece Holder

Workpiece holders hold metal in place. This is crucial for EDM. The holder has clamps. They hold the metal firmly. It stops moving. They are very strong. The holder can move.

This uses motors. They are called servos. They help with positioning. This is accurate at the micron level. What is electrical discharge machining? The holder can tilt. It makes special cuts. This is cool!

Servo Control

In EDM, servo control shifts parts. This uses motors. They are called servos. The servos have gears. They are precise. The control system employs feedback. This is very accurate.

It checks positions many times. This helps in maintaining the flow of the machine. They adjust speed. This is called velocity. Servo control gives smooth motions. This is very advanced!

What Materials Can Be Machined with EDM?

Metals

It uses sparks. EDM (Electrical Discharge Machining) is used for cutting steel and iron. The sparks in turn generate high heat. This heat melts metal. They employ Computer Numeric Control (CNC) machines. They are precise. That is key. Electrodes create sparks. This is because the tool has high voltage.

This machine employs dielectric fluid. The fluid cools parts. Electrodes erode metal fast. The gap stays constant. Some parameters do matter such as the peak current. They ensure accuracy. Voltage can reach 300V. These parts need cooling. Results are neat.

Alloys

EDM cuts tough alloys. The process uses sparks. It creates precise shapes. They use electrodes. A high voltage is present in the machine. Dielectric fluid is used to cool the tool. This fluid maintains it. The heat causes the alloy to melt. Parameters include gap width. This affects accuracy.

What is electrical discharge machining? They check peak current. It is important to establish that the tool to be used has the right voltage. It reaches 300V. Inconel as well as other alloys can be easily cut. They become neat shapes. Electrode erosion is constant. This helps cutting.

Ceramics

Ceramics are hard. EDM can cut them. It uses high voltage. The machine creates sparks. This heat melts ceramics. They use dielectric fluid. This cools parts. Electrodes erode ceramics precisely. Parameters include gap control. Peak current does matter. Voltage reaches 300V.

The degree of accuracy of the machine is quite good. Ceramics become neat shapes. It handles brittle materials. They maintain constant erosion. This process is advanced. Electrodes shape ceramics fast. Parts stay cool.

Carbides

EDM cuts carbides well. This process uses sparks. High voltage melts carbides. They use dielectric fluid. It cools tools. The fluid stabilizes parts. Electrodes erode material. Some parameters such as peak current are relevant. Gap control is crucial. Voltage reaches 300V. The machine is accurate to a high degree.

What is electrical discharge machining? Carbides form precise shapes. They become neat parts. It handles hard materials. Constant erosion helps. This ensures accuracy. The tool stays cool.

Graphite

EDM is used to cut graphite. It uses sparks. The process involves high voltage. This melts graphite. They use dielectric fluid. This cools the tool. Electrodes erode graphite. Values such as the peak current do. The gap is controlled. Voltage reaches 300V. Precision is high. Graphite forms neat shapes.

They use CNC machines. It ensures accuracy. Electrodes wear constantly. This maintains the gap. Parts stay cool.

Composite Materials

EDM is used to cut composite materials. The process uses sparks. High voltage melts composites. It uses dielectric fluid. This cools tools. Electrodes erode composites. It is important to look at parameters such as peak current. The gap is controlled. Voltage reaches 300V.

The machine is precise. These composite materials turn into neat shapes. They use CNC machines. Electrodes wear constantly. This maintains the gap. Parts stay cool. They ensure accuracy.

What Are the Applications of Electrical Discharge Machining?

Mold Making

Electrical Discharge Machining (EDM) manufactures toys molds. The EDM employs a unique electrode. It makes precise shapes. They use a high voltage such as 120V. This voltage creates sparks.

The sparks remove metal. That process forms molds. Other components are created, such as voids. The accuracy is of the order of 0.001mm EDM machines use dielectric fluid. The fluid cools it down. This assists in making better molds. They apply CNC to govern EDM. Each mold is unique.

Aerospace

EDM assists in creating airplane parts. It is capable of cutting metals of high density such as titanium. The EDM works with an electrode. This electrode creates small forms. It uses high voltage such as 150V.

Sparks melt metal away. That makes precise parts. They need smooth surfaces. The tolerance is of the order of 0.005mm EDM uses dielectric fluid. The fluid washes and cools it. This makes it work well. They use CNC controls. EDM makes many different parts.

Medical

EDM manufactures small medical instruments. It uses an electrode. The electrode shapes metal. This uses high voltage such as 110V. Sparks remove metal. That makes precise tools. They need sharp edges.

It is 0.002mm The EDM machines have dielectric fluid. The fluid cools it down. This goes a long way in making better tools. They use CNC to manage it. EDM produces many special equipment. These tools help doctors.

Tooling

EDM produces components for factories. It employs a unique electrode. The electrode shapes metal. This uses high voltage, such as 130V. Sparks melt metal away. That makes precise tools. They need exact shapes. The accuracy is 0.003 mm in case of EDM and it uses dielectric fluid. The fluid cools and cleans it.

The fluid cools and cleans it. This assists it in functioning optimally. They use CNC controls. EDM produces many different tools. Such tools assist in constructing structures.

Automotive

EDM makes car parts. It uses an electrode. This electrode cuts metal. The EDM employs high voltage, approximately 140V. Sparks remove metal. That makes precise parts. They need smooth surfaces.

The tolerance is 0.004 mm. EDM machines use dielectric fluid. The fluid cools it down. This aids it function effectively. They use CNC controls. EDM makes many of the unique parts. These parts assist in the construction of cars.

Prototyping

EDM enables creation of new things. It employs a unique electrode. The electrode shapes metal. This uses high voltage such as 125V. Sparks melt metal away. That makes prototypes. They need exact shapes. The accuracy is 0.006 mm EDM has dielectric fluid. The fluid cools and cleans it.

The fluid cools and cleans it. This assists it to function optimally. They use CNC controls. EDM does create many one-off prototypes. These prototypes help inventors.

Conclusion

What is electrical discharge machining and what are its uses, benefits and limitations? EDM cuts with sparks, high voltage, CNC machines, and dielectric fluid. It forms accurate parts. Learn more at PLASTICMOLD. Learn about EDM and its uses and parts. Find out more about its kinds and applications.