How Plastic Injection Molding Contract Manufacturing Works?

The concept of plastic injection molding contract manufacturing is very vital in today’s production industry. This blog contains all the necessary details of this process.

From the drawing board to the manufactured injection molded product, each process counts. Understand the important factors to consider when choosing an Injection Molding Contract Manufacturing company.

How Does Plastic Injection Molding Work?

plastic injection molding contract manufacturing is a delicate process, which means you need to find a expert injection molding supplier to make your products. This molding process is done by pouring melted plastic resin directly into a mold cavity. This is because high-pressure injection guarantees the detailed formation of the part. The mold cools and the shape becomes solid and fixed.

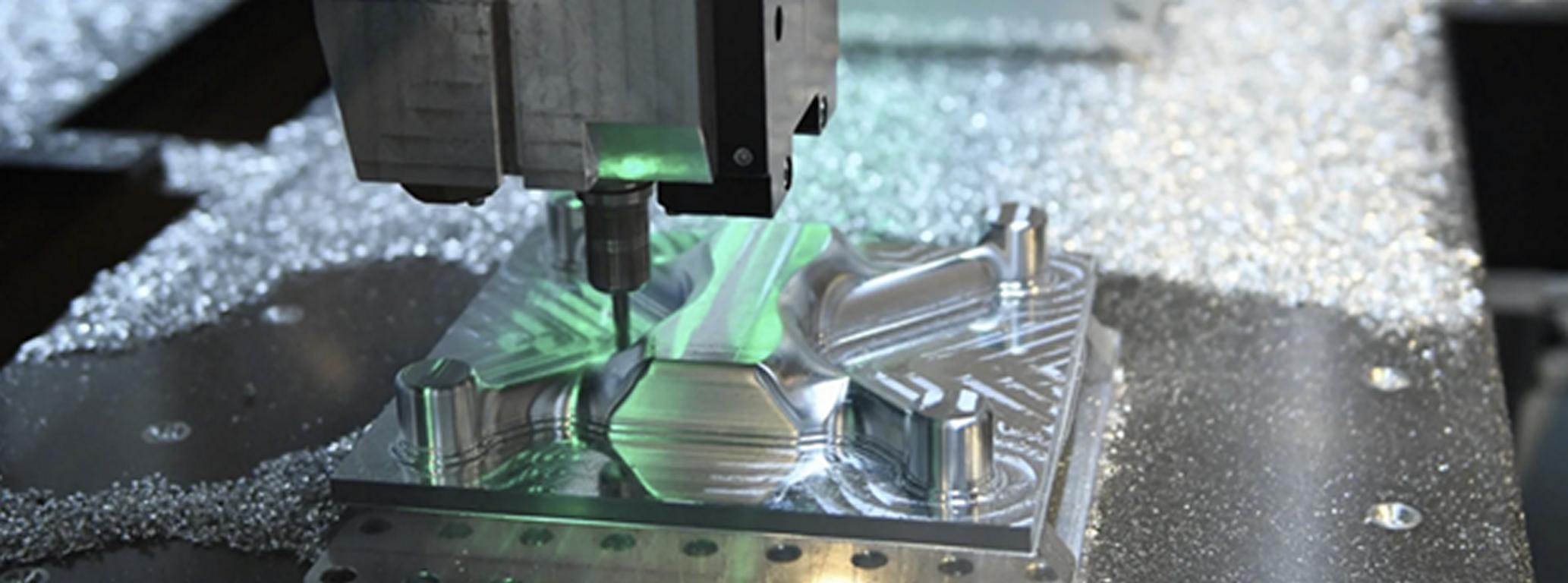

Ejector pins remove the formed part. The cycle time depends on its sophistication level. CNC-machined molds guarantee accuracy. Automated systems streamline production.

Quality control checks help to ensure that standards are kept up. This method is highly effective in mass production of complex components.

What Are the Steps Involved in Plastic Injection Molding Contract Manufacturing?

Design & Prototyping

Plastic injection molding contract manufacturing starts with CAD software. Engineers design precision molds. Every mold should have the exact sizes such as 0.001 mm.

It is possible to produce prototypes using 3D printing. Each cycle enhances deficiencies in design. Simulation tools help to forecast the behavior of injection molding.

Engineers also monitor melt flow rates and cooling times. The choice of material is critical – it can be either a thermoplastic or an elastomer. Design adjustments ensure manufacturability. The prototyping phase leads to minimizing errors in the production phase.

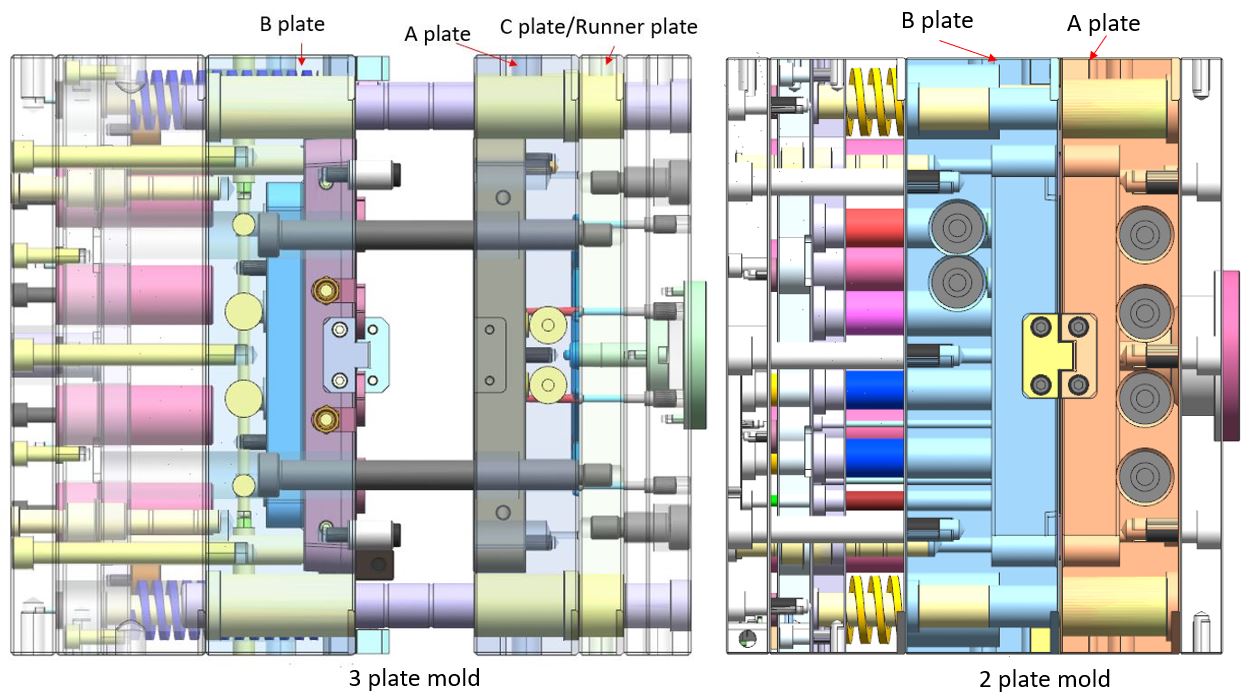

Plastic Injection Mold Making

In the field of plastic injection molding contract manufacturing, plastic mold making comes after prototyping. It is usually made of steel or aluminum. Mold making is done through Computer Numeric Control (CNC) machining. EDM refines intricate details.

Accuracy is very important, and some of parts are made to tight tolerances of 0.05 mm. The cooling channels are incorporated. Ejector pins help in removal of the part.

Polishing helps in improving surface finishes. Cores and cavities which are part of the mold are put together. Mold integrity is checked at the final stage of the process.

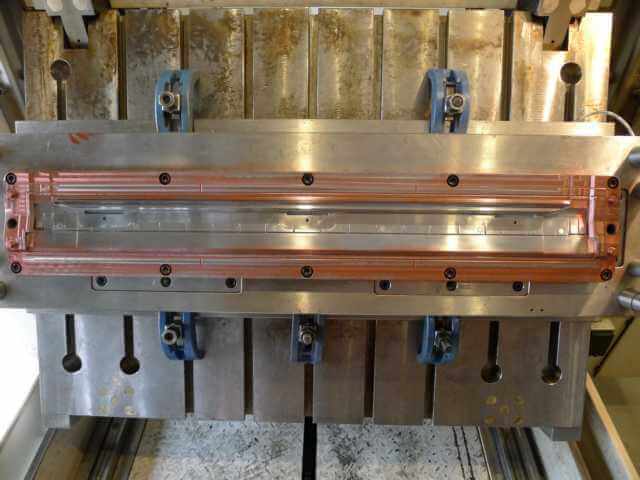

Molding Production

Contract manufacturing in injection molding of plastics incorporates high pressure injection. Molding machines use clamping forces which are in tons. The mold is then heated to certain temperatures. This is done by placing the molten plastic into the mold cavity with pressure.

The pressure is kept up until the part has frozen. Mold temperatures are regulated by cooling systems. Operating cycles are smooth and speedy. Part ejection is done by the robotic arms.

This is a way of maintaining the quality of a product or service since the monitoring is done on a constant basis. The volumes of production can be in the thousands of units.

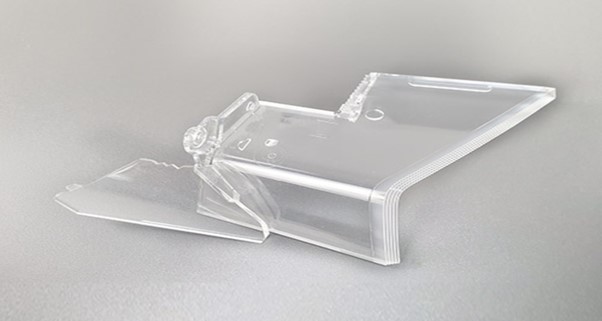

Post-Production

Common finishing steps that are part of post-production in plastic injection molding contract manufacturing are as follows. Casting is then cleaned through trimming and deburring.

Additional operations such as drilling and tapping are carried out. Coatings like painting and plating increase aesthetics. It may be necessary to assemble a number of parts.

Ultrasonic welding is the process of joining plastic parts. Quality checks ensure the accuracy of dimensions. Packaging is important to guarantee that parts are well protected. New production data are incorporated into documentation. The final product is now ready for delivery.

Quality Control

Quality control in plastic injection molding plays a significant role in delivering high quality products. Inspection begins with dimensional analysis. CMM machines measure parts. Visual inspections identify surface imperfections.

Tensile testing verifies the strength of a material. X-ray inspection reveals internal defects. Control charts are used to measure and track production stability. Every batch also goes through some tests.

Non-conforming parts are rejected. Documentation also captures all quality checks. Some the continuous improvement processes that are used include. Quality control helps ensure that the final product remains up to standard.

| Step | Description | Key Activities | Tools/Techniques Used | Time Frame (Days) |

| Design & Prototyping | Concept development | CAD modeling, 3D printing | CAD software, 3D printers | 7-14 |

| Mold Making | Creating molds | CNC machining, mold testing | CNC machines, EDM | 14-30 |

| Production | Manufacturing parts | Injection molding, part ejection | Injection molding machines | 7-21 |

| Post-Production | Finishing touches | Trimming, painting, assembly | Trimming tools, paint booths | 3-10 |

| Quality Control | Ensuring standards | Inspections, testing | CMM, visual inspection tools | 2-5 |

Table on Steps in Plastic Injection Molding Contract Manufacturing!

Why Choose Contract Manufacturing for Plastic Injection Molding?

Cost-Efficiency

This is because plastic injection molding contract manufacturing has relatively low overhead costs. There is discouragement of capital intensive machinery investment.

Bulk purchase of materials is cheaper. Automated processes enhance efficiency. Through automation, there is a reduction in the overall labor costs.

Precision tooling helps to minimize production errors. Maintenance costs are shared. Prototyping costs are clearly stated in this contract. You get predictable expenses. This method helps to manage the available budget.

Resource Optimization

Plastic injection molding contract manufacturing optimizes resource utilization. Professionals as well as sophisticated equipment are procured from outside.

Material wastage is also prevented through the use of precision molds. It cuts down for inventory costs in just-in-time production. Production capacity is flexible.

Professional approach to design and prototyping is used. Energy use is conserved through different processes. This strategy releases internal resources. Resource management becomes streamlined.

Technological Access

Contract manufacturing by plastic injection molding gives access to modern technology. CAD software enhances the design precision. CNC machines provide intricate molds for molding the objects. Robotics enhances production efficiency. Real-time monitoring ensures quality.

Simulation software predicts outcomes. Fast injection molding machines have short cycle times. In their own right, access to these technologies is unreasonably expensive. Technology integration leads to better product quality.

Flexibility

Plastic injection molding contract manufacturing provides flexibility in manufacturing. Either small or large lots are acceptable. It is easy to make changes in design. It is also important to note that multiple materials may be used. Different products are produced at the same time.

Short cycle times allow an immediate response to new demands. Production schedules are adjustable. Outsourcing helps to concentrate on key processes. Flexibility enhances market responsiveness. This approach addresses dynamic needs.

Scalability

Plastic injection molding contract manufacturing makes it easy to expand operations. Scales of production range from prototypes right up to mass production.

High volumes are easily processed by automated systems. Scaling up maintains quality. Production timelines are consistent. It can be concluded that inventory management responds to changes in demand. The supply chain is efficient. Scalability supports market expansion. This model evolves as your business expands.

What Are the Key Considerations in Selecting an Injection Molding Contract Manufacturer?

Manufacturing Capabilities

Plastic injection molding contract manufacturing is built on highly skilled processes. Make sure the provider has high-tonnage machines. Ensure that all mold sizes adheres to the required specifications. Check for multi-cavity molds. Ensure they work with different types of materials such as ABS or nylon.

Look for automated systems. Overlook secondary processes such as over molding. Make sure they have close tolerances. Capability affects the quality and productivity. Choose a versatile manufacturer.

Experience & Expertise

Relevant prior experience in plastic injection molding contract manufacturing is invaluable. Check their years of experience in the industry. Make sure the software you are considering is capable of handling intricate geometries. Look at past projects. Check the awareness of thermoplastic materials.

Make sure that the candidate has prior experience in using high-precision molds. This is true, expertise in design and prototyping matters. Experience delivers quality work. Their background affects your project in one way or another. Trust proven experience.

Quality Assurance

Quality is an essential aspect in plastic injection molding contract manufacturing. Seek out strict adherence to testing procedures. Make sure they use CMM machines in order to be accurate. Check for ISO certifications. Check up on their defect detection systems.

Ensure they adhere to SPC methods. Go over their documentation on quality control. Effective QA reduces defects. It is notable that quality assurance guarantees the reliability of products. Select a manufacturer who has quality as their priority.

Certifications

Certifications are critical in the plastic injection molding contract manufacturing industry. Verify if the company has ISO 9001 compliance. Seek for conformity to ISO 13485 medical parts. Check compliance with AS9100 in aerospace industry. Ensure that they comply with RoHS standards.

Certifications reflect process standards. They ensure regulatory compliance. Certifications demonstrate dedication to quality. It builds confidence in quality. Choose certified manufacturers.

Reliability

Reliability is an important aspect in plastic injection molding contract manufacturing. See how often they deliver their assignments on time. Seek consistency in production schedules.

Determine how capable they are of handling large orders. Confirm their maintenance practices. Reliability provides for the supply chain’s continuity.

Reliability insights gathered from customer testimonials should be reviewed. Assess their approach towards issues. The right partners help a project succeed. Reliable manufacturers maintain steady performance.

How Is Quality Maintained in Plastic Injection Molding Contract Manufacturing?

Quality Control

Plastic injection molding contract manufacturing also keep high standard of quality control. CMM machines are used to ensure accuracy in dimensions. SPC methods track the stability of processes. Real-time data analysis identifies changes. Flaw detection systems detect defects.

Random sampling also ensures that batches are consistent. There are strict tolerances are maintained throughout. Quality assurance teams monitor every production process. Documentation tracks quality metrics. Quality assurance is significant to guarantee the reliability of the product.

Standards

Plastic injection molding for contract manufacturing is very much standardized. ISO 9001 guarantees that the quality management is maintained at a certain level. ISO 13485 ensures medical device standards. AS9100 certifies aerospace compliance.

RoHS deals with the management of hazardous substances. Standards establish baseline quality. They ensure regulatory adherence. Certifications conform to industry standards. Standards can be defined as a quality framework. Compliance boosts product reliability.

Inspection Methods

The inspection methods in plastic injection molding contract manufacturing are therefore comprehensive. A visual inspection identifies flaws that are visible on the surface. CMM machines confirm compliance with dimensions.

Tensile testing verifies material strength. Ultrasonic tests detect internal defects. SPC monitors process variations. The in-line inspections yield real-time quality. Random sampling verifies consistency. Proper inspections ensure that problems are highlighted at their initial stages. This ensures high-quality outcomes.

Common Defects

As for defects of plastic injection molding contract manufacturing, precautions are taken to avoid them. Cooling defects lead to sink marks. It happens due to the differential contraction of material. Flash occurs when there is excessive injection pressure.

Short shots signify that there is inadequate material flow. Because welds occur when two or more melting fronts join, weld lines are formed.

Voids are defined as pockets of air that are enclosed in a material. Burn marks are caused by heat. Early identification of any defects also ensures that corrective actions are taken. This maintains product quality.

What Materials Are Used in Plastic Injection Molding?

Thermoplastics

Thermoplastics are often used in plastic injection molding contract manufacturing. Some of the most commonly used materials are ABS, polycarbonate, and nylon. ABS injection molding offers impact resistance. Polycarbonate provides optical clarity. Nylon adds wear resistance.

These materials are melted and injected. They solidify upon cooling. Thermoplastics are materials that can be re-melted and re-shaped again and again. They can be applied in various contexts. They are very flexible in terms of their use. Thermoplastics ensure durable products. Go to injection molding materials page to know how to select materials for your molding project.

Thermosetting Plastics

Thermosetting plastics are important in the process of plastic injection molding contract manufacturing. Some of the common examples include epoxy and phenolic. They go through a curing process. However, they cannot be re-melted once they have been cured.

These materials are highly resistant to heat. They have better mechanical properties. These thermosets are very suitable for electrical parts. Their stability is also excellent, especially when exposed to heat. Thermosetting plastics make sure of a long lasting performance. However, they are useful where their application is required.

Material Properties

Material properties are critical in contract manufacturing of plastic injection molding. Tensile strength indicates ability to resist fracture. Flexural modulus indicates stiffness. Impact resistance assesses durability. Heat stability is important when it comes to heat endurance.

Chemical resistance defines the ability of a material to operate in harsh conditions. Dimensional stability ensures that the part size does not vary. For insulating parts, electrical properties are of concern. Material properties guide selection. They ensure optimal performance.

Selection Criteria

This is because selection criteria apply to contract manufacturing in plastic injection molding. For load bearing sections, consider tensile strength. Assess thermal stability for high-temperature application. Determine compatibility for demanding chemical environments.

Choose impact resistance materials for lasting products. Investigate flexural modulus for stiffness needs. Review cost with respect to budget constraints.

Link the properties with application requirements. Selection criteria help in determining the appropriateness of the material. The proper selection increases the product quality.

SINCERE TECH is the onf of top 10 plastic injection molding companies in China. This mold company has different group team members in order to solve the consumer molding problem. One of the most important things is that this company has well qualified and knowledgeable designers. This company not only offer plastic molds, but they also offer plastic mold tooling equipment, molding machine, injection molding service, plastic mould training and more.

The plastic mold tooling equipment is available in all sizes, models as well as shapes. So, consumer can choose the equipment as per their preferred styles. Every consumer can get the molding machines through this company only, because this company only provides endless solutions for molding machines.

Each and every part of the molding machines is tested by utilizing different kinds of equipment. After that only they can deliver the machine to the consumers. This mold company can provide the mold products with full warranty and guarantee. If the customer wishes to get the molding machine, they can simply sit in their home and order the machine name through the mould company website. The Mold Company will deliver the machines from the comfort of office or home.

One main thing is that this company will provide all the plastic molded products at very reasonable rate. This company can complete the project within deadline. If the machine will get repaired means no need to worry. The mold company will send the talented engineers to their industry. This engineer will quickly repair the machines problem at free of cost. This company will produce only branded products to the consumers.

plastic mold manufacturing company

If the consumers want to know more information regarding our Plastic Mold manufacturer, contact us now.

The top rated plastic molded plastic needs gratified within no time and the special products convey the cost effective for the clients while they choose the excellent molded plastic ideas. The renowned manufacturer convey the molded plastics incorporate with injection molded plastics, electronic plastic, thermoform plastics and ABS enclosures, grommets, ink stamps, kitchen appliances, plastic carrier bins, plastic rollers, plastic collars, molded stereo equipment and so forth. The rapidness ensured by the top promoter like SINCERETECH and they care for the customer satisfaction in each and every product supply. The rush projects become flaw free and within deadline through the innovative concepts utilized in molded plastic.

Each and every plastic designed for the need of the customers and they offer the cheap cost without compromising the quality. A single terrace- SINCERE TECH Mold firm deliver the complete ABS injection moulding, PP, PA, PC, PPSU and other type of injection molding products and for obtaining the required plastic gears the customer should offer the simple details like Plastic material prototype Nr, Ral Nr or Panton Nr, the requirement/quantity as per weekly, yearly and monthly.

The packaging needs, the imperative information whether the surface treatment required or not, detail of assembling such as required or not required, the information related to the quantity and demand of colors as per product and so forth. The panel members of this firm have the extreme experience in plastic molding and they assist the clients for the necessity of various procedures such as chrome plating UV and the main surface treatment like PU painting up to packaging.

Conclusion

Get a closer look at the contract manufacturing of plastic injection molding to uncover the process’s intricacies and benefits. Starting from design to post-production, no stage is less important. To harness these benefits, go to OEM contract manufacturing China page. Take your first step with a reliable ally.