When the requirements for polymer parts go beyond 3D printing and machining, it is recommended that product engineers should turn to injection molding. Conventional injection molding entails identifying the right tooling vendor and then buying the tooling, which may take several months. It may take a long time and is very tiresome, but the cost per unit is relatively low, especially when making many pieces of the items. Fortunately, there is an alternative: short run plastic injection molding.

Comprehension Short Run Plastic Injection Molding

When there is a small production of the product, short-run injection molding employs cheaper tools as compared to long-run injection molding (or high volume injection molding). This process also does away with the conventional high-volume manufacturing system that requires much rigidity, long cycle time and large capital investment. However, in this case, short-run injection molding is more appropriate in the short run than in the long run.

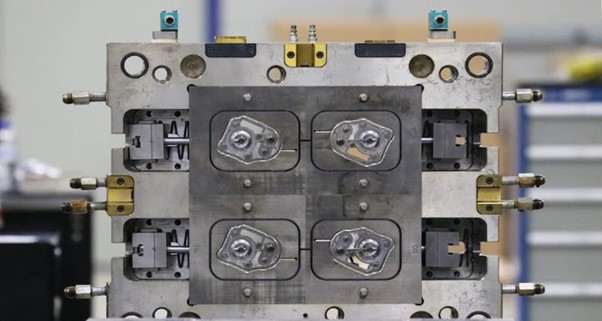

The temporary molds are of aluminum while the ‘hard’ production tools are of cemented tool steel. This metal is characterized by high thermal conductivity and good workability. Aluminum molds are slightly less rigid than steel molds, but they are the most suitable for runs of less than 10,000 pieces. In addition, they are cheaper than steel molds and the final parts are made in weeks, not in months, as is in the case of steel molds.

Short run injection molding is the most appropriate for any organization that needs quality plastic parts at an affordable price and within a short time.

Benefits of Short Run Injection Molding

The benefits of short-run injection molding are as follows:

Aluminium injection moulds are cheaper as compared to reinforced steel moulds that are available in the market today. The degree of savings is dependent on the number of cavities, the geometry of the part and the moulding issues like undercuts or inserts. However, the difference in costs is normally quite large.

But this is not the only advantage that can be derived from this, the cost factor has to be considered. The ability to make changes and the short cycle times can thus be helpful in cutting down the time taken to develop products hence, cutting down the time to market. However, unlike most organizations, our short-run injection molding service does not bind the customers to order in large quantities. They are made from materials of production-grade and have adequate surface finishes that can be used.

Short Run Injection Molded Costs For Parts Production

It is also important to note that the cost of manufacturing the short run injection mold for fabricating small quantity products and setting up is fixed and has to be spread over the number of orders.

Generally, short run injection molding is appropriate for parts ranging from 1 to 10,000. At Sincere Tech, we provide two tooling options: prototype molds, which are normally associated with a warranty of at least 2000 shots and on-demand production molds, which are associated with a mold life warranty. If the aluminum tool is spoilt, then the company will replace it without charging the customer anything. Regarding the quantity of the produced product, both options are fairly inexpensive.

Other special services are first article inspection, capability reports, scientific molding process development reports and PPAP. Some clients have realized that a short-run aluminum mold can be used as the end product mold.

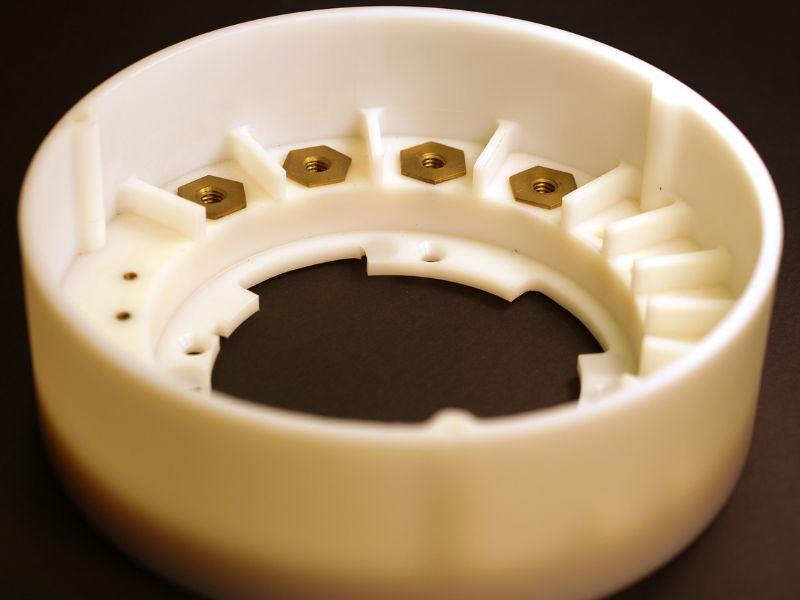

If the volumes are in the millions, then production tooling might be more appropriate. On the other hand, 3D printing can be cheaper in the instance of manufacturing a few numbers of parts. Some of the manufacturers use 3D printing to create the prototypes and then use small run injection molding.

Uses of Short Run Injection Moulding

The best strategy is relative to the needs of the organization and the situation in the organization. For example, a medical device manufacturing firm that has developed a new medical device but is in doubt about the market situation can use a short-run injection instrument. This is in favor of a “pay-as-you-go” approach during the product’s introduction. If, at some later date, they decide to invest in a steel tool, the aluminum mold can be used as an interim tool up to the time the production mold is made.

It is also significant to note that bridge tools are not limited to the ramp-up stage of the product introduction only. They can be a fairly cheap way to have an insurance policy for mature programs. For instance, an appliance manufacturer was in a position to proceed with the production process since he or she utilized a bridge tool to fix the main tool. They now have an extra mold that they can use in the future, for instance, if the demand for the product rises or if the current tool is not effective.

The short-run injection molding is a good middle ground for the designers to get the best mold design and the performance of the final product with relatively low risk as compared to the direct use of steel production tools from the 3D printed models. This is more so in industries such as medical devices where it is important to shorten the time it takes to develop these products while at the same time ensuring that the products meet the set regulatory standards since this is cost-effective.

High-volume injection molding

Our digital network is capable of producing larger and more intricate parts in high volume in case short run injection molding is not applicable to your case. Our expandable range of services includes;

- Projects for molded elements that are large, heavy and elaborate in design

- Quotes for more than 100,000 components

- Molding capabilities for parts that are up to 79 inches (2 meters) in size

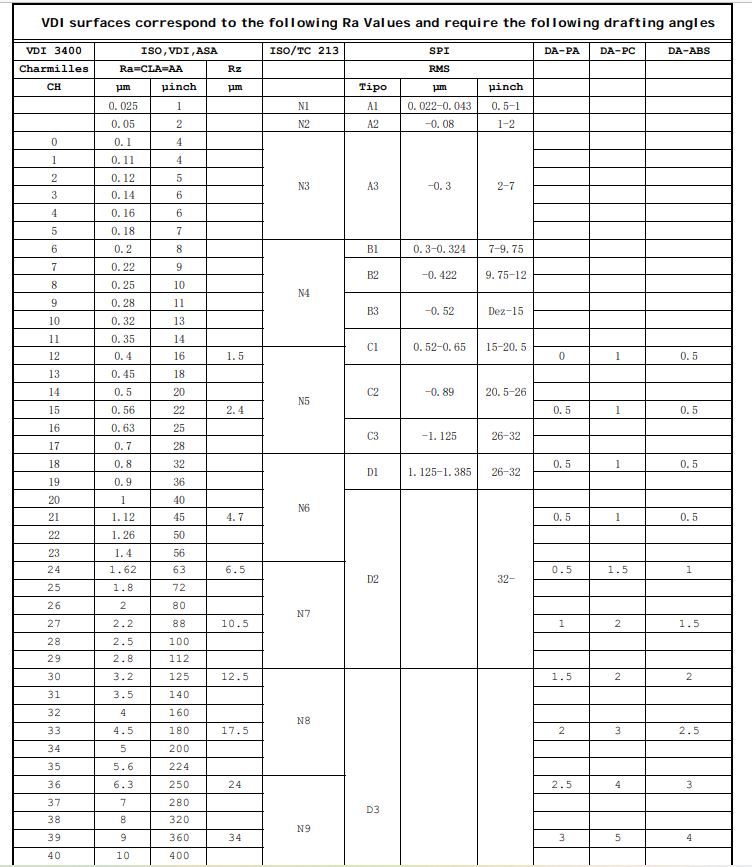

- Mold-Tech finishes and a variety of surface finishes (A1-A3, B1-B3, C1-C3, D1-D3).

- Toolings like Tool Steel P20 and Aluminium & Steel, color matching Tooling as per the requirement of the customer.

- Would you like to know more about short run injection molding? Upload a file for a free mouldability check and then speak with a member of the Protolabs molding team. Start the fast and effective production of parts with our services.

Is the Cost of Short Run Injection Molding High?

Some of the everyday products that have parts made through injection molding are electric kettles, light controls, and keyboard keys. Usually, such products are produced in large volumes, starting from hundreds of thousands of sets.

This construction method has several benefits, such as cost-effectiveness, versatility of materials, and flexibility.

This technique is the most appropriate for mass production due to its versatility, availability of numerous types of materials, and the fact that it is cheaper per part. This procedure makes the current affordable pricing possible because the cost of elements is in pennies, and cycle times are in seconds. It also applies to the choice of materials, which may be flexible elastomers and polymers that can be used where metals are normally used.

What if you require a fewer number of components?

The cost of tooling forms a significant component when a small number of parts are to be manufactured. The traditional method of manufacturing tooling is expensive and also takes a lot of time. However, there are many modern counterparts that can be pointed out to minimize expenses today.

The main cost factors are setup and recurring.

The tool is located in the molding press, the material/color is dried and provided, the molding conditions are set, and the initial quality control samples are taken during the setup. The tooling has to be protected, the rest of the material has to be stripped off, and the mold has to be opened and stored after the molding cycle. This setup is usually billed on a per-part basis, especially for short runs, and can take anything from one hour to half a day, depending on the size of the tools and the number of material/color changes.

The procedure of shaping

The costs that are incurred in the molding phase include the cost of the material used, the cost of the press, and the manual or automatic operation of the media. The cost of materials also depends on the type of material used and the amount of material that has been bought, there is a big difference between buying a small amount of material and a large amount of the same material. Specialized pigments can also cause an increase in costs since they are used in the process of producing the final product.

The factors that affect the press cost include shot weight which is the amount of plastic injected in a single cycle, and the tonnage, which is the force used to close the mould during injection. Large presses are costly due to high operating costs and depreciation of the equipment. The costs may also be affected by the need for manual operations, for instance, insert loading and discharging or any other post molding operations.

Tools that are fully automated and create volume on a constant basis are differentiated from tools that are created for small lots and require manual transfer and packing.

Alternatives to Prototyping

Prototyping in the intended production material is very advantageous. In the case of prototype and short-run production, there are many choices of tooling, and it is possible to mould as few as two parts. However, the rate of prototyping and part manufacturing can be variable, and some of the occurrences may take days. This depends on the surface, material, and geometry of the structure to be coated. The delay times are normally between two and four weeks.

Tooling expenditures

The cost of tooling depends on the complexity of the element, its size and the time required to make it. Molds are not cheap; they start from £2,000 for the simple ones, but the more complex ones range from £5,000 to £7,000. The price of large or complex items can go up to £30,000. The data of the particular project and the detailed quotation are the basis of accurate cost estimation.

For low-volume injection molding projects, it is advised that you seek advice from professionals to get a broader understanding of the possible costs and the possible feasible solutions. If you are thinking of using short run injection molding for your project and would like to know the cost of the required quantities, feel free to contact us for a quote.

Injection Molding Services Offered by Sincere Tech

Sincere Tech is one of to 10 plastic injection molding compnies in China that was founded over a decade ago and has been involved in the design and production of plastic injection-molded parts and goods. Because of our extensive expertise, we are capable of effectively managing all phases of short-run injection molding projects, including With this extensive expertise, we are capable of effectively managing all phases of short-run injection molding projects, including:

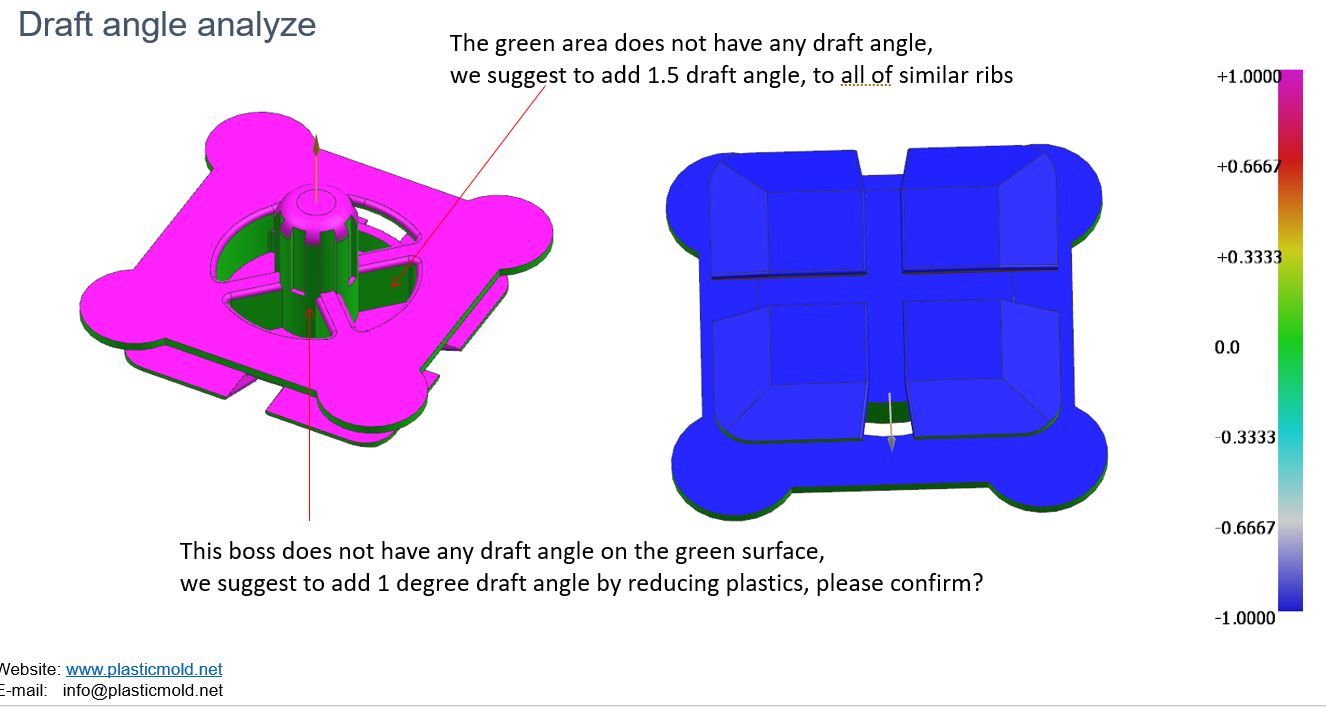

Mold Design: We use the best technologies and mold-making technologies to produce instruments that will satisfy the needs of your product. We create tooling designs based on your original drawings, schematics, or models, or we can create them for you. We have expertise in the use of AutoCAD, SolidWorks, ProE, Cimatron, and CADKey formats of CAD.

Our mold fabrication team uses up-to-date CNC machining technologies to produce high-quality and accurately dimensioned molds in the shortest time possible after the injection mold design has been completed. This is an example of custom tooling. We are able to create prototypes for various thermoplastics, including ABS, HDPE, LDPE, PE, HIPS, TPU, and PET.

Prototyping: We use 3D printing to quickly build each part to make sure that it fits the form and works as it should before the construction of the injection molding tool. We offer FDM printed prototypes in various types of materials such as ABS, PLA, and TPU. We work with other service providers for additional prototyping services, such as urethane casting, SLS, and SLA.

Injection molding: The injection molding facility is run by experienced staff and the equipment can produce a clamping force of 28 to 240 tonnes and can also show reproducibility. The material that we process during our molding operations ranges from 0 to 16 ounces per cycle. Sincere Tech is also capable of providing injection molding services for small and large quantities of products.

We guarantee that the custom plastic injection-molded parts that we will provide at Sincere Tech will be of the best quality, will be delivered on time, and at a reasonable price.