We offer CNC machining service in China delivering the world. Metal CNC machining, metal turning, aluminum CNC machining, painting, aluminum anodizing service, if you are looking for aluminum CNC machining parts, metal CNC machining parts, anodizing service for the aluminum components from China, welcome to contact us.

Aluminium is one of the most machined materials accessible today. Actually, CNC machining aluminum parts processes are second after steel in terms of frequency of execution. Mainly this is due to its amazing machinability.

In its real form, the chemical element aluminium is ductile, soft, non-magnetic, and silvery-white in look. Anyway, the element is not just used in the real form. Aluminium is generally alloyed with many elements such as copper, manganese, and magnesium to form 100s of aluminum alloys with many significantly better properties.

Advantages of using aluminum CNC machining parts

Although there are many aluminum alloys with varying degree of features, there are fundamental features applicable almost to all aluminum alloys.

Machinability

Aluminum is readily worked, formed and machined using a big range of processes. It can be fast and simply cut by machine tools because it is soft and it chips simply. It is also less costly and needs less power to machine than steel. These features are of immense advantages to both the machinist and the customer ordering the part. Additional, aluminium best machinability means it deforms less during machining. This lead to top accuracy as it permits CNC machines to get higher tolerances.

Corrosion resistance

Aluminium is scratch resistant and corrosion resistant in general marine and atmosphere situations. You can improve these features by anodizing. It is vital to note that resistance to corrosion changes in different aluminium grades. The most regularly CNC machined grades, anyway, have the most resistance.

Performance at low temperatures

Most materials tend to lose some of their best features at sub-zero temperatures. For example, both rubber and carbon steel brittle at low temperatures. Aluminium, in its turn, retains its ductility, softness and strength at extremely low temperatures.

Recyclability

Since it is subtractive producing process, CNC machining process produce a big number of chips, which are waste stuffs. Aluminium is very recyclable which means it needs pretty low effort, energy and costs to recycle. This makes it preferable to those who want to recoup expenditure and decrease material wastage. It also makes aluminium a more atmosphere friendly material to machine.

Electrical conductivity

The electrical conductivity of real aluminum is approximately 3.77 million siemens per metre at a room temperature. Although aluminium alloys may have lower conductivities than real aluminium, they are conductive enough for their CNC aluminum machining parts to find use in electrical components. On the other hand, aluminium would be unsuitable stuff if electrical conductivity is not desirable feature of a machined part.

How to find good Aluminum CNC machining Service in China?

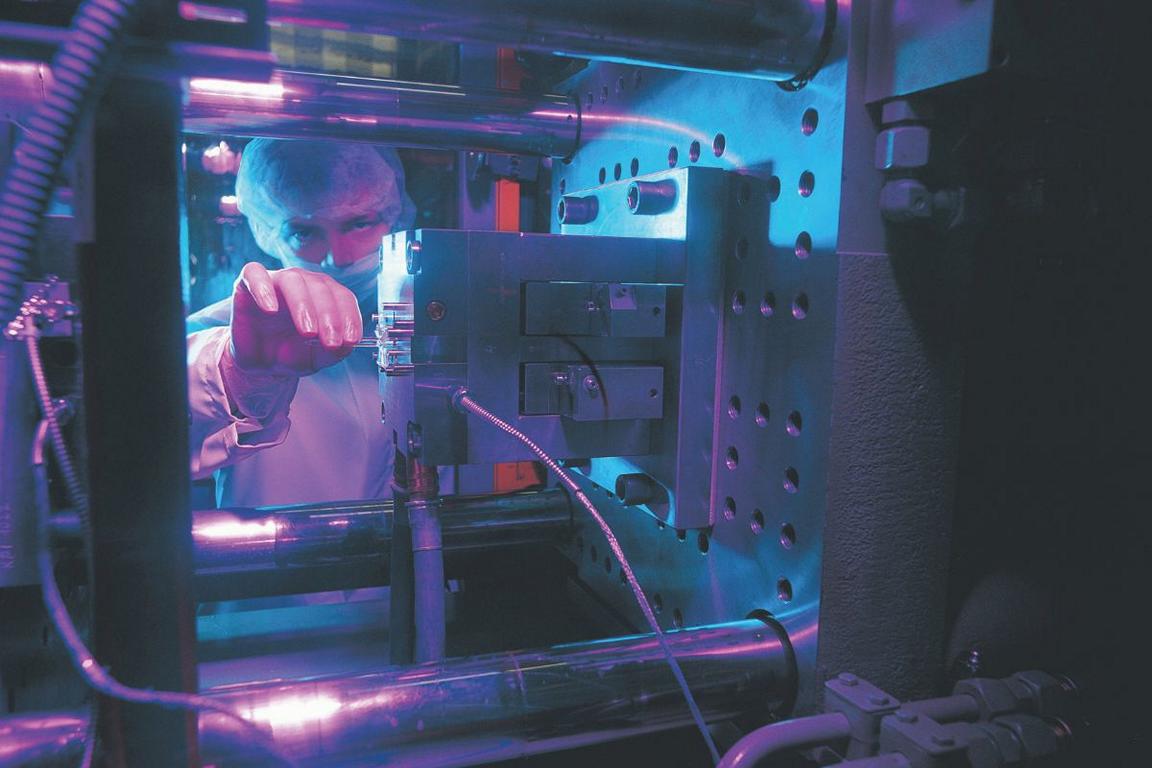

A CNC cutting machine has an important role to play in your business particularly if you are working in the machining manufacturing industry in China. It has a huge application in industrial prototyping and manufacturing. CNC refers to as many control system that uses computers to run machines that produce products. Thus, you will need to pick the good CNC machining company to make the process efficient. Otherwise, it will cost you a fortune as you try to switch to different service providers. But how will you get the best service provider?

Here are the few handy that tips that will help you pick the aluminym CNC machining company in China? Do it once and do it rightly.

Amazing experience

You will need to pick a aluminum CNC machining manufacturing in China who has a big experience with the new trends in the manufacturing industry. It is essential, particularly if you are dealing with a latest product sop that the service provider can provide you with successful manufacturing methods. A big firm would need you to pay more, anyway, you can forever be open to work with relatively new firms. Look at the aluminum CNC machining company portfolio for works done and strike a deal.

Flexibility

You will need to pick a flexible aluminum CNC machining company who will simply accommodate the changes that arises in the manufacturing process. They should job closely with you and readily accept the changes you advise. They should understand the changes in the product that you make and fast implement them to make sure timely delivery of products. It would be important to use the raw materials efficiently to make sure the least wastage and, hence, lowest cost and high quality.

Customer support

Even though it might be difficult to experience challenges when dealing with a reputable aluminum CNC machining company, at times, problems do arise. Thus, it would be essential to work with a aluminum CNC machining manufacturer with efficient customer support. They should offer prompt responses when technical issues happen to make sure no interruption in the production process.

Productivity

The level of productivity is something you should look out for in the CNC machining companies you want to pick. You can gauge this by the number of parts they generate within a specific period. Some may adjust depending your needs. A CNC machining company that can produce more parts in a particular period is the best. Your business type or the items you are dealing with will guide you when it comes to this.

Service costs

You may also want to job on a specific budget so that you make good use of your company finances. This is where you have to factor in the amount being charged for this CNC machining service. The amount you pay impact your selling price. Look for a Chinese CNC machining company that is charging reasonably so that you may also sell these items to your customers at the best rates. The top thing to do is to match service costs in different companies and look for one that is charging reasonably. Do not forget to look for the standard.

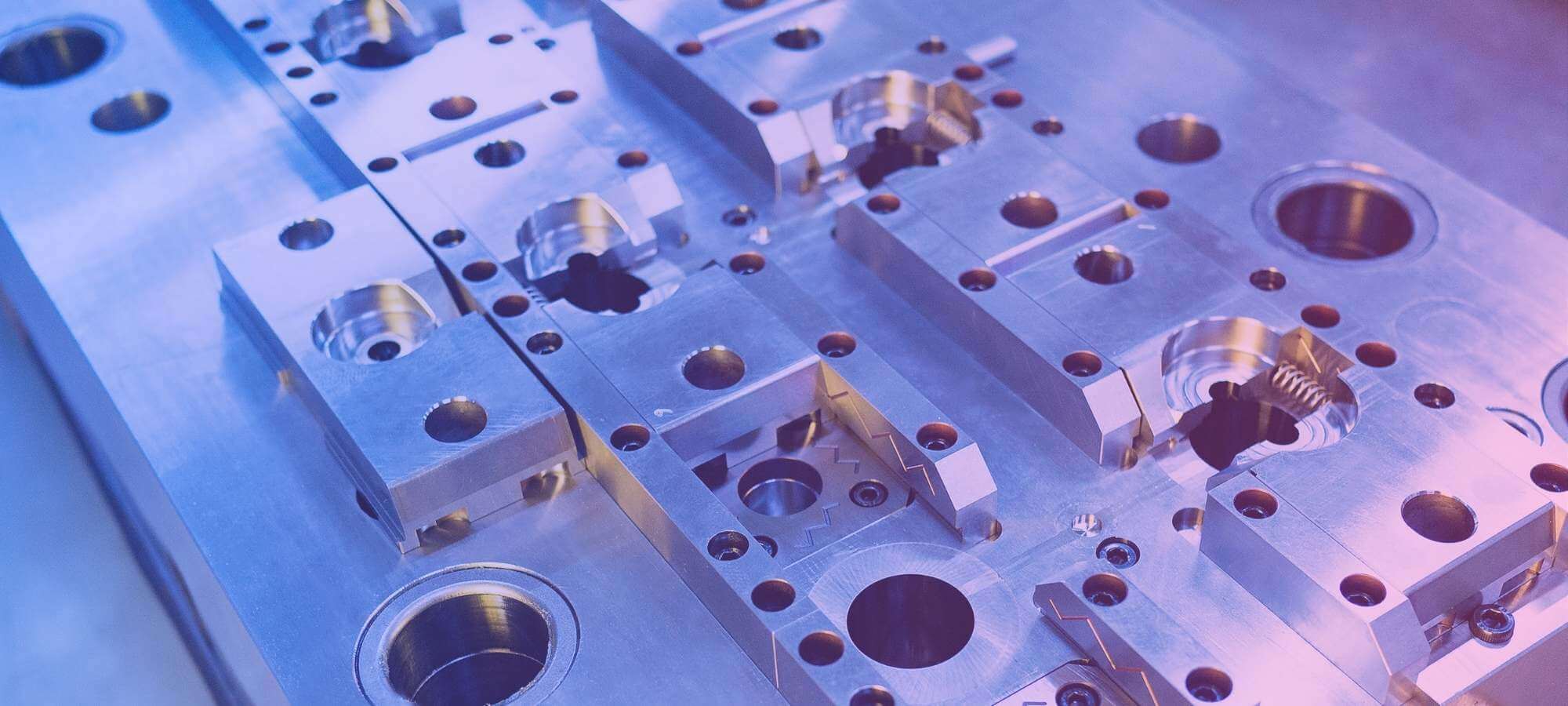

Accuracy

The level of expertise also matters who looking for a CNC machining manufacturer in China. You want to sell parts that meet the desired accuracy levels and also meet the standard required by your customers. Look for a firm with a machine that brings out parts that fit your desired level of accuracy. They should use the new technology in their CNC machining process.

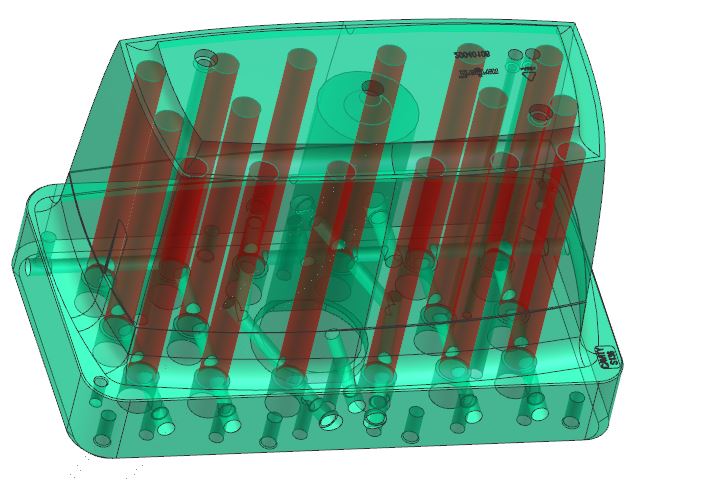

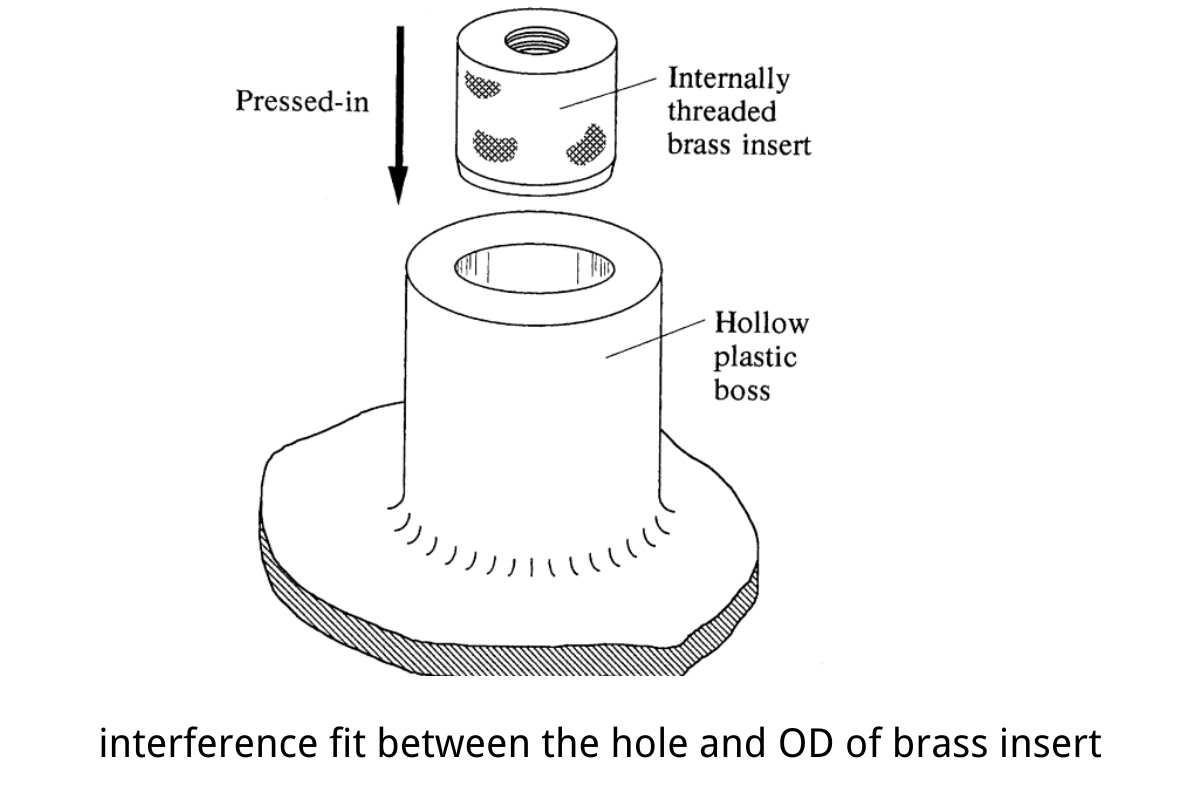

Machining capabilities

Pick a machining company that can manufacture all the items you need. Some are just limited to specific services such as CNC drilling and turning, mold manufacturing, plastic molding manufacturing, insert manufacturing, aluminum CNC machining parts, anodizing service, assembly, delivery service, etc. if they only make a single service and you have to seek other service elsewhere. A CNC machining with all the other related service will keep you the inconvenience. Picking the best machining solution will support you get standard that makes your business profitable.

In-depth knowledge

Your service provider must have amazing knowledge of CNC machining and the different aspects it entails. They will need to have best knowledge about prototyping, designing, and manufacturing. Their big knowledge of CNC products will permit them to advise a best product for your business while sticking to your budget.

Other considerations for picking a CNC Machine producer

In addition to products, strength and services of the CNC machine manufactures, there also are other considerations when picking a best CNC machine manufacture. For example, the CNC machine price. Many customers may believe that the CNC machine price is too costly. Others may hesitate whether the CNC machine is valuable. It is definitely necessary to consider these questions. Because the CNC machine price is quite high, which may cost you 1,000 of dollars.

But I advise that you go for a long-term worth, not just the cheapest price.

When it comes to aluminum CNC machining, the top equipment costs a lot for you to invest in, but they produce top outcomes in less time. Besides, too often, low prices mean low standard. Do not make this error. Look beyond the price when matching the manufactures. Consider your return in worth over the long term, which costs rarely indicates. Well-made orders delivered on time will be an excellent investment than cheaply produced parts from a cut-rate shop.

End words

Picking a best CNC machining manufacturer could be time-wasting and laborious, because there are lots of factors to consider. For example, the production capacity, qualification, English communication, pre-sale service, after-sale service, that the CNC machine manufacturer can offer. If you have time, it is top to visit the factory of the CNC machine manufactures in person to check their operation and production. Further, you shall also take your budget, the CNC machine price, and the choice of local and foreign machines into consideration.

If you are considering to pick the best CNC machine manufacturer, before you begin your investigation, please take a look at Sincere Tech. We have been committed to development, research, and production of CNC machine. Our CNC machines are sold to many countries all over the planet, and we received top praise from many customers. I trust that you will find that Sincere Tech is one of the top 10 CNC machining Services in the world.

Contact us if you have any aluminum CNC machining parts or metal CNC machining parts requirement.