Looking for Plastic Mould?

Send us your part design drawing or samples pictures

We will offer you a competitive price (40% lower price) for custom plastic mould و injection moulding products.

More than 15 years of experience providing plastic injection moulds & moulding service, plus 15 years of fluent technical English communication (technical English communication is very important to work with worldwide customers).

We 100% guarantee your project will be successful. You will be impressed and satisfied with our quality, price, and service.

What are you waiting for? Send us your requirement for quotation, you will lose nothing but having our competitive price for reference.

ما هو قالب بلاستيكي?

Plastic Mould is one of the preferred tools for manufacturing millions of injection plastic parts, is one of the most efficient manufacturing processes in the world, fast, repeatable, low product cost, and precision. But the plastic mold manufacturing cost is expensive, to make one hundred plastic parts or a half-million plastic parts, the mold cost is pretty much the same, this is the disadvantages of the قالب حقن البلاستيك.

If you have a project that needs many thousands of plastic parts or even more, then chooses plastic mold technology is one of the best options that could save cost for you.

How is this plastic molding processing works

أ شركة صب البلاستيك works on injection molding machine and قالب بلاستيكي, meltdown plastics and inject it into the mould by high injection pressure.

Once the plastics are in the mold cavity, it forms the shape of the product you desired, after the resin get cold in the mold and eject out, then we got the molded part, this one complete cycle time is plastic molding technology, the machine is standard machine but the mould is custom made for every part feature and shape.

For example, there is an iPhone case molded parts, electronic housing molding, plastic storage containers, house cook molded parts, every plastic part that needs a custom mould. However, most moulds are used for a more complex design like an automotive mould or toothbrush handle, aircraft mold and more.

The molding process creates stronger and more durable products and it is a more efficient process with min plastics waste, almost 80% of plastic parts are made by plastic molds and molding technology.

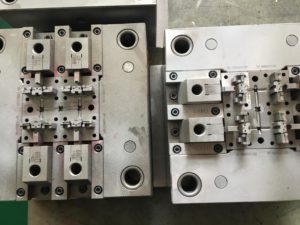

Custom Plastic Mould

The most important part of manufacturing injection molded parts is the custom plastic mold & injection molding machine. This is done by injecting melted plastics directly into the custom mold by the injection molding machine, then allowing it to cool and form the desired part shape, and eject the molded part out of the mould, this finished one cycle is called injection molding process.

تصنيع custom plastic mould makes up an important part of the mould business. The injection tooling making technology is an important factor in recognizing the company in manufacturing high quality or low-quality moulds, high quality mold make high quality injection molding parts, low-quality mold makes poor quality plastic products, the mold maker must have a perfect manufacturing technology before start cutting steel.

When the custom mould is ready, the next step is injecting parts (mould trial). Before starting to trial the mould we need to verify a couple of issues to avoid any mistake, we need to check the plastic material, color, cooling channels, surface requirement, mould temperature requirement (this is determined by the plastic material), part volume (need this information to confirm the tonnage of injection molding machine uses). After all of this information has been verified then we start to inject plastic molding samples.

Assuming you have a good understanding of the plastic mold, plastic molding technology, and processing, to make simple idea, plastic injection mold needs to work with injection molding machine, injection mould plus injection moulding machine and plus molding operator to achieve this moding production jobs.

During mold making, you can make some of the finer detail changes or improvements to the product created in the mold. Plastic is a compound that is easily molded into all kinds of shapes and sizes. From molding toys, tubes, jars, bottles, and countless other items that we all use on a regular basis, these are all made of plastics.

The high consumer demand for these products has made it necessary to manufacture them on a massive scale. The usage of goods utilizing المنتجات البلاستيكية has also increased, causing a higher volume of production.

Taking into account that plastic items today can be easily personalized, most شركات قولبة الحقن have established high-quality control procedures. This has also been a result of the development and advancements in the technology used to make plastics.

These manufacturing companies use the thermoplastic injection molding technology, along with other molding processes and systems to meet the requirements of their various client requests.

Obtaining the أجزاء صب البلاستيك for using in the automobile industry are inexpensive. The plastic mechanisms that are produced come from several different injection molding techniques used by manufacturers.

These different techniques include structural foam molding, solidity molding, thermoforming, blow molding, thermoset injection molding, thermoplastic and transferring to resin to mention just a few.

Do you have any custom plastic mold & molding requirements for your business? Contact us now

نحن نقدم mold manufacturing and injection molding services, and additional services like painting, plating, silk-screen, contract manufacturing, and assembly the components along with the plastic molding parts.

What we do: Providing قالب بلاستيكي & Molding Service

In the world of Custom plastic mold requirement is increasing, your successful business may need high-quality plastic molds & molded parts. You are welcome to the right place because we are here to solve your problems with the excellent mould design, tooling manufacturing, part production, rapid prototype tooling.

Sincere Tech is A Plastic Mold Manufacturer providing a wide range of services in mold designing, Engineering, injection moulding products, molded components, and plastic mold manufacturing. While offering high quality engineered plastics in the different type of plastic moulds and sizes that suits your products and keep molds for a lifetime.

Our focus is on YOUR needs in ensuring your success with the customers you serve. At Sincere Tech Company, we realize our growth and success as A company is directly tied to helping YOU to be successful.

Whether you are interested in making قوالب بلاستيكية أو قولبة الحقن products for your business, our expert Team will work with you to help you through the various stages of production, from concept to design, to manufacture while delivering unique and high-quality molds or parts for you. Our Vision has always been to be the customer’s choice for molded products/components, and moulds.

Contact us today and let us make your ideas, concepts, or designs become a reality with our design and production expertise. Sincere Tech is known for delivering quality services with guaranteed satisfaction, and we hope to provide the same to you. No matter what you need or when you need it, we are here to assist with your specific needs and requirements.

It is a very simple step to get a price. If you have a new project in hands that needs high-quality plastic injection moulds و injection molded parts? Send us your part design or samples and inform us your requirement, we will never share your data with any others, we are willing to sign the NDA document to prevent your project.

Our team will review your data and offer you a competitive price with technical solutions, such as manufacturing feasibility analysis, material selection suggestion, surface finish selection suggestion, draft angle suggestion, etc.

Ready to start your project? We will answer you within 24 hours.