Large part injection molding

The majority of plastic is manufactured using large injection-molded parts. The trend toward creating large plastic parts using this technique is increasing day by day. It started after the discovery of plastic injection molding machines in the late nineteenth century. The first injection molding machine was simple. So it was used to make plastic buttons, combs, and some other mini-plastic items. But now it can also mold complex materials such as metals and glass. The injection molding process is best for producing large volumes of high-quality plastic parts. Let’s shed light on the role of the injection molding process in manufacturing large plastic parts.

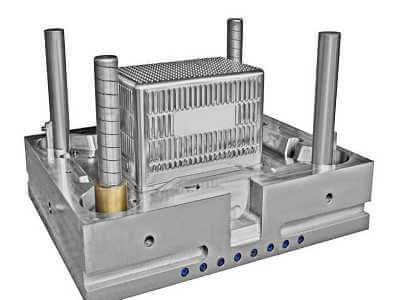

What is Large Part Injection Molding?

As you know, the large-part injection molding process makes giant plastic parts. Let us tell you the dimensions of a large plastic part. This will avoid confusion. Plastic parts having a weight of 100 pounds and a width of 10 inches are considered large. Injection molding large parts is not just enlarging small parts. It is a complex process. It requires advanced tools and equipment.

Materials Used in the Large-Injection Molding Process

A variety of materials are used for manufacturing plastic injection-molded large parts. Two different types of plastics are used in injection molding. They can be amorphous or semi-crystalline. Amorphous plastics don’t have a fixed melting point. So, they can expand and shrink easily. On the other hand, semi-crystalline plastics have fixed melting points. Thus, they are preferred over the amorphous ones. Some of the most widely used materials for injection molding large parts are:

1. PEEK (PolyetheretherKetone)

PEEK has exceptional thermal and mechanical properties. It has a high tensile strength of about 90 MPA. So, it is good for giant plastic parts. It is also resistant to chemicals. Furthermore, it doesn’t absorb moisture. Thus, it prevents corrosion. But PEEK is an expensive material. It makes high-performance components such as gears, valves, pump bearings, etc. Lear more about PEEK plastic injection molding.

2. ULTEM (Polyeretherimide)

ULTEM is an amorphous solid. Its tensile strength ranges from 70 to 80 MPA. It is moisture- and chemical-resistant. Moreover, it is thermostable. It can withstand harsh weather conditions. It is budget-friendly. Moreover, it is sterilizable. It can be cleaned easily using radiation or an autoclave. It has a high glass transition temperature. Thus, it offers the same properties as PEEK at an affordable price.

3. Carbon Fiber Reinforced Polymer (CFRP)

CFRP is a composite material. It is made of carbon fibers embedded in the polymer matrix. It has a high strength-to-weight ratio. So it is perfect for use in large parts. The carbon fibers are woven unidirectionally. So, it gets additional strength in this way.

4. PolyPhenylSulfone(PPSU)

It consists of a sulphone group linked to two phenyl groups. It can tolerate shocks and other environmental stresses. So, it has high impact resistance. Furthermore, it is resistant to hydrolysis, chemical degradation, and water absorption. But this material is a bit expensive. Learn more about PPSU.

Advanced Processes for Large Part Injection Molding

The following are the modern processes that have many applications in Large-part injection molding

1. Gas Assist Injection Molding

Gas-assisted injection molding is an improvement on conventional injection molding of plastics. Here, the high-pressure nitrogen gas is injected into the mold after the infusion of the chosen resin. It is quite beneficial as it enables equal distribution of the material, especially in large and complicated molds. It helps save material and also enhances the part’s aesthetics and time.

2. Pad Printing

Pad printing is another valuable second step, which creates detailed images and logos on the injected plastic products. It consists of the use of chemicals to engrave a design on the copper plate. So, dip it in ink, roll it on a rubber-dubbed silicone pad, and finally roll the pad on the part surface. This method is preferred because it can print thin-film-thick shapes and textured surfaces selectively with befitting quality and permanency.

3. Blow Molding

Blow molding is another technique used in manufacturing hollow parts of plastic. The preheated plastic tube (parison) is extruded into the mold, and then, through the injection of air, it is forced to assume the shape of the mold cavity. This material has found several applications in its usage. They may include the production of bottles, containers, and car parts. This process provides greater productivity, and the solutions can accommodate intricate forms. Moreover, its cost is relatively low for high-volume part manufacturing.

Large-Part Injection Molding vs Normal Injection Molding

You might wonder what factors differentiate large injection-molded parts from normal injection-molded parts. So, here is a detailed comparison for your ease.

1. Mold Complexity

Mold has a simple geometry in normal injection molding. Moreover, it has fewer cavities. The mold size in normal injection molding ranges from 1000 to 10,000 square inches. However, in large part, injection molding mold sizes range from 10,000 to 50,000 square inches. The mold, in large part, has complex geometries. It also has multiple cavities.

2. Machine Size

Large injection-molded parts require machines with larger sizes. Its clamping size typically ranges from 1000 to 5000 tons. So, it can accommodate larger molds. On the other hand, a normal injection molding machine has smaller plates. Its clamping force ranges from 100 to 1000 tonnes.

3. Material Selection:

Large injection molding parts use special materials with high thermal resistance. These materials include PEEK, ULTEM, and glass-filled polymers. In contrast, the normal injection molding process uses standard plastics like polycarbonates and polypropylenes.

4. Cooling Time

Injection molding large parts is more complex. It has a larger size. So, it requires longer cooling times. It lasts up to several minutes. Cycle time is also greater, up to 30 minutes. On the contrary, normal injection molding has a shorter cooling time. It lasts up to a few seconds. The cycle time also ranges from 1 to 55 seconds.

5. Ejection

Injection molding in large parts requires specialized ejection systems. It also requires an advanced handling system for handling such large parts. However, normal injection molding requires standard ejection systems. Similarly, it also requires general handling equipment for smaller parts.

6. Maintenance

The mold size is large. So, plastic injection molding in large parts requires extensive maintenance. In contrast, normal injection molding needs less maintenance.

So, it can be summarized in a table:

custom waterproof hard case

| Aspect | Large-Part Injection Molding | Normal Injection Molding |

| Cost Efficiency | Low cost per part in mass production | Low cost per part in mass production |

| Initial Mold Cost | High | High |

| Precision and Repeatability | High | High |

| Material Versatility | Versatile material options | Versatile material options |

| Production Speed | Fast production cycles | Fast production cycles |

| Labor Costs | Reduced due to automation | Reduced due to automation |

| Complex Geometry Capability | Yes | Yes |

| Strength and Durability | Strong and durable parts | Strong and durable parts |

| Lead Time for Tooling | Long | Long |

| Mold Design Complexity | Complex and challenging | Less complex |

| Machine Requirements | Requires large, expensive machines | Requires standard machines |

| Material Waste | Potential for material waste | Potential for material waste |

| Part Size Limits | Limited by machine and mold size | Limited by machine and mold size |

| Cooling Time and Warpage | Longer cooling times, risk of warping | Shorter cooling times, less risk of warping |

Large-Tonnage Injection Molding Machine

We have discussed plastic injection molding for large parts. The discussion is incomplete without knowing about the large-tonnage injection machine. It is a machine suitable for producing complex parts. The injection capacity, screw diameter, and mold size determine the machine’s capability. Injection capacity measures the amount of material that can be injected in a single round. Screw diameter and mold size determine the size of the plastic parts produced. Some of the key specifications of the Tonnage Injection Machine are

- Injection Capacity: Its injection capacity is 100 oz or 2500g

- Mold size: The mold size ranges from 1500 to 4000 square inches.

- Screw Diameter: Its screw diameter varies from 4 to 12 inches

- Barrel Capacity: The amount of plastic that can be melted and injected in a single cycle. Its barrel capacity is almost 550 lbs

- Control System: It comprises an advanced computerized system that controls temperature, pressure, and speed.

- Additional Features: Hydraulic drives, Multizone temperature control systems, valve gate systems, and advanced safety are its additional features

Applications of Large Part Injection Molding Process

Large Part Injection Molding is a useful process. Here are its applications in various industries:

1. Automotive Industry

The automotive industry relies heavily on large-scale injection molding. Large-part injection molding manufactures shock-resistant material. So, many large components of automobiles are created using this method. Some of them are:

- Bumpers

- DashBoards

- Door Panels

- Door Handles

- Mirror Housing

- Other Decorative Parts

2. Aerospace Industry

Injection molding makes various useful, high-volume aerospace industry products. It is widely used as it produces lightweight products. This is also an affordable method. So various aerospace products are formed using this. Some of them are:

- Air Craft Panels

- Interior Components

- Satellite Parts

- Rocket Components

3. Industrial Equipment

Large Part Injection Molding produces tough pieces of equipment. They can endure temperature extremes. So, we create many industrial components using it. A few of them are:

- Machine Housings

- Valve Bodies

- Pump Components

- Gear Boxes

- Industrial Robotics

4. Medical Devices

Large-part injection molding produces sterile products. So, it is used to make a large number of medical devices. These medical devices are easy to clean. The devices are highly accurate. The process is essential for creating critical components. Some of the important medical devices are:

- Implantable Devices (Joint Replacement, Dental Implants)

- Surgical Instruments ( handles, cases)

- Diagnostic Equipment ( Machine housing)

- Medical Imaging Equipment (MRI, CT scan)

- Prosthetic Devices

What are the Advantages and Disadvantages of large-part Part Injection Molding?

Here is a brief table to understand the benefits, drawbacks, and limitations of large-part injection molding.

| Advantages | Disadvantages |

| Low cost per part in mass production | High initial mold cost |

| High precision and repeatability | Long lead time for mold creation |

| Versatile material options | Complex and challenging mold design |

| Fast production cycles | Requires large, expensive machines |

| Reduced labor costs due to automation | Potential for material waste |

| Ability to create complex geometries | Limits on part size |

| Strong and durable parts | Risk of warping and long cooling times |

Challenges associated with Large Part Injection Molding

Nothing in this world is perfect. Everything has some imperfections and challenges associated with it. So let’s talk about the limitations of injection molding large parts:

1. High Investment

We need large molds to make large parts. So, creating large molds requires significant investment and expertise. Moreover, designing a mold with complex geometry is challenging. Mold materials must be able to endure high temperatures and pressure.

2. Shrinkage

Large parts are more vulnerable to shrinkage. During the cooling process, they may shrink or deform. Uneven cooling may also lead to warpage. This can distort the plastic structure. It may also affect the part’s dimensions.

3. Material Compatibility

Large parts need materials with specific properties. They must have the desired strength and stiffness. Additionally, they should be compatible with the mold. Meeting both of these requirements simultaneously is challenging.

4. Difficult to Eject

Larger parts are difficult to eject. They require a specialized ejection system. If not properly removed, the part formed may deform. So, demolding must be carefully controlled to prevent distortion. The ejection process must be regulated to obtain high-quality products.

Conclusion:

Large Part Injection Molding is a process that produces large parts of plastic. This method is best for mass production of the desired product. It uses highly durable plastics such as PEEK or ULTEM as raw materials. It differs from traditional injection molding in many ways. It uses more complicated molds and designs as compared to traditional molds. It produces a large volume of product using a tonnage injection molding machine. Its limitations are shrinkage, warpage, and material incompatibility.

Frequently Asked Questions

Q1. What is the maximum size for large-part injection molding?

The maximum size for injection molding large parts ranges from 10 to 100 inches. It depends on various factors. Mold design and machine design also play a role in determining size.

Q2. How do you assure dimensional accuracy in large injection-molded parts?

Dimensional accuracy is usually assured with an accurate mold design. Moreover, we can check dimensional accuracy using quality inspection methods like 3D scanning and CT scanning.