Plastic Injection mold is what people call the process of filling liquid plastic into a mold and waiting for it to take shape. An injection mold maker is the machine that makes the mold for injection molding. An injection mold maker creates molds from metals, usually steel or aluminum. The process calls for precision because a mistake means a repeat of the process or the part made will not be ale to function well enough and may be substandard.

The process of plastic injection molding relies solely on the accuracy of the injection mold. If the mold maker makes a mistake in making the necessary molds needed to produce plastic product, the over all effect will be defective. The mold maker must have the precise measurements of the mold it will make in order to fully meet the standards of the manufacturer and client.

Materials Used in the Process of Plastic Injection Molding:

The usual materials used by plastic injection molding are plastic materials like polystyrene, acrylonitrile butadiene styrene, nylon, polypropylene, polyethylene and PVC. These are the liquid plastics that are usually used by injection molds to produce the plastics that they will then sell. The polystyrene material is lower in cost and in material grade. ABS is a plastic that is hardier than the previous one but not flexible. Nylon can resist mot chemical and is more flexible the previous two. Polypropylene is the plastic usually used to manufacture containers because they are tough and flexible. Plastic Injection molding is also utilized for metal works.

A Plastic injection mold maker will have to make more molds if the molds are used for metal molding. Metal molding wears out the molds more than plastic molding because the melting temperature of metals is higher than plastics. Despite this additional cost, manufacturers still utilize injection molds for metal molding because the prices of metals that are molded this way are still profitable.

Uses of Plastic Injection Mold:

Plastic Injection molding is a manufacturing technique that is used for making parts from thermoplastic materials in production. After a product is designed by an industrial designer or engineer, the models are then made by a mold maker or toolmaker from metal, usually steel or aluminum.

Plastic Injection Mold is a method of molding in which the molding material is first placed in an open, heated mold cavity. The mold is then closed with a strong top force or plug member, and pressure is put on to force the material into contact with all of the mold areas, and then proper heat and pressure are maintained until the molding material has completely cured.

If you or your company needs plastic products with specific types and dimensions, then you should turn to custom injection molding companies. These mold manufacturers have the ability to make plastic parts for specific applications – they can customize virtually all plastic components per your requirements. They can stamp your logo or messages, produce unique colours and designs and package them specifically based on what you want and need.

Choosing Mold maker in China

Most of the mold maker in China that can produce any plastic product you specify, but not all of them go the extra mile to take care of ‘finishing services’ such as decorating, assembly, labelling and packaging. Some even have a design group that can assist clients with the plastic part and mould design. From rapid prototyping and plastic mold to injection molding, ultrasonic and plastic welding and stamping, these companies can assist you every step of the way. Go for China mold manufacturers that offer these added perks – you will end up saving time, money and effort comparing others nomral mold makers .

Note that some Mold Makers in China that do not do these extras in-house – they hire sub-assemblers and finishers, but are still able to produce products at par with your standards.

Also, examine the manufacturing company’s logistics and scheduling system. They should be able to handle your delivery needs no matter how demanding they may be. You should also go for Chinese plastic injection mold companies that implement strict controls to monitor the whole custom injection molding process. They should have the latest inspection equipment at hand to allow them to match the closest tolerance and thus provide quality consistently.

Mold manufacturers in China that plant climate is also very important. They should have facilities that ensure mold cooling system control. You may contact any plastic injection mold companies in the internet directory for your custom injection molding needs.

A successful injection moulding project begins with the plan of an item, and afterward is the manufacturing of plastic injection mold. With the requirement for more limited lead time and better quality, when you work on the plastic injection molding business, every day you will face those points.

In any business, you need to speck your I’s and cross your T’s, and you can’t sum up and call a whole nation unscrupulous. As impossible as it might sound everything boils down to correspondence, all the more decisively the breakdown of correspondence.

Right off the bat, you should comprehend that top quality mold maker in China over last 20 years. Be that as it may, you need to keep a couple standard procedures to ensure you get top quality at the right injection mold cost.

mold manufacturer china

How Can We Find A Reliable Plastic Mold Maker In China

You should clearly indicate your prerequisites and just work with a plastic mold maker in China that you’ve verified appropriately.

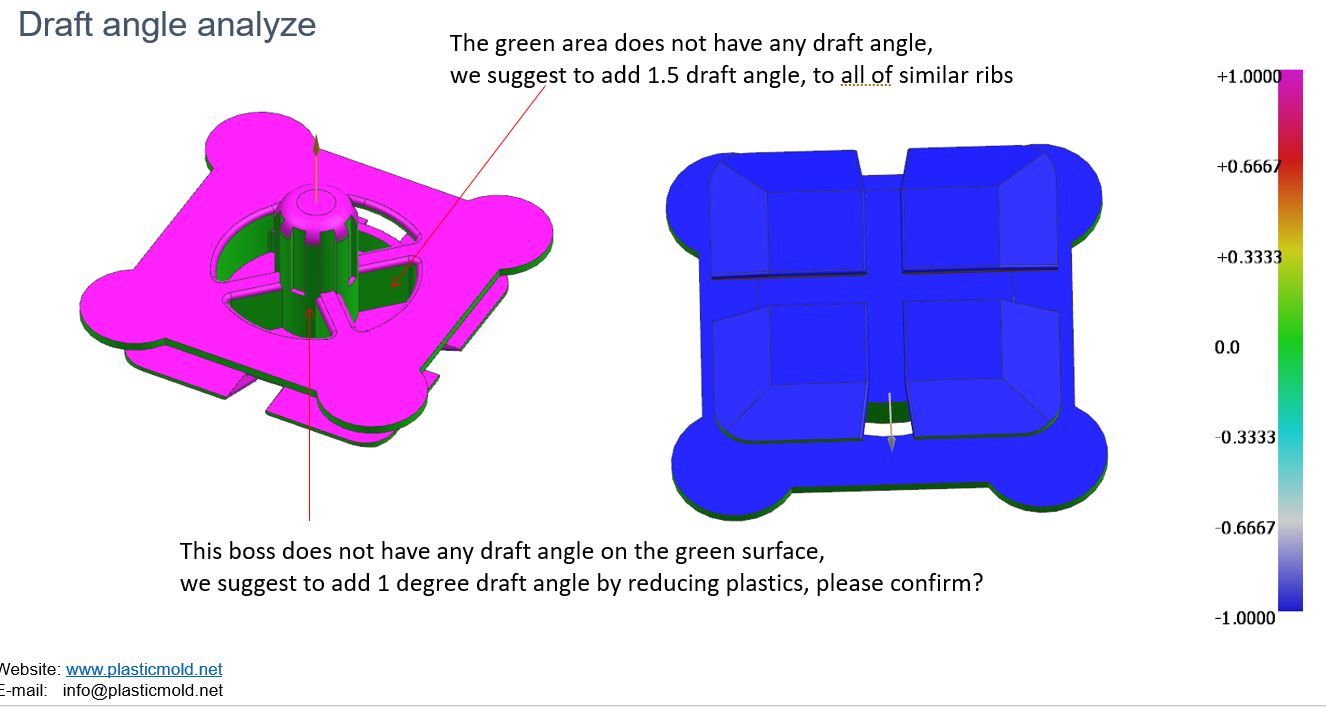

The drawings of your mold configuration should be on point and drawn up by an expert mold designer, and there can be no any sharp corner in the mold design, because that will surely effect the mold life time once in the massive production.

For a plastic mold factory to cite half not exactly that of its closest rival for the same plastic injection mould, they need to reduce their expenses to beneath half of their rivals. This is ordinarily reflected in material choice, surface completions, material hardness, absence of accuracy crushing of mating surfaces, manufacturing process, mold design skill, and absence of close resistances in divider thickness on slight divider items.

These issues can be kept away from by the unmistakable assertion of details at the RFQ stage. The issue with getting cites from mold makers in China is that when thorough particulars are required, the value differential between quality form creators gets insignificant. The complete expense of proprietorship while reevaluating plastic injection molds ought to mirror the entirety of the expenses related with testing and eventually tolerating a mold created in an outside country, and the extra precautionary measures needed to guarantee that no specialized blunders are made as a result of language boundaries.

Despite the fact that it’s moderately simple to track down a trusted, notable mould maker in Germany, UK, Japan or the US, discovering a plastic mold maker in China deserving at least some respect isn’t just about as troublesome as you may might suspect.

Guarantee That You Own the Mold and Any Rights for That Mold

In case you’re transporting the mold abroad, you will claim the form, yet at the same time there are regions you should be sure about with your Chinese mold makers, as complete possession, IP, and so forth Notwithstanding, in case you’re delivering with a production line in China it is basic you ensure that the plastic mold manufacturer comprehend that YOU have the mold ownership,

Initially – you need to make it clear to the mold maker/industrial facility in China can just utilize the molds for delivering your items and that they can’t create any items for an outsider utilizing your mold and plastic parts

Sign an NDA document in number one thing before start the project.

Some of Chinese mold makers have a solid impetus to keep your molds and keep unfamiliar purchasers from moving to another area or production line. In a ton of cases, the form epitomizes most or the entirety of the IP in the item.

For certain items, the inside component depends altogether on open source equipment. The outside walled in area around the system is, subsequently, the essential protectable IP for the item. The protected innovation lies completely in the molds used to fabricate the item case. The outside appearance of the nook then, at that point turns into the ID of the item, and if that appearance isn’t ensured, you will claim NOTHING at all in the IP of the item. Without that IP in the mould ensured, some of Chinese companies can duplicate the item as they see fit.

Then again, in certain items, the structure encapsulates in the mold holds the whole worth of the item.

In the event that NOBODY possesses any of the IP in the molds, they are adequately named an open source, which implies no one claims any of the IP in the molds or for the item, which is a frightening spot to be. Also, the Chinese plants have sorted this out which can make ensuring your molds very hard.

You or a believed outsider should lead a form test.

When the molds have been made they must be tried PROPERLY, reports recorded, input is given on the result, and generally significant of every one of any deficiencies or boundary flops should be amended.

To do this, the form is mounted onto satisfactorily estimated injection shaping machines, set up for an advanced injection cycle, and dispatched for a restricted creation run with every one of the boundaries of a full creation aim activity.

This permits you to investigate the apparatuses under genuine execution circumstances, calibrate its settings, and create a total report of discoveries including the focuses that need change or improvement and instrument alterations for a difficulty free activity that bears the cost of the mold a greatest life expectancy.

The last strides in testing the form can improve things significantly where the distinction in progress and disappointment is estimated in miniature millimeters, and there’s not a viable replacement for experience in such manner.

We are professional mold maker in China, we will never sell your molds and molding parts to any other third parties, we have many of the custom and build the trust to our customers, so once we work together, You will 100% trust us, we will keep your project from any other companies away so that no one have chance to cope your project, contact us to discuss about your project.