Polycarbonate vs Acrylic

Polycarbonate and acrylic are two familiar plastic materials. People use them extensively in many industries today. Both plastics offer unique benefits and limitations. This “Polycarbonate VS Acrylic” guide is all about these two plastics.

Both acrylic and polycarbonate are transparent, durable, and light. Because of these features, people mostly use them as an alternative to glass. Now, here comes the question: which is better? Well, the correct answer generally depends on your project needs.

This article first highlights the fundamentals of acrylic and polycarbonate plastic. Then, it compares them, taking a few critical factors into account. Overall, you can find the most suitable option for your project using the information from this article. So, let’s get started.

What is Polycarbonate Plastic?

PC, or polycarbonate, is a popular type of thermoplastic. As the name suggests, it is made of different carbonate chains. Different carbonate groups typically create various grades of polycarbonate plastic.

There are three types of polycarbonate plastic: transparent GP sheet, SL sheet, and mirror sheet. They are all strong, lightweight, and highly durable thermoplastics. In the following few sections, you will learn more about their properties.

(1) Clear GP sheets are much stronger than glass and acrylic. According to some scientific research, GP sheets are 250 times stronger than glass. On the other hand, it is 30 times stronger than acrylic. Because of these incredible strength properties, GP sheets are mainly used for glazing and protection.

(2) Clear SL sheet has improved UV resistance. Therefore, it offers excellent service in extreme weather conditions.

(3) Polycarbonate mirror sheet offers mirror effects just like glass. It also provides improved strength and UV resistance. This type of polycarbonate plastic is widely used in the car and security industries.

How does Polycarbonate Plastic Made?

Polycarbonate plastic is made in four main stages. The first stage of making PC plastic is reacting Bisphenol A or BPA with phosgene gas. We won’t go too deep about the whole reaction process. From this reaction, you will get polycarbonate material.

These materials are further polymerized in the second stage to create long polycarbonate chains. At this stage, the molten PC plastic develops its strength and flexibility.

The third and fourth stages are typically the processing parts. In the extrusion section, the molten polycarbonate is shaped into different forms. The cooling stage generally hardens the newly formed polycarbonate plastic.

Different plastic industries further refine this raw material to create various plastic products. Blending additives, heat treatments, and molding are three typical refining methods.

Benefits of Using Polycarbonate Plastic

The exceptional polycarbonate structure offers numerous benefits. Some of the critical benefits are:

- Polycarbonate plastic offers excellent impact resistance. It is virtually unbreakable and a very durable material.

- Polycarbonate is transparent. You can use it to make products that are alternative to glasses.

- This plastic is not only strong but also incredibly lightweight. It typically reduces the overall weight of various machinery and equipment.

- Polycarbonate plastic is also a flame-retardant. Because of this, PC plastic is used in many safety equipment.

- Polycarbonate plastic is easy to process, cut, and shape.

- Some PC plastic is UV resistant and often coated with UV protection.

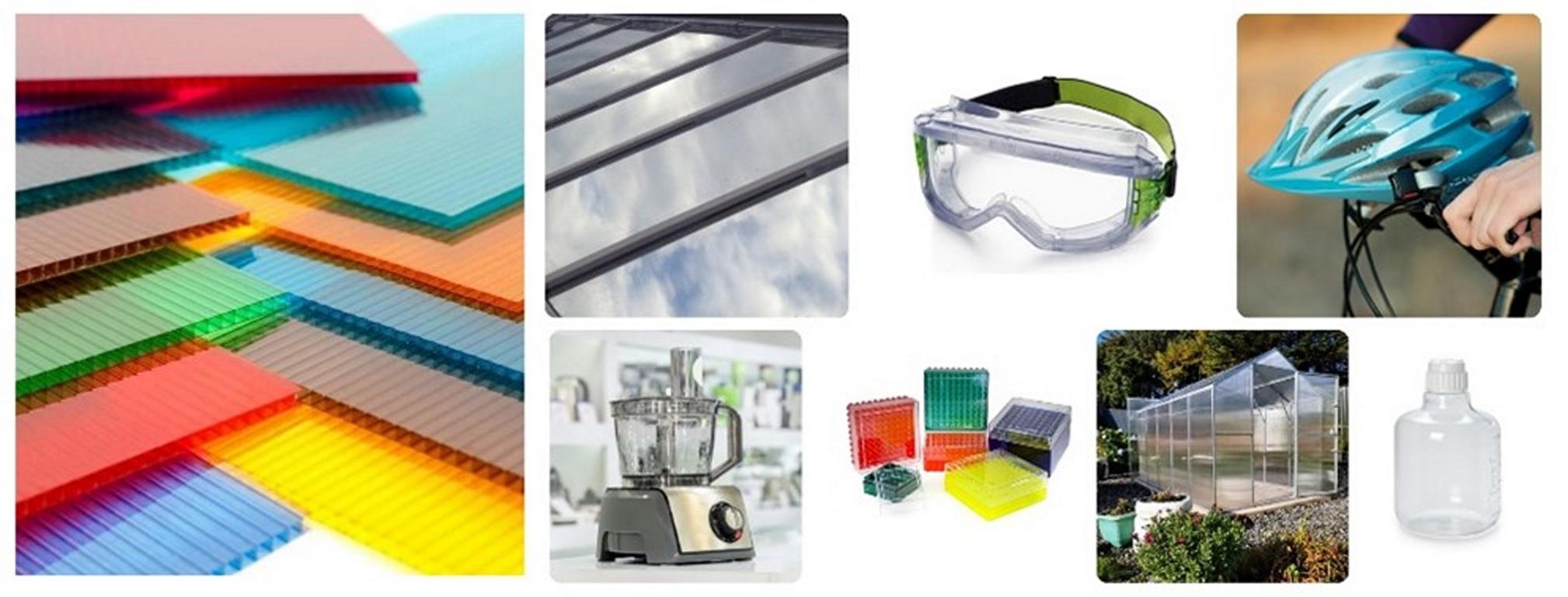

Application of Polycarbonate Plastic

Polycarbonate plastics are widely used in the construction, automotive, and electronics industries. In construction, polycarbonate plastic is prevalent for roofing and window panels. In the automotive sector, windshields, lenses, and sunroofs are polycarbonate.

Polycarbonate injection molding part is used in electronics, mobile phone screens, computer casings, and electrical connectors. It also makes helmets, goggles, and shields for safety equipment.

What is Acrylic Plastic?

Technically, acrylic is polymethyl methacrylate (PMMA). People often call it acrylic plastic or acrylic glass. It is an excellent alternative to glass because it is transparent and robust. Acrylic is also easy to shape and is mainly found as a sheet. Of course there are acrylic injection molding parts which molded from acrylic plastics resin.

There are many types of acrylic sheets, each with unique benefits and applications. Some popular types are transparent, while colored and mirrored are the most common. You may also find other kinds of acrylic, such as solar-tinted, antistatic, or textured acrylic. Understanding each type can help you find the best option for your project.

How Is Acrylic Plastic Made?

Like all other polymers, acrylic plastic is made through polymerization. The process typically uses methyl methacrylate (PMMA), which is the critical building block.

Later on, various factories employ different techniques to process the acrylic plastic. The most common methods are extrusion and casting.

In the casting method, the liquid acrylic is poured into a mold. Then, it is allowed to cool and harden into the desired shape. However, in the extrusion process, the molten acrylic is poured into a mold to create sheets or tubes. Both ways are efficient for creating durable acrylic plastic parts.

Benefits of Using Acrylic Plastic

Acrylic plastic offers several unique benefits over other plastic materials. These unique benefits typically make acrylic usable in many industries.

- Acrylic offers excellent light transmission properties. According to various scientific research, it can allow 92% of visible light to pass through.

- Acrylic plastic is much lighter than glass. Because of this, it is easy to handle, transport, and install.

- This plastic is durable, especially in UV exposure.

- Although acrylic is less robust than PC, it is still much more impact-resistant than glass.

- One of acrylic’s best benefits is its weather resistance. It can endure UV light without turning yellow. Acrylic lasts 30-50 years in a greenhouse.

- Like polycarbonate plastic, acrylic is easy to cut, shape, and polish. It can also be bent easily and, with heat, created into many forms.

- Acrylic is much cheaper than polycarbonate plastic.

- Acrylic plastic is safer than polycarbonate plastic. The food-grade acrylic is entirely safe for making food containers.

Application of Acrylic Plastic

Acrylic plastic is used in many different fields. It is used in buildings, cars, decorations, furniture, electronics, etc.

People use acrylic plastics to make skylights, windows, and walls in buildings. They also use acrylic tiles a lot, especially in bathrooms and kitchens. Acrylic is also used in the auto business to make different panels and trims for the inside and outside of cars.

Acrylic plastic is also used to make many different things, such as do-it-yourself tools, signs, furniture, and optical items. It is even used in the food business to make various food containers.

What’s The Difference Between Acrylic And Polycarbonate?

Now that you have a solid understanding of acrylic and polycarbonate plastics. In this section, let’s explore comparing these two plastics. To do this, we will use a few factors. Each factor will tell you whether or not acrylic or PC could be the best option for your project.

Polycarbonate VS Acrylic: Strength

The tensile strength of plastic is its ability to resist being stretched or pulled apart. However, impact strength is its ability to withstand a sudden force or shock without breaking. So, these two terms are entirely different.

Taking glass as a unit, acrylic typically is 17 times more impact-resistant. You will be surprised to know that polycarbonate is 250 times. This high strength is possible due to the high density of the polycarbonate.

Polycarbonate plastic has a tensile strength of 28 to 74 MPa. Compared to other plastics, this is a very high value. However, acrylic offers you more, ranging from 65 to 83 MPa.

Polycarbonate VS Acrylic: Temperature Resistance

Polycarbonate can generally withstand temperatures between 127 and 147 degrees Celsius. Acrylic, on the other hand, offers a temperature rating from 110 to 115 degrees Celsius.

Both plastics offer very high-temperature resistance. However, polycarbonate is one step ahead of acrylic, making it often a preferred choice for extreme conditions.

Polycarbonate is also a flame-retardant plastic, widely used to make safety equipment. Typical examples include protective helmets, face shields, safety goggles, and more.

Polycarbonate VS Acrylic: Water Absorption

Polycarbonate plastic typically absorbs less water than acrylic plastic. Its absorption rate typically ranges from 3 to 30%. On the other hand, acrylic’s water absorption rate ranges from 13 to 80%.

So, when choosing between these two plastics, you must know whether your application involves water exposure. If it does, polycarbonate can perform better than acrylic.

Polycarbonate VS Acrylic: Hardness

Acrylic and polycarbonate have different hardness levels. Acrylic plastic typically has a higher range, between 94 to 105. This means that acrylic is generally more resistant to scratches and surface damage.

Polycarbonate plastic’s hardness level ranges from 70 to 75. This means it is less resistant to scratching and surface damage and less effective in an abrasive environment.

Polycarbonate VS Acrylic: UV Resistance

Acrylic plastic is generally UV resistant and doesn’t need any special coatings. However, polycarbonate is generally not UV resistant and needs special coatings or chemicals to endure UV lights.

Acrylic typically lasts longer under UV exposure, usually 30-50 years, before starting to yellow. On the other hand, standard polycarbonate doesn’t have UV resistance, but if you apply a coating, it lasts up to 10 to 20 years before starting to yellow.

Because of its excellent UV resistance, acrylic is widely used outdoors. Typical examples include display cases, skylights, and greenhouses.

Polycarbonate VS Acrylic: Elongation

Elongation is the amount of stretch a plastic can take before breaking. Polycarbonate and acrylic also differ significantly in this regard.

Polycarbonate plastic has a high elongation range from 10% to 138%. Because of this, PC plastic is more flexible and impact-resistant. Polycarbonate plastic is suitable for making safety shields and many automotive parts.

Acrylic has a much lower elongation range, typically from 3% to 6.4%. This shows that acrylic is less flexible and more prone to cracking under stress.

Polycarbonate VS Acrylic: Transparency

Both polycarbonate and acrylic plastic are renowned for their clarity. Transparency means how much light can pass through them.

They both offer an excellent transparency rate of up to 93%. However, polycarbonate offers less transparency than acrylic. Polycarbonate has a transparency rate of 47 to 92%, and acrylic has a transparency rate of 50 to 93%. People prefer both, which is an excellent alternative to glass products.

Polycarbonate VS Acrylic: Chemical Resistance

Polycarbonate plastic is better at chemical resistance. You can clean it using chemicals like ammonia. However, you can use solvents to clean these two plastic materials.

Polycarbonate can generally withstand mild acids and gasoline. However, they are not recommended against strong acids, bases, or solvents. Acrylic, on the other hand, offers less resistance to chemicals. It starts cracking or discoloring in acids, bases, or solvents.

Polycarbonate VS Acrylic: Weight

When it comes to weight, acrylic is the winner. Although the difference is slight, acrylic is slightly lighter than polycarbonate plastic. Polycarbonate plastic weighs 1.2 grams/cm3, while acrylic offers 1.19 grams/cm3. This means acrylic is 10 kg lighter than polycarbonate in 1 cubic meter. For weight-sensitive equipment, acrylic plastic is the best option.

Polycarbonate VS Acrylic: Surface Damage Resistance

Recalling the hardness of these plastics, we found acrylic offers 94 to 105. On the other hand, polycarbonate plastic only provides 70-75.

Although PC plastic is strong and can resist high-impact forces, it is prone to scratching. Because of its lower hardness level, it is less resistant to surface damage compared to acrylic. However, acrylic has a higher hardness level, which can resist surface damage. As a result, acrylic plastic is widely used for windows and displays.

Polycarbonate VS Acrylic: Durability

Durability depends on the environment you are using. Polycarbonate is known for its excellent ability to endure stress, making PC plastic more durable in frequent impact jobs. Typical examples include safety shields and machine guards.

Although acrylic plastic is not as strong as PC plastic, it offers excellent UV resistance. Therefore, acrylic plastic is widely used for outdoor applications. Typical examples include greenhouses, outdoor display panels, car panels, and more.

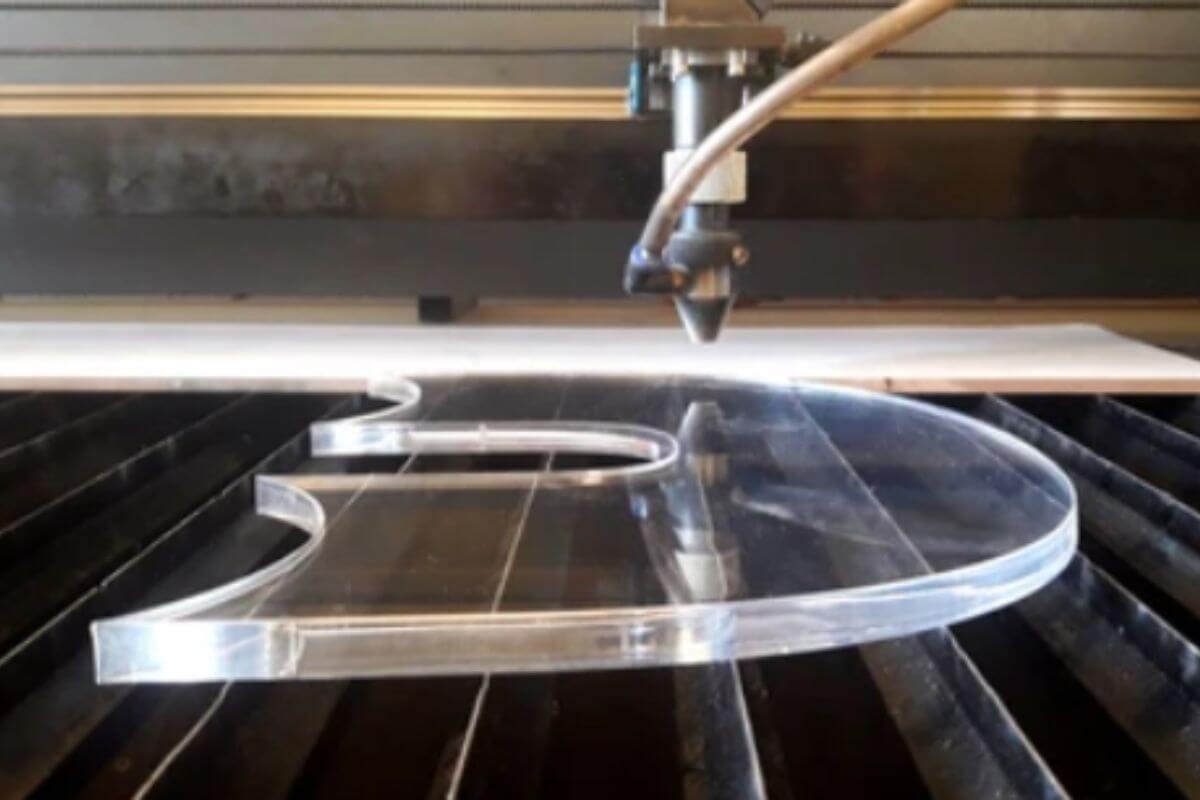

Polycarbonate VS Acrylic: Workability

Recalling the factor elongation, you know that polycarbonate offers a high elongation rate. Therefore, polycarbonate plastic is more flexible and easier to bend without breaking. These unique properties make PC plastic ideal for shaping and forming. You can drill, cut, and machine it with regular tools.

You can also work with acrylic plastic, which is more brittle than polycarbonate. It can be cut and shaped. However, it may crack or chip under stress, so be careful when handling acrylic to avoid damage.

Polycarbonate VS Acrylic: Price

The final factor that heavily differs between polycarbonate and acrylic is the price. Acrylic plastic is much cheaper than polycarbonate plastic.

Polycarbonate is relatively costlier because it needs a unique manufacturing process. As you know, Bisphenol A is used during the manufacturing process. Every factory must follow a specific method to ensure the plastic doesn’t release this chemical. This special-making process typically adds the cost.

Which Is Better? Acrylic Or Polycarbonate

Polycarbonate and acrylic are two kinds of plastic. You already know what makes them different. You can also guess what plastic might work best for your job. In this section, we will find the scopes of one kind over the weaknesses of the other, but simple suggestion will be: need strong material, then PC, need high glass and UV resistance, then acrylic, but this is not always the choose, you need to think about other factors when you select the those two materials.

Weaknesses of Polycarbonate Plastic à Scopes of Acrylic Plastic

(1) Polycarbonate plastic is much costlier than acrylic plastic. Making PC plastic requires a particular method that usually raises the cost of production. However, if you want a budgeted option, you can choose acrylic.

(2) Polycarbonate plastic is less resistant to scratches. Although the PC is much more robust, it is prone to scratching. Acrylic, in this case, can offer you higher scratch resistance.

(3) Polycarbonate turns yellow quicker than acrylic. If it turns yellow, it might become less transparent, which is crucial to consider. However, PC plastic is initially less transparent than acrylic.

(4) Polycarbonate plastic is more challenging to work with. In this case, acrylic plastic is much easier and safer. It doesn’t produce BPA.

(5) Polycarbonate plastic is less stable in UV exposure. In this case, acrylic offers you the best solution. It lasts 30-50 years before it starts turning yellow.

Weaknesses of Acrylic Plastic à Scopes of Polycarbonate Plastic

(1) Acrylic plastic has lower impact resistance than polycarbonate plastic. So, it may be more prone to breaking under impact pressure. In this case, polycarbonate plastic can provide you with the best services.

(2) Acrylic plastic is also less temperature-resistant than PC plastic. It can typically endure heat from 110 to 115 degrees Celsius. However, for high-heat uses, you must choose polycarbonate plastic.

(3) Acrylic is less flexible than PC plastic. Therefore, it is more prone to cracking or breaking. In this case, PC plastic does a great job.

(4) Acrylic is typically less durable than PC plastic, except for UV-resisting jobs. Polycarbonate is tough and durable for many heavy-duty applications.

Frequently Asked Questions

Is acrylic or polycarbonate better for a greenhouse?

Although polycarbonate is more robust than acrylic, it offers less durability under sunlight. Acrylic, in this case, is one step ahead of polycarbonate. Acrylic usually lasts 30 -50 years, then it starts fading and getting yellowish. On the other hand, PC or polycarbonate offers only 10 to 20 years, but it doesn’t easily break.

Does polycarbonate turn yellow in the sun?

Although polycarbonate has a particular UV resistance ability, it degrades at a certain period. In general, a polycarbonate lasts 10-20 years under sunlight. However, it starts turning yellow in 5-7 years. Various manufacturers might use additional chemicals to prolong this timeframe.

Why is polycarbonate so expensive?

Polycarbonate plastic is typically more expensive because of its complex manufacturing process. PC plastic contains a harmful chemical called Bisphenol A or BPA. Every factory must follow a specific method to ensure the plastic doesn’t release this chemical. This special-making process typically adds the cost.

Does acrylic break down over time?

Acrylic doesn’t easily break down, but it may turn yellow in 30-50 years. According to some researchers, acrylic may break down in 100 years, and some mentioned it may take up to 200 years. Since this plastic is not biodegradable, it will not generally break down over time.

Does polycarbonate scratch easily?

Yes, polycarbonate plastic scratches quickly because it has a softer surface. Regular use and abrasive cleaning can easily create scratches on it. However, if you want to eliminate this issue, you could use various abrasion-resistant coatings. Note that this coating can not fix the deep scratches.

Are acrylic glasses healthy?

Acrylic glasses are generally safe and non-toxic for everyday use. Thankfully, they are lightweight and shatter-resistant. Because of this, people prefer them as a suitable alternative to glass for drinking cups and food containers. However, you must ensure that the acrylic used for glass is a food-grade material.

Injection molding PMMA

Summary

Let’s wrap everything up! Polycarbonate and acrylic plastic are two popular plastic materials we use daily. Each plastic is suitable for unique benefits and applications.

PC or polycarbonate plastic is mainly prevalent for its strength and temperature resistance. This plastic works excellently in extreme conditions. Safety helmets, car headlights, roofing, and gazing use PC plastic.

Acrylic plastic can not endure high heat but works great against UV light. It is also lightweight and transparent; you can customize the colors and designs. Because of this, people prefer this plastic for signage, display cases, acrylic nails, paints, and more.

The main difference between polycarbonate and acrylic is their strength and durability. Polycarbonate is a stronger material but less durable under UV light. On the other hand, acrylic is more transparent and works excellent against sunlight.

Which is better depends on your project needs. The following table summarizes the key points of this article. You can use it to justify which plastic is the best option for your project.

| Aspect | Polycarbonate | Acrylic |

| Tensile Strength | 28 to 74 MPa | 65 to 83 MPa |

| Temperature Rating | 127 to 147 ℃ | 110 to 115 ℃ |

| Water Absorption | 0.03 to 0.30 | 0.13 to 0.80 |

| Hardness | 70 to 75 Rockwell M | 94 to 105 Rockwell M |

| UV Resistance | Yellows over time | Better UV resistance |

| Elongation | 10 to 138% | 3 to 6.4% |

| Transparency | 47 to 92% | 50 to 93% |

| Chemical Resistance | Excellent against acids, salts, and organic chemicals | Less resistant against acids and bases |

| Weight | 1.20 grams/cm3 | 1.19/cm3 |

| Surface Damage Resistance | Less Resistant to scratches | Excellent against surface damage |

| Durability | Excellent and Less under sunlight | Excellent in all situations |

| Workability | Moderate | Easier |

| Price | Higher | Affordable |

Get in Touch With Us!

Please contact us if you have any questions or want to learn more about plastic injection molding or custom injection molding manufacturing. Dong Guan Sincere Tech offers reliable and effective customer services.

Leave a Reply

Want to join the discussion?Feel free to contribute!