What is plastic injection molding toys?

Plastic injection molding toys are plastic toys that are created by plastic injection molding manufacturing processes. This plastic mold technology can produce millions of identical plastic molding toys with a high degree of precision and accuracy. The injection molding process is a highly effective manufacturing method for producing a wide variety of plastic molding toys, thereby reducing the cost per unit. During the holiday season, these toys become highly sought after.

Injecting molten plastic into a toy mold, where it cools and solidifies into the desired plastic toy shape, is the process of injection molding toys. Injection molding is an efficient and cost-effective method for mass producing plastic toys and other plastic products, enabling the creation of highly customized injection-molded toy shapes.

As Christmas approaches, many parents and gift givers start to think about what toys they will be buying for the children in their lives. Plastic injection molding toys can be a wonderful option for a number of reasons. Here are just a few:

- Durability: One of the biggest benefits of plastic injection-molded toys is that they are extremely durable. Unlike toys made from other materials, such as fabric or paper, plastic toys can withstand rough play and accidental drops. This makes them a wonderful choice for children who are known to be demanding on their toys.

- Safety: Safety is always a top concern when it comes to children’s toys. High-quality materials, free of harmful chemicals and toxins, make up plastic injection molding toys. This means that they are safe for children to play with and handle.

- Variety: There is a virtually endless variety of plastic injection-molded toys on the market. From action figures and dolls to educational toys and puzzles, there is something for every child’s interests and age group.

- Customization: Injection molding allows for a high level of customization when it comes to toy design. Companies can create custom molds for their toys, allowing them to create unique and one-of-a-kind items that stand out on store shelves.

- Affordability: Plastic injection molding toys are often more affordable than other types of toys. This makes them a wonderful option for parents and gift givers who are working with a budget.

If you are considering purchasing plastic injection-molded toys for the holidays, there are a few things you should keep in mind:

First, choose toys that match the child’s age and interests. It is also important to pay attention to any safety warnings or age recommendations that come with the toy.

In addition to these considerations, you may also want to think about the environmental impact of the toys you are purchasing. Despite the durability and long-lasting nature of plastic injection-molded toys, improper disposal can lead them to landfills. Consider buying toys made from recycled materials or easily recyclable after use to help reduce waste and protect the environment.

Important cost for injection molding toys.

If you are planning to make your own plastic molding toys and sell them on the material, then you may need to know the cost in advance. There are mainly two costs: toy mold cost and unit plastic molding toys cost. The toy mold cost is a one-time payment, and the initial mold cost is not cheap.

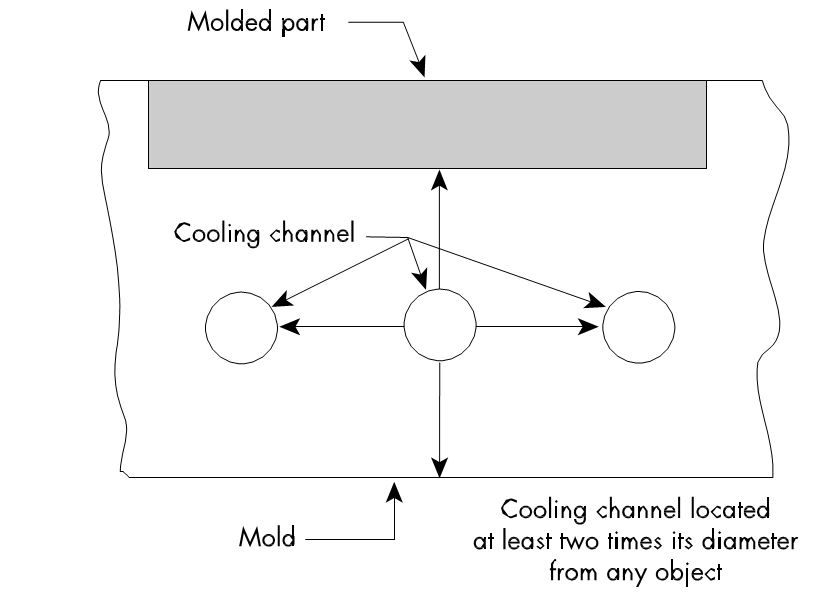

Before making injection-molded toys, you need to obtain toy molds based on your custom toy design; this represents the initial mold cost for your toy project. The metal plastic toy mold consists of two parts: the “cavity side,” or moving half, and the “core side,” or fixed half.

The size and complexity of the plastic molding toys, along with the quantity you plan to produce in a single injection mold, dictate the cost of injection molding toy molds. The basic cost for injection molding toys will be around $500 to $10,000, or even more. You can visit the “How Much Does an Injection Mold Cost” page to learn more about the cost of injection molds.

After completing the toy mold, insert it into an injection molding machine. This process, known as the molding process, involves heating plastic pellets in a hopper until they melt. We then pump the molten plastic under high injection pressure into the toy mold, where it cools and hardens inside the mold cavity and core, forming the shape of the toy. Once the plastic cools and solidifies, we open the mold to extract the toy.

You can repeat this basic plastic molding procedure several times to create multiple identical toys. We use the same process for basic injection molding to produce the plastic toys.

Basics of the plastic injection molding process for molding toys

In plastic injection molding, the process begins with melting the chosen thermoplastic to a liquid state within a hopper, then injecting it into a mold until it dries, allowing it to pop out and proceed down the assembly line for painting, staining, or further assembly if it’s a toy with multiple parts. It is also possible to insert numerous colors of plastic into the same mold so that no additional coloring is necessary afterward—a tricky and impressive process that saves both time and money. Santa is a big fan of efficiency, particularly considering he delivers toys all in one night.

Plastic injection molding processes not only produce classic plastic toys but also contribute to the production of gifts for teenagers and adults. For instance, plastic injection molding allows for the quick and easy mass production of the plastic covers on electronic gadgets like iPads. Office supplies like pen bodies, movie covers, pill bottles, makeup containers, and many more items could serve as Christmas gifts.

Overall, plastic injection-molded toys can be a great option for the holidays. They are durable, safe, and offer a wide variety of options for children of all ages. Just be sure to choose age-appropriate toys and consider their environmental impact when making your purchase.

If you are looking for any plastic molding toys or plastic Christmas toys for your business, send us your requirements for a quotation, and we will offer you the best price for any of your custom plastic molding toys or plastic injection-molded Christmas toys.

Are you having a challenge in finding plastic toy mold manufacturer to manufacture your injection molding toys? This review is a guideline on how to find an plastic injection molding toys manufacturer.

How to find a plastic molding toys company?

If you are going to make some silicone toys or injection molding toys, the first thing you need to do is find injection molding toy factories.

Below there are three ways in which you can find toys mold/molding manufacturers;

Sourcing plastic molding toys factories online

There are so many websites that you can search and find plastic molding toy manufacturers online. As we are living in a digital world, finding a manufacturer is a click or a tap away. The suggestions online are very many, so you will choose one that serves you best and has good terms. First, you start by consulting them on the price they do manufacture. Then you will compare them all, and the best choice is to hire the one with a fair price or the lowest price.

We made many type of plastic injection molding toys, contact us to get a quote now.

Moreover, the terms of the payment method are another factor to consider before you pick the manufacturer. You need to consider manufacturers whose terms and methods of payment are available and transparent to you.

After getting the price quotation, you need to ask the toy mold/molding manufacturer to send you samples of the work they have done before. Here, you will be trying to identify the one with unique and quality products. Quality is a key consideration, as you need a toy product that will last for a long time. Being unique is also a factor in avoiding monotony and commonness.

Finally, you need to know the minimum order quantity of manufacture so as to identify if the plastic toy manufacturer is within the boundaries of your order. Some manufacturers’s minimum order quantity is way too high for you to meet it. This is the easiest and most convenient way.

Find a professional plastic molding toy source agent.

Finding a professional source agent is another method to locate a manufacturer of plastic molding toys. The agents typically provide recommendations based on their extensive experience, tailored to your specific specifications and requirements.

What the agents do is act as an intermediary between you and the manufacturer. You provide them with your quotation and the specific requirements you have, and they will recommend a manufacturer based on their extensive knowledge and experience.

The agents handle all the work for you, sourcing injection molding toy manufacturers and connecting you with them directly. After the professional agent sources the manufacturer, they will advise you on the best way to make payment and get your products delivered to you within the specified period.

The only issue with this approach is that a professional source agent will incur an additional fee. As brokers between you and the manufacturer, they can recommend a low-quality manufacturer. This is a method for busy individuals who are committed to finding manufacturers on their own. I assume everyone would rather deal with the business directly with the plastic molding toys company to save cost, but this is still an idea.

Are you seeking mold suppliers to produce your injection-molded toys? Contact us to get a quote for your injection-molded toys.

By attending an exhibition to find a plastic injection molding toys factory

Attending a plastic injection molding toys exhibition can help you find a toy manufacturer. The method is convenient because you can see the manufacturer’s sample and price. Additionally, you get a chance to talk face-to-face with different manufacturers and interact on a personal level.

You have the opportunity to inquire about the product’s quality and discover why their toys outperform those of their competitors. Here at the exhibition, you gain more knowledge about the product and get to decide which manufacturer to choose, considering their product quality, price, duration of manufacturing, minimum order quantity, and method of payment.

The best thing about attending an exhibition is that you can find a plastic molding toys manufacturer who is giving a commission and save yourself some money. Attending an exhibition gives you a chance to ask for a recommendation from professionals who have no business interest in the product. Attending an exhibition is the best way to find a manufacturer who can manufacture your toys at affordable prices, with the best quality and offers.

Conclusion

In addition to these three methods, another approach to locating an injection plastic molding toy factory involves seeking recommendations from individuals in the same industry. The issue with this approach is that some recommendations may be skewed due to personal or commercial interests. You can also ask for recommendations from your friends.

The most recommended way is to source online or ask for a recommendation from your friends.

Sincere Tech ranks among the top 10 injection molding toy companies in China, producing a wide range of plastic and silicone toys for various toy companies. Some of these plastic injection-molded toys include custom plastic building blocks, car molding toys, train mold toys, plastic roof toys, plastic lifter toys, plastic doll toys, etc.

If you are seeking contract injection molding toy factories in China to manufacture your plastic or silicone toys, reach out to us for a quote. We will handle all aspects of your problem, including toy design, prototype, mass production, assembly, and packaging, providing a comprehensive one-stop service.