Looking for plastic injection molding service?

Contact us to get quote, we are A Custom injection mold maker in China that offers plastic injection molding services.

The excellent quality of our plastic molds and molded parts, coupled with our experience and the performance of our services give us today a high international recognition. Indeed, the company is specialized in International Business and has customers all over the world. SINCERE TECH has very high standards of quality control and always runs long tests to make sure that our Plastic Injection Molding Service reaches all the expectations of our customers. We believe that the quality of a company and its products are seen through time and this is why we like to build strong long-term partnerships with our customer

What is plastic injection molding process?

Plastic injection molding is a manufacturing process in which melted plastic is injected into a mold and then cooled to form a solid part. The mold is created from a metal or plastic tool (1.2344, H13, NDK80, etc.) and is typically made in two halves that are clamped together. The plastic material is heated in a barrel and then forced into the mold under high pressure where it cools and solidifies into the desired shape. This process is used to produce large quantities of identical parts with high precision and repeatability.

When do you need plastic injection molding service?

You may need plastic injection molding service when you require mass production of plastic parts with consistent quality and high precision. This process is ideal for producing large quantities of the same part, as the mold can be used multiple times to produce identical pieces. Additionally, plastic injection molding is well-suited for producing complex and intricate shapes that would be difficult or impossible to achieve with other manufacturing methods. This process is often used in various industries such as automotive, consumer goods, medical devices, and electronics.

plastic molding services

Benefits of plastic injection molding service

The benefits of plastic injection molding service include:

- High volume production: Plastic injection molding is ideal for high volume production of identical parts, as the mold can be used multiple times.

- Consistent quality: The process is highly repeatable, which leads to consistent quality of parts produced.

- Complex shapes: Plastic injection molding can produce complex and intricate shapes that would be difficult or impossible to achieve with other manufacturing methods.

- Material flexibility: A wide variety of plastic materials can be used in the injection molding process, including thermoplastics, thermosets, and elastomers.

- Cost-effective: The process is efficient and cost-effective for producing large quantities of parts, as the cost of the mold can be spread over many parts.

- Precision: The process can produce parts with high dimensional accuracy and minimal tolerance variation.

- Automation: Plastic injection molding machines can be automated for increased productivity and reduced labor costs.

Plastic injection molding is a versatile and reliable manufacturing process that can provide significant benefits for producing large quantities of complex and high-precision plastic parts.

Plastic Injection Molding Service in China

We are the manufacturer of our own moulds (toolmaker or plastic injection tooling) and support the production of Injection molded parts allowing reducing your numbers of suppliers. Our injection machines have clamping forces going from 60 to 1050 Tons (2000 Tons outside). Plastic injection molding is the process of producing parts from thermosetting and thermoplastic materials.

Our qualified teams of Designers, Quality controllers and our Research and Development Department allow us to complete our policy: achieving Customer Satisfaction through Improvement and Innovation. The quality of our products and organization permits us to obtain quality certifications (ISO 9001, ) and be awarded numerous times of “Quality Supplier” from different customers. We integrate constantly new resources into our process in order to anticipate any future need of the plastic injection molds market and we became one of the most innovative companies in the sector. The modernity and the organization of our facilities allow us to adapt very quickly to the customer’s needs.

SINCERE TECH has always the objective to stay one of the innovative leaders of the sector and play an important role in our customer’s development. The firm can now propose a total solution from mould design to the semi-finished product (All in-house). SINCERE TECH is always willing to integrate new processes to the solution proposed by staying aware of new technologies. If a customer has a special requirement, we will do everything to fulfill its needs.

Plastic Materials /Commodities

We are used to working with all the classic and less classic plastic materials except PVC (PP, PE, PC, ABS, PC+ABS, PA 6, PA 6.6, PBT, PMMA, TPU, PC+GF, AS, PTFE, POM, PEHD, PEEK…). Our main suppliers are Sabic, Bayer, and Chimei.

About the steel used for our moulds, for export plastic molds we work only with the best steel suppliers like Assab (Sweden), Buderus (Germany), Daido Steel (Japan) LKM( the biggest one in China). For our standard component suppliers, we work with Hasco and DME.

We are used to working with our suppliers the same way we work with our customers. It means good long-term relationships with high-quality policy.

Complex moulds: SINCERE TECH has a rich experience in difficult plastic mould and parts, complex moulds and is an expert in finding solutions to your issues. SINCERE TECH is a real specialist in difficult tooling. To give a classic example: many design companies create plastic products without thinking about mould construction. Then, when the designs are sent to toolmakers, it can be hard for them to make the exact parts (Difficult design, many sliders, many lifters, double injection with materials non-bonding well together, many details in awkward places…).

Most of the classic toolmakers will accept the parts and say that they are able to do it. And then, they will have problems with the plastic injection mould construction, the lead time will be extended and the quality of the tool will not be as expected. Often, these companies have to contact SINCERE TECH to help them to resolve their problems. If you are not sure about the complexity of your part, be sure about your mould maker’s professionalism. SINCERE TECH works closely with its customers in order to resolve any issues.

Thin Wall injection molding: it permits a precise, very accurate molding of plastics and gives better details to the product. This is the name referring to products with a wall thickness lower than 2mm. Usually, the flow is quick, permits a short cycle time and a cost-saving.

Hot runner mold: the special process of injection of plastics where the plastic is kept hot when going through cavities of the mould while the rest of the mould is getting cold to solidify the plastic part and create the molded part: this permits to save plastic material. This is mainly used for parts with medium or large sizes. We are used to working with all popular companies like Yudo, INCOE, Synventive, Husky, HRS… We also have the technology to make our own hot runner systems if the production of the parts (Molding) is made in-house. This again allows our customers to save costs.

Optical Lens Molding: precision molding for glass plastic. This is the technique to produce transparent plastic molded parts (For example Security cameras parts such as the dome cover or also phone frames).

Gas-assist Injection Molding: the plastic parts are gas-assisted molded which means that gas (Most often is nitrogen) is injected at the final stage of the part creation process. It permits to reduce the cycle time, the product weight, the risk of deformation and also the pressure tons injection needed. Moreover, it makes the part’s structure stronger with a better look.

LED/LCD frame molding: injection of plastics used for example to manufacture television screen monitors, computer back-light modules, GPS frames…

IMD, IMF, IML, IMR Molding: In-mold decoration. The decoration of the part is made inside the mould through a film. The film is printed before the molding with the designs wanted. It permits better productivity and extends the decoration’s lifetime. If the customer wants to change the design/decoration of the part, it is not necessary to make another mould but only to change the film. SINCERE TECH is experienced with In-mould forming, in-mold-labeling, and in-mold by roller.

Overmolding: this technique permits to join several components together with a thermoplastic material. This reduces assembly and labor costs. Because the parts are made together, this allows less risk of improper termination or misalignment and increases the design flexibility. Moreover, thermoplastic provides better resistance to vibration or shocks. This technique permits to increase resistance, reduce costs and weights.

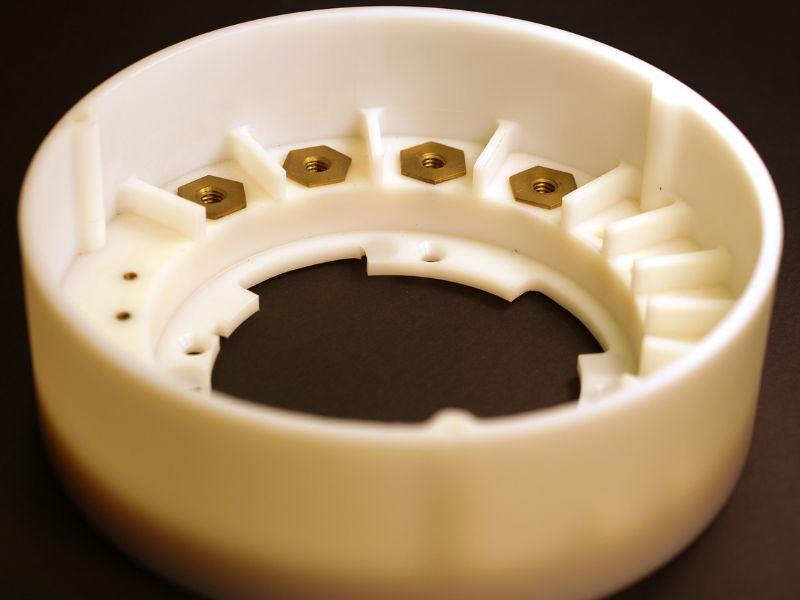

Insert Molding: this is a technique where a small part (Stamping part, optical part…) is added or inserted to the Injection molded part.

Two-Shot Molding: 2 independent injection units using 2 different materials and/or colors. The first material is injected; then, the mould rotates and the second material is injected to make 1 part. It permits a 2-colour-molding or also called double injection, 2 shot molding, two-shot injection, overmolding, 2K injection, two colour injection, bi-injection, dual shot molding or multi-component molding.

CNC Technology. CNC is an abbreviation for Computer Numerical Control. This is a machine extremely accurately controlled by computer programs permitting a CAM (Computer-aided Manufacturing) through a CAD (Computer-Aided Design). Any plastic injection tool manufacturer uses it but the value-added of SINCERE TECH is the experience, professionalism, and training of the staff.

FMMS Molding or can be called RHCM (Rapid Heat Cycle Molding): excellence surface appearance: permits to take off the welding line. This process is integrated into the molding to save time. It is used for example for clear plastic parts.

US Welding: Ultrasonic Welding: process to weld/ join/ assemble plastic parts thanks to ultra-sounds.

Silk-Screen Printing: this is to print logos or designs on parts.

Dip-Coating: this is the process of putting the component inside a liquid solution to apply a thin film on it. It permits to manage, change the hardness, the strength of the part by protecting it and expanding the lifetime of the product. Then, the excess liquid has to be drained and evaporation of the solvent is done to create the thin layer.

Laser Etching: this process is made for cutting a shape, a pattern, an image on the plastic part. It is also called laser graving.

Sputtering coating: this is the process of creating a very thin layer of conducting material on the component. It is also called Plasma Enhanced Chemical Vapor Deposition (PECVD) and can be done with most metals like aluminum, stainless steel, copper…

EMI shielding: protect parts from electromagnetic interferences. It is used to protect electrical signals from the outside world. For instance, we use it with marine radars for Garmin.

Waterproof technology: SINCERE TECH has the experience to make water-resistant parts and is able to ensure in-house tests thanks to the IP68 tests.

Sub-assembly: this is the pre-assembly of a component who will be later on being assembled in a larger product.

R&D: SINCERE TECH has its own Research and Development department in order to work with the customers on their projects, advise them on designs, resolve issues and study the feasibility of those.

Quality Control: We have very high standards of quality control in order to respect any requirements from our customers. We have a 100% quality control on our plastic molded parts, it means we control any part coming out of our production.

At Sincere Tech China mold maker, our unwavering commitment to staying at the forefront of the plastic mold industry drives us to embrace advancements and anticipate future trends. We continuously explore innovative materials and composites that offer enhanced performance and promote sustainability. By investing in ongoing research and development, we consistently deliver cutting-edge solutions that meet the evolving needs of our valued customers. As a trusted injection mold supplier in China, we take pride in our unwavering dedication to excellence.

Aligned with our sustainability goals, we place a high priority on environmentally friendly practices. We actively seek out sustainable alternatives, such as biodegradable polymers, and implement recycling initiatives to minimize the environmental impact of our manufacturing processes. By choosing our custom injection molding services, you can align your brand with sustainable manufacturing practices and contribute to a greener future.

Ensuring quality is our topmost priority, and we maintain rigorous quality control measures throughout the entire manufacturing process. Equipped with state-of-the-art facilities and staffed by skilled technicians, we subject each product to thorough inspection and testing. This guarantees exceptional performance, reliability, and customer satisfaction.

When you choose Sincere Tech as plastic injection molding service partner in China, you can expect the highest level of professionalism, expertise, and innovation. Our dedicated team is committed to helping you bring your ideas to life, delivering superior products that excel in performance, durability, and cost-effectiveness.

Partner with Sincere Tech Mould suppliers for your custom plastic injection molding service, and benefit from our comprehensive capabilities, unwavering commitment to quality and sustainability, and our drive to exceed your expectations at every step of the process. Together, let’s bring your innovative ideas to life.